New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#101 2021-09-09 06:44:47

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,827

Re: Scouting Mars for Landing Sites

For all re Lander Project ...

SearchTerm:Game Plan

Goal: launch of Falcon Heavy or equivalent in September of 2022

Step: Launch slot request granted (Requires SpaceX Commitment)

Step: IRS Tax Exempt Organization identified (to flow donations to US Taxpayer)

Step: Major Corporate or Foundation donor identified

Step: Prime contractor for lander(s) identified

Step: Detailed plans for lander(s) in work by subcontractors

Step: Plans for lander(s) published

Step: Players recruited

Step: GW Johnson draft plans for lander(s) published

Step: GW Johnson plans for landers(s) in draft stage (current status)

(th)

Offline

Like button can go here

#102 2021-09-09 10:21:51

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,827

Re: Scouting Mars for Landing Sites

For GW Johnson ....

As of this writing, the Refueling Depot document is downloaded but not yet reviewed.

***

This post is about another (careful) reading of Draft #4 of Lander proposal...

No additional editorial suggestions showed up during this reading.

However, a technical issue came to light, and I will cover it shortly ...

In the mean time... After reviewing the document with a view to considering the alternative submission path, I've decided a cover letter is needed

This document stands on its own.

The cover letter needs to contain the "ask" ... The "ask" will differ for each recipient.

***

Under Figure 1, there is discussion of fins for preventing rotation of the lander due to drilling operations.

May I offer a suggestion for your consideration?

The German digging probe demonstrated that the characteristics of the soil under the lander may not be what is/was imagined on Earth.

The suggestion of fins to prevent rotation of the lander certainly makes sense, but I'm wondering if these should be stowed in a retracted state until landing is complete?

The method of landing (described elsewhere in the document) seems (as I read it anyway) to imply considerable vertical energy is to be delivered to the regolith in a relatively short period of time. Since we don't know what we're landing on, pre-extending fins might result in delivery of one or more fins to the interior of the lander.

An alternative is to keep the fins stowed until after the dust settles, and then apply modest force to see if the fins will be permitted to descend.

I'm guessing you don't need all the fins set to achieve a reasonable level of resistance to rotation.

A time honored technique is to use explosive anchors, but the same objection seems (to me at least) to apply .... since we don't know what the terrain under the explosive is like, we would be risking the probe.

A gentle tap on the top of each fin would reveal whether it is worth continuing to attempt to drive it further.

Another (less expensive) option is to not worry about the possibility of rotation of the lander when the drill is in operation.

It seems to me that the torque generated by a 100 watt motor is enough to rotate a pipe, but insufficient to rotate a lander.

Finally, perhaps where you are leading us, and that I missed, is that you would make the bottom of the lander non-smooth, so that little indentations all over the bottom of the lander take purchase on the regolith, so that rotation forces are distributed over the entire bottom of the lander.

(th)

Offline

Like button can go here

#103 2021-09-09 14:44:18

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,070

- Website

Re: Scouting Mars for Landing Sites

I have been looking for current info about the Canadrill, but it seems to have disappeared about 2005 or so. I did find some contact info about NORCAT, where the thing was built and tested about 2004-2005. Perhaps it would be worthwhile to contact them to see if anything remains of the project. My guess is it died, when nobody "bought" the NASA lander with this drill on it. I think it was a NASA JPL group that did that design proposal.

contact data

NORCAT Sudbury

1545 Maley Drive

Greater Sudbury, ON, Canada

P3A 4R7

705-521-8324

support@norcattraining.com

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#104 2021-09-09 14:48:13

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,070

- Website

Re: Scouting Mars for Landing Sites

If I understand post 102 correctly, I need to reformat the proposal to stand on its own as a simple document, not as a letter. And, I need to take the description of the shepherding path out of the proposal, because it belongs in the cover letter.

The question about the angles on the lander bottom is good. If it should come down on top of exposed rock, the fins would do no good. I was thinking more about the wind-blown regolith that covers 95% of Mars.

