New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#51 2021-11-13 18:43:34

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

Hopefully no alternators tucked up under the engine but over the axle which is the problem with the escape.. Not only is the alternator pricey at $400 but the fact you need to remove the axle and the mount for the alternator to get enough room to remove it is trouble some at a total bill of $1600 just to replace it.

Mine is slowly failing and while I have alternator to remove from the other escape that is new last year its still a pain....

Got started with alternator removal saturday on the 2001 but did not finish.

edit sunday

Got alternator out of old escape (2001) finally on Sunday noon ish, which did not leave time to remove and install it on the newer one (2005). Found that night time driving is a huge drain on the battery as it runs.

It rained during the night and the ground is soaking wet and its cold. Will attempt to do the removal and install once the sun is up.

edit 2 monday

again a wet cold windy day to work on a vehicle out in the open started early 8:00 to put the wheel and axle . Finally got the broken alternator out of the 2004 by 5:30

edit 3 tuesday

close side by side inspection of the alternators found they are not the same even though they are both from escapes

now to go parts shopping to find the correct one.

Back from a 10 mile walk leaving at 8:30 to get the part with the old core in a carry bag got back to house at 11:00. rebuilt O'riely number $190 - core $45 leaves $145 for the alternator. Have gotten the alternator bolted in place and connected now working the plastic shield that keep dirt and water out of the unit at 13:00.

Finally all back together at 17:00 and moment of truth only to find out that alternator is not regulating but over volting at 16.6 V

sure they will get another but could careless about how many hours I spent as mechanic.

Offline

Like button can go here

#52 2021-11-13 21:05:14

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,517

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

SpaceNut,

I hear you, but I can't come up with any way to drop the price much below $15K or so. Please bear in mind that this is for a brand new 6-seat fully functional vehicle that provides generous room and bucket seating for 6 American adults, at 1/3rd the weight of a typical large SUV. It has the interior volume of a Ford F250, the strength of a NASCAR chassis, the power-to-weight ratio of a sporty little sedan, and the fuel economy of a motorcycle. This is like asking for a supersonic stealth VTOL aircraft. Achieving that will never be dirt cheap, but it doesn't have to break the bank, either.

How is that not preferable to a gas guzzling truck or a battery electronic vehicle that costs as much as a house, both of which are chock-full of non-repairable components that are nearly impossible to recycle for any reasonable cost?

This is our modern-day Volkswagen. It's a good bit shorter than a F-250 to make better use of available freeway / parking spaces, wide enough and low enough to the ground to be very stable during cornering, light enough to not require an absurdly powerful engine to motivate it to highway speeds, and we're using common materials and major sub-assemblies currently in production. The only "exotic" aspects of this vehicle are the use of steel tubing rather than steel monocoque construction to significantly reduce the weight, and the use of carbon fiber or aramid fiber fabric-over-foam panels (sheets of unidirectional fibers impregnated with a little bit of plastic, sewn into foam panels intended to give the vehicle an aerodynamic / aesthetically pleasing shape, keep the elements out, and reduce road noise.

The Harley-Davidson engine is actually the most expensive part of the vehicle. New "Screamin Eagle" crate motors are $6,500. A Trask Performance turbo kit is $5,600. Given those prices, it might actually be cheaper to source brand new aircraft engine parts to provide equivalent horsepower at lower RPM.

Offline

Like button can go here

#53 2021-11-13 21:32:12

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,517

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

SpaceNut,

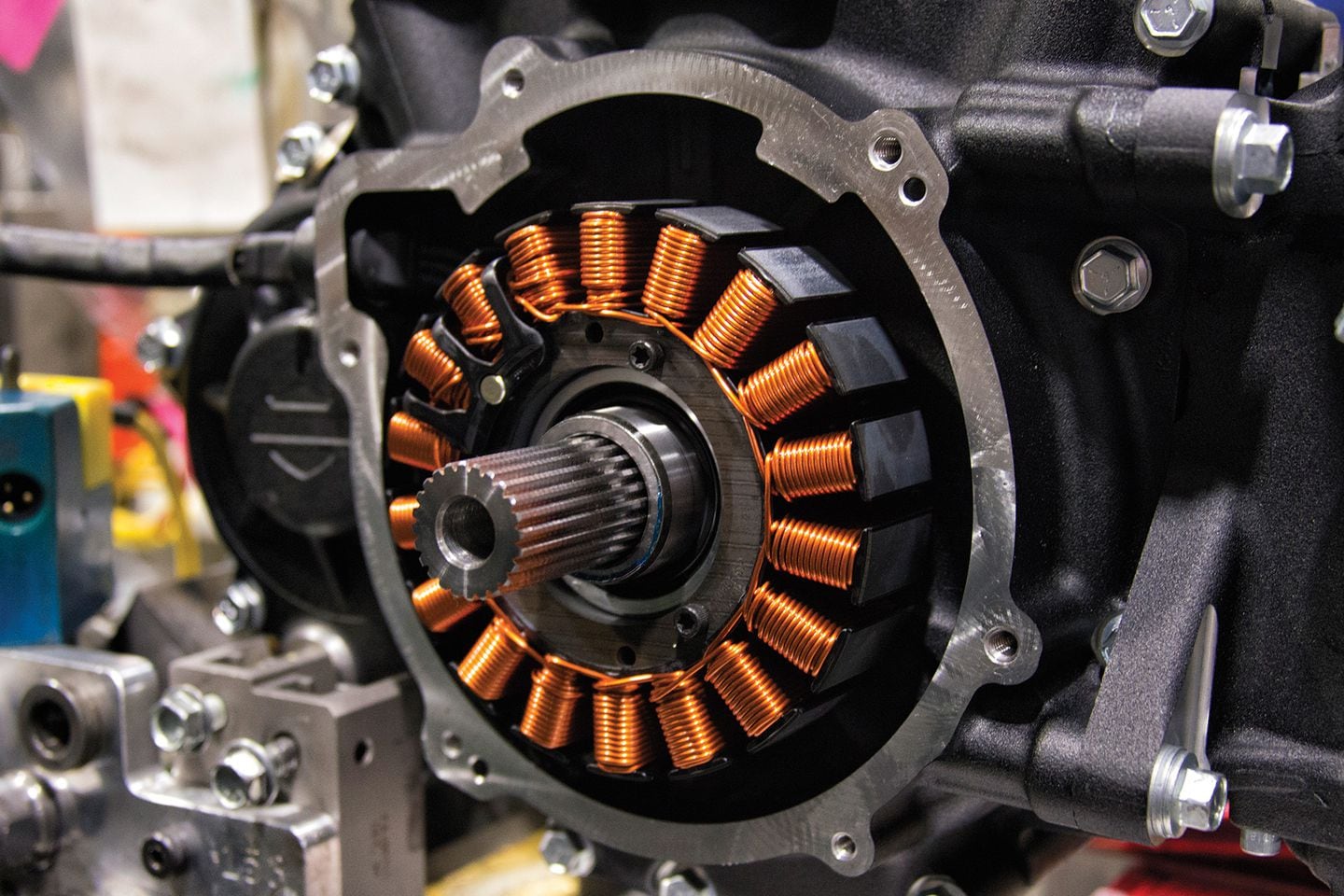

All mechanical and electrical components will be easily accessible on this vehicle. The alternator is built into the Milwaukee-8 engine. It's a relatively powerful unit, given its size, because hogs tend to have full light packages and radios. They also use electronic ignition and fuel injection. Apart from being air-cooled / oil-cooled, they function a lot like any other modern automotive engine. They can go at least 100,000 miles between major overhauls with regular oil changes.

