New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#51 2020-12-18 20:30:25

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,479

Re: Battery power construction equipment

For kbd512 and SpaceNut ....

The massive post by kbd512, created in response to SpaceNut's opening of a new topic for internal combustion engines on Mars, is packed with useful and helpful details for design of earth moving equipment for service on Mars.

A portion of the post would fit nicely into the new internal Combustion topic, while the discussion of batteries and fuel cells should provide a starting point for our prospective new member who is (hopefully) interested in designing a fully defined system for fabrication on Mars.

To bring that person into the discussion, we will need to solve the problem of access to this forum.

If a current member of the forum has someone in mind who could take this on, please let one of the Administrators know. They can convert one of the recovered ID's into a useful ID for the new member.

If a person NOT acquainted with a current member would like to participate and to help move the project along, the first step is to join the Mars Society. A student or senior can join for $25.00.

In the mean time SpaceNut and I are trying to figure out how a member of the Mars Society can contact SpaceNut in the Mars Society member forum, which is distinct from this one.

Edit#1: By way of an attempt to clarify terminology, here is a definition of a bulldozer from Wikipedia.

Bulldozer - Wikipedia

https://en.wikipedia.org/wiki/Bulldozer

A bulldozer is a large and heavy tractor equipped with a substantial metal plate (termed a blade) used to push large quantities of soil, sand, snow, rubble, or similar material during construction or conversion work and typically equipped at the rear with a claw-like device (termed a ripper) to loosen densely compacted materials.

A machine designed to lift material from the ground to an elevation (such as the body of a dump truck) is (commonly) called a payloader, although that may turn out to be a trademarked name that has been adopted by the construction industry to describe any vehicle designed to lift material.

My understanding is that a "bulldozer" is not involved in lifting, except inadvertently if the material they are pushing is being moved up an incline.

(th)

Offline

Like button can go here

#52 2020-12-23 20:22:47

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,924

Re: Battery power construction equipment

Part of the mythology that we should dispel is the notion that it's practical or even feasible to complete major construction activities, over years or even decades of continuous operations, using anything less the highest quality all-steel tracked vehicles that money can buy. As heavy as steel is, that's the material of choice for construction and hauling equipment. We still manage to break such all-steel construction equipment with regularity here on Earth, where supplies of replacement parts are plentiful and far easier to transport. If anyone thinks we're going to complete a decade's worth of construction on Mars using a carbon-fiber bulldozer chassis, you're quite mistaken. If it was even feasible to fabricate such a vehicle, irrespective of cost, then someone would've done it by now, if only for testing purposes. Nobody's doing it because it's waste of time and money, not because they're interested in making more money. If CFRP was practical, then someone would be selling premium construction equipment and somebody with more money than uncommon sense would be buying it.

Certain concessions to reduce weight we can get away with, whereas attempting to do that in other areas is only inviting an early catastrophic failure. For example, the hoods on late model Class 8 heavy duty trucks are now fabricated from lightweight (lighter than Aluminum or sheet steel and less prone to corrosion) fiberglass, because we know how to fabricate parts that can withstand that particular use case. However, every single production Class 8 truck on the road today uses a steel frame rails to connect the engine / wheels / suspension components to. We have experimented with Aluminum, Titanium, GFRP, and CFRP, but the crushing weight of the engine / fuel / loaded cargo trailer and unfavorable fatigue or heat resistance properties of those lighter substitutes were simply not amenable to typical operating environment, so that's as far as it went. In so many different applications, old-fashioned steel is really tough to beat.

NASA may pretend that they're going to invent construction or hauling equipment using spindly little composite and Aluminum wheeled vehicles more suitable for carrying passengers than cargo, but actual long duration torture testing will demonstrate the folly of that approach. No re-invention of the wheel is required here. We already know what works. Yes, it's a pity that durable off-road vehicles are so heavy, but that can't be helped. I noticed that their regolith collection robots for their ISRU equipment "evolved" from Aluminum and CFRP to steel really fast. All the countless billions of dollars spent on development and testing projects keep telling us what we already know, over and over again.

