New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#626 2022-03-07 22:30:23

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Crops

Further to margarine. Parkay brand tub margarine is made with vegetable oil with palm oil and palm kernel oil. Palm oil is from the flesh of the fruit of an palm tree, palm kernel oil is from the pit or seed of the same fruit. But Parkay margarine sticks are made with...

Vegetable Oil Blend (Liquid Soybean Oil, Partially Hydrogenated Soybean Oil), Water, Salt, Contains Less than 2% of the Following: Dried Whey, Vegetable Mono- and Diglycerides and Soy Lecithin (Emulsifiers), Potassium Sorbate and Sodium Benzoate (to Preserve Freshness), Natural and Artificial Flavor, Phosphoric Acid (Acidulant), Vitamin A Palmitate, Colored with Beta Carotene (Source of Vitamin A), Flaxseed Oil.

Hydrogenated is a trans-fat. So that's still Ok? That could be easier to make on Mars, and the large ship. If we consume margarine quickly and store in a fridge, we don't need the preservative. If we use turmeric for colour, that also adds natural flavour. Flaxseed oil just adds omega fatty acids. water and salt are required to make an emulsion. So we could make margarine from microbial oil, partially hydrogenated microbial oil, water, salt, dried whey, and lemon juice instead of phosphoric acid. Hydrogenation is done by heating oil to +60°C, and bubbling hydrogen gas over a platinum catalyst. So the next question is where do we get whey? One vegan margarine uses soy milk instead.

YouTube: Hardening Vegetable Oils (Margarine) through Hydrogenation

YouTube: Hydrogenation: transform liquid oil into solid fat

Wikipedia: whey

Whey protein is the collection of globular proteins isolated from whey. The protein in cow's milk is 20% whey protein and 80% casein protein, whereas the protein in human milk is 70% whey and 30% casein. The protein fraction in whey constitutes approximately 10% of the total dry solids in whey. This protein is typically a mixture of beta-lactoglobulin (~48-58%), alpha-lactalbumin (~13-19%), bovine serum albumin (~6%)(see also serum albumin), and immunoglobulins. These are soluble in their native forms, independent of pH.

The amino acid cysteine in whey protein is a substrate for the synthesis of glutathione in the body which is a ubiquitous cellular antioxidant; laboratory experiments have suggested that whey protein and its components might reduce the risk of cancer in animals, suggesting an avenue for future medical research.

Milk Ingredients: Whey Powder

Typical composition for Whey Powder

Total solids 96-97%

Lactose 70-75%

Total protein (N x 6.38) 10-13%Minerals

Ash 7-12%

Calcium 4500 mg/kgVitamins

Thiamine (B1) 0.4-0.6 mg

Riboflavin (B2) 2.3-2.5 mg

Pyridoxine (B6) 0.4-0.6 mg

I find it interesting that typical whey powder has vitamin D removed. Humans require vitamin D for our digestive system to absorb calcium, magnesium, and phosphate. Important D vitamins for humans are vitamin D3 (cholecalciferol) and vitamin D2 (ergocalciferol).

Lactose free margarine sounds like a good idea. So rather than dried whey, we could add whey protein (mainly lactalbumins and globulins), casein, calcium, and vitamin D. A microbial source of casein is a holy grail of vegan food. It's the primary ingredient in cheese. For the large ship, could we just skip whey?

Offline

Like button can go here

#627 2022-03-12 18:48:43

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: Crops

Growing Green on the Red Planet

Radishes grown by scientists at Wageningen University and Research, Wageningen, The Netherlands, in (from right) soil from Earth and simulated Martian and lunar soils.

