New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#226 2022-10-28 19:48:51

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,378

Re: Fixing Americas car industry

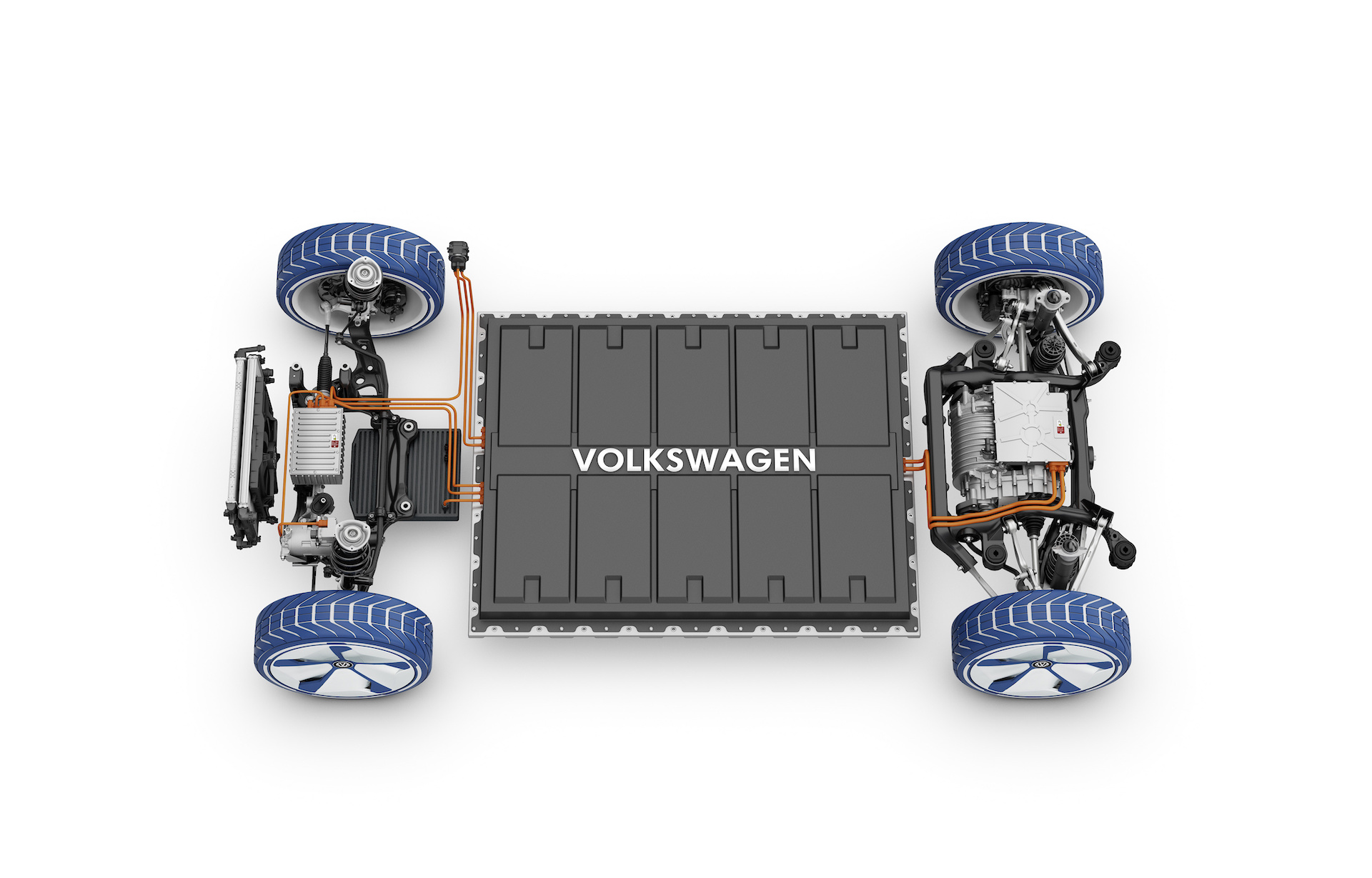

Batteries have just 2 connection points and packs are assembled that way as well to be able to design with bus work that ends with still only 2 connections.

The little tiny blue are for sensing connections

another multi pin connector to deliver the power out of each terminal connection

here is how the cabling is dressed

Offline

Like button can go here

#227 2022-10-28 22:20:49

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,471

Re: Fixing Americas car industry

SpaceNut,

Look at where the wheels are positioned in relationship to the battery pack and electric drive motors. If you had 4 hub motors instead of 1 or 2 drive motors, then the total length of power cabling from the battery pack to 4 hub motors would be almost exactly the same or slightly greater, which means power lost to electrical resistance in the wiring would be almost exactly the same. The only way to overcome that is by moving the wheels outboard and closer to the battery pack, or by otherwise decreasing the distance between the wheels and battery pack, such as changing the suspension geometry to permit the wheels to be moved closer to the battery pack. Both are doable, but neither is an indicator that the hub motor loses less power from reduced power cable length.