I can't decide if it's simpler to put the engine in front of the vehicle and make it FWD, or to put the engine in the rear and make it a traditional RWD truck or SUV. The forward location would definitely be better for engine cooling purposes, but then we'd need an electric pump to feed the fuel into the engine. We'll probably end up making this thing more like a modern FWD car and leave the fuel tank in its traditional location.

Offline

Like button can go here

#54 2021-11-14 08:26:14

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

Fwd location is better for the engine. The tank (aft) can drain by gravity to the injection pumps (fwd). Cooling the engine is always going to be more challenging than feeding it with fuel and putting it upfront allows forced air to pass through the radiator from the front of the vehicle, without having to run water pipes long distances or under the chassis. Trying to put a radiator under the chassis is asking for trouble, for obvious reasons.

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#55 2021-11-14 08:41:27

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

For those not bikers.

https://en.wikipedia.org/wiki/Harley-Da … ght_engine

https://www.harley-davidson.com/us/en/s … p/16200521

https://www.cycleworld.com/harley-david … in-engine/

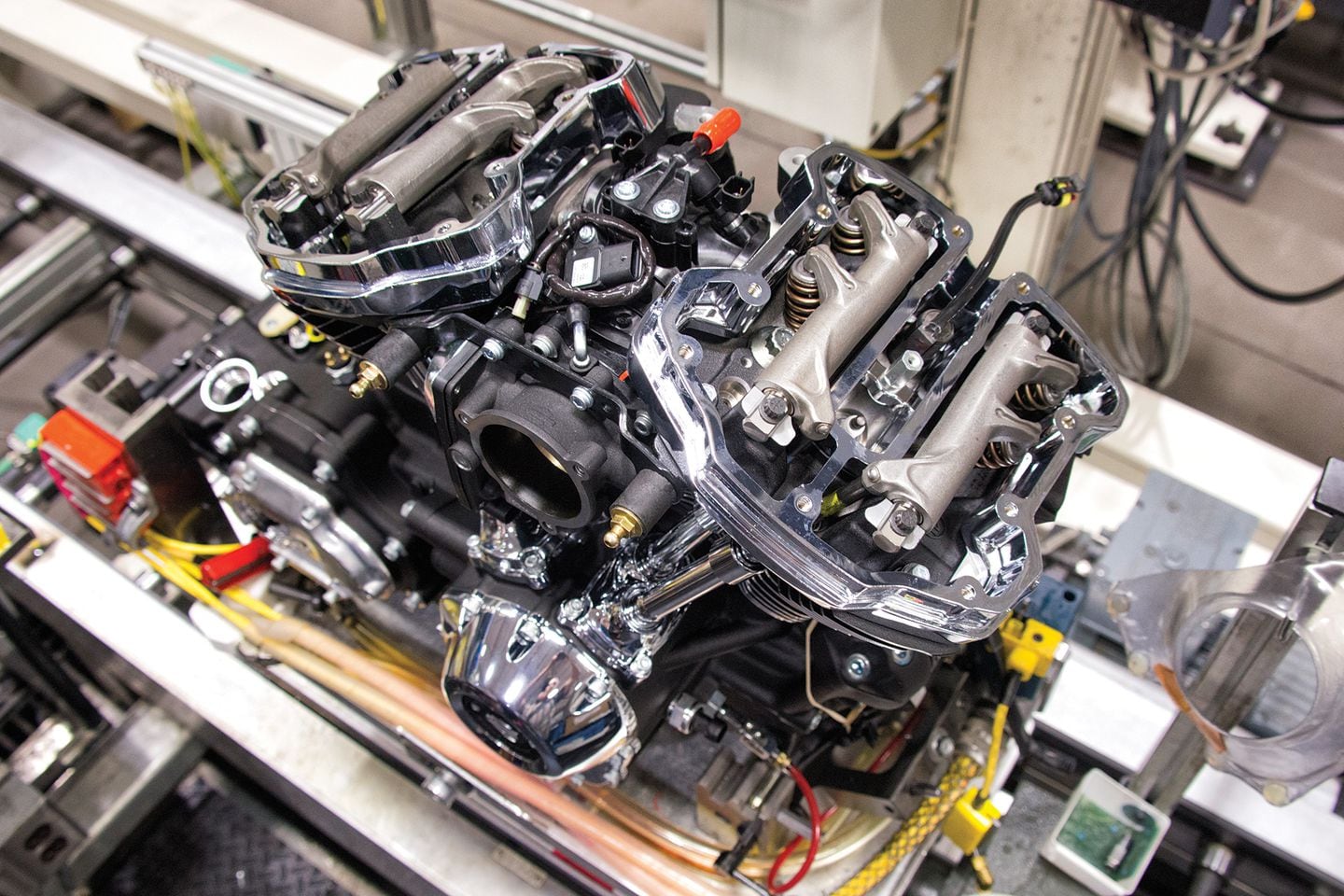

engine assembly in process

end view of alternator

Offline

Like button can go here

#56 2021-11-16 17:17:12

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

The compatibility of rovers on mars in the future is in jeopardy due to the orbital mechanics by earthly rover comparison.

Offline

Like button can go here

#57 2021-11-17 19:57:46

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

Bad luck continued today as I had a tire go flat from a side wall puncher when I stopped for coffee before trying to travel to work since the replacement would not come in until 2 pm. Had to wait until friends garage opened, where he came and got me with the flat and I travel back to home base to get a tire to put onto the flat rim. Got that on and started to travel to work but ran into an accident scene that had traffic backed up with the battery drain continuing to drop its charge on it due to the defective alternator. Turned around after getting clear of the accident scene and went back to friends garage to wait for replacement alternator. It did arrive early but they would not give it to me until the core could be returned at the same time. Friends garage allowed me to use his lift and tools to remove and reinstall the new one starting remove process about 1 pm finishing to a fully functional vehicle charging system by 5 pm. The parts store will not be compensating me for my lost hours to do this work twice.

Will definitely sway my decisions in the future to use them....

Offline

Like button can go here

#58 2021-11-17 21:25:25

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,517

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

SpaceNut,

There's been an epidemic of "bad from the box" parts. Sorry to hear that you had your own experience with that. It won't matter which parts store you go to, though. All of them are selling the same junk. That is exactly why we need to start making more high quality stuff here in America, and as customers choose to accept no grade of product any worse than the best grade we're capable of manufacturing.

If someone else can truly make a better product for less money, then of course everyone should buy it, but I've yet to see better parts made for less money. We can produce lower quality parts for less money, and that's what the OEMs have opted to do, because they've done the math and it'll cost them less to replace the bad parts they make than it will to make better quality parts. We, as consumers, have largely "done this to ourselves".

Offline

Like button can go here

#59 2022-03-21 06:57:32

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

Methane-eating bacteria convert greenhouse gas to fuel

Offline

Like button can go here

#60 2022-05-12 13:53:11

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,123

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

For SpaceNut ... this is the only topic that contains the words "fossil" and "fuels" ...

Here is a restatement of observations made by both Calliban and kbd512 multiple times, in the forum archive.

https://www.yahoo.com/news/modern-world … 35723.html

The modern World Can't Exist Without These Four Ingredients. They All Require Fossil Fuels

Vaclav Smil

Thu, May 12, 2022, 6:00 AM

Steel Production At ThyssenKrupp Duisburg

Molten iron at the ThyssenKrupp steelworks on January 17, 2018 in Duisburg, Germany. Credit - Lukas Schulze-Getty ImagesModern societies would be impossible without mass-scale production of many man-made materials. We could have an affluent civilization that provides plenty of food, material comforts, and access to good education and health care without any microchips or personal computers: we had one until the 1970s, and we managed, until the 1990s, to expand economies, build requisite infrastructures and connect the world by jetliners without any smartphones and social media. But we could not enjoy our quality of life without the provision of many materials required to embody the myriad of our inventions.