The design shown for a JPL lander with a Canadrill on it showed the craft resting on footpads. So apparently the torque to resist with friction isn't very large, even when drilling through hard rock. That being the case, I think we can just use a flat bottom.

I don't have a descent velocity figure to quote, but things like Viking 1 and 2 would have been under a meter per second at impact. I think we can do that, too. That puts a good guess for the impact forces at the Mars weight of the probe, times a factor of 2 for transient dynamics, times another factor of 2 for coming down a bit crooked.

If the thing was half a ton, that's 500 kg, for an Earth weight of 4903 N, and a Mars weight of 1883 N. About the biggest impact force applied anywhere would be on the order of 7531 N.

As for resting friction, that depends upon the static coefficient of friction between the probe bottom and whatever it rests upon Those vary a lot with different dirts or rocks. As a wild guess, use 0.5 against the mMars weight for the force to shove the thing aside. (Torque should be comparable in magnitude.) Half ton, 0.5 time 1883 = 942 N. Wild-guess the torque at ~900 N-m.

If the thing were nearer a quarter ton, cut those numbers in half.

So, which does the team prefer? The hydraulic tester or the dropped-ball tester? The hydraulic gets better results, uses a lower factor o safety, but requires a short, stiff arm with very little flex to it. The dropped ball is cruder, requires a higher factor of safety, and can use a minimal arm with flex to it.

The factor of safety I refer to is that which divides soil failure pressure, to produce the allowable we design with.

Haven't gotten feedback from anyone but you, so far.

GW

Last edited by GW Johnson (2021-09-09 15:07:58)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#105 2021-09-09 14:58:42

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,827

Re: Scouting Mars for Landing Sites

For GW Johnson ... re #104

It is possible I am not looking at the right document.

Awk! Yes! I'm looking at Draft #3, which was still at the top of the binder!

My apology! I'll find Draft 4 immediately, and look at ** it ** ...

Awk2 ... a closer look reveals I have NOT printed Draft 4 (although I thought I had!) I've marked #2 and #3 with big red X in each page.

As a suggestion ... your word processor is already placing page numbers on the page. Please see if it can add the current date to the display.

A further refinement might be a Version Number, but I think the date will probably be sufficient.

Follow up a few minutes later ... I had received the file for Draft 4. However, my procedure involves converting the file from Microsoft to something else.

I had NOT performed that step, and had therefore not printed Draft 4. I am looking forward to studying it tomorrow!

I allowed myself to fall behind, and will try to make up time.

A few minutes later ... paper's still hot .... first impression .... this (now set of) document(s) is ** really ** shaping up!

I'll (most likely) be recommending a one paragraph cover letter for each recipient. The "ask" needs to be clear and concise, and tailored to each person.

Thanks for your patience!

(th)

Offline

Like button can go here

#106 2021-09-09 15:09:20

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,070

- Website

Re: Scouting Mars for Landing Sites

Draft 4 is very little different from Draft 3.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#107 2021-09-09 18:25:09

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,827

Re: Scouting Mars for Landing Sites

For GW Johnson ... I lost a couple of days due to confusion over versions ... I've plans to study Draft 4 tomorrow afternoon. Fridays are volunteer days, so the morning is taken.

However, hopefully a bit of delay won't be too much of a problem.

Speaking of delay ... I downloaded the On Orbit document but haven't had a chance to look at it.

I'll try to do both tomorrow afternoon.

(th)

Offline

Like button can go here

#108 2021-09-10 05:52:18

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,302

Re: Scouting Mars for Landing Sites

All we really need to do is propose another Mars InSight lander mission with a real drilling rig attached to it, place a little less emphasis on nerding out over the "science return" of the mission (self-hammering nails, knowing what's deep inside the core of the planet, and similar nonsense that anyone with any practical drilling experience would never dream of doing, specifically because it's so unlikely to ever work), so we can get down to the business of locating a decent source of ice or brine. If you punch a core out of the drill and it turns into a liquid in a small storage container that you eyeball with a camera, then it's water. If you have a spectral analysis tool, you can shine a laser through the liquid to determine what's in the water.

