New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2022-08-03 18:45:26

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,765

Solar thermal converting Plastic back to diesel

Not to get topic off from sea water and solar; kbd512, to make another fuel from a different starting point one could also make use of 3 hours of 500' c heat to change various plastics back into a hydrocarbon liquid similar to diesel. There can also be injection of other chemical chains to change that into other products as well in another chamber.

tahanson43206, 2 plates with separation with media between it is electrolysis the moment you pass a current between the plates.

We know that co2 passed in a chamber with the moxie membranes would allow for oxygen to be vented with co to be made use of in the seawater process. But is there a means to use heat to break the water bond and use of a membrane to do the same without power?

I think void brought forth a titanium oxide plate, but I am having a memory gap.

edit

Seems that high temperature above 2000' c while it will cause the water to break down its the ignition of hydrogen and oxygen that soon happens. That mean you need higher temperature membranes and power to force the hydrogen towards a plate while the oxygen would go towards the other.

Seems the much lower temperature of just 500'c mean you get a lower efficiency for reaction as the 100'c for boiling is just the starting point for the bond to begin to break.

https://www.scienceforums.net/topic/113 … -pressure/

Offline

Like button can go here

#2 2022-08-04 01:39:00

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,318

Re: Solar thermal converting Plastic back to diesel

SpaceNut,

Eureka! Thanks for that.

That's probably one of the best ideas I've seen floated thus far. There's plenty of plastic garbage that's not practical to recycle, so it gets burned, which is a filthy process that releases toxic gases (Chlorine and Fluorine), so turning shopping bags / old PVC pipes / elastomers back into liquid fuel is a much better proposition. We can recover the Chlorine and Fluorine for making new plastics. Globally, we produce 400 million metric tons of plastic waste per year. America produces about 150 billion gallons of gasoline per year, which equates to 408,233,618t. As such the plastic trash would represent a considerable quantity of fuel, even though about 50% to 60% of that plastic mass is something other than the Carbon and Hydrogen that we need. It still contains a lot of Carbon.

Common plastics contain somewhere between 30MJ/kg and 40MJ/kg, which means we'll need to add more Hydrogen, but their most important chemical constituent is all the Carbon atoms we need. If we don't have to source the Carbon from somewhere else, that saves lots of energy. So long as we're dead set on producing enough plastic trash to bury a mountain, we may as well have an end-of-life plan for the trash that includes upgrading it to liquid fuel. I like that plan a lot better than burning it.

We need to convince people to give us as much of their plastic trash and fly ash from burning coal as they're willing to part with. The fly ash is mixed into concrete, so we can only take so much of that before we start affecting other sectors of the economy. Apart from burning the plastic, I don't think they do much else with it, except for the soda bottles.

Offline

Like button can go here

#3 2022-08-04 06:23:58

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,220

Re: Solar thermal converting Plastic back to diesel

Global plastics production is running at about 400 million tonnes per year.

https://ourworldindata.org/grapher/glob … production

In energy terms that is equivelent to about 8 million barrels of oil per day. That is 10% of global demand. So yes, hydro-cracking of polymer wastes could yield a valuable quantity of synthetic fuel. And the process can be optimised for diesel rather than gasoline, which is a more valuable product. Similar hydrogen based upgrading can be used to convert oxygen rich bio-oils produced through flash pyrolysis of biomass into synthetic diesel.

Synthetic liquids could be blended with heavy oils from places like Canada and Venezuela. This produces a syncrude which is acceptable to refineries. And the products of that syncrude refining will be more rich in diesel than gasoline, which is exactly what we want. So synfuels can both reduce our demand for conventional oil and make it easier to access unconventional resources. This is a double win. Light chain synthetic hydrocarbons like propane or butane could be blended into heavy oils reducing their viscosity making them refinable.

The idea of solar thermal powered fuel factories would be easier if we could start with carbon rich feedstocks that reduce the overall energy cost. For example, we could build a refinery that is optimised to produce diesel from heavy crude, coal, biomass, plastic waste or kerogen. Solar thermal would provide process heat, to reduce oil viscosity or bake the coal, biomass or kerogen. Heavy chain hydrocarbons could then be broken down by hydrogen cracking, using hydrogen generated by the solar thermal plant. This process is known as upgrading. It is unpopular in environmental circles because it fails to break human carbon emmissions. But it does allow fossil fuel resources to be extended and allows unconventional resources to be used. If solar fuel factories can be started using resources of this kind, then CO2 seawater extraction is an evolution of the technology that is then relatively easy to impliment. Fossil fuel, biomass or plastics upgrading, provides a way for the solar fuel concept to become established with favourable economics from day one.

