New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#101 2020-12-19 20:05:45

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: Space Launch System

What sort of garbage is this claim of sufficient redundancy...NASA to skip repair of Orion electronics unit

Lockheed Martin warned it could take up to a year to replace the PDU because it is located in an adapter between the crew module and service module that is inaccessible now that the two modules are mated to each other.

So it was damaged in the assembly process.

Offline

Like button can go here

#102 2020-12-20 10:51:05

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,104

- Website

Re: Space Launch System

Depends upon what this module does, how redundant it is, and how many redundant modules there are. There is also the risk: this is an unmanned mission. This is what used to be called Exploration Mission 1 (EM-1), and is now called Artemis-1. It is an unmanned SLS Block-1 with Orion/service module, going into far cislunar space for a 20-40-day trip.

This is just my own opinion, but I really was an engineering designer (among several things). A module hidden such that you cannot access it to make repairs is not what I would consider a "good" design. The more critical that module, the more important it is that one can reach it to make repairs or replacements. NASA and the "old space" contractors know better than this. They knew better decades ago. But they screwed it up anyway. Which is prima facie evidence that this SLS/Orion thing is more about corporate welfare than it is sending crews into space.

GW

Last edited by GW Johnson (2020-12-20 10:51:19)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#103 2021-01-17 15:26:53

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: Space Launch System

Nasa testing progress without blowing it up.

Sounds more like a computer coding glitch as all of the hardware is known....

Offline

Like button can go here

#104 2021-01-17 15:45:33

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,488

Re: Space Launch System

They mentioned a bit of flame coming from under one of the engine's thermal protection blanket. They managed to avoid an RUD, which itself, is important

Offline

Like button can go here

#105 2021-01-17 16:38:41

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,104

- Website

Re: Space Launch System

From what few reports I have seen, the people overseeing this test did not shut it down, the automatic controls did. That argues against a "coding glitch". It argues for a human error. I can think immediately of two: either an assembly error, or an unrecognized/undetected bad part.

The third possibility is something I do not really want to think about, but it did happen with the 737MAX: bad management prioritizing immediate profit over safety or lives or results. It's been happening with the KC-46, too, except that no one has yet been killed.

If you didn't already know, Boeing corporate management/headquarters is now in Chicago, far away from their engineers in Seattle, Wichita, North Carolina, or any other Boeing location where things are designed or built. Said corporate management has recently boasted that they turned Boeing from a high-quality-engineering outfit to a high-return-on-investment outfit. And the CEO's are no longer a short walk away from the chief engineers. It kinda shows, don't it?

Corporate culture really matters. And there is more to it than just the money.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#106 2021-01-19 21:18:00

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: Space Launch System

Here first word on the early shut down Monitor Hydraulic, Software blamed for moon rocket engine shutdown

Offline

Like button can go here

#107 2021-01-31 20:35:26

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: Space Launch System

While this is an important moment, it comes as questions are surfacing about the Artemis program’s future. The latest budget from Congress already falls short of the funding needed for a 2024 Moon landing, and the incoming Biden administration isn’t likely to prioritize Artemis when the pandemic response and economic recovery will take center stage.

We have always known that Nasa was paying to much and not getting the goods for it.

Of course with that delay comes the one which puts man on the moon as well.

Elon Musk’s SpaceX, a team of aerospace giants led by Jeff Bezos’ Blue Origin, and Leidos-owned Dynetics won a combined $967 million in seed funding from NASA last year to develop rivaling concepts for a human lunar landing system.

Last Wednesday, NASA told the three contractors that an extension to their development contracts “will be required,” picking a new award date of April 30th. Under the Trump administration’s timeline, the agency had planned to pick two of the three bidders in late February, giving a stamp of approval for two systems that would inevitably carry humans to the moon.The delay was all but certain: The spending bill Congress passed in December gives NASA $850 million for the Human Landing System program, far short of the $3.2 billion it needed to stick with the 2024 timeline.

Not happy but its only a few months

SpaceX’s lunar lander pitch to NASA is Starship, a roughly 16-story-tall fully reusable vehicle the company has been launching and landing in short, suborbital test flights — called “hops” — in Boca Chica, Texas. The company’s chunk of development funds was $135 million.