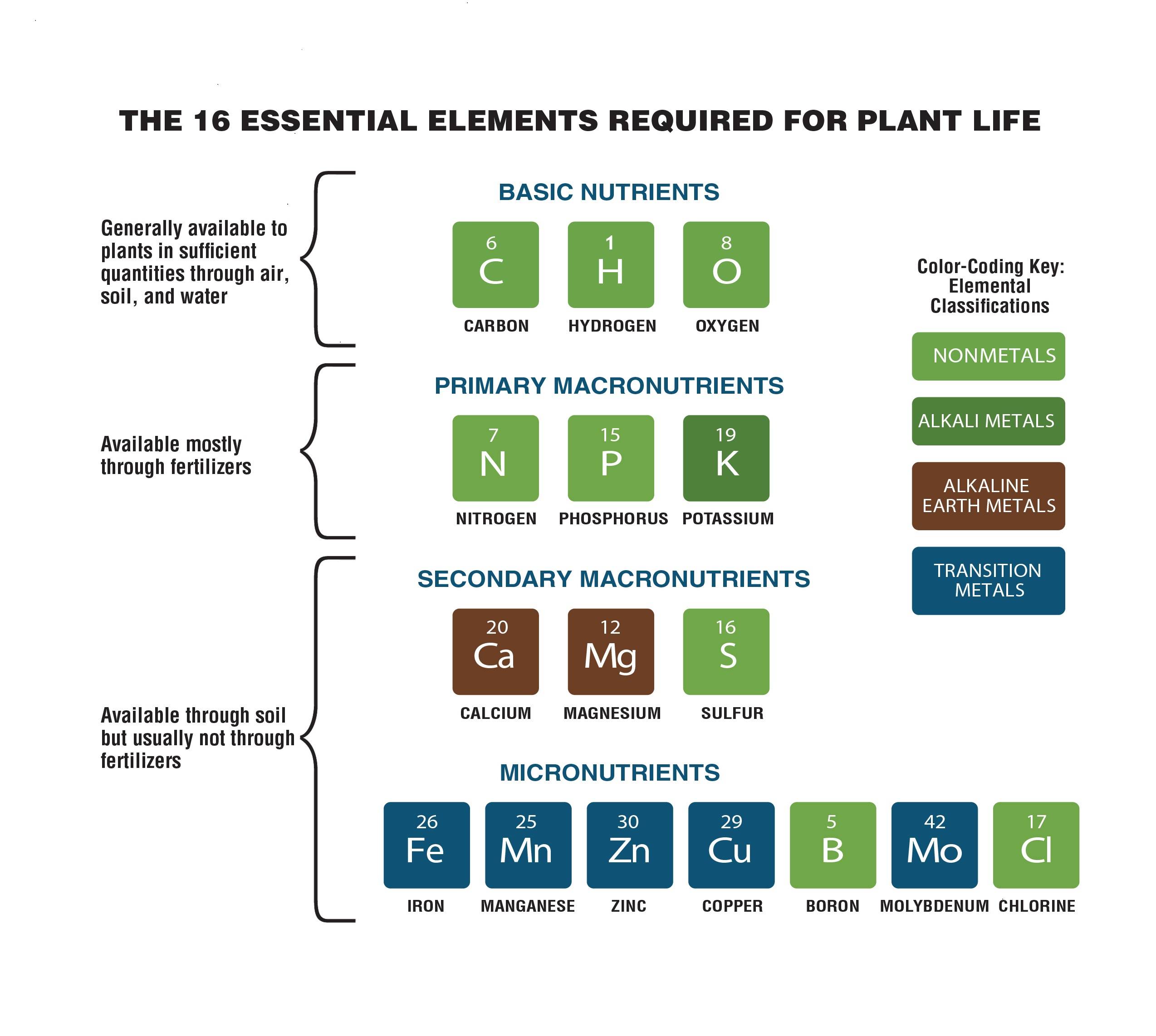

The 16 Essential Elements Required for Plant Life

Offline

Like button can go here

#628 2022-03-14 18:11:46

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,123

Re: Crops

The latest MDRS report includes a mention of an experiment to try to grow plants on a rotating turntable ... the experiment failed...

http://newmars.com/forums/viewtopic.php … 77#p192277

About our gravitropism experiment, we wanted to make plants grow on a rotating platform and make daily measures. It was planned in two parts, the first one with a horizontal rotation (the historical “Knight’s wheel experiment”), the second one with a vertical rotation. But we did not succeed in making our seed grow. We tried several times different ways. We do not know exactly why it did not work.

For RobertDyck ... this is an experiment you can perform at home, if you have a turntable able to operate at 3 RPM.

On the other hand, your current greenhouse design (as I understand it) is independent of rotation, in the sense that solar radiation into the greenhouse is constant.

However, the plants ** will ** be rotating as part of the Large Ship, and it is unknown if plants can "tell" the difference between rotation induced "gravity" and the real thing. It seems to me that since the experiment could be performed in space for a modest expense, it would be worth doing.

Plants ** are ** (apparently) doing well on the Moon, but ** that ** is NOT a rotating "gravity" field.

(th)

Offline

Like button can go here

#629 2022-03-14 20:23:29

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: Crops

crew report can be found here

http://mdrs.marssociety.org/crew-reports/

https://gardenprofessors.com/thomas-kni … ter-wheel/

A turntable for a record player spins at 33 1/3 rpm so what speed was the rotation set to?