Anyway, a Mars-ready construction vehicle looks a lot more like a Russian T-55 bulldozer than that MMSEV abortion that someone at NASA dreamed up to satisfy their cravings to prove how clever they were, rather than how practical they could be. A T-55 dozer blade-equipped vehicle weighs 28t (28,000kg), but only 10.64t (10,640kg) on Mars. It's dimensions are 6.88m L x 3.39m W x 1.58m H. It can climb over a 0.8m vertical obstacle and cross a 2.7m trench. On Earth, it's equipped with a 426.59kW diesel, for a power-to-weight ratio of 15.24kW/t. On Mars, it'll be equipped with a pair of 125kW SCCO2 gas turbines and sealed electric traction motors with magnetic reduction gearing, for a power-to-weight ratio of 23.5kWt. The tracks are 580mm wide. There's probably at least a ton of garbage included in that vehicle's weight that's part of its original design as a tank and a pre-electronics combat vehicle, but roughly speaking, this is the sort of vehicle chassis with the durability required to withstand continuous off-road use for at least a couple of decades.

Here's a website with a picture of what this former tank-turned-bulldozer looks like:

BULLDOZER BZ-55 (CHASSIS T-55)

This is just to give people an idea of what I'm talking about. I'm not suggesting that we rip out the diesel engines and send T-55s to Mars after we re-equip them. Even if we did do something that ridiculous, it'd still be a more practical vehicle than the various "experiments" I've seen over the years. However, this is intended to clue people in on what a durable off-road vehicle actually looks like. It's not light, it's not pretty, it's not an off-road truck that boys love to play with so much, but it is a simple, practical, durable, and effective piece of construction equipment that will withstand the severe use we would subject it to.

So the big question then is can we do this with electric motors and batteries or are we at the level of requiring a combustion engine to do the work...

Offline

Like button can go here

#53 2020-12-24 07:42:11

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Re: Battery power construction equipment

SpaceNut,

The viability of batteries depends almost entirely on what the continuous power output requirement happens to be, whether the battery will be temperature controlled or not, and whether or not repairability and recycling are at all important to you.

Continuous Power Output

Photovoltaic panels and batteries are optimal for use in space where there's full Sun (no day/night cycle) and warmth 24/7/365 (in the inner solar system, obviously), no electrical connector-breaking vehicle vibration to speak of (unlike an off-road truck), and the battery can be designed to be grossly over the required capacity (unlike a gravity-restricted ground-based vehicle that has to move both its own weight and any payload carried), relative to the amount of power discharged per use cycle (motor vehicles need every last Watt of power they can extract from their onboard energy storage system). Discharge 10% to 20% of a Lithium-ion battery's total capacity and it'll run like a top for many years as long as you keep it warm (constant temperature- not too hot, not too cold). Discharge it completely a few hundred times or freeze it or overheat it significantly and that's probably all she wrote for that battery pack. Putting Lithium-based cells in a refrigerator (cooling, but not freezing them) for storage is not the same thing at all as trying to charge or discharge them.

The charge / discharge cycle imposes mechanical stress on that human-hair thin jelly roll inside the can, but it has to be even thinner, to increase surface area, to cram more electrical potential into a given volume. The very slow rate of increase of cell capacity should be an indicator that we're nearing the limits of what we can do with known materials science and electrochemistry. There are indeed other options that significantly improve upon existing cell capacity, but they do so with significant trade-offs. 1,300Wh/kg Aluminum-Air batteries are a real technology that has existed for some years now, but the catch is that you get a literal handful of cycles from them (you can use them for a month or less) before you need to send them back to the factory to de-oxidize the Aluminum (you know, that 12kWh/kg process used to produce Aluminum metal to begin with). How useful is that battery technology? I guess it depends on how much energy you want to devote to transportation and recycling of Aluminum. It's certainly doable, at least here on Earth, but not very practical at all. Existing factories struggle to keep up with new battery demand, as-is. Imagine shipping about a couple billion vehicle batteries that weigh about twice what a small block all-Aluminum V8 car engine weighs, back-and-forth to the factory, about once per month.

In contrast, we design intercontinental airliner turbofan engines to stay on the wing of the airframe they're attached to for at least 100,000 operating hours before we have to ship them back to the factory for major overhaul. Some of the highest time RB211 turbofans were on the wing of an aircraft in operational use for as long as 160,000 hours. That's more than 18 years of engine operation, which is why the British thought they were such great engines, despite the fact that they couldn't compete with newer designs that run much hotter for improved fuel economy. There are no aviation use multi-MW-class battery packs that have run continuously for 18 years at or near maximum rated output, nor will any current generation Lithium-ion batteries ever accomplish such a feat.