The argument made in the article you posted was a false assertion, backed by nothing, and the photograph you just posted about the Volkswagen's battery and electric motor setup only proves it. This is both obvious and silly at the same time. My only point is that a battery pack can be built with more than 2 sets of power terminals. Nothing about the design of a battery pack forbids this, and for vehicles with 2 electric motors or 4 hub motors, there are some significant advantages, such as reduced power cable length / copper consumption / electrical resistance losses.

Some modern Lead-acid car batteries have 4 power terminals, for example:

Advance Auto Parts - DieHard Silver Battery: 3478DT Group Size, 800 CCA, 1000 CA, 115 Minute Reserve Capacity, For Lower Power Demands

Offline

Like button can go here

#228 2022-10-29 11:24:16

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,378

Re: Fixing Americas car industry

First battery power from packs is similar to a hot water solar collector that requires equalization and symmetry to the flow of current from each of the packs to the bus. The reduces the chance of hot spots in the pack currents by not sharing properly.

The battery does not have a direct connection to the motor but go to the controller that creates the pattern of power to drive the motor.

Why Electric Vehicles Catch Fire And Why It's So Difficult To Stop

Offline

Like button can go here

#229 2022-10-29 19:28:07

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,471

Re: Fixing Americas car industry

SpaceNut,

I'm already aware of this, but that doesn't explain the assertion from that media article you posted, claiming that using 4 hub motors would somehow result in reduced power loss via shorter power transfer cables. The more power inverters and power transfer cables you need, the more power is lost as heat from electrical resistance in the power cables and power regulation circuitry.

If all of my battery pack's output power is going to 1 electric motor, then I need 1 power conditioning box (to regulate voltage and amperage, and convert from DC to AC if the traction motor is AC), and 2 sets of power cables (1 set to the power conditioning box and 1 set from the box to the electric motor).

If I have 4 hub motors, then even with only 2 power conditioning boxes instead of 4, I have a bare minimum of 6 sets of power cables, and two smaller boxes that will almost inevitably lose more power from electrical resistance losses than a single larger power conditioning box. Maybe some individual power cables can be somewhat shorter, but only by changing the geometry of the car's suspension (position of the power conditioning boxes in relation to the wheels and motors). The use of hub motors is therefore irrelevant to the length of the power cables.

Within reason, we can make either setup arbitrarily shorter or longer. In either case, the actual difference between the two is almost meaningless, because the heat lost in a properly sized power cable less than 1 meter in length is very small. We can even use Aluminum wiring instead of Copper for the wiring, and the result will be both lighter and less costly. This implies proper connectors for Aluminum wiring, but nearly all high voltage overhead power lines are Aluminum, not Copper, so this is clearly doable.

If batteries can only have 2 terminals for power take-off, which is not true as I've already shown, then the wiring runs for 2 of the hub motors in a 4 motor setup are significantly longer. Again, I fail to see what you're point out to me. That article was marketing hype, not engineering reality. You and I both know that.

Hub motors significantly increase unsprung weight, which almost universally deceases acceleration and deceleration performance (requiring more power output in the motors and brakes to overcome), now there are 4 motors to control instead of 1 or 2, which means more power inverters, more connectors, more wiring, and therefore more cost (and more failure modes, which further increases cost). In short, it's a great way to drive up the cost of the vehicle while doing little to nothing to meaningfully increase performance.

How do they manage to sell this nonsense to people?

Back in the 1950s to 1980s, a 200hp to 300hp engine implied a V8. With reliable turbocharging and intercooling, today that same power level implies a computer-controlled I4 with a turbo and single or dual overhead camshafts so that it can rev to the moon while maintaining control over the valve train. If cost and weight matter, then the I4 plus turbo is the best way to achieve that power output level for a given amount of money and engine weight. Apart from trucks used for towing, there's no significant advantage in a passenger car to using a larger displacement (and larger / heavier) V8 that will consume more fuel at lower rpm operation, which is where it will spend most of its operational life. Turbos are now pretty cheap and pretty lightweight, and consume engine exhaust power to drive them. As little as 20 years ago, that was not the case.

Similarly, adding more motors and equipment to an EV car's powertrain will not make it more efficient / lighter / less costly to produce. That's a marketing gimmick, full stop. I would tell you the same thing if you were comparing a passenger car with an I4 turbo vs V8. The I4 is less costly to make and operate and it can deliver the same torque and horsepower as the larger displacement V8 by cramming more air and fuel into each cylinder (and therefore spending more time with its throttle blades closer to wide-open, increasing the thermodynamic efficiency of the engine). Doing that is predicated on a durable block and rotating assembly design that can handle the increased heat rejection and cylinder pressures, but assuming you can do all that reliably, then the I4 is the best way to do it. I'd say we can make 200hp to as much as 400hp that way, pretty reliably. Anything over the top of that enters into race car engine territory, which are known for their performance, but not for their reliability or low cost, and most passenger cars and trucks prioritize reliability and cost over absolute performance.

