New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#76 2016-03-07 00:12:45

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,363

- Website

Re: Light weight rover for Mars

None of what you want exists and it won't exist for another two decades at the earliest. SLS will still be in development into the middle of the next decade, assuming Congress or the President doesn't kill it sooner. Do you want to do the mission at all? If so, then think small.

My plan started as a modification of Mars Direct. I noticed great effort into reducing launch mass, but Dr. Zubrin missed a key point. When Apollo was developed, they first tried to design a CSM that would land directly on the Moon and return to Earth. But no matter what they did was too heavy, even Saturn V couldn't launch it. Then one engineer broke it into "mother ship" and "Lunar Excursion Module" (LEM). The name LEM was contracted to LM, but that's what they did. The CM was the same, but the service module was much smaller. Total launch mass was less than the lift mass of Saturn V. They had a little extra lift mass left over. They later used that extra for a rover, and more oxygen in suits, and more duration for the LM. One Apollo mission included some orbital instruments on the service module. But my great wonderful revolutionary idea was simply to apply the same principle to Mars. Yup, it wasn't revolutionary at all, it was just applying an Apollo principle to Mars Direct. That is, keep the return capsule in Mars orbit.

I then noticed that the hab has lots of room and artificial gravity, but the ERV was cramped. So design a DSH (to use the current term) dedicated for in-space operation. Mars Direct included a fabric heat shield that expands like an umbrella. I later learned that is ADEPT. But my wonderful idea was to use the same thing on DSH. And since it has that, why not use it for Earth as well? That allows the DSH to aerocapture into Earth orbit, then aerobrake just like MGS down to ISS. NASA attempted aerocapture for Mars Climate Orbiter, but made a US measure to metric conversion error. It wasn't fundamental to the technology, it was just a stupid math error. And I suspect it wasn't even that, it was a communication error: an aerodynamic engineer talking to software engineers. News releases called the software guys "technicians", which says something about the attitude of the aerodynamic engineers of that project. Since then NASA ordered everyone to use all metric, to prevent that problem from happening again. So the problem is solved, but some people in NASA are too cowardly to try aerocapture again. The problem is known and solved, yet they won't try it again! It isn't some decades in the future, just do it!

Again, those of us who lived through Apollo know what can be done. Redstone was an intermediate range ballistic missile, not intended to carry humans. It was used for the first Mercury launch. We went from Redstone to Apollo 11 in about a decade. From Allen Shepard's flight it was 8 years. The first designs of Mercury were in 1958. Early studies of blunt bodies were before that. Counting from the first design it's 11 years. That's what NASA can do when they really want to.

Mars Climate Orbiter was launched December 1998. This technology is overdue. To quote the Nike slogan: "Just do it!"

ISPP: Robert Zubrin's company got a NBIR contract to build a brass-board prototype. They did, it worked. In fact, that was the first time NASA heard of a Sabatier reactor. They later decided to use this key component of ISPP for Mars as part of life support on ISS. NASA also built a Mars In-situ Propellant production experiment (MIP) as one of the instruments on the Mars Surveyor 2001 Lander. That lander was put on hold after Mars Polar Lander failed. The landers were the same design. They did find the problem, and solved it. But Mars Surveyor 2001 Lander was never launched. They forgot about it. Then one scientist discovered it in climate controlled, sterile storage in preparation for launch, but no scheduled launch date. He proposed rebuilding it: removing all engineering experiments so he could add more science instruments. They did, it was renamed Phoenix. The radiation instrument was also removed, but there's a RAD instrument on Curiosity. There was also Mars Environment Compatibility experiment (MECA), designed to measure the toxicity to humans of martian soil and dust. That had multiple parts: wet chemistry, Microscopy, Patch Plates, Electrometer. Curiosity has wet chemistry and Microscopy. MIP is the only instrument not sent to Mars in one form or another. It was ready to go in year 2000. It isn't some ridiculously advanced technology, it's over due.