Four materials rank highest on the scale of necessity, forming what I have called the four pillars of modern civilization: cement, steel, plastics, and ammonia are needed in larger quantities than are other essential inputs. The world now produces annually about 4.5 billion tons of cement, 1.8 billion tons of steel, nearly 400 million tons of plastics, and 180 million tons of ammonia. But it is ammonia that deserves the top position as our most important material: its synthesis is the basis of all nitrogen fertilizers, and without their applications it would be impossible to feed, at current levels, nearly half of today’s nearly 8 billion people.

The dependence is even higher in the world’s most populous country: feeding three out of five Chinese depends on the synthesis of this compound. This dependence easily justifies calling ammonia synthesis the most momentous technical advance in history: other inventions provide our comforts, convenience or wealth or prolong our lives—but without the synthesis of ammonia, we could not ensure the very survival of billions of people alive today and yet to be born.

Plastics are a large group of synthetic organic materials whose common quality is that they can be molded into desired shapes—and they are now everywhere. As I type this, the keys of my Dell laptop and a wireless mouse under my right palm are made of acrylonitrile butadiene styrene, I sit on a swivel chair upholstered in a polyester fabric, and its nylon wheels rest on a polycarbonate carpet protection mat that covers a polyester carpet. But plastics are now most indispensable in health care in general and in hospitals in particular. Life now begins (in maternity wards) and ends (in intensive care units) surrounded by plastic items made above all from different kinds of PVC: flexible tubes (for feeding patients, delivering oxygen, and monitoring blood pressure), catheters, intravenous containers, blood bags, sterile packaging, trays and basins, bedpans and bed rails, thermal blankets.

Steel’s strength, durability, and versatility determines the look of modern civilization and enables its most fundamental functions. This is the most widely used metal and it forms countless visible and invisible critical components of modern civilization, from skyscrapers to scalpels. Moreover, nearly all other metallic and non-metallic products we use have been extracted, processed, shaped, finished, and distributed with tools and machines made of steel, and no mode of today’s mass transportation could function without steel. The average car contains about 900 kilograms of steel and before Covid-19 struck the world was making nearly 100 million vehicles a year.

Cement is, of course, the key component of concrete: combined with sand, gravel and water it makes the most massively deployed material. Modern cities are embodiments of concrete, as are bridges, tunnels, roads, dams, runways and ports. China now produces more than half of the world’s cement and in recent years it makes in just two years as much of it as did the United States during the entire 20th century. Yet another astounding statistic is that the world now consumes in one year more cement than it did during the entire first half of the 20th century.

And these four materials, so unlike in their properties and qualities, share three common traits: they are not readily replaceable by other materials (certainly not in the near future or on a global scale); we will need much more of them in the future; and their mass-scale production depends heavily on the combustion of fossil fuels, making them major sources of greenhouse gas emissions. Organic fertilizers cannot replace synthetic ammonia: their low nitrogen content and their worldwide mass are not enough even if all manures and crop residues were recycled. No other materials offer such advantages for many lightweight yet durable uses as plastics. No other metal is as affordably strong as steel. No other mass-produced material is as suitable for building strong infrastructure as concrete (often reinforced with steel).

As for the future needs, high-income countries could reduce their fertilizer use (eating less meat, wasting less), and China and India, the two heavy users, could also reduce their excessive fertilizer applications, but Africa, the continent with the fastest-growing population, remains deprived of fertilizers even as it is already a substantial food importer. Any hope for its greater food self-sufficiency rests on the increased use of nitrogen: after all, the continent’s recent usage of ammonia has been less than a third of the European mean. More plastics will be needed for expanding medical (aging populations) and infrastructural (pipes) uses and in transportation (see the interior of airplanes and high-speed trains). As is the case with ammonia, steel consumption has to rise in all low-income countries with underdeveloped infrastructures and transportation. And much more cement will be needed to make concrete: affluent countries to fix decaying infrastructures (in the US all sectors where concrete dominates, including dams, roads, and aviation get a D grade in nationwide engineering assessments), in low-income countries to expand cities, sewers and transportation.

Moreover, the unfolding transition to renewable energies will demand huge amounts of steel, concrete and plastics. No structures are more obvious symbols of “green” electricity generation than large wind turbines—but their foundations are reinforced concrete, their towers, nacelles, and rotors are steel, and their massive blades are energy-intensive—and difficult to recycle—plastic resins, and all of these giant parts must be brought to the installation sites by outsized trucks (or ships) and erected by large steel cranes, and turbine gearboxes must be repeatedly lubricated with oil. These turbines would generate truly green electricity only if all of these materials were made without any fossil fuels.

Fossil fuels remain indispensable for producing all of these materials.

Ammonia synthesis uses natural gas both as the source of hydrogen and as the source of energy needed to provide high temperature and pressure. Some 85% of all plastics are based on simple molecules derived from natural gas and crude oil, and hydrocarbons also supply energy for syntheses. Production of primary steel starts with smelting iron ore in blast furnace in the presence of coke made from coal and with the addition of natural gas, and the resulting cast iron is made into steel in large basic oxygen furnaces. And cement is produced by heating ground limestone and clay, shale in large kilns, long inclined metal cylinders, heated with such low-quality fossil fuels as coal dust, petroleum coke and heavy fuel oil.

As a result, global production of these four indispensable materials claims about 17 percent of the world’s annual total energy supply, and it generates about 25 percent of all CO2 emissions originating in the combustion of fossil fuels. The pervasiveness of this dependence and its magnitude make the decarbonization of the four material pillars of modern civilization uncommonly challenging: replacing fossil fuels in their production will be far more difficult and costly than generating more electricity from renewable (mainly wind and solar) conversions. Eventually, new processes will take over— but currently there are no alternatives that could be deployed immediately to displace large shares of existing global capacities: their development will take time.

Synthesis of ammonia and smelting of steel could both be based on hydrogen rather than on natural gas and coke. We know how to do that—but it will take some time before we could produce hundreds of million tons of green hydrogen derived from the electrolysis of water by using wind or solar electricity (virtually all of today’s hydrogen is derived from natural gas and coal). The best forecast is that green hydrogen would supply 2% of the world’s energy consumption by 2030, far below the hundreds of million tons that will eventually be needed to decarbonize ammonia and steel production. In contrast, decarbonization of cement production can only go so far by using waste materials and biomass, and new processes have to developed and be commercialized to make cement CO2-free. Similarly, there is no simple way to decarbonize plastic production, and the measures will range from plant feedstocks to more recycling and to substitutions by other materials.

And beyond these four material pillars new and highly energy-intensive material dependencies are emerging and electric cars are their best example A typical lithium car battery weighing about 450 kilograms contains about 11 kilograms of lithium, nearly 14 kilograms of cobalt, 27 kilograms of nickel, more than 40 kilograms of copper, and 50 kilograms of graphite—as well as about 181 kilograms of steel, aluminum, and plastics. Supplying these materials for a single vehicle requires processing about 40 tons of ores, and given the low concentration of many elements in their ores it necessitates extracting and processing about 225 tons of raw materials. And aggressive electrification of road transport would soon require multiplying these needs by tens of millions of units per year!

