New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#51 2022-09-03 01:34:44

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,307

Re: Wireless/induction EV charging revolution

SpaceNut,

That's one more reason not to buy any of this "smart home" crap they've been selling to the ignorant public, in an attempt to "control" other people. The people who think they need to control other people are also the ones who utterly lack impulse control, morals, and ethics.

Offline

Like button can go here

#52 2022-09-03 21:21:59

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,741

Re: Wireless/induction EV charging revolution

Seems that the power company could have predicted the lack of capacity and they chose instead to not upgrade which seems to be lacking morals and ethics to its customers so as to not need to seek to control and correct power to its customers that needed the AC to not get too hot whom bought smart gear to be sure they could control it remotely.

This is no better in brown outs or black outs to keep the grid from failing California power officials put out a plea: Shut it down at 4 p.m. to protect the grid

Offline

Like button can go here

#53 2022-11-19 21:24:37

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,741

Re: Wireless/induction EV charging revolution

We’ve Been Charging EV Batteries All Wrong

Well its a study on charging and discharging to get more battery life.

Stanford tried to charge each cell individually to increase overall longevity. Some cells are more robust and can take a lot of juice stabbed into them. Other, weaker ones need to have the electricity flow at more moderate levels to keep it from completely going out. Discharging would also have to be variable for each cell. Stanford discovered that single battery cells last longer than battery packs. But when a weaker cell dies sooner, it sucks the life out of the pack as a whole.

Sort of a duh moment

Offline

Like button can go here

#54 2022-11-24 16:28:38

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,741

Re: Wireless/induction EV charging revolution

How Much Does It Cost To Charge a Tesla on a Road Trip?

For instance, if you take your 2022 Tesla Model 3 Long Range from Orlando, Florida, to Denver, Colorado, you will need to charge for 3.33 hours along the way. That is just over 1,860 miles or 27 hours and 59 minutes of travel.

If you end up paying $0.20 per kWh and don’t incur any more costs, the estimated total charging cost for the trip: is $95.28. There is a good chance you might have to pay an additional dollar or two along the way, but the cost to charge a tesla on a road trip is still under $100.

Offline

Like button can go here

#55 2022-11-25 12:14:21

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,741

Re: Wireless/induction EV charging revolution

https://www.nationalgrid.com/us/EVhighway

National Grid estimated the future electricity demand at 71 potential charging sites, including service plazas and truck stops, in the Northeast. It assumed that all light-duty car sales will be electric by 2035 and all medium-duty and heavy-duty sales will go the same route by 2045, in line with Massachusetts' and New York's stated goals.

Offline

Like button can go here

#56 2022-11-25 12:36:50

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,307

Re: Wireless/induction EV charging revolution

SpaceNut,

In reference to Post #53, How practical is it to have a battery pack comprised of hundreds or thousands of individual cells, that must be individually charged to preserve their service life?

If they need to be charged at different rates, does that also mean they need to be discharged at different rates, and if so, does that seem practical to do?

This seems to say to me that batteries need to be built in such a way that a much smaller number of cells provide the correct voltage and amperage, or that step-up / step-down transformers are required.

Can we realistically do that?

With regards to Post #54, the key statements are "if you don't incur any more costs" and "if your electricity only costs $0.20/kWh, everywhere you go". We already know that such a statement is not reality-based, so what is the point of statements like that?

A fast charger can't be profitable at $0.20/kWh, and unless you're stopping every couple hundred miles or so, the entire premise behind that is utter nonsense. That's why we typically see fast chargers providing services to customers somewhere between $0.50/kWh and $1/kWh.

"If you can breathe underwater and drink sea water and survive temperatures far below your core body temperature, then the O2 and H2O are free and you can swim to another continent, eating the fish as you go, so you no longer need to pay for transportation or meals, nor emit any CO2 and Methane, except for all the feces and urine humans generate."

That all sounds great so long as we're living in fantasyland, but how many people can breathe underwater or drink straight sea water or swim in water with a temperature of 40F?

Do you understand how incredibly dumb statements like that sound when people make them about EVs?

You have to live in a make-believe world to accept them as having any factual basis.

In other words, all magical thinking has its limits.