Offline

Like button can go here

#630 2022-03-15 15:54:14

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Crops

For RobertDyck ... this is an experiment you can perform at home, if you have a turntable able to operate at 3 RPM.

On the other hand, your current greenhouse design (as I understand it) is independent of rotation, in the sense that solar radiation into the greenhouse is constant.

Plants do follow light. Hydroponic operations sometimes mount the light on a track, slowly moving the light from one side to the other over a day. If the light doesn't move, some crops grow straight toward the light. But that's one revolution per day. My setup would have light from mirrors overhead, so light direction won't change. For lettuce, I suggested vertical farming, with a light dispersal system of some sort. So light is not just to plants on the top of the vertical farming rack, but all plants. Since lettuce grows in shade and light in space is more intense than full sun on Earth, it can be distributed.

Plants ** are ** (apparently) doing well on the Moon, but ** that ** is NOT a rotating "gravity" field.

Wait, what? There's something on the Moon? I read about the Chinese landing a small rover, but a plant experiment?

Offline

Like button can go here

#631 2022-03-15 19:41:45

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: Crops

The Chinese rover did bring up a plant experiment that only worked for a few days before it was no more.

As far as the hydroponic some other food grow best in it as well as vertical then again we need to focus on the journey have one type of crops while on the planet we can go for longer duration ones.

Offline

Like button can go here

#632 2022-04-12 12:06:26

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Crops

Synthetic Biology

https://newmars.com/forums/viewtopic.php?id=7292

The best thing to do is to engineer a bacteria which could convert a martian CO2 into a precursor reagent for rocket fuel. I hope this is possible.

From the Booze thread

Interesting reference on the possible use of microalgae to produce ethanol.

https://www.intechopen.com/chapters/47886Comparison of yields per acre:

Wheat: 277 gal/acre.

Algae: 5,000–15,000 gal/acre.We would need to produce a blend of fermented micro algae that results in pleasant flavours that people will enjoy. But the much greater yield of micro algae and its ability to grow in panels and thin tubes, gives it an enormous advantage over other foods that we might grow on Mars. And it has the advantage that we can drain it into tanks at night time to avoid it freezing.

One of the key enabling technologies for human colonisation of Mars is our ability to grow micro algae and combine and process these algae to produce foods that are palatable and nutritious. Without this technology, each human colonist will have to be supported by hundreds of square metres of heated, pressurised greenhouses. These would be very expensive to produce and energy intensive to operate. A large part of the estimated 100kW of power capacity needed to support each colonist on Mars would be taken up by food production. Processed algae avoids almost all of this requirement. It will be the cheapest way of making food and alcohol.

If the yield estimates above are to be believed, then a single acre of algae panels (40 x 100m) will yield around 20,000 litres of ethanol per year. That is equivalent to 50,000 litres of standard 40% whisky or vodka or 500,000 litres of beer.

'Chemicals centre on Mars'

https://newmars.com/forums/viewtopic.php?id=6107

I think we need to have a part of the colony devoted to Pharmaceuticals - though they could be imported from Terra, they may have to wait 2 years to get them, and the demand is unpredictable. I'd prefer to keep them separate from the rest of the chemical processing, since these are intended to actually ingest. We're not talking about massive amounts, so we'll need to have a very versatile production ability. Fortunately, I think a lot of the processes are the same in a lot of what we'd want to produce.

Some plants have been genetically modified to produce useful things. For example, cotton has been modified to produce polyester. So the fibre is a cotton/polyester blend as it's harvested from the field, no post-processing required. Some bacteria have been developed to grow like yeast in a vat, and produce various chemicals from the human body that can be sold as pharmaceuticals. For example, human growth hormone. It used to be the only way to get that was to harvest pituitary glands from the brain of human cadavers. It took many pituitary glands to produce enough growth hormone for one treatment. But now a bacteria can be grown in a vat, feeding it water and sugar.

I don't see what role the nanoscale wires do. Cyanobacteria are the original single cell organism to develop a double photosystem. Chloroplasts are organelles in leaf cells; photosynthesis happens there. Chloroplasts are enslaved cyanobacteria; each chloroplast has a single plasmid with 85% of the DNA of cyanobacteria. You can grow cyanobacteria in a vat or a transparent plastic bag. Spirulina is a mass of a certain variety of cyanobacteria. Cyanobacteria used to be called blue-green algae, although today cyanobacteria is recognized as a bacterium, while algae is eukaryotic. My point is, why the wires?

