New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#51 2021-10-15 14:41:27

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,764

Re: Mars Water regolith soils 1 foot depth only

For SpaceNut re recent contribution by Calliban

You will certainly have read Calliban's suggestion for your Regolith Baking project.

This post is to encourage you to adopt the suggestion (if it is practical, which I can hope but not confirm).

If you have a reactor of that capability to drive the processes, you'll need some help from OF 1939 to plan the industrial scale configuration of equipment. He has expressed disapproval of the entire venture, so you'll have to persuade him to assist despite his skepticism.

We don't need to be limiting ourselves at this point. We ** do ** need to stay within the laws of physics, and I trust Calliban is doing that.

(th)

Offline

Like button can go here

#52 2021-10-15 17:46:10

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Mars Water regolith soils 1 foot depth only

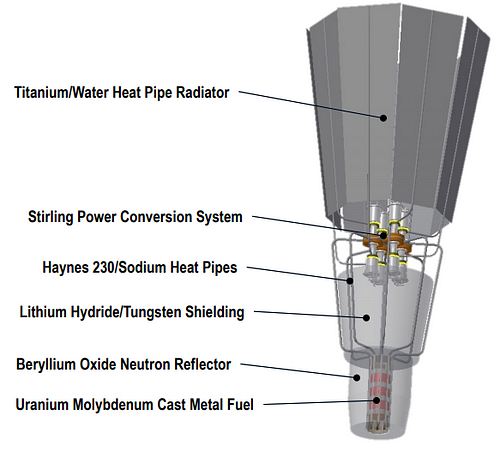

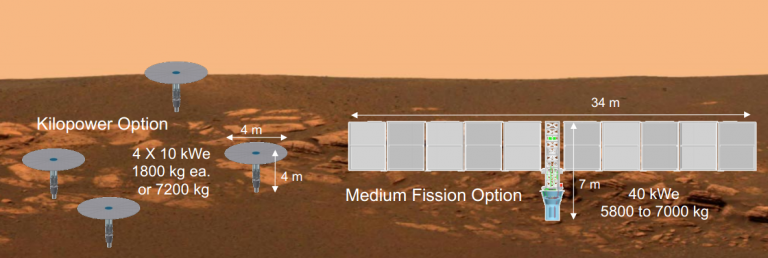

A KRUSTY reactor puts out 10 kw of electrical with 30 kw of Infrared or heat energy at the radiators so we have plenty of heat to process the soil turning the radiator section into a hot pan baking system.

https://ntrs.nasa.gov/api/citations/201 … 005435.pdf

http://anstd.ans.org/NETS-2019-Papers/T … t-94-0.pdf

https://www.nasa.gov/sites/default/file … 011618.pdf

Lunar and mars version

even better 40kW of power...

I am thinking of a design similar to a pizza oven where the soil is loaded into a tray that rides along a mesh metal belt conveyor through an opening that starts out cool and close to seal the tray inside while it bakes and as the tray gets to the end of the line it enters another cool section of the chamber to allow for the out gasses elements collected before opening the end door to allow the pan to exit. The conveyor continues on the outside for a short distance and then dumps back onto the ground or into a hauler that brings the clean soil to a future work site.

Once the tank on the unit is full of water plus the cooled gasses we bring them to the processing plant to make the fuel which is closer to the starship cargo tanks. Hopefully that location will have collected enough co2 to begin processing other wise we are storing it in the starships cargo tanks.

The first issue is identifying which perchlorate compounds is present

https://en.wikipedia.org/wiki/Perchlorate

The digger for water from soil once heated to 500'c will break down some of these.

Ammonium perchlorate ("AP") is an inorganic compound with the formula NH4ClO4. ... Upon heating to 300 °C, the AP degrades

Heating Perchloric_acid produces toxic fumes of chlorine compounds.

heating, potassium perchlorate decomposes to potassium chloride

When heated to decomposition it emits toxic fumes of /hydrogen chloride/ and Na2O.

This leaves the water processing units output less dangerous for use in planting when mixed with other minerals.

Online

Like button can go here

#53 2021-10-15 18:02:39

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,764

Re: Mars Water regolith soils 1 foot depth only

For SpaceNut ....

Your mission is to deliver 1200 tons of propellant in one (Earth) year.

If you can do that with pizza ovens, you'll need a lot of them.

Please continue to add numbers to your vision. The end product will be (hopefully) a post that contains everything you have learned over the course of weeks or months, to guide a decision maker with many millions of monetary units to invest in the project.