Offline

Like button can go here

#77 2016-03-07 00:15:32

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,363

- Website

Re: Light weight rover for Mars

Then we had the great crash and lots of work was lost.....

found another needing cleanup...

I remember that one. We were actually posting to it just last year. It started pre-crash? First post in 2002? How time flies!

Offline

Like button can go here

#78 2016-03-07 09:20:10

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,131

- Website

Re: Light weight rover for Mars

Here's some thoughts for what we are debating. First: a "base on Mars" is not necessarily a large pressurized space in which people live. A "base" is a set of machines making electricity, oxygen, water, propellants, etc. It resembles a chemical plant more than a big RV. Those are the essentials to be produced in situ. People can live inside the craft that brought them. At least for a while.

So, the pressurized habitation space of our "base" can be the lander itself. Or you can add inflatables or other volume, maybe immediately, maybe later. Point is, you leave the supplies in production. Later visitors can add living spaces.

I think the smart way to do a Mars mission is to use both (1) assembly in LEO (to avoid the need for ridiculously large and expensive launch rockets) and (2) leaving the return gear in Mars orbit by using a separate lander or landers much like Apollo (to avoid having to land such huge masses, which in turn increases masses you must throw to Mars).

Essentially that lets you "base" out of Mars orbit the same way Apollo "based" out of lunar orbit. I remember what Apollo looked like before they split off the LM: 2 Saturn 5 launches per moon mission, one a tanker to refuel the other in LEO. At that time, lunar orbit rendezvous looked less dangerous than learning how to do on-orbit transfers of LH2 and LOX. (For that matter, I remember when the Douglas Skyrocket and the Bell X-2 were the state of the art, long before there was a NASA.)

Even so, it still took almost 2 years to get NASA behind lunar orbit rendezvous, because the idea came from outside NASA. NIH ("not invented here" attitude) was strong at NASA from about 1960 forward. Such was common through the aerospace defense industry back then, and it's worse today.

If you base from orbit, your lander can be a one-shot 2-stage design with storable MMH-NTO, and you can pressurize the cargo deck as living space after you unload. Such things are big enough to bring a rover car not unlike the lunar rover. If you bring 2 or 3 of these kinds of landers, then you have some redundancy for rescue purposes, and you could possibly visit two sites.

If on the other hand, you assemble a much larger lander that is one-stage, and reusable, you can refuel it in Mars orbit and visit several sites. The number of sites you can visit is limited only by how much landong propellant you can afford to throw to Mars orbit. One stage chemical usually will size out near a 3% payload fraction, so these really are large, voluminous vehicles (with about the same pressurizable cargo space as the 2-stage design). Once again, you should bring 2 or 3 of them for the redundancy necessary for rescue.

In either case, the landers themselves can push supplies and propellants to Mars unmanned, and be waiting in orbit when the men get there. It becomes the Mars analog to lunar orbit rendezvous either way.

And if aerocapture features get used, you can still reduce the thrown masses to Mars. If you add electric propulsion, that helps, too.

Unless you insist on multiple things landed at one site (and you do NOT HAVE to do it that way, but you ALWAYS can), then your rovers do not have to be long-duration pressurized machines. They can be day-trip machines more like what we used on the moon. That's just something else to think about.

Otherwise, unless you can come up with a large, long-duration pressurized rover (and land it somehow), then you have to very reliably solve the pinpoint landing problem to land multiple vehicles at one site. To do that successfully, one must keep in mind that radio and radar will not work while the descent craft is encased in a plasma sheath during entry.

That ionized entry part is simple ballistic with inertial guidance. You cannot do radio positioning or radar homing until the speed is low enough that the slipstream gases are no longer ionized (about Mach 3-something to maybe 4). You are very close to impact at that point: too late to compensate very much, except for your final rocket-braked touchdown.

Just some things to consider.

GW

Last edited by GW Johnson (2016-03-07 09:26:11)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#79 2016-03-07 13:14:33

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,463

Re: Light weight rover for Mars

GW,

My response is somewhat off-topic, but since the reason for using a light pressurized rover for habitation only makes sense within the context of a mission architecture, I'll rehash some things here.