NASA says they want to send people to Mars. If it's not idle banter, then they need to get on with the process of retiring risks. People need water to survive and they need a Hydrogen-based liquid propellant of some kind to get home, which means Martian water and CO2 from the atmosphere. We need to know if there are any toxins (heavy metals, perchlorates, etc) in the water, we need to know if it's substantially heavy water / deuterium versus ordinary water, and we need to know if we can get a lot of relatively non-turbid (water not thoroughly mixed with silt / sand / rock) ice or brine from the well. This is simple stuff. It's not sexy or cool, but if you want to live on Mars for an extended period of time, then you have to do it.

If we can land on or very near to a buried glacier, then we're never going to die of thirst or fail to get home, given proper life support systems, propulsion equipment, and our trusty ACME "so-you-want to colonize another planet" chemistry starter set from Mattel.

We need a mission run by pragmatists, for pragmatists, squarely directed at a specific end goal, and the science / engineering return on the mission will follow suit. Whatever crazy stuff we have to do to get the probe there is simply what we have to do- parachutes / retro-propulsion, ion engines, whatever it is really doesn't matter so long as it gets there and returns results. That said, this is entirely doable and it doesn't need to cost a fortune or take ten years to plan.

We should stick with the InSight lander design, because that's a successful probe / lander design that's been proven to work, despite the failures of some of the gadgets affixed to it.

InSight had 50kg / 110lbs of science payload, so that's our mass constraint for devising a functional drilling rig, which rules out the use of steel drill pipe, and may even rule out the use of Aluminum. Way back in 2004, DoE sponsored a successful drilling project in Oklahoma that used Carbon Fiber drill pipe. We can use CFRP cores with Kevlar liners.

Development and Manufacture of Cost Effective Composite Drill Pipe

Offline

Like button can go here

#109 2021-09-10 05:59:24

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,827

Re: Scouting Mars for Landing Sites

For kbd512 re #108

SearchTerm:Insight lander as model for drill lander

Note 50 kg science payload.

Also note fixed solar panels, unable to clean themselves.

(th)

Offline

Like button can go here

#110 2021-09-10 07:04:23

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,302

Re: Scouting Mars for Landing Sites

tahanson43206,

Since Spirit and Opportunity included technology to electrostatically clean their panels, I presume the same technology could be incorporated into the lander. If we get on with the drilling schedule fast enough, then we won't need extra power anyway. The mission is to get the probe on the surface, use the coring drill to retrieve core samples, determine if there's significant water buried below the surface, and then determine what's in the water that may prevent us from using it without specialized processing equipment. That's the only activity to be conducted, which keeps the mission simple and on-point. A separate mobile probe can test regolith compaction. If both the drill and the regolith compaction tester need to be mobile, then we're talking about delivering a pair of Sprit / Curiosity sized mobile robots with speciality engineering equipment as the science payload. If both rovers were equipped with a pair of deployable solar arrays, then they could probably supply enough power for movement and experiments. To be honest, I think both robots need to be mobile. There's no guarantee that we'll hit water on our first try. This mission would be a lot easier to do with a rover the size of Curiosity, that can handle both experiments, with margin, while not mandating exotic materials for the drilling rig.

None of the designs used by NASA are ideal for a drilling rig attachment, but Curiosity / Perseverance come closest. We want a sophisticated spectral analysis tool, a heavy duty drill that is not delicate in any way, two pairs of great big solar panel wings, a drill arm that can hold other tools to help clean the solar panels, and enough room for a half dozen helicopter drones. The rover needs heavier batteries since it won't be nuclear powered, but the extra power supplied by a set of 4 solar panels, especially roll-out solar panels, could supply a lot more power than a MMRTG setup.

