New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#276 2021-04-06 17:19:34

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,224

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

Video showing rover wheels wearing out

Offline

Like button can go here

#277 2021-04-07 12:24:54

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,122

- Website

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

I think I have commented before about these wheels: aluminum is the simply wrong material to use to drive over rocks. I don't care what alloy or cold-work strength, or heat treatment. It is the wrong choice for long life.

A nuclear-powered rover has an inherently long service life, with essentially unlimited power. What is the point of sending one of these to Mars, if its wheels wear out and immobilize it in a couple of years? BTW, the new Perseverance rover has pretty much the same wheel design as Curiosity. I know they say it's improved, but it's still aluminum wheels on sharp rocks.

Once again, stupid is as stupid does.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#278 2021-04-07 12:38:04

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,880

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

For GW Johnson re #277

I was intrigued by your observations in this post ... the article at the link below is unapologetic

Surely the mission managers must have considered carbon based materials for the wheel ground contact surfaces ... I wonder how the decision making process, surely involving very smart, highly educated persons, would have resulted in the decision to stay with aluminum.

https://mars.nasa.gov/mars2020/spacecraft/rover/wheels/

I doubt very much the famous/infamous "brother-in-law" effect was at work.

There is too much at stake for NASA leadership to allow that.

(th)

Offline

Like button can go here

#279 2021-04-07 20:13:37

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,122

- Website

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

Carbon composite would be even worse than aluminum. The failure stresses are even lower, and the elongation-to-failure very far lower.

Driving in the rocks with non-inflatable wheels requires high tensile strength and large elongation-to-failure. Period. End-of-issue. You also need strength when soaked out to extreme cold.

As I said, there is no point sending a rover to Mars with a power system lifetime of multiple decades, and wheels that are useless in a couple of years. Yet NASA has now done this mistake twice.

The material of choice for this is a 300-series stainless steel. There is no other choice available. I would recommend 304L, myself. A real materials guy might have something even better, but odds are, it'll be a 300-series stainless.

Stupid is, as stupid does.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#280 2021-04-09 07:27:32

- Quaoar

- Member

- Registered: 2013-12-13

- Posts: 665

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

Carbon composite would be even worse than aluminum. The failure stresses are even lower, and the elongation-to-failure very far lower.

Driving in the rocks with non-inflatable wheels requires high tensile strength and large elongation-to-failure. Period. End-of-issue. You also need strength when soaked out to extreme cold.

As I said, there is no point sending a rover to Mars with a power system lifetime of multiple decades, and wheels that are useless in a couple of years. Yet NASA has now done this mistake twice.

The material of choice for this is a 300-series stainless steel. There is no other choice available. I would recommend 304L, myself. A real materials guy might have something even better, but odds are, it'll be a 300-series stainless.

Stupid is, as stupid does.

GW

Which is the weight difference between an aluminium wheel and a steel wheel of the same size?

Offline

Like button can go here

#281 2021-04-09 12:21:23

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,122

- Website

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

Quaoar:

For the same volume of parts, the steel part is about 2.8 times heavier than the aluminum part.

But, what is the point of saving weight on the wheels, if you cannot move the rover after about 2 years or so, when it is nuclear-powered, and would otherwise run around for decades?

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#282 2021-04-09 18:18:54

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,224

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

An alloy with Titanium as well as other blends might be able to achive the goal of strong but light mass...

Then again there is the wire mesh lunar tire which might work but it needs to be tried and tested long before its sent....+

Sterling engine produces power from the RTG which has Plutonium...

Curiosity’s RTG was designed to supply about 125 watts continous….

Offline

Like button can go here

#283 2021-05-22 18:50:46

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,224

Offline

Like button can go here

#284 2021-11-24 21:01:58

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,224

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

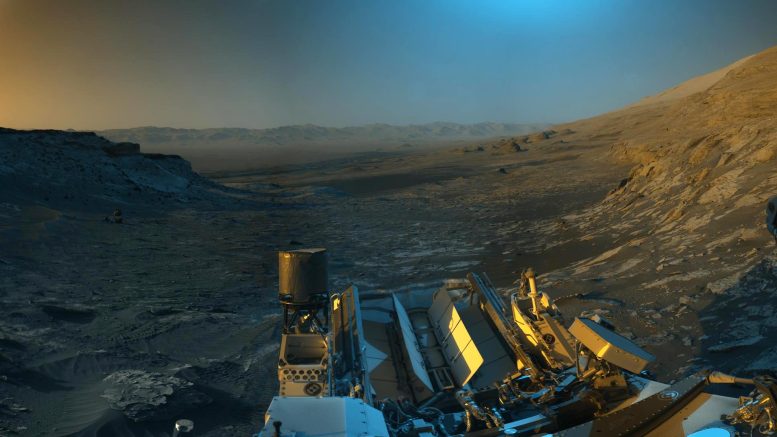

NASA’s Curiosity Rover Sends a Beautiful Picture Postcard From Mars

Blue, orange, and green color was added to a combination of the panoramas for an artistic interpretation of the scene.

