New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2020-09-26 08:27:57

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,897

Hydrogen Fuel Cell Vehicles

There is a lot of work going on (on Earth) to achieve break-even using hydrogen as an energy carrier for transportation.

The article at the link below describes the first flight of an attempt along these lines with an aircraft in the United Kingdom.

The headline writer seems to have been carried away with excitement. A comparable commercial grade aircraft flew recently in the US.

A post in this new topic about that aircraft would be welcome.

In the mean time, work is under way to compete in long haul trucking.

https://currently.att.yahoo.com/news/fi … 03456.html

(th)

Offline

Like button can go here

#2 2020-10-02 02:18:42

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,307

Re: Hydrogen Fuel Cell Vehicles

tahanson43206,

Whereupon we finally admit to ourselves that batteries will not power everything in the near future, but that there are still practical alternative solutions to reduce the use of fossil fuels, then we will have qualitatively "better" engines for transport purposes that behave as functional equivalents to internal combustion engines using liquid hydrocarbon fuels.

The combination of a fuel cell and electric motor has far fewer moving parts than an inline 6-cylinder diesel and transmission, so far fewer opportunities for highly stressed components to fail in operation. If someone proves that a fuel cell powered truck can significantly exceed the rebuild interval for an engine like the Caterpillar C-15, then even if the cost differential for the initial purchase is higher, over time you will end up saving money. A rebuilt C-15 ACERT engine runs in the neighborhood of $15K to $20K and a rebuilt engine can last for roughly a million miles between rebuilds, according to a YouTuber who rebuilds Caterpillar truck and marine engines for a living. If a fuel cell can last for, say, 2 million miles, then it will likely have paid for itself.

Caterpillar's C-15 ACERT engine weighs 1,469kg dry (no oil or optional no accessories) and for a running engine with the optional extras that most trucks require, we're looking at a bare minimum of 1,500kg. An Allison TC10 that can handle the horsepower and torque is 487kg dry and about 535kg with the 14 gallons of transmission fluid it requires. The emissions treatment module alone adds another 180kg. Figure on an absolute bare minimum of 2,215kg. The engine mounts, exhaust, and other hardware probably bump that up to at least 2,300kg or so.

An equivalent 3kW/kg SOFC would weigh in at 150kg. Given that kind of incredible weight reduction, you can get away with all kinds of other weight reduction measures to the rest of the tractor's chassis design. A tractor with 4 super single type wheels should be feasible without overloading the wheels.

Offline

Like button can go here

#3 2020-10-02 06:03:14

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,897

Re: Hydrogen Fuel Cell Vehicles

For kbd512 re #2

Thank you for the comparison of vehicle types, and for the detail of weight/mass needed, as well as estimates of lifetime costs.

It ** does ** seem as though a horse race is in progress, similar in some ways to the one going on in the privately owned vehicle catetory.

For all ... this topic is available for posts about development of Hydrogen Fuel Cell Vehicles of all kinds, and in all locations on Earth.

(th)

Offline

Like button can go here

#4 2020-10-02 15:54:56

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,743

Re: Hydrogen Fuel Cell Vehicles

For earth fuel cell use we can use the compressed air but on Mars we must carry that heavy bottle of oxygen to make them work.

Offline

Like button can go here

#5 2020-11-06 16:11:49

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,207

Re: Hydrogen Fuel Cell Vehicles

An old and somewhat cumbersome technology that may find application on Mars.

https://www.lowtechmagazine.com/2011/11 … icles.html

Basically, a vehicle powered by hydrogen contained in a thin polymer bag on top of the vehicle. As the bag is non-pressurised, it is very light and with no differential pressure, diffusion of hydrogen through the bag is slow enough not to be a problem. The main problems are air resistance, which limits top speed and low total energy density (~12.5MJ/m3) which limits range. None the less, these vehicles were used successfully in Britain and Germany in WW2 when oil was in short supply, but town gas (predominantly hydrogen) could be manufactured from coal.

On Mars, with atmospheric pressure of 6mbar and temperatures of -50C, the energy density of a non-pressurised hydrogen bag would be 100 times lower than its earth equivalent. When allowance is made for oxygen volume, energy density would be ~80KJ/m3. However, air resistance on Mars is much lower as well. So a much larger bag could be fitted to the top of the vehicle. The low temperature of Mars will also reduce hydrogen diffusion rate through the bag material, allowing thinner bags to be used.