Offline

Like button can go here

#57 2022-11-25 12:43:40

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,741

Re: Wireless/induction EV charging revolution

Your laptop battery pack has the circuitry in it that does the independent charging that car units do not have.

charger electricity from the grid could be less or more than what you are charging the customer for sure but if it's from a solar source that cost is most likely dependent on its size capacity to cost long term should be lower and making it profitable.

I have a Hannaford's that has the Tesla charging units but there is no signage, and I believed the space is leased. I imagine that this is a licensed franchise location for how it was set up.

Time to see if I can find out more.

Eversource is a deregulated power company that is forced to share the wires for other suppliers to provide power to its customers. Which means a delivery charge is part of that distribution at about 15 cents a kwh. Where the supply is 22.5 cents which brings the total charge for a kwhr to 37.5 cents for the first 400 units and increases for supply only for those above it.

Since this location has not panels it's got to buy its power even at a business discount at a cost that will be passed onto its customers.

in 2016 Hannaford did undertake putting these stations on their lots and in 2018 this one arrived

Project would add Tesla chargers at Rochester Hannaford

KJK Wireless LCC of Nashua NH is independent of Hannaford,

They did receive a PPP loan in years 20 and 21 https://www.federalpay.org/paycheck-pro … -nashua-nh

Offline

Like button can go here

#58 2022-11-25 15:10:36

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,741

Re: Wireless/induction EV charging revolution

How much does it cost to charge a Tesla at a charging station?

How much does it cost to use a Tesla charging station?

Tesla Charging Cost Calculator

The average retail price for electricity is $0.13 per kWh (see below for an average electricity rate by state) and the average cost of a Tesla supercharger is $0.25 per kWh (this varies significantly by state).

Electric car efficiency is a measure of how many miles an EV can travel on a given capacity of the battery in kilowatt-hours (kWh) of electricity. Tesla’s Tesla S energy consumption was 21.75 kWh per mile, or about 112 MPG equivalent when doing 100 miles.

What does it cost for a home stations?

Learn what you can expect a Tesla charging station to cost

How Much Does A Tesla Charging Station Cost?

Per Tesla's official page, their new Wall Connector costs $400 to obtain and another $500 to $1,500 to install in your home. Depending on your home's electrical system, and several other factors, these costs can go as high as $5,000 — though that only happens in rare and extreme cases.

Offline

Like button can go here

#59 2022-11-25 16:17:45

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,307

Re: Wireless/induction EV charging revolution

SpaceNut,

A laptop battery is also $100 to $150 for the pack. It contains up to 6 cells in it, in most cases.

A Tesla contains 2,976 to 4,416 cells in it.

Use the lower figure of $100 for the battery pack, which contains very little in the way of thermal management.

2,976 (cells in a Tesla Model 3 standard range battery pack) / 6 (cells in a Laptop battey pack) = 496

496 * $100 = $49,600 <- An equivalent "laptop-style" battery pack would therefore be equal to the total purchase price of a Tesla Model 3 standard range car (why laptop batteries are "different" from EV battery packs)

Maybe NASA can afford a battery pack thus designed, but the average consumer can't afford a $75,000+ car.

You also failed to address how a laptop battery charging scheme works differently than an EV charging scheme.

A laptop battery charges each cell individually, at a rate each cell can tolerate, which it determines using sophisticated hardware and software to "wear level" every cell in the pack. As the article and you already noted, this is NOT how an EV battery pack charges / discharges.

An EV battery takes an input voltage and amperage, both being fixed values if the regulation circuitry in the charger and battery pack function properly, and the charger then dumps that into every cell in the pack (whether the cell can withstand that charging rate or not). The applies when the battery is discharged (motor controller says, "I demand this amount of current flow to power my motor(s)", and then the entire EV pack must deliver that current flow, and whatever total voltage the series / parallel configuration that the pack is wired for, all cells in the pack attempt to deliver the current required, even though they all operate at slightly different voltages.

The reason that works acceptably well in a laptop has to do with how little current is demanded of the entire pack, and by extension the individual cells in the pack. Imagine what it would mean if every cell in an EV battery pack could ONLY charge / discharge at the rate of the weakest cell in the entire pack. That would potentially mean a slower charge / discharge rate, thus a less capable EV, or it means that some cells wear at faster rates than others, which is why they don't last as long as the marketing hype claims they could. EV batteries lasting for 6+ years, on average, means thousands of cells must be near-perfectly manufactured (incredibly tight manufacturing process control and individualized stress-testing and grouping of cells according to capabilities, which is not amenable to mass production, or inordinately high cell rejection rates for manufacturing defects that make them too deviant from normal or mean values) and almost identical in voltage output plus wear-level over time (and even if you manage to make each cell near-perfect, then you still have to solve for wear rates over time), or they don't last as long as they theoretically should in an ideal world that doesn't exist.