Last edited by Calliban (2022-08-04 06:50:33)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#4 2022-08-04 06:47:10

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,007

Re: Solar thermal converting Plastic back to diesel

Note ... this post was copied from the Propane topic to help to set up a new topic on conversion of plastic to fuels.

First.... Bravo for rapid developing support for SpaceNut's idea by kbd512 and Calliban....

(Edit) I'd like to see (am ** hoping ** to see) future posts that show readers a precise recipe for how to make propane from plastic using solar power. It is far more likely that potential readers will have access to solar power than nuclear.

Because solar power is such a diffuse energy delivery medium, prospective builders will need lots of land, or more specifically air rights over lots of land.

This is going to be a low margins business, like food delivery, so no one is going to get rich, but the business ** should ** be able to provide a modest living for it's practitioners.

In future posts, our NewMars members can (hopefully will) work toward precise definition of equipment and processes that are needed to turn this important idea into a practical, long lived business.

(th)

Offline

Like button can go here

#5 2022-08-05 19:23:27

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,765

Re: Solar thermal converting Plastic back to diesel

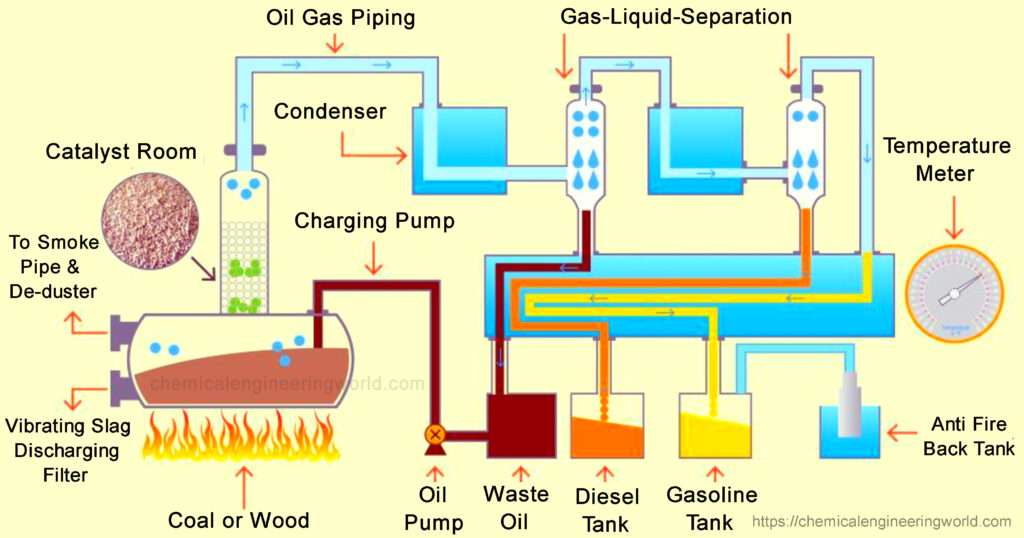

Water is added into the conversion chamber so as to remove air that would ignite the plastic to burning. That water boils off and leave a vacuum in its place as it vents from the chamber down the tubing away from the chamber where it goes through cooling as a still would do.

A good chamber to test would be an air compressor tank or something similar once modified with a entrance into the unit that can be closed.

https://chemicalengineeringworld.com/pl … s-process/

https://azchemistry.com/list-of-chemicals-in-plastic

15 List of Chemicals in Plastic – Properties – Dangers

https://www.injectionmould.org/2019/04/ … ification/

How to Identify Different Types Of Plastic Materials

Offline

Like button can go here

#6 2022-08-06 08:15:32

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,765

Re: Solar thermal converting Plastic back to diesel

https://www.bpf.co.uk/plastipedia/chemi … g-101.aspx

Chemical Recycling 101

Converting Plastic Waste into Fuel

They discovered that, using a combination of ruthenium metal and carbon as the catalyst, they can convert 90% of plastic waste into fuel in just one hour, at a lower temperature of 220°C.

We always do get ney sayers

https://cen.acs.org/environment/recycli … ws/100/i17

Plastic to petrol || How to make petrol from plastic waste video

Plastic into petrol || Produce fuel petrol from plastic waste

Offline

Like button can go here