Non-pressurised polymer bags containing hydrogen and oxygen could be used to store energy for static power applications on Mars. Essentially, we are talking about putting a polymer membrane over a crater or other depression, weighing the edges down with soil and rock and filling the inside space with hydrogen gas at 6mbar. Another neighbouring crater would contain the oxygen. Axial compressors would compress the H2 and O2 to high enough pressure to feed a gas turbine or fuel cell.

Last edited by Calliban (2020-11-06 16:14:11)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#6 2020-11-06 17:34:19

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,743

Re: Hydrogen Fuel Cell Vehicles

We did look at the Compressed gas balloon rocket for Mars launch Which seemed like it might work if you convert the gas to liquid by supper cooling it. The fuel cells need pressure or liquid to make them work.

Fire Safety for Hydrogen Fuel Cell Vehicles

Dispensing gaseous hydrogen into fuel cell vehicles presents hazards that are different than dispensing gasoline; hydrogen is transferred into the vehicle at pressures that may exceed 10,000 psi (70 MPa). The dispensing nozzle must connect to the vehicle so that, unlike gasoline dispensing, it forms a closed, high-pressure system.

Offline

Like button can go here

#7 2020-12-16 11:02:46

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,743

Re: Hydrogen Fuel Cell Vehicles

bump

Hydrogen is a key element for mars in making of fuel, water and more with the potential to make it more widely used on earth as a clean fuel.

Offline

Like button can go here

#8 2021-02-20 15:54:19

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,743

Re: Hydrogen Fuel Cell Vehicles

If it was not for greed then maybe we might be using more....the we have the power grid issue

State wastes its extra solar, wind energy. Could hydrogen be storage key?

Offline

Like button can go here

#9 2021-12-24 23:14:55

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,897

Re: Hydrogen Fuel Cell Vehicles

For SpaceNut .... the link below is to a web site that appears to offer a variety of hydrogen fuel cell products.

This topic is set up to cover vehicles, but perhaps it can include devices such as power generators.

https://www.fuelcellstore.com/up400-por … en-4035001

(th)

Offline

Like button can go here

#10 2021-12-25 04:09:55

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,307

Re: Hydrogen Fuel Cell Vehicles

H2 is 11.11% of H2O by weight, so O2 88.89% is H2O by weight. For O2 stored at 100 bar / 1,450psi, you need about 280kg of O2, stored within 0.43m^3 worth of tank volume in order to completely react 31kg of H2. Hyundai's new Excient fuel cell powered semi truck, currently being tested in California, contains a total of 31kg of H2, is combined with a 72kWh Lithium-ion battery for better acceleration, is powered by a 469hp electric motor, and has a range of 500 miles. To run that same truck on Mars, you'd need an additional 0.43m^3 of tank volume to store the required O2 at 14.5% of the pressure of the H2 gas.

We'd probably retain the battery for life support functions, but run the truck solely off of electricity generated by the pair of 90kWe / 241hp fuel cells. Either way, we're talking about enough power to easily motivate the vehicle to a maximum off-road speed of 45mph. Heavy duty off-road trucks and tanks used here on Earth are limited to around 45mph in an off-road environment, and can generally attain maximum legal road speeds of 65mph to 75mph with the governors removed. The M1 tank can attain highway speeds with the engine governor removed, but governors were quickly installed as it entered service due to its propensity to throw tracks in turns. The Baja racing vehicles / Trophy Trucks that go faster off-road also don't last very long before repairs to the suspension system are required.

We're also not accounting for the fact that this truck will only weighs 38% of what it weighs on Earth and encounter near-zero air resistance at 45mph to 70mph (not that we'd want a heavy duty truck operating at that speed in an off-road environment), albeit with significantly increased rolling resistance from operating in an off-road environment. We're still operating at a distinct energy advantage. We don't need anywhere near as much power to move 30,400lbs as we do 80,000lbs. We can easily eat the weight increase associated with carrying the 280kg of O2 onboard. The fuel cell will also be more efficient because there's no N2 mixed in with the oxidizer. We can probably also afford to store the 300kg of water produced, so that we can re-split the combustion product into O2/H2 at the next "truck stop".

Does anyone remember this ST-CAEM lander vehicle?

Replace the giant pads with tank tracks, ditch the heavy ascent vehicle and retro-propulsion engines, and then you have a long range surface exploration vehicle.