(th)

Offline

Like button can go here

#54 2021-10-15 18:32:42

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Mars Water regolith soils 1 foot depth only

Other source for water in the soils coming from Gypsum - (CaSO4·2H2O) which at a Temperatures between 100 and 150 °C (212–302 °F) are required to drive off the water within its structure and from Jarosite - KFe3(SO4)2(OH)6 for the Fe-sulfate phases that typically decompose between 500 °C and 700 °C.

So we have a value for the water to electrolysis and what we need is the electrical energy required to do so.

25 hrs x 300 sols is 7,500 hrs total

540,000 kg / 9 kg = 60,000

60,000 x 50 kwhr = 3,000,000 kwhr

3,000,000 kwhr / 7,500 hr = 400 kw

That's a big power source....400kw constant delivery for 25 hr sols at a duration of 300 sols to break down the Water to collect, separate and store of 540mT...

A single Krusty is 10 kw x 25 = 250 kwhr / 50kw hr = 5 x 9kg of water = 45 kg per sol x 300 sols = 13,500 kg and at 45 kg x 400 sols = 18,000 kg and at 45 kg x 500 sols = 22,500 kg

40 KRUSTY units would need to be supplied just to get the water divided up for hydrogen to go into the sabatier reactor...assuming the total water amount is waiting for a single unit.

So to get that number down we are going to up the number of units that break the water down to get the through put up with power source going up.

So longer times of 400 sols and the 500 sols

25 hrs x 400 sols is 10,000 hrs total

540,000 kg / 9 kg = 60,000

60,000 x 50 kwhr = 3,000,000 kwhr

3,000,000 kwhr / 10,000 hr = 300 kw

30 krusty units

25 hrs x 500 sols is 12,500 hrs total

540,000 kg / 9 kg = 60,000

60,000 x 50 kwhr = 3,000,000 kwhr

3,000,000 kwhr / 12,500 hr = 240 kw

24 krusty units

A Krusty unit mass is roughly 2 mT so there is plenty of room on a starship.

Online

Like button can go here

#55 2021-10-15 19:43:04

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,764

Re: Mars Water regolith soils 1 foot depth only

For SpaceNut re #54 and entire topic under construction

Congratulations and thanks for your latest addition to the framework!

I like the way you put together the water requirement with the corresponding energy requirement.

As a reminder, you will get Oxygen both from water you liberate, and from CO2 you harvest.

Your calculations may actually yield more Oxygen than is needed to match the Methane. It will be interesting to see how your numbers evolve as you proceed.

One small adjustment may be helpful to your present and future readers, and I will offer that at some point.

For now though, I am concerned that amidst all the flow of traffic on the forum, you may have missed the offer by Calliban to "provide" a plan/specification for a nuclear fission reactor specifically designed and sized for the job you've undertaken.

The Krusty is interesting and surely has a place in the future of Mars. it is ** not ** a good fit for your project.

Please see: http://newmars.com/forums/viewtopic.php … 07#p186107

You'll find that Calliban has proposed a reactor ** just for you **!!!

(th)

Offline

Like button can go here

#56 2021-10-15 19:55:12

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Mars Water regolith soils 1 foot depth only

We can not build or send a reactor bigger at this time and may never be allowed to do so. That said we need to get more efficient and not waste the energy that we can get.

So its time to research for that in the electrolysis arena of things and not just in that on as well.

Yes excess oxygen is a plus in a place that we can not breath so it will get used when crews are really going to need it. That's based on the chemical equations from a page ago, used to make the methane.

Online

Like button can go here

#57 2021-10-15 20:18:36

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,764

Re: Mars Water regolith soils 1 foot depth only

For SpaceNut .... re #56 .... Your mission is to design an industrial scale process to collect fuel and oxidizer for a Starship.

It is NOT time to be worrying about social problems. I recommend just going with the offer provided by Calliban, and mark "power" as checked off.

You have OF 1939 available as a potential resource to help you navigate the industrial scale chemistry needed.

Don't worry about computer control of machinery ... just assume the human resources to take care of that are available.

The output of your process here should be a detailed specification of the equipment someone (Nation or large Corporation) needs to set on Mars to complete the assignment.

(th)

Offline

Like button can go here

#58 2021-10-15 21:00:04

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Mars Water regolith soils 1 foot depth only

A the power is only part of the issue as the temperature to get the water from the Soil dryer that uses CO2 sweep gas which comes in from the putting of the soil into the chamber of which 500 deg C is needed to extract water. So no the 200'c will not work from that design. A KRUSTY unit is molten metal so that's in the 500'c plus and that is what we need....