On November 16, 2021 (the 3,299th Martian day, or sol, of the mission), engineers commanded Curiosity to take two sets of mosaics, or composite images, capturing the scene at 8:30 a.m. and again at 4:10 p.m. local Mars time. The two times of day provided contrasting lighting conditions that brought out a variety of landscape details. The team then combined the two scenes in an artistic re-creation that includes elements from the morning scene in blue, the afternoon scene in orange, and a combination of both in green.

Offline

Like button can go here

#285 2022-04-09 19:44:38

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,224

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

Mars rover spots gusty weather blowing across the Martian desert

Sometimes, Mars experiences extreme, long-lived dusty weather events, like dust storms. These storms can be huge, but they're also normal. "Every year there are some moderately big dust storms that pop up on Mars and they cover continent-sized areas and last for weeks at a time, And around every five years or so, a truly monstrous dust storm can encompass much of the planet.

In this dusty world, the Curiosity rover continues to gradually climb a region called Mount Sharp, which is a peak inside Mars' Gale crater. The NASA robot seeks to determine if the planet could have ever been habitable enough for tiny microbes to thrive, perhaps in the moist soils of lake beds or streams.

Offline

Like button can go here

#286 2022-06-05 04:28:31

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

NASA Rover Spots Extremely Weird Spikes on Mars

https://futurism.com/the-byte/nasa-rove … pikes-mars

Curiosity's next fascinating discovery: two ancient "spikes" of cemented rock

NASA Remotely Hacks Curiosity’s Rock Drill

https://hackaday.com/2018/05/25/nasa-re … ock-drill/

We have a lot of respect for the hackers at NASA’s Jet Propulsion Laboratory (JPL). When their stuff has a problem, it is often millions of miles away and yet they often find a way to fix it anyway. Case in point is the Curiosity Mars rover. Back in 2016, the probe’s rock drill broke. This is critical because one of the main things the rover does is drill into rock samples, collect the powder and subject it to analysis. JPL announced they had devised a way to successfully drill again.

The drill failed after fifteen uses. It uses two stabilizers to steady itself against the target rock. A failed motor prevents the drill bit from retracting and extending between the stabilizers. Of course, sending a repair tech 60 million miles is not in the budget, so they had to find another way. You can see a video about the way they found, below.

NASA calls what happened “MacGyvering.” The drill bit is fully extended at all times. Now the rover has to use the entire arm to push the drill forward and recenter without the stabilizers. The arm has a force sensor made to detect if the arm strikes something. That sensor now has a new purpose, to monitor the progress of the drilling.

NASA's Curiosity rover finds a mysterious doorway on Mars, spark speculations

https://www.cnbctv18.com/science/nasas- … 607052.htm

Rover used its Mast Camera, or Mastcam, to capture this mound of rock nicknamed “East Cliffs”

PDF link

Drill samples already taken uncovered organic molecules of benzene

https://authors.library.caltech.edu/869 … ode-SM.pdf

and propane in 3 billion year old rock samples in Gale

Offline

Like button can go here

#287 2022-09-14 05:06:33

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

Sols 3592-3593: Onwards

https://www.marsdaily.com/reports/Sols_ … s_999.html

Curiosity is back on the road! The arm (seen above while conducting science activities on sol 3583) is good to go, so the team planned a full day of activities. Curiosity has been sitting in the same place for a few sols, so the team has been taking advantage of that to get extra observations in this area.

Offline

Like button can go here

#288 2023-01-08 10:20:58

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,280

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

Opals discovered on Mars.

https://www.forbes.com/sites/davidbress … 733ad23359

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#289 2023-01-08 18:09:57

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,224

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

Seems we have big news that Curiosity rover may have found a water source on Mars

This explains Calliban's opal post, but it also means this is about past and not present water sources unless they are deep inside mars.