It's an artist's rendition of the lander vehicle that comes from this document:

Space Transfer Concepts and Analyses for Exploration Missions - Boeing Defense and Space Group

Last edited by kbd512 (2021-12-25 04:12:44)

Offline

Like button can go here

#11 2021-12-25 17:50:46

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,743

Re: Hydrogen Fuel Cell Vehicles

Give the unit a skyscane like rig to lower the manned section to the surface and fly off problem is solved.

The good part of hydrogen oxygen fuel cell use is it can be recycled for ever just about so long as we have some means to break it back down and pressurize it back into the vehicles holding tanks.

Offline

Like button can go here

#12 2021-12-25 23:01:04

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,307

Re: Hydrogen Fuel Cell Vehicles

SpaceNut,

The problem with the Skycrane approach is that it requires a completely separate vehicle that must cut all lines at the same time and fly off to avoid crashing into the vehicle payload lowered below it. Skycranes clearly work, but it's not optimal when the payload is not a robot. With Curiosity and Perseverance, nobody would die if the Skycranes malfunctioned. The American tax payer writes off two billion dollars, but that's the extent of the damages. The fixed engine and fuel tank approach leaves the descent engines / tanks / avionics / wiring available for subsequent reuse or repurposing, as necessary. Trashing the Skycranes to get the rovers to the surface of Mars was a necessary sacrifice, but human missions will have uses for that hardware if some part of the mission hardware suffers a casualty.

Boeing designed the ST-CAEM lander to include both the habitat module and ascent vehicle in a single delivered package. My assertion is that this is almost correct. The ascent vehicle should land first, followed by the astronauts. If the ascent vehicle makes it to the surface in one piece, then the astronauts will follow in a separate vehicle purpose built for mobile surface exploration. The descent engines for the mobile surface habitat will be removed on the surface using an onboard crane / manipulator arm, wrapped in plastic, and their location marked with a transponder. If those engines are required as replacements for the ascent vehicle, then they're available for reuse. The propellant tanks will be retained and reused to store collected water, reactants for the fuel cells, LCO2 for air tools, etc.

Once on the surface, the vehicle will propel itself using onboard regenerative fuel cells and fully sealed high torque low-speed electric traction motors. The first order of business will be using solar or nuclear power to split the reactants from the distilled water carried onboard, compress / store the O2/H2 in tanks. After that operation is completed successfully, then mobile surface exploration and ice drilling operations will begin. Locating a clean source of ice is of paramount importance to colonization. If we want to use O2/CH4 in SOFCs, then we will bring an initial supply of H2O and LCO2 and a Sabatier reactor. We're bringing LCO2 to power the air tools anyway. CH4 provides a tank mass advantage for a given total output, as compared to O2/H2. That advantage is then immediately offset by the requirement for a Sabatier reactor and to radiate excess heat from the very high temperature SOFC. SOFCs are more compact relative to PEMFCs, but must be very well insulated and still require thermal control to remove excess heat generated at the high reaction rates necessary to produce the 10s of kilowatts of power to move the vehicle.

Everything is a trade-off. PEMFC is very well developed and operates at relatively low temperatures, but requires expensive catalysts and has an exceptionally low fuel density for gaseous Hydrogen stored at 10,000psi, relative to gaseous Methane stored at the same pressure. SOFCs also have the issue of storing CO2 and H2O byproducts, whereas PEMFC produces the same output water as the input water used to produce the reactants. We need to experiment with several fuel cells technologies, though. Alkaline fuel cells are an optional alternative to PEMFCs, with the advantage of marginally lower operating temperatures (80C to 200C for PEMFCs; ambient to 90C for AFCs). SOFCs run at temperatures that are literally as hot as or hotter than the combustor cans inside jet engines, which is why no steam reforming of H2 inside the fuel cell is necessary with SOFCs, unlike PEMFCs or AFCs using CH4 / C3H8 / NH3. Alkaline fuel cells could feasibly use LNH3, but then you need another type of reactor to regenerate the LNH3 fuel. The benefit is that LNH3 stores as much H2 as LH2, per unit volume, so the reactant storage tanks could be smaller than either O2/H2 or O2/CH4.

Holding onto LOX/LH2 or LOX/LCH4 without constant high power input and superb insulation is problematic at best, which is why this "option" remains an aspirational goal for NASA. Even during the winter at the Martian poles, you still need input power to dump heat into the environment to keep O2/CH4 in a liquid state. At the poles it can get down to -200F during the winter, but LOX boils at -297F and LCH4 boils at -259F, which means insulation and cryocoolers are mandatory. The alternative is highly compressed gases or moderately compressed liquids like LNH3. I realize that we've left out alcohols, but many of those can still freeze at night. That will never happen with the rest of the fuel options.