If you told me your EV was primarily intended for off-road use at low to moderate speeds and needed AWD as a result, then I would tell you to consider the 4 hub motor setup, because then that makes a lot more sense, and at that point your vehicle is so heavy, in order to be durable, that the increase in unsprung weight is far less important than its ability to deliver power to whichever wheel has best contact with the ground, and that's easiest to achieve using 4 independent motors. An EV semi-truck is another reasonably good application of hub motors, largely for the same reasons- the weight of the rest of the drivetrain in a traditional setup is so extreme that using hub motors would be lighter, it takes power to move all of those other heavy duty drivetrain components, and the total mass of all the sprung components is so great that the unsprung mass of the hub motors is practically meaningless by way of comparison.

Offline

Like button can go here

#230 2022-10-30 10:23:07

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,378

Re: Fixing Americas car industry

Hub motors are direct drive no gears, clutch, transmission ect that in itself makes that more efficient.

The hub motor is also going to be small in wattage as a result of torque is equalized to all 4 wheels even when summed as compared to the much large unit. So, each unit assembly will draw less current across all cabling which means smaller wire gauge can be used and at less wattage lose across them.

Symmetrical bussing from the battery pack also means less lose to bring the batteries connection to the assembly for use. AWD is for stable road traction even when wet to snow or ice covering.

Offline

Like button can go here

#231 2022-10-30 10:57:34

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,293

Re: Fixing Americas car industry

Hydraulic hybrid:

'One research company's goal was to create a fresh design to improve the packaging of gasoline-hydraulic hybrid components. All bulky hydraulic components were integrated into the chassis. One design claimed to reach 130mpg in tests by using a large hydraulic accumulator that is also the structural chassis. The hydraulic driving motors are incorporated within the wheel hubs and reversing to recover braking energy. The aim is 170 mpg in average driving conditions. Energy created by shock absorbers and kinetic braking energy, that normally would be wasted, assists in charging the accumulator. An ICE sized for average power use charges the accumulator. The accumulator is sized to run the car for 15 minutes when fully charged.'

https://en.m.wikipedia.org/wiki/Hybrid_ … drivetrain

A 130mpg fuel consumption would be revolutionary. Getting 170mpg sounds too good to be true. The interesting thing about this technology is that it can be applied to cars, trucks, buses and trains. It could therefore improve fuel economy across all transportation sectors.

Last edited by Calliban (2022-10-30 11:00:36)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#232 2022-10-30 12:47:29

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,471

Re: Fixing Americas car industry

SpaceNut,

Hub motors with no clutch means no free-wheeling, so it's either drawing current from the battery or acting as a generator at all times. Hub-motors with no gearing means no torque multiplication at low speed, so that the much smaller hub motors can produce equal torque to a much larger and centrally-located motor. Torque production and rotor volume are related to each other. There is much less rotor volume inside a wheel cavity that must also include brake rotors. Transmissions are also used for torque multiplication, but not as necessary using electric motors that produce most of their rated torque from a dead-stop. If you want to make a reasonably light hub motor, then you need gearing because the motor's rotor is only moving at 1,500rpm at most, at highway speeds.

Unless all 4 hub motors generate the same amount of power output as the larger central motor(s), then they're not as powerful, so we have an unequal comparison. Drawing less current per motor is irrelevant if all 4 hub motors produce the same total power output. The total current draw on the battery pack is the same, or greater in your "equalized buss" scheme (4 smaller batteries within the overall battery pack, acting as independent battery packs, with each smaller pack supplying power to an individual hub motor).

Using smaller cables without also increasing voltage means more electrical resistance losses per cable or less total power output. You can only increase the input voltage to a point without exceeding insulation capabilities, or you can increase the current flow. After about 240V or so, preventing arcing and sparking requires very effective insulation, and the limitation here is primarily the electric motor's internal windings, more so than the power cables feeding power to the motor. That is much easier to do with a centralized motor that is not confined to the interior of a wheel hub, while sharing that volume with a brake assembly.

There is no "winning" here, only trade-offs that optimize the powertrain solution for a specific use case and vehicle weight and performance characteristics. The hub motor setup can be more effective at apply torque to the ground under scenarios not common in passenger car driving on a prepared roadway. If your vehicle is primarily driving in a straight line at modest speeds, then so-called "torque vectoring" is not a significant advantage. You primarily accelerate in a straight line, brake to reduce speed in turns, and you're driving over a surface that's optimized for wheeled motor vehicles to use. There are few sharp turns, even less hard acceleration through sharp turns, such as merging onto a highway, etc, where hub motors would really shine. Passenger cars are not typically taken off-road, either.