We also need thermal energy for the sabatier reactor to work as a chamber preheat and as a means to keep the reaction going as we feed co2 and hydrogen into it.

https://tfaws.nasa.gov/wp-content/uploa … S-2018.pdf

An additional electrical energy of 0.4 kWh/m3 is calculated to heat the CO2 and H2 mixture (1:4) up to 300°C for the catalytic reaction.

Online

Like button can go here

#59 2021-10-16 06:46:01

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,764

Re: Mars Water regolith soils 1 foot depth only

For SpaceNut re #58

Your vision requires collaboration ...

This is a situation in which you have the lead, but you need lots of help.

Calliban has offered to help with the power supply... This text is from Post #243 in Nuclear Safe topic

This sounds like a concept that will be needed early in the colonisation effort. The reactor concept that powers it will need to be developed soon, quickly and cheaply. I would suggest an aqueous homogenous reactor. This is a tank of water with uranium sulphate or nitrate salts dissolved in the water. Quick, cheap and easy to build. Not particularly efficient, because operating temperature is no greater than 200°C. But this operation needs a lot of direct heat for regolith baking. An AHR would be ideal for that purpose. It would require enriched uranium salts to be imported from Earth. The reactor is self regulating, because increased temperature results in boiling that increases neutron leakage from the core. So control is easy. Waste heat can be used for regolith baking. The electric power can be used for the other things. Generating efficiency would be about 20%. The concept should be designed to use COTS equipment, like turbine, steam dryer and generator.

Starship stainless steel fuel and oxidizer tanks can be used as reactor vessels for subsequent Mars-built AHRs. Martian thorium salts can be added to the reactor vessel along with uranium salts, to produce converter reactors that will breed their own fuel in addition to a small surplus. The liquid plutonium reactor would be a second generation concept developed using plutonium separated from AHR fuel solutions.

For Calliban ... if you can spare the time, please take a look at the concerns of SpaceNut, as he is attempting to visualize a facility for manufacture of 2400 tons of propellant in 365 Earth days. He will need to achieve an average production rate in multiple tons, while maintaining the cooled state for the liquid products.

Your description of a simple reactor for this purpose indicates a maximum sustained operating temperature of 200 Celsius, and in Post #58 SpaceNut is calling for 500 Celsius. I'm assuming the 500 Celsius can be achieved using electric heating, with power generated by the reactor.

Mars is (presumably) a good heat sink for heat engines, so I would imagine steam from the reactor would drive piston machinery or turbines to make electrical power. However, the 200 Celsius temperature of the reactor would work well to pre-heat the regolith.

All-in-all, this sounds (to me at least) like a practical source of sustained power for SpaceNut's plant.

Please add to your description of how this particular design would work.

What does SpaceNut need to order from suppliers on Earth to put this design into practical use on Mars?

(th)

Offline

Like button can go here

#60 2021-10-16 11:06:08

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Mars Water regolith soils 1 foot depth only

The KRUSTY reference is for a known functioning molten Metal reactor that when we scale the size by 40 units we get power that can only do the electrolysis but here is the kicker, the unit mass is 2.5mT so scaling it means we have eaten up the entire starship payload in fast transit to mars and with slow you might have the room for the machine to do the electrolysis and that's all.

The CO2 capture is going to be just as problematic as will the remaining items to get what we need done.

One of the good things is that the 2 cargo starships will have landed with the fuel margin hopefully still unused in the header tanks. This will be on a 10 - 15% levels of the starting point before de-orbit and landing was 100mT leaving around 10 mT to 15 mT in each ship that we can transfer once we have crews on the surface. Also note that when the next window for mars opens there would be 2 more cargo ships going with the crewed vehicle. That means we will also use that same trick to move the remaining fuels to lessen and missed capability.

Found another topic that is working the numbers for the sabatier reaction

Online

Like button can go here

#61 2021-10-17 12:02:01

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Mars Water regolith soils 1 foot depth only

I am including this post as it reflects what we gain from baking the soils in addition to getting out the water

As Mars has no tectonic activity, some artificial process needs to be applied to bake out volatile elements that have become trapped in hydrated minerals within the crust. Probably the easiest option would be to shut off selected areas of the Martian surface and then bake it to several hundred K using orbital mirrors. We would bake areas of several thousand square km, for at least a few centuries, to ensure that the local crust is warmed down to the mantle. The volatiles released would directly enter the atmosphere and vent holes could be drilled to facilitate this. A portion of the escaping water vapour would break down through UV flux adding oxygen to the atmosphere, with the hydrogen escaping into space. The majority would freeze out at the Martian poles.