In the real world, that's a bunch of nonsense. NASA can afford to pay $1,000,000 per kilowatt for their defense contractors to voltage-match individual photovoltaic or battery cells with extreme precision, but that doesn't work for the rest of us. The average consumer cannot afford to pay such outlandish prices, given that all of their money is privately-generated by their own labor, rather than publicly provided by the labor of everyone in the entire country.

Once again, far too much magical thinking and far too little acceptance of the practical limits of technology.

Back in the day, a soldier could afford to pay a blacksmith and master craftsman the equivalent of a month's wages for his sword. Every forged steel sword was individualized to its user, and that was a workable scheme because there were so few soldiers and blacksmiths could afford to make other Iron-based implements (farming tools such as axes / hoes / rakes, knives, door hinges, horseshoes, etc) to account for the fact that swords were time-consuming to make and only a few could be made per blacksmith per year.

Fast forward to today, and although we still make swords and knives and farming tools, almost all of them are produced by semi-automated machinery in factories capable of churning them out by the tens of thousands to millions. There's no such thing as an "individualized sword" or "individualized rifle" equipping any military, because they could not afford to pay for them. There are other priorities beyond the making of the weapons, such as salaries to discourage them from working for your enemies, housing and families (so you can create the next generation of soldiers), food, clothing, training, research and development into the next generation of weaponry and defenses against said weaponry, etc.

It might be physically possible to create personalized weapons for all soldiers, but not terribly useful. The military has already identified all the features that make weaponry ergonomic and easy to use, so putting a personal touch on mass-produced tools used to kill your enemies, which must also be done at the lowest practical cost, is not at all relevant to modern industrialized warfare. On a modern battlefield, the skill and training of the weapons user, as well as his or her logistical support, is what matters most. Even the "special forces" frequently use standardized weapons, with the extent of customization being limited to cutting down the barrel of their rifle or adding a sound suppressor and fancier optics to it. At some point, most of those special forces guys also realize that having a "special rifle" is not necessary and detracts from money spent practicing to use their weapons to lethal effect.

Can each individual car owner afford to have some sort of personalized or "bespoke" battery solution optimized for their car and driving habits and range requirements?

I seriously doubt it. Cars are already highly complex machines, and batteries plus even more electronics have already reached absurd levels of over-complexity masquerading as "improvements". The sticker price that the average car buyer must pay for a new car has been improved by leaps and bounds, but has vehicle range per unit of input energy or general utility achieved similar levels of improvement? I've seen no such evidence of night-and-day improvement.

A 1984 Ford Escort would provide 39mpg city and 47mpg highway from a 54hp 1.6L Mazda diesel engine, and a 1,918 pound curb weight.

In the early 2000s, 20 years ago, a Ford Escort would get 44mpg on the highway, even under the latest / newest mpg rating system.

Original MSRP for the 1984 gasoline engine base model was $7,939.

A 2021 Ford Escort, no longer sold in America but now sold in China, weighs 2,767lbs to 2,866lbs, so 849lbs to 948lbs heavier than the 1984 model my family owned. Predictably, even with modern EFI and improved aerodynamics, fuel economy / mpg is no better than the 1984 models. Why is that? It's all that added weight, obviously. Physics is real.

According to inflation from 1984 to 2022 (261.7%), a 2022 Ford Escort should cost $20,776, but you can no longer buy one here in America. Instead, Ford is now selling their "EcoSport" SUV, which gets 27mpg to 29mpg, for $25,000+, with most models actually available at dealerships hovering just under $30,000.

What did Ford "improve"?

It clearly wasn't the cost of purchase or ownership.

What are we "improving" with batteries, such as the new "Mach E" Mustang EV?

The cost of purchase and ownership, obviously.

You will never save a penny. The new EV will cost inordinately more than the gasoline engine it replaced, and the total weight and therefore cost of materials continually increases over time. Pretty soon, we're going to have family cars that weigh more than the heavy duty trucks did when I was a kid. The Mach-E Mustang has a curb weight of 4,394lbs to 4,920lbs, so as heavy or heavier as my regular cab 2012 Chevy Silverado. The new Hummer EV curb weight is 9,063lbs. The Hummer H2 had a curb weight of 6,614lbs.