The RTGs will supply thermal power to heat the CO2 prior to feeding it into the air tools. Air tools are light, compact, simple, reliable, powerful for their size, field repairable, and contain no electronics or batteries to degrade / overheat / become inoperable due to electrical or electronic failures.

The residual gases can be stored in purpose built high pressure tanks. PEM fuel cells provide a 5:1 to 10:1 weight advantage over batteries after all system masses and inefficiencies are taken into account. That's approximately the same power-to-weight that Earth-bound vehicles require for similar masses to their combustion engine powered counterparts.

Life support functionality can be provided by onboard solar panels and batteries. CAMRAS and IWP need extensive real world testing in the Martian environment. Most of this technology derives from the Orion program and has already been long duration tested aboard ISS. To provide emergency life support power and thermal control, we will use Strontium-90 RTGs. Carbon-14 will supply electrical power to the various electro-optical sensors, life support electronics, and communications equipment. Strontium titanate is the material used in the Russian RTGs, as well as some American-designed units, because Strontium is a plentiful waste product of nuclear fission that's produced in nuclear reactors, and comparatively much cheaper than Pu238 production. Strontium-90's relatively short half-life of 28.8 years is not a serious problem for these comparatively short duration exploration missions. The alternative is paying to store excess Strontium-90 here on Earth, because current production provides more than nuclear medicine consumes.

DOE Isotope Program R&D and Production of Isotopes for Space Applications

One of the program goals of the mobile surface exploration concept is to evaluate the long term durability of the current generation of solar panels, batteries, fuel cells, and various nuclear devices so that their suitability for colonization can be characterized. We're going to test out Louis' assertion that solar panels can be cleaned off with a feather duster robot to restore power output, and monitor the UV degradation of the latest and greatest photovoltaic panels in Mars' high-UV environment. We've never determined what percentage of reduction of initial output was due to accelerated UV degradation versus dust accumulation and that is critical to know for colonization. Similarly, we need to evaluate the suitability of propellant / fuel cell reactant production plants to synthesize O2/H2/CH4/NH3. A single long duration test under actual Mars surface conditions is more valuable than all the speculation and simulation in the world. If everything we've hypothesized and simulated here on Earth checks out, then great. If not, then back to the drawing board we go. We're not going to bet hundreds to thousands of colonist lives on untested assertions. The same applies to human and plant adaptability to the 0.38g Mars surface environment, radiation tolerance, the psychological aspects of living on Mars, etc.

Offline

Like button can go here

#13 2021-12-26 09:53:21

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,743

Re: Hydrogen Fuel Cell Vehicles

So the crane system stays attached to the top and is removal able from the start of a missions first Mars walk to remove the cradle and engines which we do not need. The big thing is to land on the tracks. That said lines going to the tanks will be detached and plugged so we can reuse them. The cradle will be separated from the main unit and we are ready to lift the assembly off once wires are unplugged.

At that point it can set where we put it until we want to reuse it later.

Offline

Like button can go here

#14 2022-05-11 18:44:04

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,897

Re: Hydrogen Fuel Cell Vehicles

The article below is about a massive mining truck that uses hydrogen... the details of how the hydrogen is used may be available in the article, but I didn't pick it up at first reading ...

GEEKWIRE

Mammoth zero-emission mining truck makes its debut

Post author

By Alan Boyle

Post date

May 6, 2022

No Commentson Mammoth zero-emission mining truck makes its debut

Anglo American mining truck

Anglo American’s zero-emission haul truck stands three stories tall. (Anglo American Photo)

After years of development, the world’s largest zero-emission vehicle was unveiled today at a South African platinum mine, with a hydrogen-fueled hybrid powerplant designed and built by Seattle-based First Mode.Anglo American’s three-story-tall, 200-ton nuGen hybrid mining truck received a grand sendoff from South African President Cyril Ramaphosa at the Mogalakwena open-pit platinum mine. “It is a smart step for Anglo American, but a giant leap for South Africa’s hydrogen economy as we move into the future,” Ramaphosa said. “The hydrogen economy is beckoning us as a country and as an industry.”

Chris Voorhees, president and CEO of First Mode, said zero-emission industrial power will play a key role in addressing the global climate crisis. Large trucks currently account for 70% to 80% of diesel fuel consumption at Anglo American’s mines, but one nuGen truck is expected to keep the equivalent of carbon dioxide emissions from 700 cars out of the atmosphere.