Modern economies will always be tied to massive material flows, whether those of ammonia-based fertilizers to feed the still-growing global population; plastics, steel, and cement needed for new tools, machines, structures, and infrastructures; or new inputs required to produce solar cells, wind turbines, electric cars, and storage batteries. And until all energies used to extract and process these materials come from renewable conversions, modern civilization will remain fundamentally dependent on the fossil fuels used in the production of these indispensable materials. No artificial intelligence designs, no apps, no claims of coming “dematerialization” will change that.

Adapted from HOW THE WORLD REALLY WORKS by Vaclav Smil, published by Viking, an imprint of Penguin Publishing Group, a division of Penguin Random House, LLC. Copyright © 2022 by Vaclav Smil.

(th)

Offline

Like button can go here

#61 2022-05-13 09:23:58

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,517

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

tahanson43206,

I can't say that I'm familiar with who Vaclav Smil is, although now I might peruse one of his books to see if I've missed anything, but it's good to see that you finally found some random author of whatever who also knows exactly what I've spent so much of my time and so many electrons attempting to convey to you and others. Maybe you consider him to be an "authority figure" on the subject, whereas I'm just some uneducated peon. Isn't it remarkable how a college professor and an uneducated peon both came to the same conclusion? There was never any question in my mind about where all the energy was coming from. We've experimented with a bunch of energy production and storage technologies, but none are as "tangible and fungible" as hydrocarbon fuels, to use the terminology that someone with a background in banking can (hopefully) understand. The only thing this "green energy" fetish is presently doing, is obscenely increasing hydrocarbon fuel consumption. Why is that? Well... Simple energy physics and basic math will not be overturned by any technology that humanity actually knows how to make, deploy, and use at a global / "human civilization" scale. Simple heat engines, for all their perceived inefficiency in comparison to electrical technologies that never have been like-kind replacements, are the bedrock foundation of modernity in all its forms.

The entirety of our energy supply will not consist of electricity generated and consumed by fantastically complicated electronic devices that appear indistinguishable from magic to those who are unfamiliar with how they work / how they were built / how they fail- not now and not within the lifetime of anyone who is alive today. If it was ever practical and reasonable to do that, then we would've done it already. We did not lack for energy or material wealth in the past, we simply understood and accepted that some types of technology were far outside the realm of practicality, if not feasibility as well. Nothing has fundamentally changed in that regard since I've been alive. Gas turbine powered cars never caught on for that reason, either. We have the technology to make them, but there are "aerospace costs" attached to "aerospace engine technology". The "great transition" hasn't already happened, because it's not at all practical using known science reducible to repeatable engineering practices that scale up to the level required to replace "what came before". It's not for lack of trying, it's not because we're dumb, and it's not for any other reason except the exorbitant material consumption and therefore energy costs associated with "electric everything".

I didn't hear about any of this in some university class, I haven't made a career out of telling people simple truths about the engineered world that they live in, and I don't require any credit for explaining the basic "facts of life" to people who have never been taught any better by all these mass-indoctrination centers that were supposed to be providing useful and practical education to their pupils. These "food comes from supermarkets" people are the ones who desperately need an eyeful of what their fetishized "green energy" technologies actually looks like, although I think Michael Moore already did that for me better than I ever could, so I don't feel the need to reinvent that wheel. It's not a simple matter of money. The money is a stand-in for the associated energy costs.

When used appropriately (not artificially manipulated by governments for ideological purposes or simple greed), money and economics are non-interventionist ways to limit the excesses of bad ideas in societies blessed with functional and impartial governance bodies. Money does this by tempering the enthusiasm for "great ideas" (that may not work well enough or at all in some cases) with "let's not throw out the baby with the bath water" pragmatism that doesn't care how potentially "great" some new technology could be when said technology also requires 10X or 100X or 1,000X greater expenditure of energy and labor, and therefore money. What I do want, is for enough of these people to pull back just far enough from their ideological indoctrination to see that all these new technologies consume materials and energy at astonishing rates, and worst of all, they are seldom if ever used to produce the next similar example of the technology. We don't use batteries to make new batteries. We don't use solar panels to make new solar panels. We don't use wind turbines to make new wind turbines.

If there was ever a place to start "de-carbonizing" (at present, a total farce of a concept pretending to be something it's clearly not in actual practice), then you would have to start all the way back at the sources. Modern human civilization, which you and I both live in, was the end result of using mind-boggling quantities of steel, concrete, and glass. All those materials were and are the end product of enormous quantities of very cheap and readily obtainable energy, almost entirely provided by hydrocarbon fuels. Until that changes, fantasy-based ideas about how their modest, though admittedly useful, energy efficiency improvements they could at least conceptually provide, actually materializes. Thus far, all they've done is drastically increase total energy usage, and most of that energy is hydrocarbon fuels. Whenever emissions from countries that have deployed the most solar panels and wind turbines continue to increase or are almost the same as before their deployment began, then that's a giant red flag that whatever the desired result was, the new technology is having the opposite effect.

Driving an electric car, massively expanding the electric grid in an attempt to overturn the pitiful energy density of all known battery cell chemistries / photovoltaics / wind turbine fields, is a massive waste of time, money, and most importantly, ENERGY!

If "net-zero" is the goal, presumably without inducing mass starvation and death to a large swath of the human population, then an energy source at least equal to what created global warming is required. Thus far, no other form of energy generation is used at anything approaching the same scale as hydrocarbon fuels.

We possess the base level of technology to scale solar thermal heat engines to synthesize the fuels we require by extracting CO2 from sea water and the atmosphere to convert into hydrocarbon fuels. We vacuum up, store, and then sell these CO2-based products. That concept is in contrast to the present schemes that apply punitive measures like "carbon taxes" or "tax credits" for purchasing battery electronic vehicles, because that is essentially subsidizing the purchasing expensive electronics toys for the wealthy using the tax money extracted from people who may never be able to afford their own EV at the rate we're going. Instead, we supply energy-dense hydrocarbon fuels through CO2 recycling. We sell a product that people can use to keep themselves alive / fed / clothed / housed. We then use part of the profits from this operation to sequester additional CO2 in the form of other saleable products such as plastics or Carbon Fiber or CNT fiber. Those materials will be used to fabricate ultra-light vehicles that are affordable to the masses.

If it was affordable to mass-manufacture the base materials required to fabricate CFRP or CNTRP monocoque chassis passenger vehicles, then we can probably power those vehicles with less powerful internal combustion engines that consume less fuel while still providing equivalent power-to-weight ratio to what they replace.

Is Carbon Fiber the Future of Truck Bodies?

Chevrolet Silverado ZR2 Composite Body Concept Vehicle:

From the article:

...

The lighter body produces better fuel economy and lower emissions, equipping fleets to support company sustainability initiatives. According to the U.S. Department of Energy (DOE), for every 10%t of weight eliminated from a vehicle's total weight, fuel economy improves 6% to 8%. Therefore, if truck body weight is reduced by 50%, 60%, and even 70%, significant fuel cost savings can be achieved. Extrapolate the savings over the number of units in fleet, whether 10, 50, 100, 1,000 or tens of thousands of vehicles, the reduction in a fleet's fuel bill could be staggering - money that goes straight to the company's bottom line.

...

Paul offers this example as a frame of reference: "The weight of a typical 8-foot steel service body is 1,248 lbs. The weight of our [composite] body, which is a hybrid of aluminum and fiberglass, is 590 lbs. We believe we can build a body out of carbon fiber for around 400 lbs.," says Paul.

...

According to the 2008 Progress Report on Lightweighting Technologies by Oak Ridge National Laboratory (ORNL) - a science and technology laboratory managed for the U.S. Department of Energy (DOE) by UT-Battelle, LLC - carbon fiber is too expensive at $20 per pound for large-scale automotive use. The cost must be cut to $5 per pound before significant use of carbon fiber is seen in the automotive industry.