2024 Hummer EV vs 2003-2009 Hummer H2:

This is getting ridiculous. It's not sustainable, it's not environmentally-friendly, and there's nothing "green" about it, except for the color of money flying out of the wallets of consumers falling for this cheap advertising gimmick. There is no "revolution" going on here, except for the rate at which people are about to impoverished to satiate the vanity of "green evangelists", who I award no more points to than the equally silly "televangelists" (people claiming to believe in "god" while demanding more and more money from their ignorant religious followers) that I grew up with.

Offline

Like button can go here

#60 2022-11-25 17:14:58

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,741

Re: Wireless/induction EV charging revolution

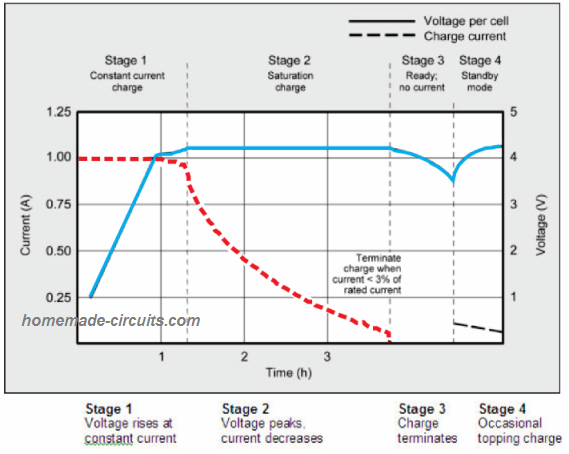

When you build a non-control cell pack there is this little bit that is missed by most building them and that is cell matching. That is why constant voltage and constant current fail as these are complex parallel series assemblies inside of the packs. This is why they break down as that type of circuits create heat inside the batteries. Keep in mind that not all lithium cells are a 3.7 v construction in that they change with other characteristics such as the AA cell size is 2.4 v cutoff for a full voltage charge.

https://www.homemade-circuits.com/simpl … y-charger/

This is what the charge must do and if it's not you end up with a fire as the cells breakdown.