In addition to relatively modest technology development requirements, and hopefully procurement, the architecture I've proposed makes every attempt to minimize extreme performance requirements. Virtually every other mission architecture I've seen has extreme performance requirements for one or more mission hardware components.

Examples of extreme performance requirements:

reusable Mars landers (we hashed out what this actually entails in terms of tonnage delivered in another thread)

Earth return vehicle fueled on Mars using ISPP

40t surface habitat (creates extreme performance requirements for lift vehicles or requires multiple lift vehicles)

40t+ deep space habitat (creates extreme performance requirements for lift vehicles or requires multiple lift vehicles)

130t+ super heavy lift vehicle

100t+ SEP-CTV

Even if we could develop any or all of the above listed hardware, is any of that actually required for human exploration of Mars? If we just wanted to do the mission, what's the most mass efficient solution that requires the least expensive technology development programs with the least extreme performance requirements?

My admittedly limited knowledge of super heavy lift vehicles and reusable spacecraft is that this kind of hardware is really expensive, difficult to develop, and has extreme performance requirements. With respect to large habitats, the habitat itself may be rather simple, but seems to drive extreme lift vehicle performance requirements.

Everything I've proposed has modest lift requirements and modest performance requirements because of the actual funding availability to NASA.

* More rockets and minor assembly is required with my architecture, but it's not outlandish (if we can't launch 2- 4 cargo flights and 1 human flight per year, then something is very wrong with our human space flight program)

- DSH's require no assembly for TMI (MDV and TMI stage are physically connected to each other at launch), but are launched unmanned (as stated elsewhere, the crew could launch inside the DSH, but there's no possibility of escape from a stricken lift vehicle and that's is a no-go; it is possible to use the MDV for launch to eliminate the requirement for a separate capsule launch) and crews transfer to them using a separate capsule (if a DSH launch fails, there's no reason to send a crew)

- A capsule (Dragon V2 or Orion or CST-100, any will work) docks with the DSH to transfer crew and perform inspection prior to TMI (in my mind, it's sensible to inspect a vehicle you're totally dependent upon for six months in deep space prior to departure)

- TEI kick stage must be mated to DSH for return to earth, but the TEI kick stage has modest performance requirements and weight (SEP-CTV attached to TEI kick stage spirals in to LMO to mate the TEI stage to the DSH)

- MAV has to dock with DSH prior to TEI to transfer crew and perform inspection prior to TEI (inspect everything, assume nothing)

That's one orbital assembly event in LMO and three docking events (LEO, LMO, GEO or EML1). If mating a TEI kick stage or docking with the DSH three times (crew transfer for TMI, crew transfer for TEI, crew transfer for return to Earth) is too complicated, then perhaps it's best if we call this whole thing off.

* DSH is a two crew member vehicle, so no super heavy lift launch vehicle is required

* DSH does not have to survive aerocapturing or aerobraking, so no technology development required for this

* DSH uses TMI / TEI kick stages for orbital transfers and integrated SEP for LMO and GEO or EML1 orbital insertions only

* DSH can be spun to produce AG to reduce in-transit crew deterioration

* MDV only has to make it to the surface in one piece and is not expected to provide long duration life support

* MAV only has to make it to LMO in one piece and is not expected to provide long duration life support

* LPR only has to store one quarter of consumables and does not require non-existent battery, solar, or life support technology to function

* LPR only weighs .95t fully loaded, so it has the weight of a Ford Fiesta on Mars

* LPR has the same atmosphere as the pressure suit, so there's no pre-breathe prior to EVA and no requirement for LN2 storage

* LPR rings the landing area, so if your landing accuracy is within a 75km by 25km ellipse, one or more rovers will be on top of you within a few hours or less (sit tight and wait for the cavalry to arrive)

* Every piece of mission hardware has a backup that is included as part of the mission and we can do this because there are no outlandish performance or mass requirements that dictate extremely expensive mission hardware or launch vehicles

* MAV is the most complicated item to deliver and it's still less extreme than other proposed solutions because it's much smaller and lighter than other solutions

Offline

Like button can go here

#80 2016-03-07 17:53:08

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,352

Re: Light weight rover for Mars

Post mission archetecture in its topic Mars Mission Comparisons - updated with kbd512's proposal and small pressurized rover in the other .Combining the Rover and Hab - Go RV'ing! .... to which this topic is not for either.....