If you can affordably purchase much cheaper composites, then you can drastically reduce the weight of the vehicle, thus its fuel consumption. A 15% fuel economy improvement across most passenger vehicles used in the US represents a staggering amount of fuel, which is about what a CFRP body or chassis would provide. A CNTRP chassis could provide a 20% to 25% fuel consumption reduction. The US consumed about 135 billion gallons of gasoline in 2021, so pervasive CFRP would provide a fuel consumption reduction of 20.25 billion gallons and CNTRP would provide a fuel consumption reduction of 27 to 33.75 billion gallons.

For Carbon Fiber or CNT to become a practical automotive construction material, cost has to be reduced. The prime driver of cost for both materials is the high energy consumption associated with producing them. If that is effectively zeroed-out by making them from "unwanted" CO2 that we've collected but not used to synthesize fuel, then the end result is incredibly cheap aerospace fibers with the strength and stiffness required to fabricate strong but light automotive bodies or chassis. We can make SUVs and pickup trucks that weigh no more than an ordinary passenger car using affordable CFRP or CNTRP technology. We can make then make a miniaturized version of the Cummins 6BT engine that's based upon the thoroughly-proven Cummins 6BT design, that incorporates the technology from the 161hp Cummins R2.8 4-cylinder engine. If we knock out 1,000 pounds of body and chassis weight, then we don't need a large displacement LS V8 gasoline or DuraMax V8 diesel engine to power the thing. It'll haul or tow just as well as the previous models using less power and less fuel.

Why can't we already make vehicles like this?

Vehicle Cost = Embodied Energy Cost + Labor Cost + Delivery Cost

There's only so much labor cost we can remove through automation. At present levels of assembly line automation, most of the vehicle cost is tied up in the machine time and materials. Start with a well-proven design, avoid unnecessary electronic crap that adds little to no value to the utility of a vehicle as a passenger transport, apply cheaper fabrication materials that also reduce weight and increase fuel efficiency at the same time, and then source your fuel from 90% efficient solar thermal power that ultimately draws down emissions by recycling all the existing CO2 into both fuels and lightweight structural materials.

If the problem is global warming, then the solution can't be a total farce that only accelerates global warming through massive over-consumption of materials and therefore energy. You can't use an energy storage mechanism that's orders of magnitude less energy dense than what it's supposed to replace, but only 50% more energy-efficient than liquid hydrocarbon fuel under the most ideal circumstances that ignore all losses, and then also ignore the fact that there's not even close to enough supply of the required input materials to actually re-power enough machinery to make a difference at a global level. In the real world, the word "economy" means economy of energy and economy of labor. There's nothing economic about technology that requires orders of magnitude more energy input, which is a feature of all electronic devices. At some point, reality needs to take over here. If you don't want to extract hydrocarbon fuels from the ground, then you have to synthesize them from scratch using an energy source that can cover more than 100% of the demand without massive additional energy inputs. That describes solar thermal power to a "T". Photovoltaics won't do it, wind turbines won't do it, geothermal won't do it, and nuclear won't do it, either. Nothing else will do.

We can afford to consume the Aluminum and stainless steel required to make enough trough-type reflectors to process sea water and CO2 into fuels and materials. We could never afford to manufacture enough Lithium-ion batteries using current technology, because we'll run out of that metal long before demand is satisfied. Even if private transportation didn't exist, there still wouldn't be enough Lithium. The materials used in photovoltaics are equally scarce. Since batteries and photovoltaics are electronic devices, they have severe service life limitations that affect all electronics controlled by microchips. Wind turbine blades are composite structures subjected to gravitational forces so severe that they would instantly destroy any fighter jet airframe ever made, so those are also strictly service life limited. Once software-control is introduced to those devices, all bets on service life are off. Any significant software glitch can destroy a software-controlled device at the speed of light. Beyond that, recycling microns-thick layer cakes of dissimilar materials will always be a nightmare proposition.

So... As unpalatable as hydrocarbon fuel and simple solar thermal heat engines initially appear to those with ideologically-caused mental issues, or futurism and complexity fantasies, those are the ultimate power sources that make modern life possible. Without them, you return to pre-industrialization- a time when life was short, bleak, and brutal. There will be no space program to colonize other planets, no advanced medicine, no mass transportation, no clean drinking water, and no food to feed at least half the people presently living on Earth. Along the way, every scrap of combustible material that can burn, will be burned for energy by the people who are being impoverished in the name of "saving the planet", so say goodbye to all those trees because they won't exist inside of a generation if this ideologically-motivated energy poverty idiocy is continually pursued to its illogical maxim.

We need practical storable energy supplies made from recycled CO2 in sea water. We could never obtain enough Lithium from conventional sources to make all the batteries that our technophiles want to consume, so extraction of Lithium from sea water is required to do what they want to do to begin with. Civilization was built using the materials we had in abundance, not the materials we wished we had. A future that most of us want to live in will not be created using technologies or materials we don't have. Tearing down what we've already built is not a solution, either.

Offline

Like button can go here

#62 2022-05-13 12:55:05

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

This may be useful information regarding materials embodied in a solar thermal plant.

https://www.researchgate.net/publicatio … _materials

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#63 2022-05-13 13:32:46

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,517

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

Calliban,

I'll take a look, but the end goal here is to concentrate enormous quantities of process heat for processes that are mostly chemical in nature. We're not attempting to generate or distribute electricity anywhere outside the fuel production plant. The hydrocarbon products will be pumped from the plant holding tanks through pipelines to reduce vehicular transport of fuels. However, the Lithium, Magnesium, Uranium, Carbon Fiber, and CNT products will require trucks to remove them. Any salts removed will be used as thermal power stores, or simply piled up on the ground until we have tanks to put it in. If we have to build more storage tanks to hold more molten salt or hydrocarbon fuels, then we'll build more tanks. We know how to do that and we're good at it.

We're also primarily interested in trough-type solar concentrator panels that do not mandate enormous quantities of steel-reinforced concrete or very high temperature materials. This scheme will not use solar power towers because those are not particularly cost-effective and require complicated control electronics for all of the field's mirrors to focus their reflected light onto a single point in the sky.

We have no shortage of otherwise unused land to use for this purpose, and the end result is products that everybody needs / wants- namely, energy stores, high-demand metals, and high strength Carbon-based construction materials.

Offline

Like button can go here

#64 2022-05-13 14:15:07

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

This may be useful information regarding materials embodied in a solar thermal plant.

https://www.researchgate.net/publicatio … _materials

I decided to do a few checks on the amount of materials different power plants require per TWh. I decided to limit the comparison to iron and steel, as steel content per TWh correlates quite well with the embodied energy needed to produce a TWh of electricity from the source.

Below is a link to the 2015 Quadrennial energy review, produced by the US department of energy

https://www.energy.gov/quadrennial-tech … eview-2015

Go to Section 10, Table 10.4 for a summary of materials inputs into several different types of powerplant in ton/TWh. Here are some tallies per TWh:

Nuclear (PWR) = 160t steel

Wind = 1800t steel

Solar PV = 7900t steel

The link below provides materials requirement for two types of solar thermal powerplant; solar tower based and trough based.

https://www.researchgate.net/publicatio … _materials

I took the amount of iron and steel needed per TWh per year, and divided it by an assumed powerplant lifespan of 40 years. Here are the results:

Solar thermal (trough): 5,825t steel

Solar thermal (tower): 3,800t steel

This would put the amount of steel needed by the solar thermal trough powerplant about three times as much as wind turbines per TWh. However, steel requurements are about 30% lower than an equivelent PV powerplant. This may reflect the higher efficiency of thermodynamic energy conversion. The tower method uses less than half of the steel compared to PV, and only two thirds the steel of the trough method. This is presumably because the collector area is comparable, but the much higher temperatures allow superheated steam to be raised in the tower method.