' Flow honey - better be'

https://newmars.com/forums/viewtopic.php?id=9410

Health?

https://newmars.com/forums/viewtopic.php?id=7454

Gravity on Mars is ~ 40% of that here on Earth, which should keep the hormonal control system functioning pretty well. In hindsight, the ISS should have been built to the von Braun "bicycle wheel" model wherein the numbers of gees could be varied for experimental purposes. Why NASA overlooked that possibility astounds me.

Psilocybin Frees Up Depressed Brain, Study Shows

https://www.bbc.com/news/health-61070591

Psilocybin, a drug found in magic mushrooms, appears to free up the brains of people with severe depression in a way that other antidepressants do not, a study has found. The BBC reports:

The results, based on brain scans of 60 people, mean the drug could treat depression in a unique way, the researchers say. Patients with depression are warned not to take psilocybin on their own. A synthetic form of the drug is tested on people in trials under strict medical conditions, with psychological support from experts provided before, during and after it is taken.

With depression, the brain can get stuck in a rut and locked into a particular negative way of thinking, he said. But when given psilocybin, people's brains opened up and became "more flexible and fluid" up to three weeks later. This could be seen in increased connections between regions of the brain when patients were scanned. These patients were more likely to experience an improvement in mood months later. Similar changes were not seen in the brains of people treated with a standard antidepressant.

The results, published in Nature Medicine, are taken from two studies. In the first, everyone received psilocybin; and in the second -- a randomized controlled trial - some were given the drug while others were given a different antidepressant. All participants also received talking therapies with registered mental health professionals. Brain scans were taken before, and then one day or three weeks after taking the therapy.

Offline

Like button can go here

#633 2022-08-16 14:27:40

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Crops

I saw this on Facebook - Happy Sandy's Kitchen. I wrote earlier about vanilla extract, but here's a recipe.

Vanilla Extract:

I was asked to re-share how I make my vanilla extract so here it is!

Here's how I make my vanilla extract. At the end I'll give a link to where I buy my Vanilla Beans.

Homemade Vanilla Extract:

3 Vanilla beans for every 8 ounces of liquid - this time I actually used 4 vanilla beans per bottle and each bottle is 8 ounces.

Vodka - you can use any brand - it doesn't have to be an expensive brand. In fact I usually get the least expensive I can find.

Take a sharp knife and cut from almost the top to almost the bottom of the bean - but don't cut through. Scrape the inside a little to get the stuff loosened up a bit

Put the vanilla beans in your jar. I really like these new bottles I just got!

Cover the beans with your vodka. I use a funnel to keep from making a mess!!

Put the lid on your jar, shake it gently a couple of times, and then place in a cool dark place.

Shake it gently every day for a week and then once a week for the duration.

You can use it after 6 weeks but it gets better the longer it steeps. I often let mine steep for 4 or 5 months.

If you want double strength Vanilla Extract just use extra beans.

Just an aside - for the size of these bottles I had to cut the beans in half first so they would fit in the bottles.

That's it folks. These make wonderful gifts that your friends and family will love.

Enjoy!!

I buy my vanilla beans at 'Native Vanilla'. You can get as little as 5 beans for $9.99 - compared to $11.99 for 1 bean at Walmart! The link to their site is https://nativevanilla.com

There's a little drop down thing in the upper left side of the page that allows you to sign up for their emails and get 10% off your first order!

And here's the link to where I got my bottles...

https://www.amazon.com/gp/product/B08P86M9L7

Offline

Like button can go here

#634 2022-08-16 20:15:07

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: Crops

Well What Is Vanilla Bean? how do we grow it?

:max_bytes(150000):strip_icc():format(webp)/vanillaforms_getty2400-56a498453df78cf77283281d.jpg)

Vanilla is the fruit of an orchid plant, which grows in the form of a dark brown bean pod that is long and skinny. Vanilla orchids are grown in tropic climates, including Mexico, Tahiti, Reunion, Mauritius, Comoro, Indonesia, Uganda, and Tongo. Three-fourths of the world's supply comes from Madagascar. Vanilla is enjoyed throughout the world. The beans are used to add real vanilla flavor to sauce, frosting, syrup, ice cream, beverages, and a variety of desserts.

There was another plant that had a vanilla flavor to it, but it was not a bean from when I was young, but it escapes me now...

Ther flavoring is used in lots of products here on earth but would we be doing the same on mars in time?

Offline

Like button can go here

#635 2022-08-17 00:56:01

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Crops

Artificial vanilla extract can be made as a byproduct of processing wood for paper. It can also be made from petroleum. My argument was a small Mars base would not have the industrial infrastructure to do that. For one, Mars has no trees, you would need a pressurized greenhouse to grow trees. You would be better off building a greenhouse to grow real vanilla vine.