I do want to hear about those in there respective topic as that makes for a better flow of conversation.

Offline

Like button can go here

#81 2016-03-07 19:24:18

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,463

Re: Light weight rover for Mars

SpaceNut,

I'd really like to put the light pressurized rover in its own thread because RV'ing on Mars is a general topic and this is a specific proposal. Feel free to move my posts and responses to its own thread. I'll stick to ideas about light unpressurized rovers in this thread.

Feel free to move my comments about mission architecture out of this thread and into the Mars Mission Comparisons thread. GW made comments about mission architecture and I responded. It's all somewhat OT, but explains why we'd want LPR's for exploration and bases with LUPR's for general utility transportation.

Offline

Like button can go here

#82 2016-03-07 19:38:59

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,352

Re: Light weight rover for Mars

Have created the topic with the couple posts.....

Offline

Like button can go here

#83 2016-03-23 20:35:51

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,352

Re: Light weight rover for Mars

Nasa has implied if not said that a Permanent Mars Colony Is 'Long Way Down the Road' of course we here are all asking, Why?

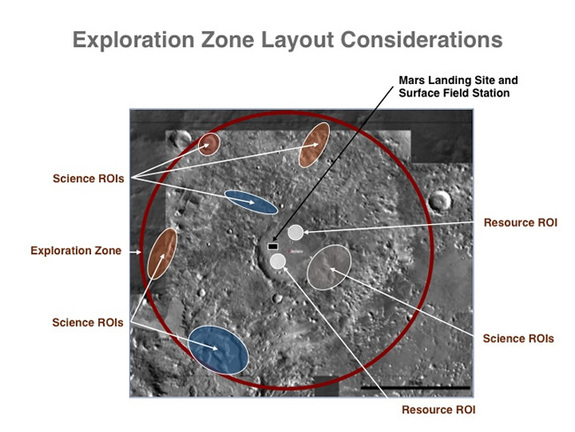

According to NASA's current plans, the Mars outpost — which NASA hopes to set up by the end of the 2030s — will serve as a hub that accommodates astronauts on a temporary basis, said Ben Bussey, the chief exploration scientist in NASA's Human Exploration and Operations Mission Directorate.

The agency is currently evaluating 45 potential sites in a circle with a radius of roughly 62 miles (100 kilometers) — about the amount of ground NASA envisions its astronauts will be able to cover comfortably in 2030s Mars rovers.

Crew quarters and other buildings — the EZ's "habitation zone" — will sit at the center of this circle, which will also contain science and resource "regions of interest" (ROIs). Astronauts will visit science ROIs to hunt for signs of Mars life and perform other investigations; resource ROIs will provide the pioneers with water ice and other raw materials needed for day-to-day living.

This is simular to the setup and will function much like McMurdo Station, the United States' research facility in Antarctica. This will allow for the crew to be self-sufficient as you can, and that's a mixture of having systems that recycle your products, as well as making use of local resources all while doing science.

"The idea here is that you would have your exploration zone that you set up for the first crew," Bussey added. "And that crew would leave, and then you send another crew at the next good launch opportunity. So it isn't permanently occupied, but it is visited multiple times

This post also applies the the small pressurized rover use as well....

Offline

Like button can go here

#84 2016-03-23 21:29:39

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,463

Re: Light weight rover for Mars

I think the presence of usable water is a virtual requirement for a Mars colony. The technology already exists to make oxygen and nitrogen or argon from Martian atmosphere. Plants can be genetically modified to grow in a range of soils or to grow in no soil at all. The equipment required to mine ores on Mars can be built on Mars using 3D printing.