Compared to a pressurised water reactor, concentrated solar using trough collectors, requires 36.4x more steel per TWh; whereas the tower method requires 23.8x as much.

However, for synthetic fuel production we are replacing the steam plant with a chemical plant. How significant a difference this would make I don't know. But concentrated solar technologies do not appear to offer dramatic improvements over PV in terms of the quantities of materials used. This is disappointing. I expected a lot more from this technology. But logically, the reflector area in a concentrated solar thermal plant must be about the same size as the panel area of a PV power plant. So there won't be a huge difference in power density between the two, but the superior efficiency of thermodynamic cycles vs PV (30-40% vs 20%) will reduce collector area by 1/3rd to 1/2 compared to PV. This is reflected in the reduced steel content of both trough and tower concentrated solar, compared to PV.

Last edited by Calliban (2022-05-13 14:44:51)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#65 2022-05-13 14:32:29

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,123

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

For Calliban re recent posts...

Thank you for adding the several comparisons you provided in recent posts!

For kbd512 ... if you are in a mood to try to turn this discussion into a business plan, I'm interested in trying to help.

The question that a financier would have to assess is whether there is a profit waiting at the end of some period of years, for investment in your vision.

You already have a question on the table, to explain trough over tower, and you've already answered it in part in your reply to Calliban.

it appears (as I understand Calliban's posts) that trough consumes more raw material, but (here I'm looking for your input) I'm guessing the trough is more ** practical ** in various respects.

The 40 year lifetime looks reasonable to me for planning, although I'm guessing your funders will want to see the first profit after five years.

If you have a few minutes, please post a comparison of trough vs tower that a financial analyst can understand.

The allure of "newer" solar concepts may distract from the down-to-Earth reliability of trough.

(th)

Offline

Like button can go here

#66 2022-05-13 16:12:51

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

Whilst the materials requirements of solar thermochemical fuel production do look quite high, this could be made to work. Let us assume that the solar chemical plant can produce fuel energy at the same efficiency as electrical power. With that assumption, the amount of steel needed to produce 1MJ electrical energy is the same as needed to produce 1MJ of chemical fuel. A few numbers can give us a feel of how practical this idea is from a resource viewpoint.

In 2019, global diesel consumption was 28 million barrels per day. That is 17,100TWh per year. To produce 1TWh of electricity using trough solar power requires 5920 metric tonnes of steel. I worked out that figure by assuming that a power plant producing 1TWh of energy per year, had a lifetime of 40 years. So to produce 17,100TWh per year, requires solar thermal fuel factories containing some 4.048 billion tonnes of steel. That sounds like a lot, and it is. Global steel production in 2020 was 1877.5 million tonnes. So those fuel factories will need just over two years of global steel production to build them. The numbers will be similarly large for cement and glass.

But: (1) Once built, each factory should last 40 years. This is standard for steam plants and refineries; (2) We don't need to replace the entire diesel production of the world overnight. We just need to be able to offset the global decline in diesel production from natural sources. These two factors, taken together, should allow synthetic diesel production to ramp up gradually, as conventional oil production declines. World conventional oil production appears to have been declining at a modest 1% per year in recent years.

https://peakoilbarrel.com/decline-in-wo … -peak-oil/

If we assume that diesel production from conventional resources are declining at the same rate, then we need to bring solar diesel factories on line at a rate of 280kb per day, each year. That would require about 2% of global steel production and similar proportions of concrete production. That is an achievable goal and it is sufficient to offset the diesel shortages that are driving prices so high.

Last edited by Calliban (2022-05-13 16:26:09)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#67 2022-05-13 19:02:38

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,517

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

Calliban,

This is not about electrical output. If you compare solar power towers operating near "molten lava" temperatures vs parabolic troughs operating near "molten Lead" temperatures, then you will obviously see an electrical conversion efficiency increase using molten lava. However, hydrocarbons do not form at molten lava temperatures. That is why we never drill near the edges of tectonic plates. You seldom, if ever, find any hydrocarbons there, because they do not form at such extreme temperatures. We primarily require the thermal power output of the plant, not electrical output, and it needs to fall within a range at which hydrocarbons can form, which is typically between 60°C and 120°C, and near 90°C is the sweet spot for crude oil. Any higher than that, and most of what forms is gas. We do require pressure and electricity across the catalyst to produce the chains of molecules that we're after.

However, I also accept that conversion will always require more energy input than output, perhaps a significant amount more, so we're saying that the conversion process is around 33% efficient, because that's roughly what you get when converting thermal to electrical energy in the temperatures generated in solar trough type concentrators.

Offline

Like button can go here

#68 2022-05-13 20:15:07

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,517

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

tahanson43206,

Yes, we should work on development of a business case for this technology, because when we run out of gasoline and diesel we will have mass starvation and death. Nobody who is sane and rational wants that.

Offline

Like button can go here

#69 2022-05-14 06:46:02

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,123

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

For kbd512 re #68

If you are attending today's meeting of the North Houston NSS, you may be able to find support for a business venture.

The key question (in my mind at any rate) is whether you are both able and willing to serve as temporary leader for an enterprise. Anyone can be a follower.

The world consists ** primarily ** of followers. There is no shame in being a follower! Most of us (humans) spend most of our time on Earth as followers or supporters.

However, a project of this magnitude requires sustained, durable leadership.

Very few humans have the capability to serve as a leader in any capacity, and even fewer as leaders in ** this ** situation.

Best wishes for success in finding support!

Ma Nature provides ** ALL ** the energy and material needed at no charge to anyone.

The miracle of leadership can transform humans who are twiddling their thumbs into a productive work force.

(th)

Offline

Like button can go here

#70 2022-05-14 12:27:06

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,517

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

tahanson43206,

I have to take my daughter to archery practice today because my wife has a doctor's appointment at the same time. However, if Keith from NSS wants to discuss the possibility of laying out the business case for why we need synthetic fuel production to make up for the lack of Lithium resources required to electrify most food production and cargo transport vehicles, we can do that during the Sunday call.

The only miracle that will save us from poor decision making is acknowledging the nature and severity of the problem we're going to face in the coming years as conventional oil production declines.

I sent a message via LinkedIn to reach out to Prometheus Fuels to see if they are willing to consider modifications to their processes that reduce total energy demand. To wit, using sea water as a source for CO2 should reduce the energy required to enrich the water's existing CO2 content to the 2% that they require to make alcohols that can then be transformed into gasoline or diesel in subsequent process steps. As far as I'm aware, they're using a four-step process to produce diesel and kerosene. The first step is blowing atmospheric CO2 into water and then using that mixture to produce alcohols such as Ethanol, that are later refined into gasoline / diesel / kerosene in the last process step.

Offline

Like button can go here

#71 2022-05-15 09:07:56

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

Methanol synthesis from hydrogen and CO2.

https://www.sciencedirect.com/topics/en … -synthesis

'Methanol synthesis is considered via the direct CO2 hydrogenation process concept proposed by Bongartz et al. (2019) (Figure 2). AA-grade methanol is produced at a reaction pressure of 70 bar, a reaction temperature of 250°C, a molar H2:CO2 ratio of 3.0 and application of commercial Cu/ZnO/Al2O3 catalyst.'

The reaction consumes 3kmol (6kg) of hydrogen (HHV = 849.6MJ) to produce 1kmol (32kg) of methanol (HHV = 630.4MJ).