To be honest, we should be sending a brand new design, similar to the Boston Dynamics Atlas robot, with a backpack loaded with goodies, preferably canisters of roll-up solar panels and Lithium-ion batteries, drill pipe, and a pair of human-like hands that provide human-like dexterity for removing stuck drill pipe or securing a much smaller rig to the ground using pitons. The drill rig can be tiny if we do it this way, and the regolith compaction probes / test instruments can be dropped pretty much wherever a human can go, which includes lots of places that the big wheeled rovers have to avoid, due to the presence of rocks. Boston Dynamics is years ahead of where NASA's robotics program is presently at. Atlas has the ability to curl up in a ball for reentry, stand up straight, sit, crouch, jump, run, open doors and boxes (think experimental apparatus such as the spectrum analyzer or punching our cores from drill pipe the way a human would), etc.

Offline

Like button can go here

#111 2021-09-10 08:47:09

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,302

Re: Scouting Mars for Landing Sites

This is just something to keep in mind, as we send ever-more sophisticated computerized devices in space:

Offline

Like button can go here

#112 2021-09-10 09:36:40

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,827

Re: Scouting Mars for Landing Sites

For kbd512 re #111

SearchTerm:radiation faults computers Video includes description of alpha particles generated by memory chip packaging material

Thanks for the reminder ... it's been a while since I've checked to see how marc is coming along with his robust ultra-fault tolerant non-nanoscale computer.

Regarding prior post #110

This post contains some interesting ideas, and is definitely forward looking.

A humanoid robot able to change drill tubes appears to be in Elon's vision set, but I don't think it will be ready by September of next year.

I do agree with your recommendation the site pounder should be mobile and separate from the drill.

The argument for a light drill is that we can send more than one on the same launch vehicle, if the drill is light enough.

Not long ago, someone (it might have been Mars_B4_Moon?) reminded the forum of Dr. Zubrin's idea (I'm reporting third hand so could be wrong) of moving an instrument package using a hydrogen balloon.

That is an idea (whether from Dr. Zubrin or someone else) that would (or could) solve the mobility problem for a large, heavy drill.

Your suggestion of electrostatic dust dumping is one I'd not heard of before. I have definitely NOT heard that it was a success.

If you (or someone) has time, please investigate to see if the electrostatic dust dumping idea was any good, or if it was a total bust and has quietly been forgotten.

I think the idea of GW Johnson, to build the solar panels so they can rotate on their mounting arms, is definitely worth considering for any future probes that go to Mars, regardless of the Nation that sends them.

***

Finally for kbd512 ... I sent out Draft 4 from GW Johnson, and then managed to lose track of it. By any chance, have you had a chance to give it a detailed scrubbing?

Massive changes would seem inappropriate right now ... we're closing in on a version that will be committed to the task at hand.

Mission creep can occur later, when we have a firm customer acceptance to work with.

(th)

Offline

Like button can go here

#113 2021-09-10 11:05:21

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,302

Re: Scouting Mars for Landing Sites

tahanson43206,

I read it, but haven't commented directly on the proposal. I want to see what GW wants, in finalized form. He's an aerospace engineer and I'm not. I've been throwing out some ideas to read about and basic concepts related to drilling and coring. To the best of my ability, I will try to gather the required info for a detailed drill design, based upon something actually used for coring. In simple terms, we need an electric or electro-hydraulic drill that drills slowly enough to not dull the coring bits, but fast enough to complete at least one coring operation per day. Short of drilling through solid granite, that should be easily achieved.

Offline

Like button can go here

#114 2021-09-10 11:50:29

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,827

Re: Scouting Mars for Landing Sites

For kbd512 re #113

Thanks for confirming you've looked at Draft 4 ... I'm planning to study it today.

Thanks for standing by to help with detailed design if we get past the proposal stage ...

(th)

Offline

Like button can go here

#115 2021-09-10 15:52:06

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,827

Re: Scouting Mars for Landing Sites

For SpaceNut .... I have started detail review of Draft 4, and sent the first of what could well be many suggestions.