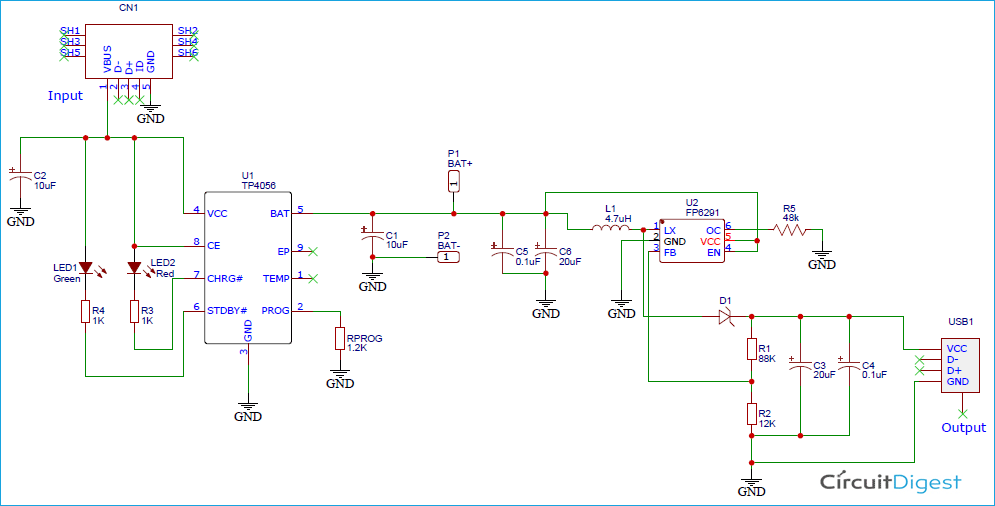

https://circuitdiagram.net/lithium-battery-charger.html

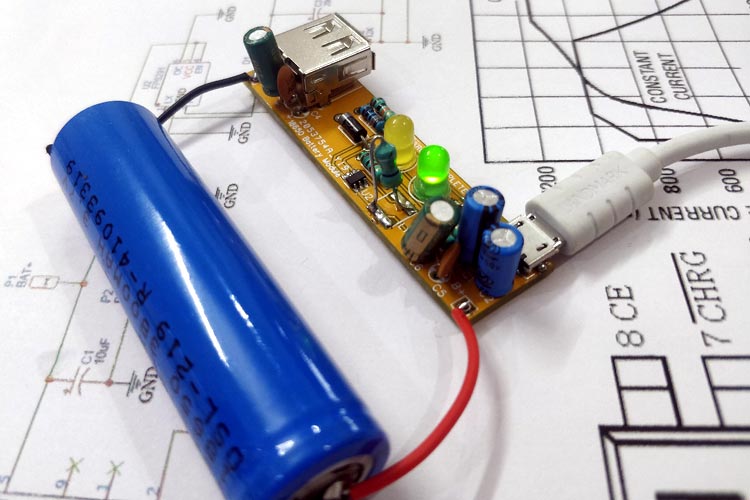

This is the typical cellphone battery pack or cell for boosting the phones charge

https://circuitdigest.com/electronic-ci … ter-module

Notice that the output is regulated

Offline

Like button can go here

#61 2022-11-25 18:23:41

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,307

Re: Wireless/induction EV charging revolution

SpaceNut,

Cell-matching can only be done when time, money, and labor are not considerations. When all those concepts do matter to the affordability of the end result, then cell-matching becomes impractical, if not impossible, when the total cell counts range into the thousands per battery back, as they do for an EV battery pack. You want something that can't be done for reasonable cost. This entire process would take a bare minimum of 2 shifts at the plant to complete, per individual cell. Even if nobody's time is required to test or move cells, which won't be the case in the real world, cars can't go out the door without their batteries. Each cell would have to be bar-coded in order to be machine-selected for assembly into a battery pack. Think about how much extra cost is associated with an extra 16 hours of plant processing time for every vehicle produced.

As-is, total assembly time for a Model 3 is 48 hours. You want to add another 16 hours on top of that, in order to voltage-match the batteries and the assign the cells to voltage-matched battery packs. Presumably, at the rate cells are produced they'd all find homes in packs inside of a week. However, the additional cost of having incomplete vehicles sitting on the shop floor, for up to 2 shifts, is unacceptable. To begin with, there's nowhere to put the half-finished vehicles. As large as a GigaFactory is, the floor space is already spoken for. Beyond that, the car requires 40 assembly stations and 90 minutes to fully assemble into a working / driving car. Further impeding that assembly process is not acceptable. Almost any engineer at Tesla would tell you the same thing. They've worked very diligently to drastically reduce assembly steps and time. Voltage-matching is desirable to have, but not at the cost of having hundreds of non-functional vehicles occupying badly-needed shop space, which is the antithesis of assembly-line mass-production (pushing the finished product out the door, on a fixed time table and with a fixed cadence).

This should be very simple to understand, whether you agree with it or not.

Offline

Like button can go here

#62 2022-11-25 18:38:28

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,741

Re: Wireless/induction EV charging revolution

So, when will we be building the 12v lead acid battery as a cell pack made up of the original 1.2v cells that they came from. The mind set of building by small blocks may be cost and standardizing but it's not the only game and so long as battery manufacturers want to sell the smaller cells in greater numbers than we are not going to change the auto industry and we will continue to have car battery fires.

Here is another technology even thou it seems too not be practical.

New 48-Volt Quant supercar can go 600 miles on a tank of ‘salt water’

So often would you go to the beach to fill it up?

Offline

Like button can go here

#63 2022-11-25 19:02:51

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,307

Re: Wireless/induction EV charging revolution

SpaceNut,

That thing is a 2-seat truck without a bed to haul anything. It weighs 4,012lbs and has a pair of 200L capacity "fuel tanks", with about 106 gallons of total capacity.

The 2019 Mazda Skyactiv-G powered hatchback averaged about 63.5mpg when driven at 56mph.

AutoEvlution - Mazda3 Hatchback SkyActiv-X Averages 3.7 L/100 KM (63.5 MPG) At 90 KM/H

If that same Mazda Model 3 was equipped with a 106 gallon tank, which would be stupid, then it should have 6,731 miles of driving range when driven on the highway. So, 10X more range, or the same driving range as this Quant48 absurdity, but using a 10 gallon gasoline tank instead of 106 gallons of this "secret gizmo juice". Orders of magnitude have meaning.