I think we're getting ahead of ourselves here. Humans have yet to set foot on the planet.

Offline

Like button can go here

#85 2016-03-24 19:22:32

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,352

Re: Light weight rover for Mars

Actually we need to plan before we go to Mars or the science returned will not have targeted the mysteries that we wanted to have answered. We will not have the correct mineral deposits checked for future missions.

Devising a machine that can scoop and build what we need from a 3D printer would be great but all seem to need quite a bit of processing of the media that is feed into the machine to be able to perform the miracle of building what we need.

So the question is do we send a robotic mission or 2 to the same site to build what we need and then go as we can make use of much smaller landers and just move the support systems from them into the newly create habitas built by the 3 D printers or do we just go for it with way more small landers or some other method to garantee sucess....

Offline

Like button can go here

#86 2017-05-08 18:56:02

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,352

Re: Light weight rover for Mars

Bumping this topic as its simular and may benefit from the thoughts...

louis I like the ability of being able to put together such a machine for quick space suit use via insitu build as that a huge step down the path of sustainability.

The other thoughts were about the power source being changed from batteries to a RTG and supercapacitor bank (thanks kbd512) which could be in a box lined with the "with PE foam or BNNT wool fabric for radiation shielding" in the open seater design....

The in hub motors also make the machine more versitile in the event of a motor going bad as you can still move on the front or the rears depending on which one has failed unlike a single common motor design....

Not sure how much night time riding would be done but its a small amount of mass to add to what a crew would bring.

Offline

Like button can go here

#87 2018-04-09 19:35:32

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,352

Re: Light weight rover for Mars

Have been doing tonnes of research and posting of DIY build which would allow for repairable product on mars from the average person in the Mars Cart page 4 topic to which building more from insitu would make sense as a first buildable item on mars as well.

Offline

Like button can go here

#88 2018-12-28 19:44:42

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,352

Re: Light weight rover for Mars

Whether we go small, fast or RV nuclear powered we will not want to go on mars Living Without A Car but there are some doing just that here but would we even want to consider it.

This is something I have faced all to well when the car was broke, still needing to work while it was broke and no money or materials to fix it with. So we may need to use what we can to make life easier on mars and not totally rely on it to get man from place to place.

We will really need to plan ahead for repairs or going simple so as to make the design robust with few parts to break.

Offline

Like button can go here

#89 2018-12-29 06:20:31

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,463

Re: Light weight rover for Mars

I have some updates to this concept.

Electric Motor Tech:

AML Superconductivity and Magnetics has a new double-helix coil design that permits current densities as high as 200A/mm^2. That's pretty spectacular for a pure copper based electromagnets- for a motor application, in this case. Operation at high power levels would require active cooling, but lower power and thermal sinking into the hub / wheel structure could produce featherweight motors with extreme power-to-weight. The technology was developed in conjunction with funding and support from NASA for active electromagnetic shielding of spacecraft to reduce crew radiation exposure.

Battery Tech:

3D batteries are just now coming to market, but not at the desired energy density. 500Wh/kg seems to be what's on offer. I think we need to figure out how to deploy a flexible solar panel for daylight mobility without rattling the thing to pieces.

Recent dry pile batteries can provide approximately the same power-to-weight as our Pu238 RTG's, but without the advantage of the thermal power. This is a similar technology to that developed by Bloom Energy.

Wheel Tech:

Aluminum CMC's can provide the strength and toughness required for use on Mars. The CMC's are significantly harder in comparison to ordinary 7075-T6, pound for pound 4 times stronger, only very slightly heavier than 7075, and more fatigue resistant. A superb suspension system would be required or the ride could be pretty jarring. Maybe there's some sort of ultra-low Tg rubber such as Thoreaus metallic rubber that would cushion some of the impact.

Suspension Tech:

Perhaps the heritage 6x6 rocker-bogie suspension system would work best. A fiber-reinforced Aluminum (MetPreg) would form the suspension arms and the upper arms will see double-duty as containment for batteries. That gets around the problem of protecting the batteries using the classic GM / Tesla "skateboard" design or putting potentially flammable batteries inside the rover.