If you have your copy of Draft 4 handy, please look at the Reference line on Page 1

The details for that line need to be provided, and you are the team member (by far) best qualified to find what is needed.

At a minimum, links to online documents would be helpful.

If there is an actual pdf available, it might be considered for inclusion in the package.

Thanks for all the help you've provided already. We are in the final phase of adjusting the proposal for presentation.

For RobertDyck .... knowing you are out (somewhere in the wilds of) Canada, this is for when you get back ... you are (possibly) the best person to help to enlist CanaDrill experts/participants to help with the current proposal.

For kbd512 ... if you have time, please re-read Draft 4 with a critical eye, as though you were our customer(s). This is not a time for major changes. You and I agree on separating the drill from the pounder, but we have not yet convinced Dr. Johnson. Here is your opportunity to make a case for separating the two functions. Please note that the video you showed us (Helsinki) shows a small tracked vehicle that could hold the pounder.

Send any comments you may have to Dr. Johnson directly. We want (or at least ** I ** want) to have this package complete within no more than a week. The goal is a launch in September of 2022. This first step is a big one, but I think we (team) can pull it off.

(th)

Offline

Like button can go here

#116 2021-09-10 18:53:54

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,722

Re: Scouting Mars for Landing Sites

This is just something to keep in mind, as we send ever-more sophisticated computerized devices in space:

The issue is with low volume manufacturing of harden components and that super high price tag there is little wonder why we are using more off the shelf to build with...

In the 80's the computer manufacturer that I work for made there own parts out in sunny vale and would build there own costumed parts as well and while the off the shelf functioned there was the tolerance issues of generic parts versus the much tighter tolerance that was required for higher speed in computing.

Good to see correspondence with regards to the project...

The escape tower shape I am wondering what is the smallest diameter and height that would be required to send a multi packed payload of 3 to 4 units to makes surface on the single falcon 9 heavy launch vehicle?

https://www.spacex.com/vehicles/falcon-heavy/

PAYLOAD TO MARS, 16,800 kg / 37,040 lb …

https://www.spacex.com/media/falcon-use … 021-08.pdf

https://www.spacex.com/rideshare/ would be ideal for cost but they are only going to orbital

I am also wondering if the super Draco engines could be purposed into the design since we have run the calculations for mars landings of a Red Dragon....

Offline

Like button can go here

#117 2021-09-11 15:09:04

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,722

Re: Scouting Mars for Landing Sites

currently the crew of 17 first mission is to

Geologist triad: They will be tasked with collection of samples and determination of WHERE to put the permanent habitation modules. Do studies of weight bearing capabilities of potential landing sites and layout of the landing complex. Search for water.

Of course thats with a starship where as the Nasa plan is with masses of 20 mT and up to be at a given site. That said we should target not just starship but be able to apply knowledge gained to lesser mass landings.

A good question is do we target the existing sites that Nasa has collected some data or do we go to a place not yet explored?

Then again do we want to target the unknown for starship?

Offline

Like button can go here

#118 2021-09-11 17:46:47

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,722

Re: Scouting Mars for Landing Sites

I have been looking at the solar fold out panels and orientation upon landing as they could be facing north south rather than east west so the quest then is adding of rotation to the system to allow for this mismatch orientation or adding another drop out set of panels which makes 4 fold out sets not 2....

Another thing to consider is mission time allotment to achieve testing goal of depth pressure test and water sample analysis?

The rovers had tools for some things

https://www.jpl.nasa.gov/missions/mars- … mer-spirit

we may want some of these

Instruments

Panoramic camera (Pancam)

Microscopic Imager (MI)

Miniature Thermal Emission Spectrometer (Mini-TES)

Mossbauer Spectrometer (MB)

Alpha Particle X-ray Spectrometer (APXS)

Rock Abrasion Tool (RAT)

Magnet arrays

Hazard Avoidance Cameras (Hazcams)

Navigation Cameras (Navcams)

Simular but different items

https://mars.nasa.gov/msl/mission/science/summary/

since we are looking at a lander only different these items on the phoenix could also apply

https://en.wikipedia.org/wiki/Phoenix_(spacecraft)

The optical microscope, designed by the University of Arizona, is capable of making images of the Martian regolith with a resolution of 256 pixels/mm or 16 micrometers/pixel.