“At First Mode, we know we are at a ‘fire-everything’ moment,” Voorhees said in a news release. “The urgency in front of us requires that we deploy every tool and every technology to battle climate change. I’m so proud of the team and our partnership with Anglo American, focused on decarbonization at the source to effect the meaningful, necessary change we all seek.”

GET THE FULL STORY ON GEEKWIRE

Tags

Climate change, Energy, Environment, First Mode, Hydrogen, Mining, Technology

(th)

Offline

Like button can go here

#15 2022-05-11 18:50:41

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,743

Re: Hydrogen Fuel Cell Vehicles

The hydrogen supply and all facets are possible but at what energy cost?

Next is the fuel cell cost to longevity of plausible use.

Offline

Like button can go here

#16 2022-06-16 17:55:47

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,897

Re: Hydrogen Fuel Cell Vehicles

Recently, one of our members expressed skepticism about hydrogen as a fuel.

It appears that while many share that view, there are a view who are willing to invest against the odds.

https://www.msn.com/en-us/autos/enthusi … cf433fef8b

Autoweek

AutoweekFollow

Volvo Creates First Hydrogen Articulated Hauler

Jay Ramey - 8h agoVolvo Construction Equipment partners with PowerCell Sweden and a number of research organizations to build a prototype hydrogen fuel-cell articulated hauler.

The 35-ton construction dump truck has an operating time of about four hours, carrying 12.5 kilograms of hydrogen.

Hydrogen is a promising zero-emission fuel for vehicles that would otherwise need large and expensive EV batteries, with a number of automakers working on this tech for large trucks.Despite a decade's worth of efforts by Toyota and a number of other automakers to popularize hydrogen fuel-cell cars, the technology remains a niche concept that is overshadowed by electric cars with each passing year, even if EV adoption is not exactly rocketing ahead. But if there is one segment where hydrogen fuel-cell technology appears to be gaining momentum, it's in heavy cargo trucks. A number of producers are now eyeing the creation of hydrogen corridors between large European port cities and inland manufacturing centers as a viable step forward, with efforts under way to build more hydrogen stations in Europe and the US.

But until now we haven't seen hydrogen fuel cells applied to some other types of heavy trucks.

Volvo Construction Equipment is seeking to change that, with the debut of the HX04 articulated hauler used in mining and construction. The prototype results from a collaboration between Volvo and PowerCell Sweden as part of a project launched in 2018 with funding from the Swedish Energy Agency, Swedish Innovation Agency VINNOVA, and Swedish Transport Administration.

The 35-ton, six-wheeled articulated hauler was built in Braås, Sweden, where the first articulated hauler was created back in 1966. The fuel cell itself has a capacity of 12.5 kilograms (27.5 pounds), which gives the truck about four hours of operation, and can be refilled in just seven and a half minutes.

As with other hydrogen efforts, infrastructure is key, and as a part of this project Shell installed a hydrogen refueling station at the Volvo CE test facility in Braås.

"While an early prototype, this innovation will give valuable insights into the opportunities of hydrogen in the energy transformation alongside battery-electric solutions," said Carolina Diez Ferrer, head of advanced engineering programs at Volvo CE. "We believe that by exploring multiple technologies and working in partnership, we can create the best path forward to decarbonize the construction industry."

Related video: Volvo Cars’ path to zero collisions | Spotlight | Unreal Engine

Electric mining trucks of different types have been around for decades, of course, but with this project Volvo is testing the technology's suitability for heavy construction equipment, which in Europe and the US is mostly powered by diesel fuel.

Despite having an industry-leading lineup of electric trucks on sale at the moment, Volvo seeks to explore hydrogen in this particular application for reasons that include battery weight. In a 35-ton hauler a battery that would allow it to operate for four hours could be prohibitively heavy and expensive, but a hydrogen tank combined with Volvo's own electric motors could be a far more realistic solution, especially when it comes to owner expenses.

"Vehicles with fuel-cell electric powertrains have an uptime, range, and fueling time similar to that of combustion-engine powered vehicles," the truck maker points out.

It's also worth noting that construction trucks of this type, if they were battery-electric, would not be able to use public charging stations, necessitating their own infrastructure in either case.

At the moment Volvo has most of the necessary tech to build more examples of the HX04, but expects wider commercialization of hydrogen-powered trucks to occur in the second half of this decade. As with EV cargo trucks, quite a bit still depends on infrastructure, especially the creation of regional hydrogen networks that are still in their infancy.