For semi-trucks, hub motors could reduce total drivetrain weight and complexity, decreasing costs. For a passenger car that's not driven like a race car, I'm not so sure it meaningfully alters performance, except for reduce braking and acceleration performance at increased cost. Tesla has plenty of money to test these concepts, but they didn't think it was worth the increased cost and complexity.

Hub motors are also subjected to the same impact and vibration punishment as the wheel and tire itself, which means they must be sturdily built, therefore heavier and cost more. If money is no object, then any solution will do. If you want optimal road car performance on a road, up to 75mph or so, for minimal cost / complexity / smooth ride / good acceleration and braking, then you're not using hub motors to do that.

Offline

Like button can go here

#233 2022-10-30 13:09:11

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,471

Re: Fixing Americas car industry

Calliban,

Whenever we tell these people on the left, "Hey, bubba, the implied engineering trade-offs in your solution means it won't work the way you want it to", then instead of taking that as a "clue" that what they want isn't doable, they double-down and triple-down on something that clearly doesn't work the way they want it to.

Hub motors with equal power output to a Tesla create unsprung weight equivalent to an all-Aluminum LS-series small block V8, or they require gearing and other tricks because the rotor volume is so small. Whatever advantages they may have provided were immediately given up in the form of other inefficiencies. Now the wheels, tires, shocks, and other suspension components have to be bigger / stronger / heavier as a result. LightYear Zero / LightYear One uses hub motors, so why can't we do that for other cars? Yeah, but those cars also cost a quarter of a million dollars and must drastically compensate in other areas, such as using a full CFRP chassis to reduce the weight of the rest of the vehicle to tolerable levels, they give up range via a smaller battery pack, and undoubtedly feel like driving a race car with a stiff suspension that provides a jarring ride. Case closed and game over. Next.

Offline

Like button can go here

#234 2022-10-30 16:04:41

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,293

Re: Fixing Americas car industry

Hub motors mean having 2-4 motors with 2-4 power supplies instead of just one. They eliminate the need for a drive shaft. But each of those motors must be seperately controlled, cooled and supplied with power. Power supply cables are really impressive when you are supplying 450HP (340kW) at 12v. That is lots of amps and even a small amount of resistance creates a lot of heat. They aren't so much cables as solid bars of copper. When the weight of those thick conductors is accounted for, you aren't saving very much weight over a drive shaft. And the drive shaft is steel not copper. Steel is cheap and abundant. Copper is neither. So I wouldn't expect hub motors to radically improve the viability of BEVs. Maybe a hydraulic power transmission system would be better? The electric motor could drive a hydraulic pump, with hydraulic motors onneach wheel? The hydraulic oil can also cool the motor and distribute the heat throughout the chassis.

Last edited by Calliban (2022-10-30 16:12:04)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#235 2022-10-30 16:48:33

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,471

Re: Fixing Americas car industry

Calliban,

At times I wonder if people think that engineers simply try random things, hoping for the best.

For a 208kW rear drive Tesla Model 3 electric traction motor, the battery pack operates at a nominal 350V and the traction motor operates at 335V, which implies 621A of peak current delivered to the motor by the power inverter. In order to make the motor smaller, it's geared and spins between 6,000rpm and 8,000rpm, and supplies 260ft-lbs of torque up to about 5,500rpm. The gearbox provides a fixed 9:1 reduction, so multiply that torque figure by 9 and that's about what the Model 3 can put to the ground, assuming it can maintain traction.

Anyway, that's an incredible amount of current for any conductor to carry, when fitted to a moving motor vehicle. At that point, the conductor does more closely resemble a bar of Aluminum or Copper, much thicker than the heavy duty 240V power cables used to power electric dryers in homes. It's a good thing those cables are really short.

Offline

Like button can go here

#236 2022-10-30 16:57:04

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,378

Re: Fixing Americas car industry

Yes, there are tradeoffs for any changes in design connectivity of hub motors and being direct or geared. That is the issue for every car gasoline powered as well.

Could Hybrid Transmissions Save Traditional Internal Combustion Engines?

The aero dynamics is different for hub motors are they are in the wheel drag envelope and do not extend into the air as larger motors do.

The separate hub motor controllers can be smaller, and they do not need to change in voltage to get the same drive capability. The voltage is changed to make the wire size smaller as a function of current that is also lessened as a result of the power deliverable from those changes. The power is a pulsed current and not steady to the motor also changes the wire sizing.

Offline

Like button can go here

#237 2022-10-30 17:09:21

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,471

Re: Fixing Americas car industry

SpaceNut,

The juice isn't worth the squeeze. Pretty much all motors and engines don't contribute significantly to aerodynamic drag because those parts of the vehicle are inside the chassis. Again, making more smaller hub motors and controllers does nothing to improve performance. The vehicle isn't lighter, and there's no drag penalty or benefit either way.

Whether you need 4 wires to carry 335V at 310A or 2 wires to carry 335V at 621A, the ampacity of wiring is a fixed value. The individual power cables are smaller, yes, but now you need more of them, along with more power inverters, stiffer shocks and springs, stronger wheels, and stronger tires that carry the full weight of the traction motors without the benefit of being suspended on top of the shock absorbers.