The robotic arm was designed to extend 2.35 m (7.7 ft) from its base on the lander, and had the ability to dig down to 0.5 m (1.6 ft) below a sandy surface. It took samples of dirt and ice that were analyzed by other instruments on the lander.

Lander systems include a RAD6000 based computer system for commanding the spacecraft and handling data

670 kg (1,480 lb) Includes Lander, Aeroshell (backshell and heatshield), parachutes, cruise stage.

Lander Mass

350 kg (770 lb)

Offline

Like button can go here

#119 2021-09-11 17:55:00

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,827

Re: Scouting Mars for Landing Sites

For SpaceNut re 116, 117, 118, 119

Thanks for doing all the research to collect those links, and for making comments that explain why they may be helpful.

Regarding solar panels and orientation ... please take another look at Draft 4, and specifically the line about solar panels. It seems to me your idea fits into the existing text ... please take a look so see if you think so as well.

I'm only part way through a detailed review of #4, so will hold off on further comment.

(th)

Offline

Like button can go here

#120 2021-09-11 20:56:20

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,722

Re: Scouting Mars for Landing Sites

Saw what you are reading for dust removal but that would only be half of the rotation to be able to do tracking of the sun.

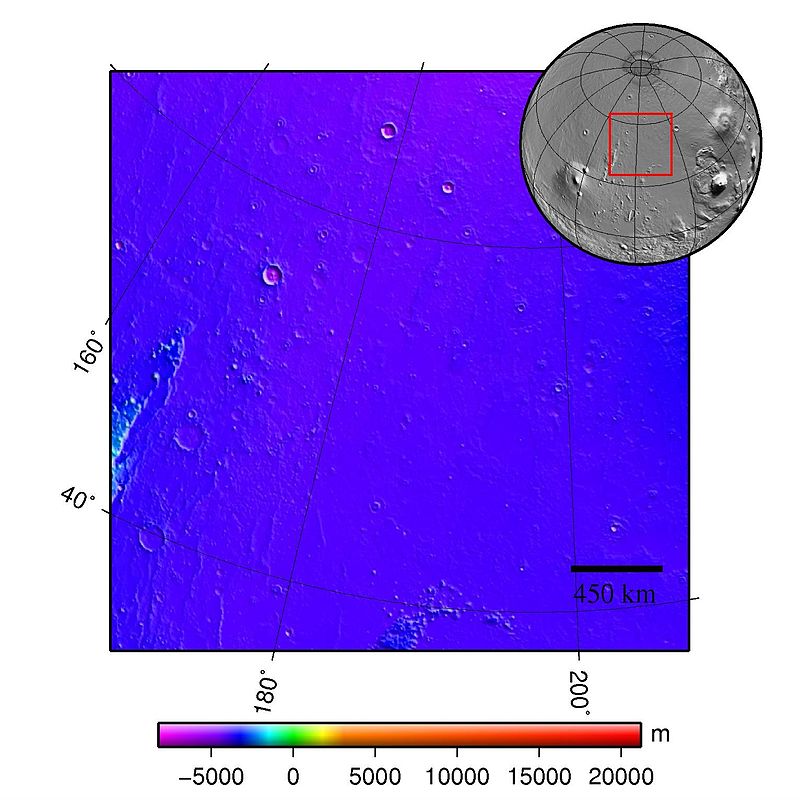