A new study examined older images from Curiosity’s mission to learn more about the halo-like fractures found across the Red Planet’s surface. While these halos intrigued scientists enough to gather samples of the Martian rocks, scientists weren’t sure what to make of them. Now, though, they believe those halos could be opal deposits.

Offline

Like button can go here

#290 2023-01-08 18:19:04

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,880

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

For SpaceNut re #289

Thanks for the link you provided in post! I did not realize opal contains so much water. It seems to me your mechanical water idea is looking a ** whole ** lot better, given the abundance of opal in the landscape. My recollection is you where hoping to find 1 to 2% water molecules in each sample of regolith. Opan looks to provide a much better payoff for the work of collecting and grinding it into powder...

The significance of finding opal on Mars will have advantages for future astronauts, and exploration efforts could take advantage of these widespread water resources. Opal itself is made up of predominantly two components: silica and water - with a water content ranging from 3 to 21 percent by weight - with minor amounts of impurities such as iron. This means that if you grind it down and apply heat, the opal releases its water. In a previous study, Gabriel and other Curiosity rover scientists demonstrated this exact process. Combined with growing evidence from satellite data that shows the presence of opal elsewhere on Mars, these resilient materials may be a great resource for future exploration activities elsewhere on Mars.

Material provided by the Arizona State University.

David Bressan

(th)

Offline

Like button can go here

#291 2023-01-08 18:56:11

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,224

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

The water as ice is grains in between the sand and not really the opal but if that can boost the levels all the better.

So, grind and then what do we do to it to release the water from it?

Offline

Like button can go here

#292 2023-01-08 21:00:12

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,880

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

For SpaceNut re #291

Based upon the text in the article (I am working from memory here but the text is available per the link provided earlier), the water in opal can be secured by grinding the stone and then heating the powder. My recollection is that you were planning a similar process for your mechanical water "mining" equipment.

The difference may be (and again I am working from memory) I ** think ** you were hoping to avoid grinding the regolith.

What interests me about both your regolith proposal, and the opal "mining" suggestion, is that both are mechanical (rather than chemical) processes.

However, ** now ** I am suspicious about opal NOT being a chemical bond ...

I'll ask trusty Bing in this case ...

It came back with a report that "Opal is a hydrated amorphous form of silica (SiO2-nH20)"

I am guessing the structure of the chemical formulation is chosen to show that the water is NOT held by a chemical bond.

so now I'll ask Google to explain the bonding of hydration ....

OK ... per Google...

What is hydration bonding?

In chemistry, a hydration reaction is a chemical reaction in which a substance combines with water. In organic chemistry, water is added to an unsaturated substrate, which is usually an alkene or an alkyne. This type of reaction is employed industrially to produce ethanol, isopropanol, and butan-2-ol.

Hydration reaction - Wikipedia

en.wikipedia.org › wiki › Hydration_reaction

More results

What bonds are formed during hydration?

What is the nature of bonding in h2o?

Is hydration an example of hydrogen bonding?

Searching for guidance on hydration, Google found this:

Hydrogen Bonding - Chemistry LibreTexts

chem.libretexts.org › ... › Intermolecular Forces › Specific Interactions

Sep 10, 2022 · This process is called hydration. Water frequently attaches to positive ions by co-ordinate (dative covalent) bonds. It bonds to negative ions ...

I get the impression there are multiple kinds of bonds between atoms and molecules, and that hydration bonds are less strong (weaker) that other bond types.

This may explain why the article cited earlier in this topic asserts that water can be liberated from silicon-dioxide in opal, by heating the powder.

Google found this snippet:

[PDF] Hydrogen Bonding in Water - Esalq

www.esalq.usp.br › lepse › imgs › conteudo_thumb › Hydrogen-Bon...

The water hydrogen bond is a weak bond, never stronger than about a twentieth of the strength of the O-H covalent bond. It is strong.

At this point I do not know if a "water hydrogen bond" is a hydration bond by another name, but if it is, the 20:1 ratio of strength seems helpful.

It would be great if we had a chemist in the active membership, but (at the moment) we don't, so I'll leave the matter only partially resolved.