In the real world, 4 smaller battery packs vs 1 large pack means lower operating voltages or more losses getting the voltage up so that the power cables can be smaller.

All of these trade-off don't do anything positive for passenger cars, except for increasing their cost and weight.

Offline

Like button can go here

#238 2022-10-30 17:39:09

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,378

Re: Fixing Americas car industry

The battery is not 4 smaller battery packs it's the same battery only internally bussed differently to support the connecting points.

Time to standardize The size and shape of a plug-in hybrid electric vehicle’s (PHEV) battery pack might seem like an odd thing for the government to get involved in.

Are hub motors the future choice for EV power train ?

The motor technology used in this motor is brushless dc technology. Brushless dc ( BLDC ) motor is the next generation of DC motor technology where the mechanical commutation is replaced with electronic commutation. This removes all the contacts between rotor and stator and gives a longer life for the motor. Use of BLDC Motor technology helps to improve the power density of a motor. i.e. For the same power rating, BLDC Motor will be smaller than DC Motor. This scaling up of the power density is attainted by usage of Neodymium Iron Boron magnets. Let us limit the details of BLDC for now and talk more about the hub motors.

The Protean drive is a 75-pound electric motor that generates 100 HP and 735 lb-ft of peak torque. The motor does not require external gearing, drive shafts, or differentials. The motor package, which contains an inverter, control electronics, and software, fits easily in the unused space behind a conventional 18 to 24 inch.

unsprung is what the entire car is....

Hub Motors for All-Electric Vehicles Still Have Some Technological Challenges to Overcome

The Active Wheel

The Active Wheel, a hub motor from Michelin, Greenville, S. C., that has been in development for at least a dozen years, has appeared on several concept cars but no actual production vehicles. It is an advanced hub motor in that it uses two electric motors: one to turn or stop the wheel and the other to power an active suspension. It also contains a brake and uses regenerative braking. The total weight is 95 lb per motor.The drive motor, a 30-kW, water-cooled version, mounts off-center where its shaft turns a spur gear which drives a ring gear on the hub and, thus, turns the vehicle’s wheel. The suspension motor operates the active suspension via a gear rack and pinion that replaces a hydraulic shock absorber. It controls ride height, pitch under braking, and roll during cornering, and reacts within 0.0003 sec. A coil spring in the wheel supports the static load of the car. The Active Wheel mounts to the vehicle chassis using a single lower-control-arm suspension.

Two Active wheels deliver about 40 hp, which can peak at up to 80 hp. That’s enough to take a 2,000 lb car from 0 to 60 mph in about 11 sec, and give it a top speed of 95 mph.

I see planetary would be better.

Offline

Like button can go here

#239 2022-10-30 19:35:03

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,471

Re: Fixing Americas car industry

SpaceNut,

If you're drawing the same amount of power from the battery but have a more complex setup required to do that, then... It costs more money and adds more weight. BLDC motors use rare Earth magnets, whereas a Tesla's AC induction motor does not. Again, more cost, equal complexity, and more difficult to recycle.

Unsprung weight refers to weight not sitting on top of the vehicle's suspension system. Wheels and brakes are unsprung weight, and all other automotive manufacturers try to keep that low, for some strange reason. Maybe none of them know what they're doing, but I kinda doubt it.

Protean's PD-18-4250 data sheet lists the motor weight alone at 36kg, which is 79 pounds and some change, which means in addition to the weight of the wheel and brakes, the traction motor alone weighs more than the tire and wheel on my wife's Cadillac Escalade, implying that that's how much inertia is being overcome for a passenger car. In addition to the weight of the wheel and tire, you're moving the mass equivalent of a Cadliiac Escalade wheel and tire (and then some) along with it. I'll go way out on a limb and state that overcoming the inertia of that much extra unsprung weight will hurt performance. If the vehicle is absurdly heavy, as nearly all EVs are, then no biggie. However, no matter what marketing mumbo jumbo is asserted, it's going to cost more, weigh more, and decrease performance over alternatives.

Offline

Like button can go here

#240 2022-10-30 20:25:15

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,378

Re: Fixing Americas car industry

To energize the inductive core means more energy is drawn into it as compared to a BLDC permanent magnet which is less power.

Offline

Like button can go here

#241 2022-10-30 21:04:00

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,471

Re: Fixing Americas car industry

SpaceNut,

That part is actually true, but AC induction motors also need less cooling than BLDC because there are no PMs that can overheat, losing their magnetization in the process, and AC induction can generate considerable torque for brief periods of time, which sounds an awful lot like motor vehicle acceleration to highway speeds. So... Take that same BLDC motor, attach it to a drive shaft so that you don't have to overcome 150 to 300+ pounds of inertia every time you want to accelerate or decelerate the car, and once again, the arguments in favor of BLDC hub motors go right out the window. AC induction functions well over a much wider range of speeds and temperatures than BLDC, which is why Tesla uses them.