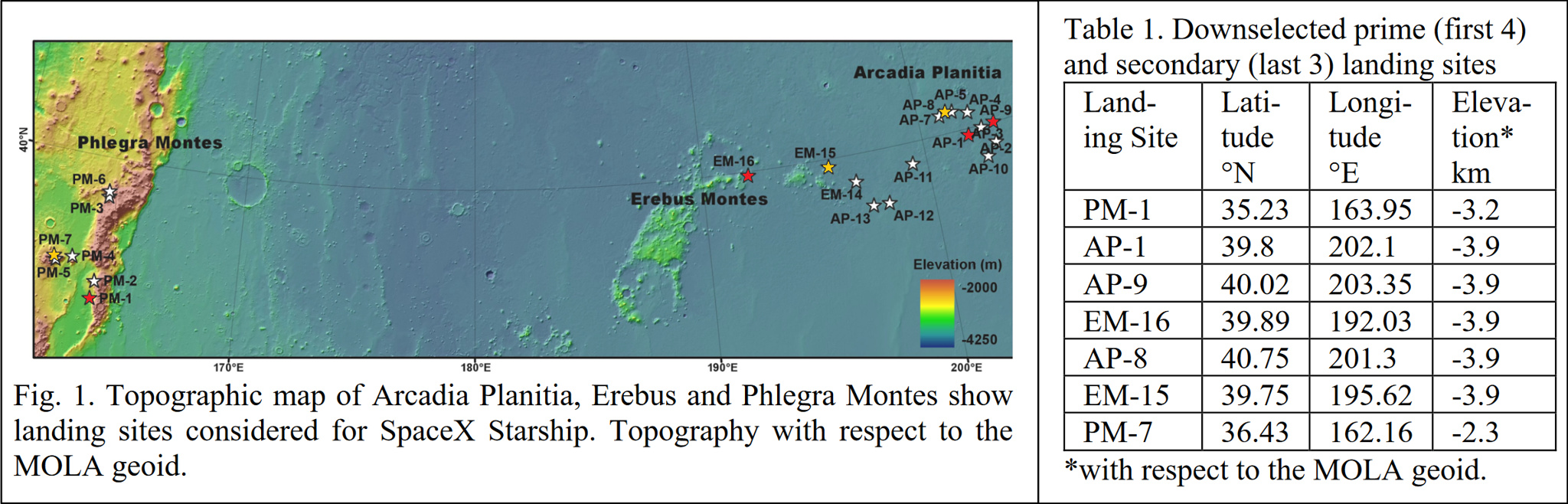

A suggested ice location at strange craters 1,075 to 1,410 feet (328 to 430 meters) wide.in a region called Arcadia Planitia

https://www.space.com/30502-mars-giant- … y-mro.html

The ice the scientists found measures 130 feet (40 m) thick and lies just beneath the dirt, or regolith, or Mars. "It extends down to latitudes of 38 degrees.

https://en.wikipedia.org/wiki/Arcadia_Planitia

https://www.humanmars.net/search/label/ … 20Planitia

which is the starship identified areas of interest

Offline

Like button can go here

#121 2021-09-12 05:57:21

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,827

Re: Scouting Mars for Landing Sites

For SpaceNut re #120 .... Thanks for confirming you picked up on the idea of GW Johnson to plan to build the solar panels so they can rotate to clear dust. it is a small step from there to allow for rotation of the panels to track the Sun. However, if you want your idea to be incorporated in the proposal, you have started the process by posting your ideas in the public forum, but if you have time, please consider dropping a note directly to Dr. Johnson.

***

Your report of a potential ice field is very interesting. That sure does look like a ** very ** good place to put the ice drill. However, I cannot tell from your wording in post #120 if this ** is ** a landing site SpaceX is considering, or if you think it ** should ** be? Can you / would you clarifiy that?