The reaction is exorthermic, so a well designed chemical reactor should not need additional external heat once reaction temperatures are established. The energy requirements of methanol synthesis are dominated by the energy needed to create hydrogen. The CO2 harvesting from sea water will require trivial energy in comparison.

Hydrogen can be produced thermochemically using the iodine sulphur cycle. This requires high heat - 800°C or greater. It can also be produced via electrolsis of water. Alternatively, or in addition:

CO + 2H2 = CH3OH

If you begin with a syngas that is already rich in CO and H2, then far less hydrogen need be added to produce a syngas with the right CO and H2 ratio for methanol synthesis. Biomass is fixed carbon is the form of cellulose and lignin. Cellulose is C6H10O5.

https://en.m.wikipedia.org/wiki/Cellulose

If biomass can be gassified into a synthesis gas efficiently, then we get a syngas with composition: CO + H2

If we add 1 mol of additional H2, produced by electrolysis to the syngas, we have a syngas with the correct proportion of CO to H2, to produce methanol.

CO + H2 + H2(e) = CH3OH

However, compare this to direct CO2 methanol production:

CO2 + 3H2(e) = CH3OH + H2O

If we begin with biomass as the carbon feedstock, rather than CO2, we need add only one third as much H2 to the syngas compared to full conversion of CO2. Begining with biomass rather than CO2 requires one third as much energy. So, if you want to make synthetic hydrocarbons, begining with biomass or some other material containing reduced carbon, will save you a ton of money.

There are many potential sources of fixed carbon. Crop residues, forestry wastes, biomass crops like miscanthus, sea weed, micro algae, plastic waste and other trash, sewage, carbon rich sediments, etc. Alternatively, there is oil shale:

https://www.usgs.gov/centers/central-en … /oil-shale

'The Eocene Green River Formation of Colorado, Utah, and Wyoming contains the largest oil shale deposits in the world. Oil shale, despite the name, does not actually contain oil, but rather a type of organic matter called kerogen, a precursor of oil that is converted to a type of crude oil when heated to about 450 – 500° C. The oil shale deposits are in three structural and sedimentary basins that have been recently assessed:

2010 Piceance Basin in western Colorado

2010 Uinta Basin in eastern Utah and western Colorado

2011 Greater Green River Basin in southwest Wyoming and northwest Colorado

Estimated total in-place resources are about 1.5 trillion barrels of oil for the Piceance Basin, about 1.3 trillion barrels of oil for the Uinta Basin and 1.4 trillion barrels of oil in the Greater Green River Basin. The Piceance Basin is the smallest of the three principal basins of the Green River Formation in terms of area covered and contains the highest concentration of high-grade oil shale (capable of generating at least 25 gallons of oil per ton of rock), with approximately 352 billion barrels of in-place oil resource.'

To release the oil, heating to 450-500°C is required. As these deposits exist in areas that have plenty of sunlight, concentrated solar power could meet this requirement. There are also high temperature nuclear reactors that produce temperatures in this range.

Last edited by Calliban (2022-05-15 10:12:15)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#72 2022-05-16 04:57:00

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

Reposted from other thread.

All liquid synthetic fuels start with hydrogen in one way or another. Turning CO2 into methanol requures 3 mols H2 for every mol of CO2. Ammonia requires 3 mols of H2 for every 2 mols of ammonia produced. If you want to produce synthetic liquid fuels from coal, tar sands or kerogen, then you need hydrogen to crack those long carbon chains into shorter carbon chains. If you want synthetic fuels that are as cheap as diesel was back in the good ol bad ol days, before 2007, then cheap hydrogen is the key.

But producing synthetic diesel cheaply enough to lift everyone out of poverty is a tall order. This link shows historical retail diesel prices in the US.

https://fred.stlouisfed.org/series/GASDESMDiesel prices rose above $1.5/gallon back in 2004 and have never been so cheap ever since. It was rising energy prices that drove inflation leading up to 2007. It was that and the interest rate rises that were intended to combat inflation that caused the great financial crisis. Over indebted people suddenly found themselves squeezed from both ends. So we can set $1.5/gallon as a very approximate threshold beyond which economic growth becomes difficult. That is about 40 cents per litre.

One litre of diesel contains about 10kWh of chemical energy. So it implies a cost no greater than 4 cents to produce each kWh of diesel. That includes the energy needed to make the hydrogen and the capital and maintenance cost of all the infrastructure. This is why it makes sense to begin with some form of fixed carbon rather than pure CO2. If you begin with some form of biomass, then the energy cost of producing a litre of diesel is reduced by a factor of 3 compared to having to reduce CO2. Even so, it is a tall order being able to produce synthetic fuels as cheaply as diesel. Even $5/gallon would be a challenge.

The production of synthetic diesel shouod be combined with investments to improve the economic value extracted from each unit of diesel. This means extending rail and water based transportation wherever possible and implimenting fuel efficiency measures. The further we can go with improving fuel efficiency, the higher the sustainable price of diesel can be without crashing the economy.

Calliban,

The US Federal Government has blown mad money on all manner of idiotic and wasteful endeavors. If necessary, we will force them to do everyone a solid by underwriting the expenses for this project, and then run it the same way we run our government arsenals. Even the Derpistanis we presently have in power can be convinced if you threaten to remove them from power.

We're going to apply enough horsepower in the form of photons to solve this problem, because it needs to be solved. If there are ways to finesse the energy requirements to lower values, then so long as that doesn't represent another huge energy / technology / capital sink, we'll do it. Otherwise, we'll use brute force, because we can.

Everyone else is hoping for a miracle breakthrough or dithering while the problem continues to worsen. We don't need miracles, and no miracles appear to be forthcoming anyhow. Simple engineering principles, applied at the appropriate scale and using resources we have rather than resources we wished we had, will solve this problem, even though the overall solution is still fantastically complex.

I've already looked at every manner of biomass solution. They all fall woefully short of the output side unless deployed at scales that become unmanageable, and they're still dependent upon factors outside of our control.

Last edited by Calliban (2022-05-16 04:58:01)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#73 2022-05-16 05:14:45

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

Everyone else is hoping for a miracle breakthrough or dithering while the problem continues to worsen. We don't need miracles, and no miracles appear to be forthcoming anyhow. Simple engineering principles, applied at the appropriate scale and using resources we have rather than resources we wished we had, will solve this problem, even though the overall solution is still fantastically complex.

I've already looked at every manner of biomass solution. They all fall woefully short of the output side unless deployed at scales that become unmanageable, and they're still dependent upon factors outside of our control.

Let us assume that what is being proposed [mass production of alcohol based fuels through reduction of CO2 using hydrogen] is the best solution to the problem of fossil fuel depletion.

What is needed to achieve this is the cheapest possible source of hydrogen. Once that hydrogen is provided, it is the starting point for synthetic fuel production, ammonia production, synthetic polymer production, cement production and steel production. All of the cornerstones of industrial civilisation can be weaned off of fossil fuels if cheap hydrogen is available.

The hydrogen itself does not neccesarily need to be stored or transported any distance, because the infrastructure that uses it will be built on the same site where it is generated and will consume it at the same rate at which it is generated. So the average lifetime of a hydrogen molecule will be very short. It will be used as a fuel directly (cement production), or used as a chemical reducing agent (synthetic fuel, polymers and steel) or as an ingredient (ammonia). But low cost hydrogen production is the key enabling technology.

To produce hydrogen cheaply, there are two technological options: (1) Thermochemical; (2) Electrochemical. The former uses chemical cycles to split water and requires high temperatures. The second uses electrolysis to split water.