Offline

Like button can go here

#242 2022-11-05 15:33:11

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,378

Re: Fixing Americas car industry

Koenigsegg's Tiny Quark Electric Motor Produces A Whopping 355 Hp And 443 Lb-Ft

This teeny tiny unit Quark electric motor will not be available only in a single unit (shown in the pictures below and above) weighs only 63 pounds, due to its power output and innovative use of the Raxial Flux topology, which stands for the combination of radial and axial flux topology.

The Swedish manufacturer also developed a self-contained electric-drive unit called the Terrier, which actually composes two Quark motors, two gear sets, and an inverter.

At 187 pounds, the unit also plays the lightweight-design card without compromising the power output. The Terrier should deliver a stunning 670 horsepower and 811 lb-ft of torque of peak power and find its place in a new Koenigsegg hypercar.

Offline

Like button can go here

#243 2022-11-05 15:52:07

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,471

Re: Fixing Americas car industry

I discovered this man named Casey Putsch last night while working on a data conversion project. Casey is an actual engineer who has stated absolutely everything I've stated, oddly enough his actually built car design is incredibly similar to what I've proposed doing, and he's done it using off-the-shelf combustion engine parts and engineering materials that already exist.

The engine used for his vehicle is a Vollkswagen 1.9L turbo diesel.

While thrashing on his car during "performance testing", he achieved 80 miles per gallon.

He built the car to out-accelerate his V-10 powered Dodge Viper, from 0-60. He came within a few tens of a second of the performance of the gigantic 8L+ V10 that powers his Viper, an American muscle car well known for it's drag-racing type of straight-line acceleration.

Mr. Putsch speaks to my points about motor vehicle design, such as absurd levels of over-complexity, at some length, through an entire series of videos about his Omega car concept, which he's actually built and tested and measured both raw performance and fuel economy.

Casey's OMEGA CAR because the AUTO INDUSTRY doesn't GET IT!

On a separate YouTube video I'm currently watching, released yesterday, where legendary British-American engine designer / builder David Vizard spoke with "Uncle Tony" from the "Uncle Tony's Garage" YouTube channel (which focuses on teaching young men and women how to build performance street engines and low-budget race cars for people of average means, mostly using careful selection and assembly of factory-style components, with an emphasis on classic Chrysler / Mopar muscle cars), there was this little gem in Mr Vizard's comments:

"You select components for your engine based on what it needs to make power, not what you want. What you want is irrelevant."

This is perhaps the least appreciated aspect of design in general, and is especially applicable to all energy-using systems. What you want is utterly irrelevant if basic physics determines how well the end result will work. For whatever reasons, mostly aesthetic in nature so far as I can tell, a lot of people cannot accept this.

Offline

Like button can go here

#244 2022-11-05 16:17:45

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,378

Re: Fixing Americas car industry

Acceleration is handy when changing ramps exits to getting moving under a stop but after that its used to pass a slow vehicle that may not really be moving slow but is in your way or view for a clear road. That is torque that allows for the hard change to happen to a mass. Electric motors use tons of current under that hard accelerating condition and if they are the recharging unit that is where heat buildup comes into play.

I keep hearing of battery charging caused fires from even e-bikes being inside a building. This happens when the charge does not have a shutoff feature for when a battery is full. These chargers are cheaply made and are voltage charging not current as that is what is truly required for lithium. The sense circuit detects full voltage and stops the charging with a latching circuit so as to keep it from coming back on while the unit is still powered up.

Offline

Like button can go here

#245 2022-11-05 16:57:00

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,471

Re: Fixing Americas car industry

Koenigsegg Gemera's 3-cylinder 600hp Engine

The Gemera is the first four-seater car built by Koenigsegg and the first to be powered by a compact engine weighing only 70 kg (150 lb). The engine is so small because it is a camless piston engine, the first such engine announced for a production car. Called the Tiny Friendly Giant (TFG), it displaces 1988.25cc and has two turbos and three cylinders driving the front wheels and charging the batteries. It is rated at 590 hp (440 kW) at 7500 rpm, with a redline at 8500 rpm, and 600 N⋅m (443 lb⋅ft) of torque from 2000 rpm to 7000 rpm.

...

These outputs are produced when the engine runs on E85 fuel, but it can run on any major fuel from E100 to standard gasoline.

...

The total dry weight of the motor and attached components (alternator, water pump, transmission) is listed as 366 pounds.

The fuel economy of the "TFG" engine is 45.2 MPG (5.2 L / 100km).

The difference between the Quark electric motor and the "Tiny Friendly Giant" engine is that the "TFG" engine can make 590hp without being connected to a 600 pound battery. The fuel tank capacity is listed as 4.6 gallons, which implies a driving range of over 200 miles. The fuel and tank would add about 32 pounds to that 366 pounds figure, for a total weight of 398 pounds.