Louis raised an idea some time back about placing aerogel sheets over the surface of Mars to trap sunlight and warm the surface. This would work provided someone was around to remove accumulated dust from the aerogel surfaces. A similar idea would be to build a solar chimney. This would consist of a large, circular, non-pressurised greenhouse, with a tall chimney in the middle. The area under the greenhouse would be baked to temperatures above ambient. The water vapour released has lower molecular weight than CO2 and will rise through the chimney. The chimney will be several km tall, allowing moisture to be deposited high into the Martian troposphere, where UV will dissociate some fraction of it. The concept could be assisted by orbital mirrors or nuclear waste heat pipes beneath the greenhouse.

Ideally, we would build terraforming towers that inject water vapour directly into Martian ionosphere, where collision with energetic ions would fully dissociate it. However, this would mean building towers 100km high, which would be difficult to achieve. Assuming that towers of this height can be built, then we could pump water into the ionosphere by injecting a mixture of water and liquid CO2 into a tube running up the tower. The CO2 would dissolve into the high pressure water at the bottom of the tower. As height increases and hydrostatic pressure drops, the water-CO2 mixture would turn to froth and would practically explode at the top of the tower, propelling ice crystals high into the atmosphere. Given that Mars has large reservoirs of frozen CO2 and may have liquid brines, a terraforming tower working on this principle can deliver huge fluxes of water vapour into the Martian ionosphere with minimal requirements for artificial energy. The injection of liquid water and liquid CO2 will require pumping power. But most of the power needed to raise the water column through the tower would come from phase change of the liquid CO2, which would convert a portion of the water column into ice crystals. Probably the best place to build something like this is the polar caps, where large quantities of dry ice are available.

TH has raised the idea of using geothermal energy in another thread. If we were to drill a sufficiently deep borehole into the Martian crust and fill it with brine and liquid CO2 (which is denser than water), natural convection would bring heat to the surface. The geothermal heat could be used to melt both CO2 and water ice into liquids that can be injected into the tower. Temperatures far beneath freezing can do this, as brine melts at temperatures down to -90°C with heavy perchlorate concentrations and liquid CO2 remains liquid down to -53°C at pressure greater than 5.1bar. Geothermal heat can provide the pumping power needed to inject water and L-CO2 into the tower, by boiling L-CO2 in boilers that directly power the pumps.

Which brings me to the capture and containment volumes of the processing aspects to the rover that is digging up the soil, baking it and then storing what is gained in the process.

Online

Like button can go here

#62 2021-10-17 12:12:10

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,764

Re: Mars Water regolith soils 1 foot depth only

For SpaceNut re #60

The KRUSTY is NOT a molten Metal reactor. Please edit your post!

The fact that sodium is used in the cooling lines does NOT qualify the reactor as a "sodium" reactor. It is NOT.

The post is in error. Please fix it.

In the past we (all of us) have left errors in our posts and gone on as though they will never be read again.

** This ** topic is (most likely) going to be studied by students and others.

I would very much like to see any errors that might show up scrubbed and replaced with accurate information.

This is NOT a reflection on the author. We all make mistakes, and all we have to do is to fix them.

(th)

Offline

Like button can go here

#63 2021-10-17 13:22:11

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Mars Water regolith soils 1 foot depth only

Heat pipes containing molten sodium a metal when heated as its not pure as it will still have some water very low percentage as well as combinations of things not chloride or potassium which makes it just that a source of heat via a salt form and its not just part of the cooling as it brings the heat to the sterling generator heads where it becomes solid and falls back down the tube to the core which then reheats it.

It requires no pumps to thermal cycle the molten metal (salt/sodium) in the tube unlike other reactor designs. Which force the salt through the turbine system some melted and solid grained and then returns it back to a bowl where the reactor heat sits. Nuclear material is enclosed in a pipe to keep it from being eroded by direct contact to the salt.

All Nuclear reactor designs systems have something that act as a coolant to the cores to take heat away from the core.

Sodium is the sixth most abundant element in the Earth's crust and exists in numerous minerals such as feldspars, sodalite, and rock salt (NaCl). Many salts of sodium are highly water-soluble: sodium ions have been leached by the action of water from the Earth's minerals over eons, and thus sodium and chlorine are the most common dissolved elements by weight in the oceans.