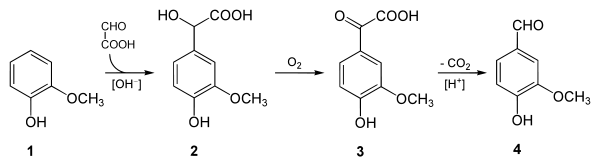

Chemical synthesis

The demand for vanilla flavoring has long exceeded the supply of vanilla beans. As of 2001, the annual demand for vanillin was 12,000 tons, but only 1,800 tons of natural vanillin were produced. The remainder was produced by chemical synthesis. Vanillin was first synthesized from eugenol (found in oil of clove) in 1874–75, less than 20 years after it was first identified and isolated. Vanillin was commercially produced from eugenol until the 1920s. Later it was synthesized from lignin-containing "brown liquor", a byproduct of the sulfite process for making wood pulp. Counterintuitively, though it uses waste materials, the lignin process is no longer popular because of environmental concerns, and today most vanillin is produced from the petrochemical raw material guaiacol. Several routes exist for synthesizing vanillin from guaiacol.

At present, the most significant of these is the two-step process practiced by Rhodia since the 1970s, in which guaiacol (1) reacts with glyoxylic acid by electrophilic aromatic substitution. The resulting vanillylmandelic acid (2) is then converted by 4-Hydroxy-3-methoxyphenylglyoxylic acid (3) to vanillin (4) by oxidative decarboxylation.

Wood-based vanillin

15% of the world's production of vanillin is produced from lignosulfonates, a byproduct from the manufacture of cellulose via the sulfite process. The sole producer of wood-based vanillin is the company Borregaard located in Sarpsborg, Norway.

Wood-based vanillin is produced by copper-catalyzed oxidation of the lignin structures in lignosulfonates under alkaline conditions and is claimed by the manufacturing company to be preferred by their customers due to, among other reasons, its much lower carbon footprint than petrochemically synthesized vanillin.

Offline

Like button can go here

#636 2022-09-07 06:03:51

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Crops

Grass species Oryza sativa Asian rice or less common Oryza glaberrima African rice. It feeds most humans of this Earth and agricultural commodity with the third-highest worldwide production, after sugarcane and maize.

Chinese Astronauts Successfully Grow Rice in Space

https://www.universetoday.com/157453/ch … -in-space/

Rice is one of the world’s staple crops. It is regularly eaten by more than half the world’s population. And now, it’s been grown in microgravity, on board the newly launched Chinese Wentian space laboratory.

Ethanol or Alcohol production, CH3−CH2−OH or C2H5OH or C2H6O. Rice wine is an alcoholic beverage fermented and distilled from rice, traditionally consumed in East Asia, Southeast Asia, "sake", in Japanese, literally means "alcohol", and the Japanese rice wine usually termed nihonshu 日本酒; "Japanese liquor" the Korean Makgeolli 막걸리, raw rice wine alcoholic beverage, milky, off-white, and lightly sparkling rice wine, Tapuy, a is a rice wine produced in the Philippines and Handia is a rice beer originating from the Indian subcontinent.

Last edited by Mars_B4_Moon (2022-09-07 06:25:04)

Offline

Like button can go here

#637 2022-09-07 20:41:27

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: Crops

What We Can Learn From Moss — Mosses can grow in space, survive in ice for 1500 years, clean up oil spills, remove arsenic from water, and grow everywhere on Earth. Moss teaches us there are no limits to how versatile an organism can be.

Is this something that can be adapted to our diet or is it for another purpose?

Offline

Like button can go here

#638 2022-09-22 15:06:38

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Crops

I gave an old 'Moss' forum discussion a bump

Space agriculture boldly grows food where no one has grown before

https://www.britannica.com/story/space- … rownbefore

To reach Mars, we need biotechnology

https://www.labiotech.eu/in-depth/biote … ce-travel/

The race to reinvent the space station

https://www.ft.com/content/f50fba1d-5f0 … 5319f9338c

Offline

Like button can go here

#639 2022-10-03 08:51:19

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Crops

How John Deere plans to build a world of fully autonomous farming by 2030

https://www.cnbc.com/2022/10/02/how-dee … -2030.html

Offline

Like button can go here

#640 2022-10-03 09:17:08

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,123

Re: Crops

For Mars_B4_Moon

Re # 639 !!!

Thank you for finding and posting this report!