The 16.6 kWh 800V battery pack provides the Koenigsegg Gemera with 31 miles of electric-only driving range. That battery pack weighs just shy of 200 pounds. To provide equivalent electric driving range to the gasoline engine, multiply 31 by 6.7, and you arrive at a battery pack weight of 1,340 pounds.

As-is, the Koenigsegg Gemera's electric motors, battery pack, and gasoline engine cause the car to post a curb weight of 4,079lbs.

If we subtracted out the 398lbs for the combustion engine and added in the batteries and kept the electric motors (4,079 - 398 + 1,340 = 5,021). That's a 23% increase in vehicle weight, which would likely require a complete redesign of the entire vehicle. The Tesla Model S Plaid edition weighs 4,766lbs with its 100kWh 407V battery pack, but clears 396 miles of range using half the voltage of the clearly far less efficient 300-mph-capable Gemera hypercar.

Would the Tesla do significantly better by operating at double its current battery pack voltage and using Quark electric motors?

That's very doubtful. The "proof" is the Tesla Model S Plaid's driving range.

In other words, if overall vehicle efficiency is at all important, then I think Tesla takes wins that contest, hands-down.

I wonder how much lighter and more fuel efficient the Gemera would be if Koenigsegg dumped the EV powertrain and "settled" on a car with "only" 600hp. Most semi-trucks don't have 600hp. Think about that for a moment. We're designing road cars with 600hp to 1,000hp engines. All I ask is, "To what end?" What the heck does a "grocery getter" need 1,000hp for?

Are these cars intended for commuter driving, NHRA drag racing, or toppling land speed records?

If instead we designed efficient gasoline engines with 25hp to 100hp, because the vehicles those engines were dropped into were less ridiculous in terms of curb weight or trying to turn passenger cars into race cars, and therefore power requirements stayed within the realm of sanity for something I'm using to drive my kids to school and then go to work, then think of how small / light / efficient they could be.

An adult could easily remove the engine from the engine bay, by hand. A 50hp variant of the "TFG" engine should weigh about 33lbs. Oddly enough a German-built Wankel engine that weighs about that much, already makes 50hp and has been used in Go-Karts for more than a decade.

Offline

Like button can go here

#246 2022-11-06 11:06:42

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,471

Re: Fixing Americas car industry

Koenigsegg Quark Torque and Horsepower Output Chart:

250Nm is about 184ft-lbs.

Koenigsegg FreeValve / "Tiny Friendly Giant" Torque and Horsepower Output Chart:

Optimization of FreeValve´s fully variable valve control system for a four-cylinder engine

According to the chart, Koenigsegg's FreeValve / "Tiny Friendly Giant" / "TFG" engine also maintains a virtually flat torque profile up to about 6,000rpm, and then it drops off.

Offline

Like button can go here

#247 2022-11-06 11:54:09

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,471

Re: Fixing Americas car industry

For those who think diesel engines cannot be replaced with spark-ignited Propane engines, I present "the solution":

GM Authority - Katech Has Built A 1,000 Lb-Ft LSX Propane Engine For Buses

Edit (image link):

KaTech's LSX-platform LPG-fueled Engine for Buses

From GM Authority and KaTech:

Most General Motors enthusiasts probably know Katech for its relation to Corvette Racing and its numerous other motorsports endeavours.

Katech built the V8s engine that powered Corvette Racing’s Corvette C5-R and Corvette C6.R GT1 to a myriad of victories, including six class wins at the 24 Hours of Le Mans, and also helped Cadillac Racing achieve its championships in the SCCA World Challenge series with the Cadillac CTS.V.R Sedan and Coupe. The fifth-generation FIA Chevrolet Camaro GT3 car also used Katech power, along with the Grand Am Chevrolet Camaro GT.R and..well, you get the picture.

The company has expanded its business beyond high-performance racing engines in recent years and today has a wide portfolio of powertrain-related services available to consumers, race teams, OEMs and anyone else who could benefit from its technical expertise. It recently put together a video documenting its new GM LSx-based alternative fuel engine, which makes 1,000 lb-ft of torque at engine speeds of just 3,000 rpm using liquid petroleum gas (LPG).

This engine is destined for use in Class 6 passenger buses in Europe, or city buses with a maximum weight of around 26,000 lbs. Katech says that in addition to this LPG engine, it can also produce similarly high-output engines using compressed natural gas as a fuel. It’s planning on putting the engine into production in numerous locations as well, allowing it to more easily serve the global market. The alternative fuel V8 will only be built at Katech’s HQ in Michigan to begin with, however.

Katech’s CEO believes the internal combustion engine will always be around and thanks to mass transit, shipping, heavy industry and other such applications, he’s right. The fuel type could change though, especially with regards to industrial applications, which is why Katech is diversifying its business and working on cleaner, more efficient engine designs.

Hear what Katech has to say about the alternative fuel LSx engine in the video above.