Sodium at standard temperature and pressure is a soft silvery metal that combines with oxygen in the air and forms grayish white sodium oxide unless immersed in oil or inert gas, which are the conditions it is usually stored in.

Online

Like button can go here

#64 2021-10-17 17:00:05

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,279

Re: Mars Water regolith soils 1 foot depth only

Nothing that I have read about this reactor concept indicates the involvement of molten salt. The core is a cast slug of uranium-molybdenum alloy, with a single control rod passing through a cylinder running up the middle. Heat pipes run up the outside of the slug, between the slug and the beryllium reflector. The heat pipes carry liquid sodium, which transfers heat through a convection to the Stirling motors. A simple and elegant design.

The main sticking points with KRUSTY are: (1) Relatively poor power to weight ratio. The problem here is high neutron leakage from a core so small, requiring a lot of fissile fuel per unit power and a large reflector. By the time you get down to a core that will support a 1kWe power generator, a 10kWe system weighs not much more. This is about the smallest you can get using enriched uranium in a fast reactor. Moderated systems would use less fissile material, but would be bulkier. (2) Use of highly enriched uranium. This makes the unit expensive per unit power and politically difficult, as pure 235U is basically bomb material. Musk can probably arrange to buy these units, but it will cost him.

The really good thing about the Kilopower units is that after a decade of operation they shutdown, with 99% of the fissile 235U still in place. They provide excellent starter material for heavy water aqueous homogenous reactors, which we can build on Mars using old Starship fuel tanks. Using Martian thorium blankets, or thorium nitrate blended into a single tank along with uranium nitrate; these reactors provide us with all of the starting materials for an expanding Martian breeder reactor programme.

Last edited by Calliban (2021-10-17 17:07:19)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#65 2021-10-17 17:06:53

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Mars Water regolith soils 1 foot depth only

As far as I know, there are no KRUSTYs for sale at the moment and unlikely to be in a timeline that works with Space X's plans. They would delay launch approval in any case.

Musk would certainly have no problem buying them. He's now the richest man on the planet, worth $230 billion. He supports solar power for a Mars mission.

https://www.dailymail.co.uk/news/articl … erson.html

Nothing that I have read about this reactor concept indicates the involvement of molten salt. The core is a cast slug of uranium-molybdenum alloy, with a single control rod passing through a cylinder running up the middle. Heat pipes run up the outside of the slug, between the slug and the beryllium reflector. The heat pipes carry liquid sodium, which transfers heat through a convection to the Stirling motors. A simple and elegant design.

The main sticking points with KRUSTY are: (1) Relatively poor power to weight ratio. The problem here is high neutron leakage from a core so small, requiring a lot of fissile fuel per unit power and a large reflector. (2) Use of highly enriched uranium. This makes the unit expensive per unit power and politically difficult, as pure 235U is basically bomb material. Musk can probably arrange to buy these units, but it will cost him.

The really good thing about the Kilopower units is that after a decade of operation they shutdown, with 99% of the fissile 235U still in place. They provide excellent starter material for heavy water aqueous homogenous reactors, which we can build on Mars using old Starship fuel tanks. Using Martian thorium blankets, or thorium nitrate blended into a single tank along with uranium nitrate; these reactors provide us with all of the starting materials for an expanding Martian breeder reactor programme.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#66 2021-10-17 17:10:47

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,279

Re: Mars Water regolith soils 1 foot depth only

I thought we had established through repeated analysis, that a solar power system wasn't workable within the payload budget of a mission, not when engineered for sufficient reliability?

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#67 2021-10-17 18:12:32

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Mars Water regolith soils 1 foot depth only

Its then a molten alkaline group metal ..done...

Neutron leak is not a problem in an unmanned use plus it can be shut off allowed to radiation cool and can be worked on by man without any special equipment.

The point is the temperature of the molten metal requirement for use to bake out the water and volatiles from the scooped up regolith.

https://www.periodic-table.org/sodium-melting-point/

Melting point of Sodium is 97.8°C. Boiling point of Sodium is 883°C.

They do not need to be on sale for the purpose of generating numbers and its doubtful that anyone will sell the materials let alone a functioning reactor.

Back to getting calculations

The unit will travel while in the process to clearing a 1200m x 1200 meter area a distance of 1,440 kilometers to accomplish the task. With an up and back being 2400 meters of which to save on making extra trips for a full tank we need to size the tank for the unit.

min collected water 2400 x 9 liters = 21,600 liters Tanks size is 21.6 cubic meters which seems quite large. That said a tank that extends over the tracks where the space between them being 1 m would make the tank 1.5m wide x 2 m deep x 7 m long.

which makes 600 round trips to still get it all with a single unit. So this is where the scaling comes in to accomplish the tasks with multiple units that are still under the mass limits to send with all of the other stuff needed to make fuel for a single starship.

min collected atmosphere and volitiles is an unknown calculation at this time plus is heat controlled for releasing

need to find the sample tests with the data from the rovers.