It is a perfect fit for a mini-project I have in the early starting stage.

(th)

Offline

Like button can go here

#641 2022-10-11 14:53:50

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: Crops

Video of growing potatoes in a 5 gallon modified pale

https://youtu.be/1hIRCnhrJt0

Offline

Like button can go here

#642 2022-10-12 14:32:02

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Crops

Lettuce and wheat grown in space

Offline

Like button can go here

#643 2023-01-02 14:39:48

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: Crops

I agree with void in that first crops will be less energy intensive for heating needs if we are doing so on the surface.

Those could be moved into and out of the canal. Sadly, some of the crops they mention would not like nighttime's just a fraction above freezing. But for some it would work just fine. So, these would actually be some table foods we would be familiar with or could adapt to.

Here are some cold hardy plants: https://gilmour.com/cold-weather-crops# … 20Beans%20

Here are some more: https://www.outdoorapothecary.com/cold-weather-crops/

Quote:Here’s a handy list of cold weather crops to consider for growing in the fall and winter.

Arugula 30-40 days to harvest

Beet 50-65 days to harvest

Broccoli 60-70 days to harvest

Cabbage 50-65 days to harvest

Carrots 55-75 days to harvest

Cauliflower 65-75 days to harvest

Cilantro 60-75 days to harvest

Collards 55-60 days to harvestGarlic in the spring

Kale 45-60 days to harvest

Kohlrabi 55-65 days to harvest

Lettuce 45-60 days to harvest

Leek 85-105 in ground all winter

Mustard 30-50 days to harvest

Green bunching onion 55-60 days to harvest

Snap Peas 55-60 days to harvest

Radish 25-40 days to harvest

Spinach 37-50 days to harvest

Swiss Chard 50-60 days to harvest

Turnip 45-60 days to harvestIf you wanted to do things like Tomato's, you would likely need a heater method. That could be passive solar storage actually. Perhaps a tank of water under the plant bed that absorbed heat from the day. It would need good insulation under and on the sides of it. But then each thing that has to be fussed with has to be justified in a cost benefit analysis.

Offline

Like button can go here

#644 2023-03-22 05:54:07

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Crops

'China ‘Colonizes’ Space with Its First Rice Harvest. The cultivation of food in orbit is part of a larger push by the Chinese space program toward a lunar base.'

https://www.defenseone.com/ideas/2023/0 … st/384285/

Why Future Space Farms Depend on Plants Grown in Antarctica

https://www.yahoo.com/now/why-future-sp … 55472.html

What’s on the Menu? Food and Culture on the International Space Station

https://scitechdaily.com/whats-on-the-m … e-station/

Space Food Challenge

'NASA Announces Finalists in Challenge to Design Future Astronaut Food'

https://www.nasa.gov/directorates/space … onaut-food

A first-of-its-kind coordinated effort between NASA and the Canadian Space Agency (CSA), the Deep Space Food Challenge aims to kickstart future food systems for pioneering missions to the Moon, Mars, and beyond. The multiphase technology competition invites problem-solvers around the world to design, build, and test new ways to sustain astronauts in space for months or even years at a time.

The following U.S. finalists will each receive $20,000:

InFynity (Chicago, Illinois) is utilizing a fungi protein to prepare nutritious and delicious foods.

Nolux (Riverside, California) is producing plant- and fungal-based food using artificial photosynthesis.

Mu Mycology (Hillboro, Oregon) uses a closed-loop mushroom cultivation system allowing for scalable growth of various edible mushrooms.

Kernel Deltech USA (Cape Canaveral, Florida) produces inactivated fungal biomass using a continuous cultivation technique.

Interstellar Lab (Merritt Island, Florida) produces fresh microgreens, vegetables, mushrooms, and insects to provide micronutrients for long-tern space missions.

Far Out Foods (St. Paul, Minnesota) developed a nearly closed-loop food production system called the Exo-Garden that is capable of producing a variety of mushrooms and hydroponic vegetables.

SATED (Boulder, Colorado), or Safe Appliance, Tidy, Efficient, & Delicious, cooks a variety of well-known foods from long-shelf-life ingredients.

Air Company (Brooklyn, New York) developed a system that captures carbon dioxide exhaled by astronauts, combined with hydrogen made with water electrolysis, to produce alcohol that is then fed to an edible yeast to make proteins, fats, and carbohydrates.Additionally, NASA and CSA jointly recognized three international finalist teams from outside the U.S. and Canada:

Enigma of the Cosmos (Melbourne, Australia) created a food production system with an adaptive growing platform that could increase the efficiency by at least 40%.