The 2021 Mazda Model 3 hatchback has a curb weight of 3,383lbs and seats 5 people versus the Quant48, which seats 2 people (not a problem for most driving, but shows how much internal volume is devoted to its "fuel tank").

Offline

Like button can go here

#64 2022-11-25 19:22:22

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,307

Re: Wireless/induction EV charging revolution

It seems as if EVs are "solving" a problem that nobody needs to solve:

How do we maximize the cost of going short distances while carrying very little payload, to the point that they're always more expensive than equivalent gasoline powered vehicles when total cost, which is a proxy for total energy cost (the only real figure of merit)?

This presumes that the general idea is to provide a car to every adult on the planet, so that they can easily travel to work, take the kids to school, get groceries, and take a vacation somewhere else once per year.

We could all drive around in cars powered by gas turbine engines, with a chassis made from Lead or maybe Silver and Gold, if dumping energy into low-energy-density metals-based battery solutions is how we purport to "solve" that problem.

So long as it takes power to move weight, combustion is king of energy density. Everything else is a joke by way of comparison, which is why battery powered cars lasted for a couple of decades back when cars were new technology, then became a means to start a real engine capable of providing substantial range and power.

More metal and more energy dumped into low energy density metals-based batteries to power vehicles of significant weight is clearly not the answer. At best, this is an unhelpful and very expensive diversion from building metals-based solar thermal or nuclear thermal power plants for synthesizing fuels. Those fuel synthesis plants don't have to meet any power-to-weight figures in order to be useful to humanity.

Offline

Like button can go here

#65 2022-11-25 19:46:35

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,741

Re: Wireless/induction EV charging revolution

The Tesla is about a decade old and is becoming a study in that many parts that normally wear out do and while these are common to cars with gasoline engines the vehicle is said to be capable of 100 years for other parts and that the 500,000 mile battery is still at 80% of its life for being a decade old.

There are not to many things that last that long which are used daily.

Offline

Like button can go here

#66 2022-11-25 20:28:01

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,307

Re: Wireless/induction EV charging revolution

SpaceNut,

We've been over this silly nonsense before. The Tesla in question is a taxi cab that's had its battery replaced 3 times and its drive motors replaced 1 or 2 times that we know of.

How many Teslas never made it to 500,000 miles?

The guy (Hansjörg von Gemmingen-Hornberg) drives an average of 365 miles per day, which is more range than the car's battery pack had when it was brand new, so his entire life revolves around recharging has taxi cab at least twice per day. If anything, there's something to learn about his particular recharging habits to assure the life of a Tesla-type battery pack.

More to the point, the life of the batteries and the electric motors is no better in practice than a well-maintained diesel engine, and they cost more than a brand new diesel engine to replace. The parts of Teslas that wear out faster than traditional cars are brakes and tires. My nextdoor neighbor works for Tesla and she says the tires and frequently the brakes need to be replaced once per year.

One of the oil execs I used to work with told me how great his Tesla Model S was, which was in the shop for a month while they did "routine maintenance" on it. This was a car bought brand new and driven less than 50,000 miles at the time. He was provided with a loaner vehicle during the repair period, which was very considerate of them. I don't know if he still has it, nor what they were replacing that took a month to repair. He thought it was great because he wasn't paying for it. I asked him if dropped the $100,000 on the car and extended warranty, to which he responded in the affirmative. I told him, "well, then, you did pay for it."

There's also a singular 1966 Volvo P1800 with more than 3,000,000 miles on it, but that is exceptionally atypical. Most 1966 Volvo P1800s no longer exist, because they were no longer economical to repair.

Cherry picking factoids that ignore all aspects of how a particular vehicle was used and how well-maintained it was, are irrelevant.

Well-maintained Cummins turbo-diesel engines typically, as in many thousands of examples to go off of, last for around a million miles between rebuilds. These engines are intended to be rebuilt 2 to 4 times, and then they're scrap Iron.

Some aircraft engines have been rebuilt a dozen times or more, but that's another case of "money is no object" silliness.

A garden variety new car will last 10 years or so before it's no longer economical to repair, no matter who made it.