Ultimately, it will take closer cooperation and investment between truck makers and hydrogen station builders like Shell to make hydrogen trucks of various types more realistic for owner companies.

Continue reading

(th)

Offline

Like button can go here

#17 2022-06-16 18:00:21

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,743

Re: Hydrogen Fuel Cell Vehicles

as we found recently that the use of energy to create the fuel was only 75% efficient and then to use it for the fuel cell is only going to achieve a 40% return of energy when using a fuel cell to make energy for electrical use.

Offline

Like button can go here

#18 2022-06-16 18:08:33

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,897

Re: Hydrogen Fuel Cell Vehicles

For SpaceNut re #17

If you are in Europe, and do not have access to oil from the ground, hydrogen made from abundant water is an alternative.

Under those circumstances, an oil powered engine is 0% efficient.

However, you've introduced a point that seems worth considering in more detail.

It should be possible to identify the efficiencies at every stage of manufacture of hydrogen (on one hand) and manufacture of gasoline or diesel on the other.

For hydrogen, all you need is water.

For gasoline or diesel, you also need CO2 from the atmosphere to supplement whatever you can pull from water.

Please account for the energy you will be spending on preparing the CO2 for use, by pulling it from the air or water.

Whatever processes you choose, I think you'll find none is more than 50% efficient, so the more processes you introduce to the sequence, the less efficient your final product will be.

Under those conditions, I would be surprised if you get 1% efficiency for your gasoline or diesel solution.

(th)

Offline

Like button can go here

#19 2022-06-16 18:39:24

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,743

Re: Hydrogen Fuel Cell Vehicles

For a vehicle as well as for home power it would seem that on demand hydrogen production that is directly used in the engine is the more efficient as far as I can see but we need more information.

Offline

Like button can go here

#20 2023-02-10 14:11:48

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,897

Re: Hydrogen Fuel Cell Vehicles

The article at the link (search string) below is about conversion of aircraft to use hydrogen.

The key concept appears (to me at least) to be the packaging concept reported at the end of the article.

Search term: universal-hydrogen-receives-faa-approval-for-dash-8-test-flight

SimpleFlying

View Profile

Universal Hydrogen Receives FAA Approval For Dash 8 Test Flight

Story by Linnea Ahlgren • 10h ago

CommentsThe battle for the flight of the largest hydrogen fuel-cell-powered aircraft is on. ZeroAvia recently completed its first flight with a 19-seater Dornier 228. However, Universal Hydrogen is nipping at its heels - and looking to up the ante with a Dash 8-300 testbed.

Universal Hydrogen Receives FAA Approval For Dash 8 Test Flight

Universal Hydrogen Receives FAA Approval For Dash 8 Test Flight

© Provided by SimpleFlying

Earlier this week, the California-based startup announced it had been granted a special airworthiness certificate in the experimental category by the Federal Aviation Administration (FAA) to proceed with the first flight of the aircraft.The FAA approval clears the way for the first flight of the Dash 8-300, which Universal Hydrogen says will happen before the end of Q1, 2023. It will take place at Grant County International Airport in Moses Lake, Washington. The company also released a video of the retrofitted turboprop's first taxi, along with a short interview with the project's Chief Test Pilot.

Second-largest hydrogen-powered plane to fly

The founder and CEO of Universal Hydrogen is Paul Eremenko, former Chief Technical Officer at Airbus. If successful, Universal Hydrogen's testbed Dash 8 will be the second-largest hydrogen-powered aircraft ever to take to the skies, beaten only by the direct combustion engine fitted onto a Soviet Tupolev Tu-155 in 1988. And it will be the largest ever hydrogen fuel-cell powered airframe.Eremenko commented,

“We are simultaneously providing a pragmatic, near-term solution for hydrogen infrastructure and delivery, as well as for converting existing passenger aircraft to use this lightweight, safe, and true-zero-emissions fuel. Today’s milestones are essential, important steps to putting the industry on a trajectory to meet Paris Agreement obligations. The only alternative is curtailing aviation traffic growth to curb emissions.”

The Dash 8-300 has been retrofitted with a hydrogen fuel cell in one of the nacelles. This is in a configuration that resembles the first engine product Universal will bring to market - a conversion kit for the ATR 72-600. According to the current timeline, this will be certified and delivered for commercial passenger service in 2025.