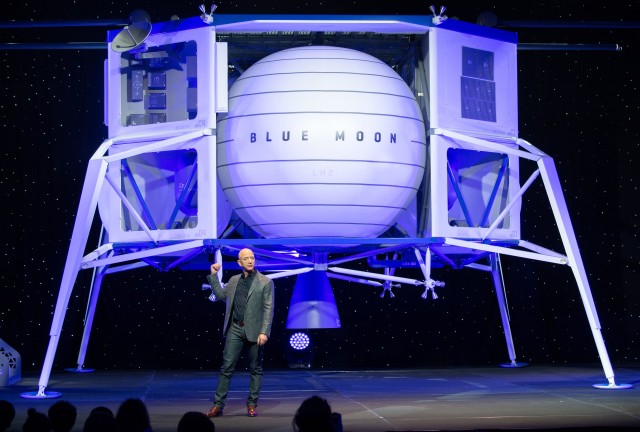

Jeff Bezos’ Blue Origin got the largest award, $579 million, to develop its Blue Moon lander. The company announced a “National Team” in 2019 comprised of Lockheed Martin, Northrop Grumman and Draper to work on the project. Dynetics got $253 million for its lander and has partnered with Sierra Nevada Corp.

So the SN8 and soon to be SN 9 would be for the Lunar design which needs quite a bit of work still...

The others we have not seen any prototypes so we have not much to make a decision on...

Blue Origin and SpaceX win contracts to develop NASA's Moon spacecraft

Blue Origin says the cargo variant it has just revealed can carry 3.6 metric tons to its destination. It's also working on another variant that's capable of carrying a "6.5-metric-ton, human-rated ascent stage."

Offline

Like button can go here

#108 2021-02-12 20:11:44

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: Space Launch System

Offline

Like button can go here

#109 2021-02-13 12:13:28

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,296

- Website

Re: Space Launch System

They should be able to fix the problem and confirm with another test the same week. But they can't fix it the same month!?! Or even the same year!?!

Offline

Like button can go here

#110 2021-02-21 19:20:01

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: Space Launch System

Early test shut down is blamed on Aggressive gimbaling test trips hydraulic system limits...

NASA, Boeing adjusting SLS Core Stage parameter limits for second Green Run firing

NASA completes Exploration Upper Stage CDR, focuses new office on SLS Block 1B development

At its widest, the larger Exploration Upper Stage (EUS) is the same 8.4-meter diameter as the SLS Core Stage, uses the same hydrogen-oxygen commodities for its four Aerojet Rocketdyne RL10 engines as the Core Stage uses for its four RS-25 engines, and will increase the SLS’s overall payload performance from approximately 27 metric tons to 38 metric tons when inserting the Orion spacecraft on a trans-lunar trajectory.

Offline

Like button can go here

#111 2021-03-08 20:44:49

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: Space Launch System

There have been many that have said something simular SpaceX Should Build NASA's Rockets Amid $20bn SLS Cost: Ex-NASA Administrator Lori Garver

Offline

Like button can go here

#112 2021-03-09 08:51:17

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Re: Space Launch System

SpaceNut,

No kidding! $20B dollars later, a former NASA administrator is just now "figuring it out". Amazing.

Offline

Like button can go here

#113 2021-03-11 22:31:29

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: Space Launch System

Here is one of those reasons that it was not killed while in the constellation phase of development.

NASA's SLS twin booster rockets ready for launch

Offline

Like button can go here

#114 2021-03-19 00:38:55

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,488

Re: Space Launch System

Well. The SLS completed the Green Run successfully with no "hiccups."

Offline

Like button can go here

#115 2021-03-19 18:22:55

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: Space Launch System

To tested all functions for throttling separate engines for a total flight to orbit fuel use of 8 minutes.

Offline

Like button can go here

#116 2021-03-19 19:27:58

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Re: Space Launch System

SpaceNut,

If we gave $20B to SpaceX, we'd have a fully reusable 500t payload colonization class launch vehicle. The amount of money it would've taken to develop THAT would've been worth waiting for 10 years and spending 20 billion dollars. At that point, we'd have the physical capability to land people and cargo on Mars. We may still not have every other piece of technology ready to go to actually live on Mars, but at least we could get to Mars. That's kinda important, presuming the end goal is to send people to Mars to explore Mars.

Anyway, hopefully the first launch takes place soon. We need a win.

Offline

Like button can go here

#117 2021-03-20 12:26:12

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: Space Launch System

The expense topic has many posts in it.

The folly started in 2004 and was sanded bag by the preferred contractors, bad contract writing and via the Senate stone walling.

Space x falcon 9 heavy needs a larger diameter core for a larger capsule since that's where we are with that system.

Starship still needs tons of work

..

Offline

Like button can go here

#118 2021-03-20 12:46:14

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Re: Space Launch System

SpaceNut,

SLS still needs a ton of work as well. After we shoot this SLS rocket off into space, it'll take at least another year to build a new one.

Offline

Like button can go here

#119 2021-03-20 14:58:32

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: Space Launch System

Contractor build contract as the design seems solid for all parts and all phases of operation. All that remains for moon is a lander. For Mars a lander plus habitat as well as a return capability which is not there.

Offline

Like button can go here

#120 2021-03-21 01:36:56

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,488

Re: Space Launch System

Space x falcon 9 heavy needs a larger diameter core for a larger capsule since that's where we are with that system.

Starship still needs tons of work

..