Achieving excellent battery life is quite similar to the way a normal car engine is operated. Car engines don't particularly respond well to extreme thermal cycling of extended runs at hight output levels, either, although large blocks of metal are far more forgiving than modern batteries. For most of its operational life, a car engine is running at no more than 20% of its maximum rated output. Aircraft engines run at 75% to 100% of their maximum rated output for the overwhelming majority of their service lives between overhauls, thus their services lives are comparatively short as a result. As a general rule, liquid-cooled engines with good thermal regulation live longer than air cooled engines, on account of the fatigue life of Aluminum at elevated temperatures. Engines run at very modest output levels can run for decades on end. There are plenty of examples of low-speed diesel pump engines have been run for multiple decades in oil fields without ceasing to operate. In contrast, there are no batteries from the late 19th or early 20th century that are still producing power. None. That is simple technological reality that persists to this very day. We've mastered combustion engines. We have not mastered electrical engines.

Power-to-Weight Ratio

If you need to generate 250kWh for 8 hours straight, then 2MWh of stored electrical power will minimally require a 6,666kg battery pack, presuming the pack level energy density of Tesla's new battery pack is 300Wh/kg using their new 4680 batteries and a convective cooling system that wouldn't work on Mars because the atmosphere there is 6mb at Mars sea level vs 1,013.25mb at Earth sea level. The temperature range that the pack can tolerate is so narrow, relative to a gas turbine, that you're not going to charge the batteries at night without heating them first. For a practical system that can reject enough low-temperature heat while running the pack at full output, we're probably looking at a total mass nearer to 7,000kg, and we'd need a very high surface area Aluminum radiator panel with a coolant that remains liquid at mildly cryogenic temperatures.

Using the T-55 example from the post you quoted, that's 1/4 of the total weight of the stock tank-based bulldozer-type vehicle. The T-55 tank was originally a 36t (36,000kg) vehicle so the chassis can easily tolerate the additional weight of the battery pack, but it won't perform any better than a vehicle equipped with a 300kg SCCO2 gas turbine power pack (I don't know what the PCHE will weigh could be 30kg to 100kg or so, but I do know that a Copper radiator to dissipate the 125kWt waste heat at 700C is only about 2.7m^2, given a 20C Martian summer, perhaps 50kg, and the Hamilton Sundstrand 250kVA VFG is 90.42kg), 1,429kg of LCO and 714.5kg of LOX (assumes 50% thermodynamic efficiency already demonstrated in testing). Incidentally 2.5kW/kg, if you recall, was about where batteries need to be, in terms of energy density, in order to replace gasoline engines used in cars on a kilo-for-kilo basis. Thankfully, low-speed vehicles operated on a planet with 38% Earth gravity and no atmosphere to produce any aerodynamic drag to speak of are relatively insensitive to such weight increases. That said, you still have to ship it there. Want more than a few hundred cycles from that battery by allowing for a 50% DoD? Now we're talking about half the vehicle weight being batteries, which doesn't seem very practical, even though the chassis could tolerate the weight increase on Mars. The cells themselves, not including the entire pack assembly, would occupy at least 1/4th of the vehicle's interior volume, so it's basically a rolling battery pack at that point. If we only wanted the dozer variant, that's not an actual problem. If we also wanted a personnel carrier variant, then it would definitely affect the usability of the vehicle. The V12 diesel used in the Earth-bound variant takes up quite a bit of space, so it's not a deal breaker, but it simply can't perform to the same level as a gas turbine powered analog, even one running on LOX/LCO.

Efficiency

The astute will note that the 50% efficient SCCO2 gas turbine actually requires 4MWh worth of that low-energy LOX/LCO combo, and that even more input solar power than that will be required to collect, chemically split, and liquefy the LOX and LCO. However, the mechanism responsible for those tasks need not have much in the way of sensors or control electronics, very few moving parts so it won't appreciably degrade over a decade or so, and it does not require as much maintenance as a photovoltaic array. In fact, some LCO2 boil-off can be periodically sprayed onto the fresnel lens to clean it, perhaps once per day.

The batteries are clearly far more efficient, nearing 95% charge / discharge efficiency, but the efficiency of photovoltaic panels is relatively pedestrian, even with strict voltage regulation of individual cells and Sun tracking, to the point that a solar thermal power system is even more efficient since much of the input power from the Sun can be converted into heat and directly used or stored in working fluid.