Thermochemical cycles have an advantage in theory over electrochemical, because heat is employed directly, without the capital cost of first generating electricity and then employing an electrolyser. But it requires high heat, in the region of 800°C. Concentrated solar using towers can achieve these temperatures. High temperature nuclear reactors can achieve these temperatures. Electrolysis is arguably a better option in terms of technological readiness. It will accept electricity from any source and could be deployed at scale relatively soon. Cutting out hydrogen storage greatly improves economics. And as we have noted already, hydrogen storage is not needed for a hydrogen economy to be succesful.

Both methods of hydrogen production depend upon four factors to achieve low cost hydrogen production.

(1) Cheap primary energy (Ce). This means either cheap heat (thermochemical) or cheap electricity (electrochemical).

(2) High capacity factor (close to 100%) (Cf). For thermochemical cycles this is important because thermal cycling would be severely limit plant lifetime. In the case of both thermochemical and electrochemical, the hydrogen generation equipment has high capital cost. Minimising costs per unit product requires us to maximise the output. That means operating equipment at 100% capacity, as close as possible to 100% of time.

(3) Without hydrogen storage, the operating capacity of downstream hydrogen consumers (fuel, ammonia, plastics, cement, steel) will depend upon the output of the hydrogen plant at any point in time. They have their own capital costs and thermal cycling issues, so close to 100% capacity factor is doubly important.

(4) All fixed unit costs tend to decline with increasing scale (S). This is true both for the number of plants operating and the size of individual plants. For miniumum cost design, we need hydrogen facilities capable of each producing gigawatts of hydrogen. To meet the demands of the entire planet, we need terawatts of generation in total.

Cost = f(Ce, S, Cf^2).

What this drives us to is an energy source capable of providing gigawatts of heat or electric power at a chosen location (S); very cheaply (Ce) and at a capacity factor close to 100% (Cf). Ideally, we should be able to build it quickly and this will have a direct bearing on generating cost (Ce). At the moment, there is no energy source capable of meeting all of these requirements simultaneously. Is there anything that could (in principle at least) do all of these things, lets say with near term technology or by relaxing certain constraints?

Last edited by Calliban (2022-05-16 05:47:54)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#74 2022-05-16 05:55:42

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,123

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

For Calliban re moved posts and new additions to the flow ...

Thank you for continuing development of this important line of thought ...

We (forum members) have an opportunity to have a (small) part in shaping the future, in collaboration with members of the North Houston NSS chapter.

kbd512 will be away for a couple of days on business, but from recent posts and last night's Zoom, I am persuaded of his long term interest in moving the ball toward a goal of harnessing solar power to make useful fuels.

Nuclear power is not an option in Texas (unfortunatly) but solar power is accepted and there is land available.

The two of you seem to be apart (a bit) regarding trough vs tower, so that needs to be resolved.

The proposal in work is to look for a partner (a fossil fuel power plant) that would be willing to deliver exhaust to a company set up to collect it.

The two of you differ on how to cool/compress the exhaust and separate CO2 from the nitrogen.

kbd512 appears to be in favor of using compressors (which requires energy of course) while you have offered the interesting idea of using solar power to make liquid air that can be used to cool the exhaust.

Either way, energy has to be invested to cool (and separate) the CO2 for input to the industrial process that will lead to fuel.

In the Zoom, we noted that there are intermediate products in the chain to gasoline or diesel that might have immediate market value.

We have a person familiar with financing available to take a look at the business case(s) for the various scenarios.

I am targeting a two year time frame to put something in place.

As numerous NewMars authors have noted, there are good and sufficient reasons to expect that a well designed and executed business plan will succeed in competition with residual fossil fuel suppliers.

Ultimately the fossil fuel suppliers will (probably) transition to making fuels, after success has been demonstrated by others. An optimum outcome is for those suppliers to transition to providing lubricants, instead of burning irreplaceable resources stored up over millions of years.

Thank you again for your assistance as we proceed!

Closing thought: Nuclear power would be an excellent way of addressing this problem. If you can find a business partner willing to pursue that path, I hope you will do so at the fastest possible pace. That is not an option in Texas for (what I gather are) social reasons.

(th)

Offline

Like button can go here

#75 2022-05-16 07:55:47

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Prometheus Fuels Lower Cost Than Fossil Fuels

Let us assume the use of concentrated solar power to generate electricity, which is then used to produce hydrogen through electrolysis. We are situating this power plant on the coast and degassing seawater to provide a CO2 feed to the chemical reactor. The degassed sea water will be used to remove waste heat from the condensers of the steam plant, before returning to the sea. Here is a quick calculation to give an estimate of the price of synthetic fuel. I am going to focus on energy costs and leave out capital and operating costs for the time being.

The chemical reaction is:

CO2 + 3H2 = CH3OH + H2O

A total of 6kg H2, combines with 44kg of CO2, to produce 32kg methanol and 18kg water. Let us assume that the CO2 can be obtained for zero energy cost and the water is recycled back into the electrolyser. We must provide 6kg H2 (HHV = 851.16MJ) to get 32kg methanol (630.4MJ). The reaction is exothermic, so no additional energy is needed to drive the chemical reactor. The maximum efficiency of the reaction is therefore 74%. The efficiency of electrolysis varies according to design parameters. A high power density electrolysis stack will have lower efficiency but lower capital cost. And vice versa. So the designer would balance electrolyser capital cost against energy cost in an attempt to reach the lowest net cost of product. But let us say for the sake of argument that efficiency is 80%, which is towards the high end of real systems.

One litre of diesel fuel contains 10kWh of stored chemical energy. There 3.76 litres in a US gallon. So that is 37.6kWh of stored energy. What is the minimum amount of electricity that is needed to produce synthetic fuels with energy equivelent to 1 gallon of diesel?

Energy = Stored energy in diesel / (efficiency electrolyser x efficiency chemical reactor)

Energy = 37.6kWh / (0.8 x 0.74) = 63.5kWh

How much would that electricity cost? Below is a link describing a large solar power plant in Morroco, which uses a mixed trough and tower concentration scheme, with molten salt storage allowing night time generation.

https://en.m.wikipedia.org/wiki/Ouarzaz … er_Station

Generation cost = $0.196/kWh.

Assuming that our synthetic fuel facility can be built on site, the cost of 63.5kWh gives us a steer for the energy cost per equivelent gallon:

63.5kWh x $0.196/kWh = $12.4 / gallon.

How much would we have to add on for the electrolyser and chemical plant maintenance and capital amortisation costs? I don't know at present. Much will depend upon the capacity factor of these units.

If nuclear power cannot be used as the primary energy supply for electrolysis, then I would suggest a combined approach of solar PV, solar thermal and wind power, providing electrical input to the electrolyser. I would oversize the molten salt reservoir relative to the solar thermal collector and instal heating elements that can be switched on to absorb any excess electricity from the wind and PV plant. The combination of wind and solar helps even out seasonal fluctuations in solar and wind energy production. The molten salt store would be sized to provide 24 hours of storage, which should dampen daily fluctuations.

We could use sensible heat thermal stores if we needed to store heat for longer. These would be pre-stressed concrete shells, containing crushed rock, probably with CO2 circulating gas. Dry sand would be the insulating material. The rock would be heated by blowing gas across a hot heat exchanger and then through the rock. To raise steam, hot gas would be blown through a boiler. We could heat quartz or granite rock to temperatures up to 1000°C. If the rock has a density of 3000kg/m3 and a specific heat of 1KJ/kg.K, then 1m3 of rock heated to 1000°C would store some 800kWh of thermal energy. To achieve those sorts of temperatures, we would have electrically heat the rock.

Last edited by Calliban (2022-05-16 08:35:16)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here