Modular delivery system testing in Toulouse

Universal Hydrogen began life as a hydrogen infrastructure facilitation project. As can be seen in the post above, the company intends to the challenges of getting hydrogen to where it needs to go through a capsule system. The first operational tests of this modular delivery system took place at Universal's engineering center in Toulouse, France, in December 2022.

(th)

Offline

Like button can go here

#21 2023-06-15 18:24:43

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,897

Re: Hydrogen Fuel Cell Vehicles

The article at the link below appears to be a financial puff piece ... However, despite that dubious connection, it appears to contain some interesting data.

https://www.yahoo.com/finance/news/hydr … 04836.html

Hydrogen-Electric Vehicles Are Outperforming EVs In Range And Refuel Speed

Aran Richardson

Thu, June 15, 2023 at 11:44 AM EDTThe automotive industry is undergoing a transformation, driven by the urgent need for sustainable and eco-friendly transportation solutions. While electric vehicles (EVs) dominate the news, with the latest offerings from Tesla Inc., Hyundai Motor Co. Ltd. and Rivian Automotive Inc., there is an emerging promise with hydrogen-electric vehicles (HEVs).

Don’t Miss: Why Silicon Valley Elites Are Betting On This Startup's Vision For Reuniting American Families

Clean And Sustainable Energy

Hydrogen offers numerous advantages over traditional fossil fuels. It is an abundant resource produced through a variety of renewable methods, including electrolysis of water, biomass gasification and harnessing solar energy. By using hydrogen as a fuel, HEVs produce zero tailpipe emissions, making them a clean and sustainable transportation alternative. Zero emissions are essential for combating climate change and greatly diminish vehicle-related pollution in densely populated urban areas. While EVs are an important part of a cleaner transportation sector, they still produce emissions when the electricity powering the vehicles comes from fossil fuel generation. Due to the rising popularity of electric cars, many industries continue to innovate and produce electric options for traditional vehicles that would otherwise use engines. For example, Volteq is a startup building all-electric construction equipment, such as their Sky 1000 Skid Steer with over 15 attachments.

How exactly do these vehicles work? Instead of using a battery pack, HEVs produce a chemical reaction within a fuel cell that transforms hydrogen into electrical energy. This charges the electric battery on board, which then provides power to run the vehicle. It's a similar design to a battery, where the fuel cell separates hydrogen into protons and electrons, which are then separated. It's the separation that creates an electric current that serves as the power source. Water and heat are the only byproducts of this power-producing process.

Extended Range And Quick Refueling

One of the primary challenges for EVs is their limited driving range and lengthy recharging time. HEVs overcome this obstacle with their extended driving range and quick refueling capabilities. While battery-powered EVs require hours to recharge, hydrogen refueling stations can replenish the fuel cell in a matter of minutes, offering an experience similar to refueling a gasoline-powered vehicle. This advantage makes HEVs more practical for long-distance travel and eliminates range anxiety, making them a viable option for a broader range of consumers.

Scalable Infrastructure Development

A crucial factor that determines the adoption rate of any automotive technology is the availability of supporting infrastructure. The infrastructure for hydrogen refueling stations is not widespread but is gradually expanding, with governments and private enterprises investing in their development. Hydrogen infrastructure is scalable as suppliers can use existing gas pipelines and integrate hydrogen fueling into current fuel distribution networks. Hydrogen refueling stations are also suitable for remote areas where building electric charging infrastructure may prove challenging or is not financially viable.

Diverse Applications

HEVs offer a versatile solution for various transportation needs beyond cars, including heavy-duty vehicles such as trucks and buses and even trains. By leveraging hydrogen fuel cells, these vehicles can achieve substantial power and torque, making them ideal for hauling heavy loads over long distances. Additionally, HEVs can serve as a sustainable energy source in remote areas or during natural disasters, providing reliable electricity through their fuel cells.

Collaboration And Technological Advancements

The broad development of HEVs requires collaboration between automakers, energy providers and governments. Numerous global partnerships have emerged to promote the adoption and advancement of hydrogen technology. This collaborative effort is resulting in significant technological advancements, including improvements in fuel cell efficiency, durability and cost reduction. As technology continues to evolve, HEVs' cost-effectiveness will improve, mainly through cheaper hydrogen extraction processes, making them more accessible to a wider consumer base.

This article Hydrogen-Electric Vehicles Are Outperforming EVs In Range And Refuel Speed originally appeared on Benzinga.com

.