I advocated a larger than Falcon 9 intermediate rocket be built several years ago. Falcon 9 is 12 feet in diameter, or 3.7 meters. I modest increase in diameter would seem very feasible--say to 5 meters. Using the Falcon 9 side boosters would seem to be a no-brainer.

I believe the main reason for the diameter of F9 was transportation on the highway system. With the advent of Boca Chica, and Musk getting the H*ll out of California, building the intermediate vehicle would seem to be a easier matter than starting completely from scratch. The Merlin engines are well-developed and tested, and use Keralox as the propellant system. I would propose something of an expanded Dragon capsule design, but with an integral elongated trunk for fuel, additional crew space, supplies, living quarters, and a radiation shelter. Maybe it would be powered by 3 to 5 vacuum Merlins? It could be a deep space only craft after initial launch and could rendezvous with the ISS on return from either the Moon or Mars. I'd suggest a simple and disposable throwaway "kick stage" for Earth departure. Maybe the deep space only modules should use a non cryogenic propellant system. NTO and MMH?

I'm dredging this up from 4-5 years ago and my concept for a modular system--mix and match components.

I'd really like to hear GW's comments and maybe a few calculations on this "paper experimental design."

Offline

Like button can go here

#121 2021-03-21 09:38:45

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,296

- Website

Re: Space Launch System

I advocated a larger than Falcon 9 intermediate rocket be built several years ago. Falcon 9 is 12 feet in diameter, or 3.7 meters. I modest increase in diameter would seem very feasible--say to 5 meters. Using the Falcon 9 side boosters would seem to be a no-brainer.

Falcon 9 is manufactured in California, transported to Florida by truck. Bridges along the road limit the load to about 14.5 feet in height. That includes booster diameter and truck wheels, truck bed, etc. Do you know an alternate route that doesn't have any bridges? Perhaps to Boca Chica, Texas, then by barge? Corpus Christi, Texas, has a commercial port capable of handling tanks that large. Can you get out of Hawthorne, California, without passing under any bridges?

Offline

Like button can go here

#122 2021-03-21 10:09:10

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,104

- Website

Re: Space Launch System

You avoid the dimensional restrictions for transport if your factory is at your launch site. That's why Starships and Superheavies are built at Boca Chica, and why Musk bought two offshore drilling platforms to use as Superheavy launch sites.

While cheapest, it still costs, but barge transport from Boca Chica to Cape Canaveral using the Intracoastal Canal is feasible. That makes launching Superheavies from Canaveral feasible, if the explosion hazard size and noise levels can be tolerated. They cannot at Boca Chica itself, but could be at those offshore platforms.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#123 2021-03-21 11:00:20

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,296

- Website

Re: Space Launch System

That makes launching Superheavies from Canaveral feasible, if the explosion hazard size and noise levels can be tolerated. They cannot at Boca Chica itself, but could be at those offshore platforms.

After spending all the time and money to build the facility at Boca Chica, they're now moving to an off-shore platform? Frustrating!

Offline

Like button can go here

#124 2021-03-21 11:17:06

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,104

- Website

Re: Space Launch System

Robert:

It's not that bad. Those platforms are just a stone's throw away, as we say in Texas, at around 10 miles off shore. That's far enough that no one is endangered if the rocket explodes, or endangered by the lethal levels of launch noise. It's still quite close to the factory at Boca Chica, just a very short barge ride away.

There isn't a practical alternative; the town of Boca Chica is too close, and so are some villages in Mexico. Not to mention the outskirts of the big city of Brownsville. Buying all that out would be an international problem. Easier to just go out far enough onto the ocean with no neighbors to annoy or endanger.

Long ago, NASA was looking at some rocket designs even bigger than Saturn 5. These designs were collectively referred to as Nova. Thrusts were somewhere in the 15-30+ million pound class. It was not possible to get nearly 10 miles clearance around the Cape Canaveral launch site, required to protect people from the explosion hazard, and the lethal launch noise. More than anything else, not having the space to mitigate those hazards is why we never built rockets that big, back then.

Superheavy is getting into that Nova class at around 15 million pounds of takeoff thrust, and 4000+ tons of propellants that could explode. That's why they are doing what they are doing. It's the only practical thing to do.

Starship at only around 1.5 million pounds of thrust or thereabouts is just not that big a threat. That's why they are flying it out of their Boca Chica site. It's about like Saturn 1.

Yep, we are literally talking about Earth-shattering kaboom stuff!

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#125 2021-03-21 11:30:45

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,488

Re: Space Launch System

Robert-I am well aware of the reasons for not building anything larger in Hawthorne. I was suggesting building the intermediate, exploration vessel, at Boca Chica.

GW-I was hoping you would consider crunching a few numbers on an intermediate spacecraft, such as the one I proposed in post #120.

Offline

Like button can go here