Solar Foods (Lappeenranta, Finland) uses gas fermentation to produce single-cell proteins.

Mycorena (Gothenburg, Sweden) developed a circular production system utilizing a mix of microalgae and fungi, resulting in a microprotein using minimal resources while generating minimal waste.

Offline

Like button can go here

#645 2023-05-26 09:08:06

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Crops

Some articles on Sugars a mix of new and old

Growing corn

https://extension.umn.edu/corn/growing-corn

Wheat Growers Grow Corn, Soybeans But Name's The Same

https://www.iatp.org/news/wheat-growers … s-the-same

Modified starch market size to grow by USD 2,862.71 million from 2022 to 2027

https://finance.yahoo.com/news/modified … 00584.html

Sugar Biobattery Outlasts Lithium-Ion

https://www.designnews.com/sugar-biobat … ithium-ion

A sugar battery is an emerging type of biobattery that is fueled by maltodextrin and facilitated by the enzymatic catalysts.

Sony, a Japanese corporation, first published the theory of sugar battery in 2007. This type of sugar battery is air-breathing and utilizes the oxygen as the oxidizing agent. Thermoenzymes, enzymes with high thermostability, are used as the non-immobilized enzymes to ensure stability. In the sugar battery, the thermo enzymes are produced by Escherichia coli, a kind of bacterium. Then the enzymes are purified through heat precipitation method and put into use. The battery achieved expected high energy density and reasonable output voltage. Then the company shifted its researching direction in 2012 to the paper battery, which uses paper as fuel. After 2013, Sony didn't release more information about their research project on the biobattery. The sugar battery generates electric current by the oxidation of the glucose unit of maltodextrin. The oxidation of the organic compound produces carbon dioxide and electrical current. 13 types of enzymes are planted in the battery so that the reaction goes to completion and converts most chemical energy into electrical energy. The experimental results have shown that the sugar battery of the same mass can store at least two times, up to ten times electrical energy than the traditional lithium-ion battery can. The sugar battery is expected to be the next general type of mobile electric power source and the possible power source for electric cars. But the sugar battery's output voltage(0.5V) is lower than that of the lithium-ion battery (3.6 V), which causes its electric power (the rate of electrical energy transfer) to be low. Sony, a Japanese corporation, first published the theory of sugar battery in 2007. A research team led by Dr. Y.H. Percival Zhang at Virginia Tech provided the latest version of it in 2014. In 2019, Dr. Zhang was acquitted of 19 counts but found guilty of conspiring to commit federal grant fraud. Since 2014, Several Chinese universities, including Zhejiang University and Tianjin University, started working on researches on the sugar battery. Compared to the currently widely used lithium-ion battery, the sugar battery has potential benefits in many aspects. Compared to the traditional lithium-ion battery, sugar battery does not require toxic metals in manufacturing and releases only carbon dioxide gases. The production of the standard lithium-ion battery would require several metals, including but not limited to lead (Pd), Cadmium (Cd), and Chromium (Cr). The leakage of these metals accumulates inside the vegetables and animals that humans depend on and finally reach humans. Besides, overheating may cause the lithium-ion battery to release up to 100 types of harmful gases to the human body. In some instances, the rechargeable lithium-ion battery explodes to cause a physical casualty.

http://www.sony.net/SonyInfo/News/Press … index.html

https://www.bbc.com/news/technology-16288107

The primary fuel of the sugar battery, maltodextrin, can be enzymatically derived from any starch, such as corn and wheat. Therefore, maltodextrin is renewable.

Last edited by Mars_B4_Moon (2023-05-26 10:25:09)

Offline

Like button can go here

#646 2023-11-11 11:56:06

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Offline

Like button can go here

#647 2023-11-11 15:02:21

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Crops

This thread has estimates for area required for each crop. I'll dig through later to find them. But I checked Google Maps satellite image of the house where I grew up. When I was a child, my parents had a garden 130 square metres. It was cut in half when they built a double car garage. But a garden to feed 2 adults and 3 children would have to be much larger. The garden helped, and my maternal grandfather took my father hunting, but they still bought groceries.

Offline

Like button can go here

#648 2023-11-12 15:15:15

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Crops

A 370m2 plot is equivelent to a square 19.2m aside. That is 19.2m x 19.2m of pressurised, heated greenhouse. Or a polytunnel 2m wide and 185m long. Just to support 1 person. Is that really going to be affordable, long term? With a potato rich diet, land requirements might be reduced to 120m2 per capita. But that is still a 60m long, 2m wide polytunnel. Still expensive. A 1 million person city would need to be supported by a farm covering somewhere between 120 - 370km2. That is a lot of greenhouse.