Offline

Like button can go here

#90 2018-12-29 06:37:14

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Light weight rover for Mars

500Wh/kg is a major advance I think...I thought generally the upper limit was around 300Wh/kg.

I've been interested in on board PV generation. Maybe something like the ATK fans at the sides behind and vertically above the vehicle would work. Alternatively if one was using ultralightweight PV you might be able to set up a kind of rig that extends above, either sides and behind the rover with PV panelling over. The whole thing might weigh only a few kgs. As winds are so low powered on Mars, you don't need a lot of structural strength, just a few poles from which you can suspend the rigging (narrow wires).

Otherwise, I think the waystation approach will work - ie laying down small solar power stations with batteries at regular intervals (can also include water, oxygen, food and other essentials). The Rovers could then

I have some updates to this concept.

Electric Motor Tech:

AML Superconductivity and Magnetics has a new double-helix coil design that permits current densities as high as 200A/mm^2. That's pretty spectacular for a pure copper based electromagnets- for a motor application, in this case. Operation at high power levels would require active cooling, but lower power and thermal sinking into the hub / wheel structure could produce featherweight motors with extreme power-to-weight. The technology was developed in conjunction with funding and support from NASA for active electromagnetic shielding of spacecraft to reduce crew radiation exposure.

Battery Tech:

3D batteries are just now coming to market, but not at the desired energy density. 500Wh/kg seems to be what's on offer. I think we need to figure out how to deploy a flexible solar panel for daylight mobility without rattling the thing to pieces.

Recent dry pile batteries can provide approximately the same power-to-weight as our Pu238 RTG's, but without the advantage of the thermal power. This is a similar technology to that developed by Bloom Energy.

Wheel Tech:

Aluminum CMC's can provide the strength and toughness required for use on Mars. The CMC's are significantly harder in comparison to ordinary 7075-T6, pound for pound 4 times stronger, only very slightly heavier than 7075, and more fatigue resistant. A superb suspension system would be required or the ride could be pretty jarring. Maybe there's some sort of ultra-low Tg rubber such as Thoreaus metallic rubber that would cushion some of the impact.

Suspension Tech:

Perhaps the heritage 6x6 rocker-bogie suspension system would work best. A fiber-reinforced Aluminum (MetPreg) would form the suspension arms and the upper arms will see double-duty as containment for batteries. That gets around the problem of protecting the batteries using the classic GM / Tesla "skateboard" design or putting potentially flammable batteries inside the rover.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#91 2018-12-29 06:53:45

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,463

Re: Light weight rover for Mars

Louis,

I was actually thinking about using roof-mount thin film PV with the new deployment structures that NASA is testing for ROSA. It's a system that is stiff enough to withstand the acceleration loads from driving around over rough terrain at low to moderate speed and very lightweight. Direct PV power and permanent / dry pile battery for life support is how I intend to minimize mass. I can't think of any other tech besides dry piles that are pressurized-environment "safe". It'll be as heavy as a RTG for the power provided, but there's a dry pile in your neck of the woods, I believe, that has been in continuous operation for the past 200 years or so. They don't outgas or explode and some use completely non-toxic materials.

If there's a way to negate the need for any form of expensive nuclear power, then that's desirable. That said, I'm a stickler about never running out of power, as you well know. We could potentially use PV with super caps embedded in the suspension arm structures instead of Lithium-ion batteries to further improve cold performance and preclude any "thermal events" with Lithium-ion batteries, as GM would call them. Since this is an exploration rover, short bursts of power to move from site to site are all that's really needed.

Offline

Like button can go here

#92 2018-12-29 17:02:50

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,352

Re: Light weight rover for Mars

Louis, Motors are quite wide in variety in that they can have a Stator be made without an iron core, with permanant magnets, some uses AC power and others make use of Comutated DC or pulses of DC via a control electronics, The windings are looped or considered as lines in how they are placed into the stator, With the Armature having many of the same considerations to make for trade offs as were made with the Stator design and we still have induction motors which have some of the same features to consider.