CO2 released by

1. Absorbed atmosphere <200C

2. Oxidation of organic material >200 C

3. Thermal decomposition of carbonates >450

CO2 released by

1. Dehydroxylation of clays <350 C

2. Decomposition of non-metal and metal oxides >500 C

CH3Cl and CH2Cl2 released by

1. Decomposition of Mg(ClO4)2 perchlorate >200C

The scooping, separating of large rocks, cooking and collection is all the mass of a complete unit at this point of which the design numbers are still being worked.

Relating back to the 1m x 1 m square for baking at a 10 cm depth seems to be optimal for a time with the elevated temperature of 500'c for 15 minute time frame unless the water content is higher as it will take longer to bake it out. Wet sand 725kg for each meter square to depth so we are processing 145 kg mass in each baked pan for 1.8 liters of water.

So we need to get more than 1 pan at a time in the length of the oven but still have some sort of entry and exit for the length which can be not more than 5 m in length to allow for this to occur. A flap entry closes after all the pan moves in and to exit the door flap opens to break the chamber seal the elevated temperatures inside will cause the water and gasses to rise inside of the chamber. A hood inside of the chamber with suction vacuum pump could be used to draw the contents out before we have cool down.

Hopefully more than one heating chamber can be created with in the foot print to increase meters of soil being cleared of moisture to satisfy the need for the water.

Online

Like button can go here

#68 2021-10-18 21:53:13

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Mars Water regolith soils 1 foot depth only

I am digressing a little by talking about ground vehicles and letting my imagination run away with me.

For near term applications in which units are shipped from Earth, the Kilopower units are close to completion and it would be most sensible to base applications on these units. They could be operated remotely, or with an operator in a pressurised cabin. For remotely piloted vehicles, shielding mass can presumably be reduced, but in that case, work must stop if a human being is present in the area.

The primary nuclear systems are fully developed. It is just a case of integrating the units into vehicles and other functions. Most of the mass of these units appears to be associated with power conversion equipment. If we are using liquid CO2 as propellant within engines, then radiators and bulky Stirling cycle engines are not needed. Compact gas turbines driving hydraulic pumps and storing energy in hydraulic reservoirs, would be better options. We would surround the reactor units with tanks of liquid lead, which would serve as both shielding and thermal energy stores. The lead tank would contain a heat exchanger, which would boil water or CO2, generating high pressure gas for the engine. The reactor would operate at steady power, charging the thermal energy store. The power generation cycle would charge the hydraulic accumulator. For construction equipment, like diggers, this allows short bursts of power, which greatly exceed the reactor power capacity. The hydraulic accumulator allows for rapid transients, the power generation cycle may be more sluggish.

A small closed loop generator would run a compressor, compressing and liquefying CO2 from ambient air, 24/7. With air temperatures of -50°C, very little pumping power is needed to produce liquid CO2, as this is close to CO2 triple point. The liquefaction device would be carried on board a long-range rover. But for construction equipment, it is more efficient to keep it separate and stationary from the vehicles, refilling L-CO2 tanks from a central reservoir when they run dry.

The engine would exhaust gaseous CO2 at a temperature of at least a few hundred °C. It would be sensible to pass exhaust CO2 through some sort of recuperator. This would reduce required reactor power, extend core life and reduce shielding mass, given that this is a function of reactor power. A 10kWe Kilopower unit has a continuous operating life of 10 years. So with a 50% utilisation rate, it should be good for the entire operating life of any vehicle on Mars.

Thanks for the system vehicle use an other possible uses.

Online

Like button can go here

#69 2021-10-18 22:28:39

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Mars Water regolith soils 1 foot depth only

water truck style vehicle to haul 21,600 liters are huge

https://gfworldwide.com/wp-content/uplo … ER-2-1.jpg

CLASS CAPACITY MODEL

40 T (36 mt) 9,000 G (34,068 L) 9W

Looking at the collecting of soil being 10 minutes, moving to trays 5 minutes and the 15 minutes to bake at which time we repeat until done. Means 2 cycles for every hr. we have an issue which is corrected by adding number of units that each starship cargo ship would carry.