If we are serious about actually colonising Mars, we need a better solution for producing food that reduces the infrastructure needed. Greenhouse domes and polytunnels can be part of it. Thin panels containing chloroplasts can provide a source of sugar. Algae grown in panels can provide oils, carbohydrates and proteins. The trick is how to combine all of this into foods that people want to eat. Some low mass, high value ingredients can be imported from Earth. Flavourings, colourings, etc.

*******

The use of acetate as an artificial energy source for plants has been discussed on this forum before.

https://www.nationalgeographic.co.uk/sc … ng-out-how

The production steps are: (1) Solar energy is turned into electricity by PV cells; (2) Water containing dissolved CO2 is subject to electrolysis, producing acetic acid; (3) Acetic acid reacts with a base producing an acetate salt. (4) Acetate provides an energy source for algae, yeast, bacteria and fungi, allowing them to grow in the dark. The entire process from sunlight to carbohydrates, is 4x more efficient than photosynthesis. If we assume that food plants are 1% efficient at converting sunlight to calories and taking PV panels to be 20% efficient, the conversion rate of electricity into food energy will be 20%, using the acetate route. The average human needs some 10MJ of food energy per day. If this can be produced from electricity at 20% efficiency, it equates to a continuous electric power demand of 579W. If we relied upon acetate food production entirely, then a 1 million person city could be fed by a 600MWe nuclear power supply. This will be far more compact and affordable than hundreds of square kilometres of greenhouses.

Last edited by Calliban (2023-11-12 16:37:18)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#649 2023-11-13 17:24:45

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Crops

How acetate can replace photosynthesis as the energy source for a plant.

https://m.youtube.com/watch?v=zZrmp5xNcuY

This video goes into more detail.

https://m.youtube.com/watch?v=pQT3_Bjo5Ns

Petrov also discusses a recent breakthrough by genticists, who were able to infuse bacteria with cadmium. The bacteria incorporated the cadmium into their cell walls, where it functions as an extremely efficient photovoltaic cell. The resulting bacteria are able to convert sunlight into acetate with 80% efficiency. That is astounding. Most crops have overall photosynthetic efficiency of 1-2%. These bacteria manage 80%. Panels containing these bacteria on the Martian surface could be used to produce acetate which then provides an energy source for indoor farms. This would allow humans on Mars to be fed using a very compact array of outdoor plastic panels.

Last edited by Calliban (2023-11-13 18:00:38)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#650 2023-11-18 23:36:42

- Steve Stewart

- Member

- From: Kansas City (USA)

- Registered: 2019-09-21

- Posts: 161

- Website

Re: Crops

On the subject of the amount of area required to feed one person, SpaceNut (post#646) posted the article:

Could We Turn Mars Green Sooner Than Expected?

Which states "It takes around 370 square metres to feed a single person on a vegetarian diet."

The (tentative) plan for Artemis 3 is to land two astronauts on the surface of the Moon and stay for about one week (subject to change). If a crew of two were to have an extended stay on the Moon and only eat what is grown on the Moon, it would require a growing area that is 740 square meters in size (about 8,000 square feet). (Based on SpaceNuts post of 370 square meters per person).

One thing to keep in mind, is that humans do not produce enough CO2 for a garden that is big enough to feed themselves. In other words, two astronauts on the Moon will not breath out enough CO2 that a 740 square meter garden would consume. Eventually the plants will die due to a lack of CO2, or the astronauts will die due to starvation. Bryce Meyer has pointed this out a number of times, including in the following YouTube videos. (2nd point below).

Image above is from YouTube video:

Mr. Bryce Meyer: Space Farming, Menus, and Biological Life Support: For Here and There

Image is at 24m 25s into the video.

In the following YouTube video, Bryce explains why humans cannot exhale enough CO2 to feed themselves:

Video: NSS Space Forum -Bryce Myer - Farming in Space for Future Space Settlement

At 16m 50s

"Here is the problem. You do not exhale enough carbon dioxide to feed yourself."At 17m 48s

"The CO2 required to produce enough calories for you is 1.5 times the CO2 from your breath."

Using the image above, Bryce explains why this is true.

On Mars this isn't an issue because there is plenty of CO2 in the Martian atmosphere. The Moon does not have an atmosphere, so on the Moon, finding CO2 for plants is an issue.

Last edited by Steve Stewart (2024-08-03 23:49:46)

Offline

Like button can go here