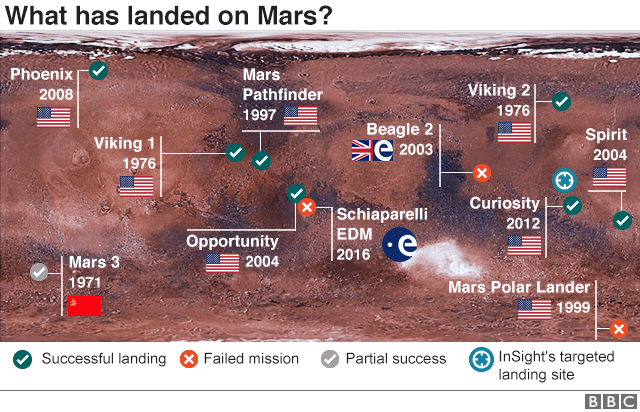

Not long ago, you posted images of Mars terrain showing landing sites of existing probes. It is entirely possible you also posted images of prospective landing sites. I'm a bit vague on that, because a lot of content flows by in this forum, and in the Internet as a whole.

To be as specific as possible.... does the ice field you reported correspond to a proposed SpaceX landing site?

To clarify even further ... are you recommending that this site ** should ** be considered for the ice drill? Is there anything about the terrain that makes it suitable for a Starship landing pad?

If there is ice just below the surface, can the overlay be removed by a scraping robot? Is that even feasible? Would the ice beneath have the strength needed to support the arriving Starship, let alone one refilled for launch?

(th)

Offline

Like button can go here

#122 2021-09-12 10:54:55

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,827

Re: Scouting Mars for Landing Sites

For GW Johnson re Draft #4 of Landing Pad Probe initiative

This is an initial report after reading Draft #4 through ...

The appendices are helpful! Somewhere along the line either your text improved or my reading of the text improved, but I ended up understanding why the flexing of the arm of the pressure tool is not important. It is the observed sudden change in pressure (at some known depth of the tip in the regolith) that provides the needed data.

However, it is also good to know you are starting to consider separating the drill function from the pounder function.

***

For all ... we are rapidly approaching a final cut on this document. If you have **not** yet had time to study the text with a view to helping Dr. Johnson with the upcoming peer review, please try to make time and send your comments directly to him via the email address you have on file.

(th)

Offline

Like button can go here

#123 2021-09-12 12:44:45

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,722

Re: Scouting Mars for Landing Sites

potentail huma landing sites map

sub surface ice for the propose landings sites for the starship slide image last one in #117 and follow up close up in 120.

here is another view of the starship selections

if we have multiple drill towers landing from a common payload to pin down the selection from its corners then these need to stay common under the 1 parachute until the release point to keep them from spreading out to far from each other.

Offline

Like button can go here

#124 2021-09-12 12:57:34

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,827

Re: Scouting Mars for Landing Sites

For SpaceNut re probes to multiple sites ....

My I suggest using intelligent guidance for the lander? As I understand the most recent landing (Curiosity) the lander included an intelligent guidance package that used real time data from the surface, and a map of the surface compiled from orbital data, to precisely guide the package to its destination.

In this case, I'd like to suggest the equipment for a given landing site be independent of all the others. Placing all the landers under one parachute seems risky to me, even if it is possible. Keeping the guidance package and landing equipment sized to a smaller mass seems like a good way to increase chances of success.

As you will note from the paper by GW Johnson, his concept is to keep the lander mass under an amount that allows for use of previously proven equipment.

(th)

Offline

Like button can go here

#125 2021-09-12 14:57:12

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,722

Re: Scouting Mars for Landing Sites

Seperate parachutes can even with a target software control to aid with landing is still at the whim of the Martian atmospheric wind conditions drift and even is higher being seperate on orbit for the entry which is not controlled.

Since the last 2 rovers used a large parachute to support the sky crane plus rovers for the use, one could make the argument that a lander that is only half of the mass to mars would be able to support 2 landers at a time minimal with the same levels of mass.

The lander is not of the design or any previous lander and has different characteristics.

The smart terrain unit only controls when the lander seperates from the parachute. Its still on a dead course until the engines come on to make the final slow down to landing.

Offline

Like button can go here