The baked soils water is clean as the dirt and dust are not present from evaporation and condensing.

Digging ice would have trapped impurities that would mean a heating process is needed to do the same evaporation and condensing to get clean water.

“Mining” Water Ice on Mars, An Assessment of ISRU Options in Support of Future Human Missions

oh wow page 34 has the drill test article image

Melting Ice at a site might not be possible if found but is with equipment design plausible and would capture clean evaporation before condensing.

Engineering Mars commercial rocket propellant production for the Big Falcon Rocket (part 1)

Engineering Mars commercial rocket propellant production for the Big Falcon Rocket (part 2)

Then to allow for the electrolysis time to take place for each load gathered plus compress it to pressure before we can make methane. The break down makes oxygen that is compressed and cooled before we continue.

Co2 must be filtered for particulates and compressed as well before we can use it to make the methane.

Sabatier System Design Study for a Mars ISRU Propellant Production Plant

Addressing the Mars ISRU Challenge: Production of Oxygen and Fuel from CO2 Using Sunlight

Methane is made in the sabatier reactor for cycle 1 which has methane and water as the end processing content.

Development of a Microchannel In Situ Propellant Production System

The water is again sent to the electrolysis to break it down before we can make use of it for the completion cycle of original water. The break down makes oxygen that is compressed and cooled before we continue.

The hydrogen is fed into the second cycle with more co2 to finish the cycle of the sabatier reactors use with exhaust of oxygen that is collected along with methane.

This reminds me of setting up a jetline or lean balancing of que times to make the flow none stop.

That said we do not get to use the total sols for any one process and must bring up levels for each.

A shortening of time mean an increase in power to perform tasks.

Online

Like button can go here

#70 2021-10-19 06:30:03

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,764

Re: Mars Water regolith soils 1 foot depth only

For SpaceNut re #69

It looks as though you are solidly back on track in developing this topic....

Question:

That said we do not get to use the total sols for any one process and must bring up levels for each.

A shortening of time mean an increase in power to perform tasks.

Could you (would you) please expand upon that text? Because your process does not use solar power, it should be able to operate 24x7.

Perhaps you are pointing out that some processes depend upon others?

Is there a reason why the flow cannot be continuous, once material is delivered to the input hopper?

There might be!

(th)

Offline

Like button can go here

#71 2021-10-19 18:11:35

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Mars Water regolith soils 1 foot depth only

Mars day is a sol..

The total accumulative times for each step from start of gathering soils in the processing to the last drop is in the tank for fuel...

Each step relies on the completion of the previous one such that the input is great enough to start the next going.

Electrolysis is a wait state until we gather the soil and bake it for the water.

Cryro generation of liquid Oxygen is waiting until electrolysis can feed it

Co2 needs gathering before we can pressurize and cool it for use

Sabatier reactor is in a wait state until co2 is gathered and hydrogen is ready for combining in the heated chamber.

Output methane is cryro cooled to make it liquefied.

Online

Like button can go here

#72 2021-10-19 19:02:03

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,764

Re: Mars Water regolith soils 1 foot depth only

For SpaceNut re #71

You need to develop a continuous process to deliver 1200 tons of propellant in 365 Earth Days.

Edit: Corrected 2021/10/20 from 2400 .... the original quantity of 1200 tons was given by GW Johnson earlier in this topic.

This would be slightly fewer Sols.

My recommendation is to design a plan that feeds output continually from one stage to the next.

If you have to operate in batches, then each batch from one operation needs to feed automatically into the next.

Multiple lines can (and obviously must) be operating in parallel.

(th)

Offline

Like button can go here

#73 2021-10-19 19:52:01

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,405

Re: Mars Water regolith soils 1 foot depth only

If you use the heat directly from the KiloPower reactor, then you can obtain 400kWt worth of power from 10 units. Full thermal power output is around 43kWt. KiloPower can feasibly scale up to around 100kWt, but no more than that without a complete redesign.

We're not being very creative about how we use the heat from the reactor core. A much larger heat sink of molten metal / reactor coolant surrounding a removable regolith pot, could vaporize the ice in the regolith much faster. This is the basic design principle behind those stainless steel "survival kettles" that surround your pot of water or snow with fire, in order to heat up the water faster / more efficiently, using less wood.

With the help of some piping and a second tank containing cold / product water, the heat in the kettle drives the steam towards the condensing tank where the water vapor cools and turns back into liquid water.

If we elect to use solar thermal power, then this same basic concept works equally well, but we'll need a greater mass of equipment to do it.