(th)

Offline

Like button can go here

#293 2023-03-12 12:48:31

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

Pretty Sun post card picture, designed to explore the Gale crater on Mars in 2012 as part of NASA's Mars Science Laboratory MSL mission

Ghostly photos from NASA's Curiosity rover reveal beautiful, unusual clouds and the first sun rays ever spotted on Mars

https://uk.news.yahoo.com/ghostly-photo … 11800.html

The 36 holes the Curiosity rover has drilled to date. A rock sample was taken with each one.

https://twitter.com/DELTA_V/status/1586746602663780355

Maybe an Aircraft or Titan Dragonfly or Balloon will one day break the record. Opportunity's total odometry to 25.01 miles 40.25 kilometers, part of the twin MER mission with Spirit, Apollo Astronauts went many distances with their LRV, rover-car or Moon Buggy, the Russian Soviet remote-controlled robot moon rover traveled 23 miles, China has robotic Rovers on the Moon and Mars but Opportunity by far has clocked the longest distance ever driven by a rover.

Curiosity has driven 18 miles 29 kilometers, the Rover is still healthy but wheels look beat up.

Last edited by Mars_B4_Moon (2023-03-12 13:04:01)

Offline

Like button can go here

#294 2023-04-29 09:18:27

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,880

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

The recent discussion of "artificial intelligence" in this forum and elsewhere inspired this post ... It appears that the limited "intelligence" of Curiosity has been enhanced!

https://news.yahoo.com/curiosity-rover- … 42718.html

Curiosity rover on Mars gets a brain boost to think (and move) faster

Robert Lea

Fri, April 28, 2023 at 3:00 PM EDT·5 min readcuriosity mars rover on the surface of mars, surrounded by boulders. behind is a peach, dusty sky

NASA's Curiosity Mars rover will soon race over the surface of the Red Planet more quickly thanks to a new upgrade.

The software update aboard the Curiosity rover, completed on April 7, brings around 180 improvements to the robot, the most significant of which are boosted driving capabilities that will also reduce the wear and tear on Curiosity's wheels.

Curiosity, which has been exploring Gale Crater on Mars since August 2012, went into hibernation between April 3 and April 7 to receive the upgrade. The software boost will assist Curiosity in its mission to search for traces of extinct microbial life in this ancient dry Martian lake bed, NASA officials wrote.

"The flight software is essential to our mission, so this is a big deal for our team,” Curiosity project manager Kathya Zamora-Garcia, based at NASA's Jet Propulsion Laboratory in southern California, said in a statement. "This is a major software update, and we had to make sure we did it right."

Related: NASA's Mars rover Curiosity sees dazzling 'sun rays' over Red Planet

The biggest changes in the update are to Curiosity’s mobility, however, and these improvements could help the robot keep rolling over the Martian surface for many more years, NASA osaid. uality of messages relayed back to Earth.

Other changes simplify code that has been part of Curiosity since 2012, which NASA says will improve the robot's abilities for many more years of Mars trekking. (The rover as received multiple software patches during its 11 years of Mars exploration so far.)

bedrock image with an illustration of lines showing where fractures are present

A Curiosity image shows light-toned fracture crosscutting bedrock. These fracture networks would have served as safe havens from harsh surface conditions in a modern period on Mars. (Image credit: Malin Space Science Systems/NASA/JPL-Caltech)

Curiosity now 'thinks on its feet' like Perseverance

Curiosity's fellow Mars rover, the car-sized Perseverance, landed on Mars in 2021 and can "think on the move." This capability allows Perseverance to navigate around rocks, sand traps, and other obstacles in its stomping ground, which is another dry Martian lake bed dubbed Jezero Crater.

Story continues

Google found this snippet ... I couldn't remember how Curiosity is powered ...

Nuclear generator powers Curiosity Mars mission

MIT Technology Review

https://www.technologyreview.com › ... › Clean energy

Aug 7, 2012 — The heat is piped through the Curiosity carried by liquid Freon. Thermoelectric devices on the generator convert the heat into electricity with ...

I note the use of Freon to move heat from the radioactive source to where it is needed.

(th)

Offline

Like button can go here

#295 2024-03-05 03:58:48

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

Curiosity 3d interactive with music video

https://www.youtube.com/watch?v=sIfLkcFaFQY

Things You Didn't Know About NASA's Mars Rovers

https://gizmodo.com/nasa-mars-rovers-fa … 1851221481

Offline

Like button can go here

#296 2024-10-03 18:59:14

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,224

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

Offline

Like button can go here

#297 2024-10-04 08:38:37

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,122

- Website

Re: Official MSL / Curiosity Rover Thread | Aug 5, 2012 10:31 p.m. PT

The lesson here is stark: if you are going to use metal wheels, they need to be made of a steel with very high ductility while very cold. That's a 300-series stainless, likely 304 or 304L. Aluminum, which they used on Curiosity, simply does not qualify metallurgically.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here