571hp at only 3,000rpm, in an engine that should weigh about 710lbs with the supercharger and engine accessories. LSx is an Iron block that adds over 100lbs of weight to the all-Aluminum LS-series engine blocks, but also quite a bit of bottom-end strength. Corvettes have all-Aluminum engines, but the Iron block truck engines are far more common. I think this is a 6.2L dispalcement setup, which would be stock displacement for the similar all-Aluminum Corvette engine. LSx's supercharging is similar to the LT5, and a stock LT5 Corvette engine makes 14 pounds of boost using its supercharger. I wager they had to produce similar boost, 21 to 28 pounds of pressure per square inch (over atmospheric) to produce similar output to the 6.6L L5P DuraMax V8 diesel engine (which also uses an Iron block and Aluminum heads).

GM produces a similarly capable 6.6L L5P DuraMax V8 diesel engine (greater displacement) with a dry weight of 835lbs, but to get 571hp you'd have to tweak the engine and add more intercooling capacity. It's doable, but the engine is much heavier. Street performance tuned variants of the DuraMax make right around 1,000ft-lbs of torque at 3,000rpm, and of course, horsepower is identical. Peak boost pressure is 28psi, which is probably similar to what that belt-driven supercharger on the KaTech engine is making. IIRC, variants of this engine have also been powered by Propane. After you add in all the exhaust treatment accessories for the diesel, you're looking at 1,000lbs to 1,100lbs if I remember what Gale Banks said correctly, but Propane doesn't require some of those treatments, so maybe 900lbs in total- about 200lbs more than a spark-ignited engine that's running similar compression ratios (Propane octane rating is 104 to 112) and similar boost levels.

Last edited by kbd512 (2022-11-06 20:30:14)

Offline

Like button can go here

#248 2022-11-13 13:50:05

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,378

Re: Fixing Americas car industry

Today is a rainy day but the Toyota began to misfire, and the check engine came on so off I went to get new spark plugs to change. While they seem to have given a bit better performance the light on the dash remains which means getting a garage to reset it to see if more problems are being detected.

Of course, the fancy electronic dash is little more than a modified calendar for component replacement and not an actual information board to display what the car is actually doing. Not even a coolant temperature value can be found.

Offline

Like button can go here

#249 2022-11-13 14:20:03

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,471

Re: Fixing Americas car industry

SpaceNut,

Out of curiosity:

Were the old plugs excessively fouled or damaged in any way?

Did you try cleaning them if they were merely fouled (with a Propane torch to burn off the Carbon, or brake cleaner, or a soft wire brush)?

After cleaning, did you check the resistance of the old plugs with a multimeter before discarding them?

Did you check the new plugs, given how much "bad-from-the-box" garbage is being produced these days?

I've seen shops throw away perfectly good plugs that simply needed to be cleaned off. Other than that, there was nothing wrong with them, from an electrical standpoint.

The multiple cylinder misfire issue that my Charger had was apparently the result of someone changing the timing chain on the engine, installing the new or old chain backwards, as well as off by one or two teeth or notches (backwards installation probably would've made no difference at all, but being "off" because you couldn't see and line up the timing marks certainly would). That was really weird and it would never have occurred to me that someone would put the timing chain on backwards and off by a tooth, but I guess they didn't bother to read Chrysler's instructions for changing the timing chain.

Air entering the exhaust (bad exhaust manifold gasket allowing air into the exhaust), bad O2 sensors giving faulty readings, bad wiring or ground, or a bad computer can also cause that.

Did anyone mess with the engine's timing before you purchased the car?

In my case, engine timing was off because someone messed with it, the O2 sensors were very BBQ'd, the replacements were of the wrong type that caused the computer to throw error codes, and the catalytic converters were both shot. The wiring turned out not to be a problem, although I also cleaned lots of corrosion off various grounding points that the wiring harness was attached to on the engine or chassis and also tried using another ECU (didn't help, because the computer and wiring were not the problem).

Edit:

I almost forgot, but I also replaced the fuel injectors and the seals on the intake manifold, because the seals were shot and the injectors were internally corroded. I cleaned the gunk off the throttle body but did not replace it. Come to think of it, I also replaced the MAF sensor and the seals for the EGR valve.

Last edited by kbd512 (2022-11-13 14:23:22)

Offline

Like button can go here

#250 2022-11-13 17:57:41

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,378

Re: Fixing Americas car industry

I remember the issues that you came across and hope that the repairs will last.

Searched for a bit before I got started through the tools for the sockets and wrenches to be able to start the repair. Just need some more replacements as the sets seem short for some sizes in them.

I found no fouling but 1 plug I could see a filament that stretched across the tip to the anode. All plugs were replaced, there was a rust ring around one in addition for appearance. I removed the air breather and noticed the fuel injector wires were cut into but still intact near the connector which means splicing in a new connector with wires once I get to it.

Offline

Like button can go here