© 2023 Benzinga.com. Benzinga does not provide investment advice. All rights reserved.

(th)

Offline

Like button can go here

#22 2024-04-19 21:21:55

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,897

Re: Hydrogen Fuel Cell Vehicles

The article at the link below is about a Green Hydrogen ocean going ferry planned for Norway.

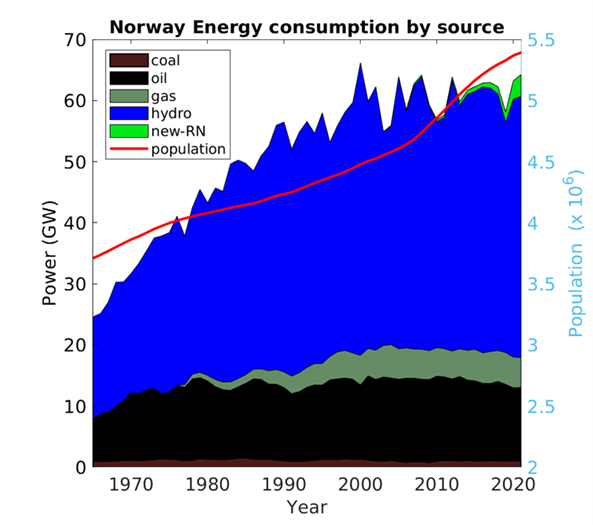

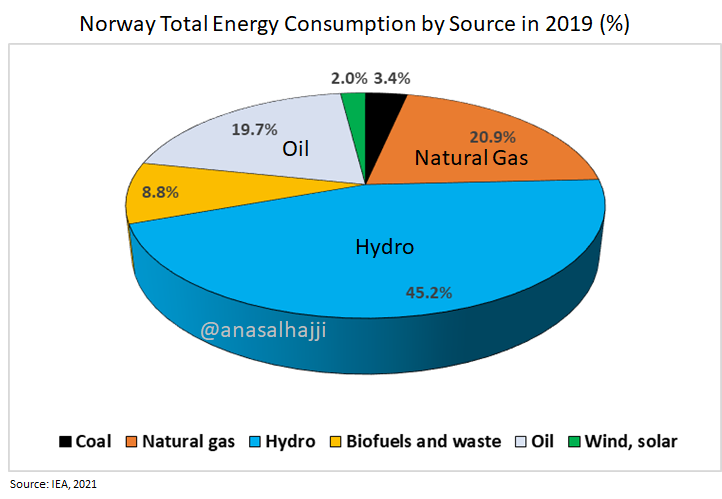

The hydrogen will be sourced by a non-fossil system. Norway has hydroelectric power.

According to Google, Norway secured 98% of it's energy from a combination of hydropower and wind.

https://interestingengineering.com/tran … 19.04.24_3

(th)

Offline

Like button can go here

#23 2024-04-19 23:01:02

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,307

Re: Hydrogen Fuel Cell Vehicles

Well,

At least we know how Norway financed all of their green energy:

Norway expects to earn record $131 bln from oil and gas in 2023

Maybe Google thinks electricity is the only kind of energy consumed by Norway. People who are less ideologically motivated, or slightly more inquisitive, know otherwise.

The government’s total net cash flow from the petroleum industry is estimated to be NOK 986 billion in 2023 and NOK 832 billion in 2024. The estimate for 2023 is NOK 299 billion lower compared to the net cash flow in 2022.

Green is indeed the color of money, but not energy. Hydrogen has no color at all.

Offline

Like button can go here

#24 2024-04-20 06:23:59

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,897

Re: Hydrogen Fuel Cell Vehicles

For kbd512 ....

This topic is about hydrogen fuel cell powered vehicles.

The Norwegian ferry is a hydrogen fuel cell powered vehicle.

Your post is about something other than hydrogen fuel cell powered vehicles.

We may need a topic for forum members to collect information about mismatches between information sources, or between information for one year collected from another year.

We actually have a Category where such reports might fit... Not so free Chat ...

***

For all ... the Norwegians appear to have made significant progress in harnessing hydrogen on a large scale.

Posts by members about the planned ocean going ferry in Norway would be welcome here.

Posts about other subjects may be interesting but are not likely to be a good fit.

(th)

Offline

Like button can go here

#25 2024-04-20 07:04:48

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,743

Re: Hydrogen Fuel Cell Vehicles

The "Why the Green Energy Transition Won’t Happen" comes to mind.

Offline

Like button can go here