Offline

Like button can go here

#67 2022-11-27 20:47:19

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,741

Re: Wireless/induction EV charging revolution

To fill those giga plants you need raw materials and it seems that some have been found Large deposit of rare elements and minerals discovered in northern Maine

It is still too early to know the exact size and composition of the deposit, or whether it should or could be mined despite strict state regulations. But geologists say it may rival similar deposits discovered in Australia and China, and one estimated the potential value of the Pennington Mountain deposit in the billions of dollars.

These rare earth elements and trace metals of niobium and zirconium can be used to make a wide range of products: from night vision goggles to stealth technology, cellphones to flatscreen TVs and solar panels, to electric vehicle batteries to wind turbine generators.

The use of rare earth elements and trace metals in renewable energy technologies has fueled tensions in Maine and around the nation between the local environmental impacts of mining and the global climate benefits achieved through the use of those mined materials.

Offline

Like button can go here

#68 2022-11-28 03:46:59

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,307

Re: Wireless/induction EV charging revolution

SpaceNut,

Are the Democrats going to allow mining in the US again so that we can get at the minerals needed to produce all these batteries?

This is another case of Democrats fighting other Democrats, which is yet another reason why I don't hold much hope for batteries powering everything. The moment we try to get the resources to produce battery magic, the yellow-bellied one-eyed one-horned flying purple people eaters are "endangered" and we have to "save the planet" (but not for humanity, apparently).

Offline

Like button can go here

#69 2022-11-28 20:37:32

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,741

Re: Wireless/induction EV charging revolution

Maine law will be what will dictate if it's going to happen not whom you vote for, or which party is in charge of a state. If they have best interest for the people, then they will do right for the people regardless of what label.

Both Maine and NH have a mix of both parties in the house and senate so that is not going to hinder getting what is of value if it is really in sufficient quantity to justify destroying the land.

https://www.usgs.gov/media/images/penni … l-minerals

https://www.anyplaceamerica.com/directo … in-573168/

Rare earth elements found at Pennington Mountain

https://www.pressherald.com/2022/11/27/ … ern-maine/

Offline

Like button can go here

#70 2022-11-28 21:24:17

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,307

Re: Wireless/induction EV charging revolution

SpaceNut,

What have you seen in the past couple of decades which makes you believe that?

Offline

Like button can go here

#71 2022-11-29 11:21:59

- Void

- Member

- Registered: 2011-12-29

- Posts: 8,934

Re: Wireless/induction EV charging revolution

OK, I will stir the hornets' nest.

https://www.bing.com/videos/search?q=Me … &FORM=VIRE

I am not in a position to validate or refute the materials in the post.

It is of interest though.

Done

Last edited by Void (2022-11-29 21:30:18)

Is it possible that the root of political science claims is to produce white collar jobs for people who paid for an education and do not want a real job?

Offline

Like button can go here

#72 2022-11-29 11:45:18

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,892

Re: Wireless/induction EV charging revolution

For Void re #71

Thanks for the link you provided!

In the vicinity of that link, I found another article that is in text, which I prefer.

The text article explained that 500 miles is (apparently) a sweet spot for long-haul trips, because (at least in the US) drivers are expected to take a break after 8 hours. The article also predicted that Tesla will be the first customer for the new vehicles, because they do a lot of shipping by truck, and they can recharge at both ends of a run, so they can save large sums over diesel fueled tractors.

The article predicts that large companies who do a lot of shipping will be looking to convert to Tesla Trucks as their diesel tractors expire.

Thanks again for the link!

(th)

Offline

Like button can go here

#73 2022-11-29 14:02:27

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,307

Re: Wireless/induction EV charging revolution

Void,

Post edited.

Nah, you know what, if people actually believe this stuff, then they'll believe anything and there's no point to refuting anything.

Last edited by kbd512 (2022-11-29 14:39:40)

Offline

Like button can go here

#74 2022-11-29 14:58:33

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,892

Re: Wireless/induction EV charging revolution

For Void ... please see if you can find out more about the claims of 500 mile range.

We now have two people publicly disputing the claims.

The Icelandic chap you showed us, and kbd512 in a now deleted/edited post.

I asked Bing what is going on, and got this result:

what is the truth about the tesla truck run over 500 miles with a full load

About 4,050,000,000 results Any timeWhen fully loaded, the Tesla Semi should be able to achieve over 500 miles of range, achieved through aerodynamics and highly efficient motors. This truck will be able to reach an efficiency of over 0.5 miles per kWh.