I have made post to the solar topic...

Offline

Like button can go here

#93 2019-01-28 18:30:09

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,352

Re: Light weight rover for Mars

Why design something special if we can take a New half-ton electric pickup costs just $5,700

It’s called the Pickman and the tiny truck only costs $5,700. It’s made by China’s Kaiyun Motors and has a 5.5 hp motor that's good for a top speed of just 28 mph, which classifies it as a low-speed or neighborhood electric vehicle (LSV/NEV). Regulations regarding their operation vary state to state, but they are street legal in some places. It's aimed mainly at commercial customers and has a range of 75 miles per charge. While the $5,700 version is a very basic vehicle, its options list includes features like air conditioning, heated seats and alloy wheels that can bump the price up near $9,000. One could arguably call it a half-ton, however, as the Kaiyun says the rear-wheel-drive vehicle can carry up to 1,100 pounds on its fully-independent suspension.

Of course its got to be mars readied but that is not all that much....

Offline

Like button can go here

#94 2019-02-16 21:14:41

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,352

Re: Light weight rover for Mars

Making a mars rover move means we need to learn about the basic parts that make movement possible.

1. Battery or Batteries

2. Electrical and electronic controllers

3. Electric motor

Of course if you are not an engineer for some of these its hard to understand what could go wrong with there use let alone how to go about repairs.

EV Motor Not Powerful Enough? Make Your Own.

This one is how to convert a gas engined vehicle to making it an EV.

https://evrater.com/build-your-own-ev

https://www.wired.com/2009/11/diy-ev/

https://www.instructables.com/id/Build- … ctric-Car/

There are also a variety of motors

http://www.ev-guide.com/acdc-motor

Of course we have our pick of battery types to make use of if we are going to stay on mars but we could use lithium ion

http://www.thedrive.com/tech/17505/the- … tery-folks

Next up is what controls the motor when we step on the gas pedal to make it move

https://www.instructables.com/id/200kW- … ctric-Car/

Offline

Like button can go here

#95 2019-12-17 21:13:20

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,352

Re: Light weight rover for Mars

Posting a resource of parts for possible use in a machine which we must be able to repair.

https://www.electricmotorsport.com/ev-parts

https://didyouknowcars.com/what-are-the … ar-engine/

I missed the charging unit, display of use informations in voltage, amperes, speed and other interal or external vehicle conditions that need to be monitored.

The concept is to design based on what can be built under a give mass performance values desired for the total machine and not of anyone specific item to be used.

Offline

Like button can go here

#96 2020-02-07 19:25:45

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,352

Re: Light weight rover for Mars

NASA to Industry: Send Ideas for Lunar Rovers

in mind when the topic was started...

Offline

Like button can go here

#97 2022-04-04 12:54:22

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Light weight rover for Mars

Nissan rolls out driverless buggy to traverse dusty lunar surface

https://www.asahi.com/ajw/articles/14493743

maybe NASA or JAXA could give a lander solution for ESA?

ESA ExoMars Rover is ready for launch. What are the next steps?

https://spacechannel.com/esa-exomars-ro … ext-steps/

Offline

Like button can go here

#98 2022-04-12 10:41:33

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Light weight rover for Mars

Companies build up teams to compete for Artemis lunar rover

https://spacenews.com/companies-build-u … nar-rover/

Companies are adding to or creating new teams in anticipation of a NASA competition for a lunar rover to support later Artemis missions to the moon.

Lockheed Martin announced April 4 that it was adding Canadian company MDA to its partnership with General Motors to develop a rover. MDA, which developed robotic arms for the shuttle and International Space Station, will provide a robotic arm for the Lockheed-GM rover.

“It’s built on the decades of experience that we have on Canadarm,” said Holly Johnson, vice president of robotic and space operation at MDA, during a presentation about the partnership April 4 during the 37th Space Symposium. “We will be using the same software and control systems and operational lessons learned that we gained over the decades, but it will look a little bit different.”

Offline

Like button can go here