Constructing huge arrays of photovoltaics, with their associated wiring nightmare, power transformers and inverters, sensitive control electronics, and cleaning requirements, is an utter waste of time and money. Electricity should be used where required, not "just because we can".

No electronics or electrical power is required to do this, nor is it desirable. You need a heat source, storage tanks (could be stainless steel or coated iron or simple ceramic pots if the eventual goal is to make the storage pots on Mars), and piping. Keep it simple, stupid. That is how we distill water and alcohol here on Earth. We need a well-thought-out and simplified system for Mars, with minimal control gadgetry.

I would like to see both concepts (nuclear and solar thermal water distillation) in operation, because both use the same underlying technology. Whichever concept scales up for less money is what we'll end up using, out of necessity.

Offline

Like button can go here

#74 2021-10-19 20:38:03

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Mars Water regolith soils 1 foot depth only

Things that I have been able to derive is lifting a 1m x 1m x 0.5m into waiting pans and baking water out in 1/2 hour to get soil water of 9 liters approximate.

We need to cover an area of 1200m x 1200m to get sufficient amounts of water.

It moves slowly as it scoops and processes the regolith so we are going to need quite a few units or to examine how to up the through put.

Time units for Mars 200 sols at 25hrs with 2 cycles is 10,000 units. 1,440,000 lift and bake puts the vehicles at 144 to get the quantity delivered ahead of schedule for next steps. Of course using more time gets the numbers to drop but with less processing time.for other steps to complete. The only way forward is shorter bake times with more water content to lower the vehicle count. Of course a wider pass than a 1 m width would also lower the units and make it more likely to succeed.

Night time temperatures are also going to slow the bake time as well.

Much like the gathering of water from soil the gathering of Mars air for co2 is also an independent function that run non stop until its gather all that is needed.

The period of time to gather water must allow for all of the following steps to accomplish.

We know that once we have the time for each steps defined that parallel paths can be used when balanced.

The electrolysis unit sits idle until we have enough water to begin processing and needs feeding to keep it from becoming dry which stops the process.

Its at this point that the sabatier reactor can start to process co2 + H into Methane and water of which the water is recycled into a second unit where the output is methane and oxygen.

Cryro cooling of co2, Hydrogen and Oxygen starts once we have the feed stock for each to make use of.

Currently an optimized electrolysis is required to lower the electrical need as the number of units of kilowatt type filled a starship payload as time to break bonds of water is less than half of the total days which will drive the mass up once more.

The latest kilo watt powered axial turbine concept looks promising to get co2 with a final stage piston pump and cryro cooler but still looking for numbers. Substituting heat generated rotation to the shaft of the turbine directly means less to wear out and still room for the Stirling generator is a plus to making this device.

Online

Like button can go here

#75 2021-10-20 09:19:15

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,764

Re: Mars Water regolith soils 1 foot depth only

For SpaceNut re topic ....

The "facts" that I have so far are:

http://www.kylesconverter.com/time/sols … (sidereal)

We need to create and save 2400 tons of propellant in 365 Earth days, or 354 Sols

We are going to scrape a volume of regolith 1200 meters square and half a meter deep.

2400/365 >> 3.3 tons per day

You are describing (as nearly as I can tell) a batch process:

1) Scrape regolith and deliver it to a hopper

2) Intake regolith from hopper and pack it into an oven for baking

3) Bake regolith until (a) all free volatiles are expelled and (b) all chemically bound volatiles are expelled

4) Simultaneously (in parallel) collect CO2 from the atmosphere

5) From step 4, process the collected CO2 to yield CO and O2

6) From step 3, collect water for processing, and save other valuable volatiles (*)

7) Simultaneously, make methane, compress and cool it, and save it in extended storage container

(*) The baking process ** should ** yield bricks which can be transferred back to the regolith work area to make a landing pad

Given specific equipment, compute the yield you can expect from a single string of equipment.

Divide that yield into your target of 3.3 tons per day and you'll know how many strings of equipment you need.

A practical way to achieve this is to package one string of equipment in a single Starship that can land on a field prepared thanks to engineering probes reports.

There would need to be as many Starships of equipment as are needed to make fuel for ONE Starship with passengers to arrive next cycle.

SpaceNut ... this is NOT rocket science.

If you are able to (somehow) persuade OF 1939 to help, you can deliver to this topic a complete, detailed specification of equipment needed for one production string that can be shipped in a single Starship.

The total number needed can be computed from the yield of one string.

(th)

Offline

Like button can go here