Tesla says Tesla Semi electric truck's weight is on point, and that'…

electrek.co/2021/08/13/tesla-semi-electric-truck-weight-on-point-crucial/

A useful (or at least interesting) comparison would be a railroad situation, with steel wheels rolling on steel rails.

The claim that two (seemingly) reputable people are disputing seems to be that an electric tractor with only it's internal batteries to do the work, can move a fully loaded 18 wheeler cargo pod 500 miles.

It would be a shame for such reputable people as we have in this forum to discover they made an error. It would be better (from our point of view) if the reporter can be found in error.

Since highly paid, highly educated people are working this problem, I would expect they would have delivered what is claimed, but the doubts raised here and in the video you showed need to be addressed.

(th)

Offline

Like button can go here

#75 2022-11-29 17:14:49

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,307

Re: Wireless/induction EV charging revolution

Tesla first claimed that their semi-truck could maintain 65mph up a 5% grade, then lowered that figure to 60mph up a 5% grade, but it has 1,000hp on tap. That's about double what most semi-trucks can generate at full output, so something is either very wrong with the reporting of that figure or it lacks greater context, perhaps related to achieving claimed range, but that's just a guess.

Total semi-truck energy usage, from 10 years ago, was estimated at 400kWh, at 65mph.

34% of the losses are rolling resistance and aerodynamic drag losses, so 136kWh of the total energy expended is largely unavoidable losses associated with a semi-truck moving down the road at 65mph.

The tires must have some rolling resistance in order to generate traction on a roadway. The vehicle is passing through the air near sea level at 60mph to 75mph, which generates about half of the total force that the engine or motor must overcome to maintain highway speeds.

Average semi-truck fuel consumption was 47.6L per 100km traveled.

Diesel is about 10,000Wh/L, so that's 476,000Watt-hours.

60% of that was due to engine-related losses, or 285,600Watt-hours.

That leaves 190,400Watt-hours associated with overcoming air and rolling resistance. Transmission losses are no more than about 3% of the total power expenditure.

Tesla's claim is 120,000 Watts per hour, which equates to a 37% reduction in air and rolling resistance.

If such reductions were actually achievable, then we'd surely see them applied to other semi-trucks.

In other news Tesla claims that the glass used in their semi-trucks is "thermonuclear explosion proof". Along with all other claims, that claim has yet to be independently verified. The US government has also stated that there will be severe and immediate consequences for anyone who does. I also have a bridge in Brooklyn that I'm willing to sell at a very good price.

From Forbes:

“It's probably smarter to transport potato chips,” said Glen Kedzie, vice president and environment and energy counsel for the American Trucking Associations. With such light cargo, “you're going to get a longer range out of the battery,” he pointed out, and you’d be able to haul the same amount of product as a diesel truck. Maximizing battery life will be important, given that a Tesla Semi’s price tag may be $400,000, he said.

If the truck is driven the same 120,000km / 75,000 miles per year, then $15,000 per year in electricity costs.

Diesel consumption will be 15,090 gallons per year, or $45,270/year at pre-brain dead moron for a President / Biden (yes, that was repetitively redundant) prices.

Semi-trucks made after 2014 are legally required to achieve at least 7.2mpg, so 10,417 gallons per year, or $46,875 at brain dead moron prices of $4.50/gallon.

Daimler-Benz "Super Truck" purportedly achieved 12.2mpg, 6,148 gallons per year, or $27,666 at brain dead moron / Biden prices of $4.50/gallon. At that point, you're at $436,660 for the $160,000 semi-truck, plus 10 years of fuel at $4.50/gallon. This presumes that wasn't a load of BS as well, but at least a national laboratory conducted the testing.

Tire wear will be exactly the same for a vehicle that weighs as much as a regular semi, so no savings there.

Electricity is $0.10/kWh or $100/MWh, national average here in America (80% powered by coal and gas across the entire country, including California), so after 5 years that's the break-even point on the cost of a regular diesel-powered semi-truck, if Tesla semi-trucks cost $400,000 per copy. This also presumes there is zero cost associated with building out the presently non-existent Tesla "MegaCharger" network to recharge all the vehicles. 10 years from whenever these vehicles hit the road, all the trucks batteries will need to be recycled, because there won't be enough Lithium by then to make any new ones, as evidenced by the fact that we're already experiencing Lithium shortages.

Offline

Like button can go here