I'm not against using batteries if that's the best solution available, but it should be understood that absent an order of magnitude improvement in their energy density, they will inherently limit the range and power-to-weight ratio of the vehicle they power. Even with low-energy LOX/LCO, we can easily double the run time for the same weight as the batteries.

As you require more and more pieces of construction equipment or higher continuous power output, batteries quickly become an untenable solution. Current batteries have such exceptionally poor energy density, relatively short service lives if completely discharged, and require so much in the way of sophisticated electronics to control charge / discharge, that they'll become the limiting factor on how quickly useful work can be done, potentially a liability during a dust storm.

Repairability and Recyclability

There's no such thing as repairing or recycling a battery on another planet. You're never going to simply "melt them down" and make new ones. We can't even recycle the Lithium waste stream here on Earth, for purposes of making new batteries. We do recycle the Lithium to use it for other purposes, but it's never pure enough to use to make a new battery without introducing lots of virgin Lithium, so it's an impurity-laden metal for alloying at that point, never to become another battery. That's a bit of a problem for a fledgling civilization, wouldn't you say?

By way of comparison, the moving components of the SCCO2 gas turbine, gas turbine housing, heat exchanger, piping, and fittings are nominally refractory Nickel-Iron alloys, which are readily recyclable or field repairable without excessive processing. The radiator is Copper, which is also recyclable. The combustor can would be difficult to recycle, but it's also the size of coffee cup, a couple of pounds of ceramic at most. We can probably afford to deliver lots of spare turbines, combustor cans, pintles, fittings, and VFGs. All of those parts are small enough not to be an excessive logistical burden. A 250kVA VFG is a bit heavy at 90kg, but small. The heat exchanger and radiator are also fairly heavy, but very sturdily constructed and contain no moving components, so absent a fabrication issue or physical impact outside of a vehicle, the repairs on these components should be few and far between.

Offline

Like button can go here

#54 2020-12-24 08:53:26

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,479

Re: Battery power construction equipment

For kbd512 re #53

http://newmars.com/forums/viewtopic.php … 45#p175245

SearchTerm:Tutorial on battery types - comparisons - features

This post comes across to me as textbook grade writing. This forum is indeed fortunate to be hosting contributions by kbd512 and GW Johnson at this level.

SpaceNut reported that web crawlers such as Google are collecting data from this forum. I hope that is the case, and also hope that visibility extends to the minds of at least a few people around the world who are young enough to realistically imagine being part of the second wave of Mars visitors.

I know this is a big ask, but we have several PhD level members. It is a lot of work to compose at the level kbd512 and GW Johnson are demonstrating, but I am inviting you all to consider making the effort. There is ** so ** much practical knowledge stored in minds with write access to this forum. I would very much like to see it posted here for future Mars settlers.

We also have members who are not holders of PhD's but who are contributing at a comparable level. In the same spirit as above, I'm hoping you will continue to contribute to the accumulation of practical knowledge and just plain common sense advice for young readers who have not had a chance to accumulate the potentially lethal life experience available from those who've been there and done that.

Links are helpful, but (in general) please be sure to add text that explains why a particular link is worth the reader's time.

***

This topic is about Battery power construction equipment

The post by kbd512 immediately above appears (as I read it) to be a solid contribution to the topic.

I would like to see follow up with equipment designs, including specifications for components and materials needed.

This request does ** not ** have to fall on kbd512, although he may choose to add to his posts.

If there are readers of this forum who are already members and who can add something, please do so.

If there are readers of this forum who are NOT already members, we have a problem. At present, we have no mechanism through which you might be able to communicate a desire to participate.

There ** is ** a solution, but it is convoluted. On the other hand, if you are the kind of person who would like to assist with this topic or any other, a minor hurdle or two would be of little consequence.

I am a regular contributor to Dr. Lewis Dartnell's Knowledge forum. Dr. Dartnell does NOT accept unvetted registrations, but he ** does ** allow registration applications to appear, and spammers show up there periodically. The registration application form contains a Signature line. That line can be used to communicate with me. It is like a Tweet in length, but it is more than sufficient for you to establish contact.

I'll keep an eye on the registrations to see if anyone wanting NewMars membership shows up. Be sure to include NewMars in the name of the registration, or in the Signature line, so I know the application is for the NewMars forum and not just another spammer.

(th)

Offline

Like button can go here

#55 2020-12-25 03:19:35

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Re: Battery power construction equipment

tahanson43206,

These are more like random thoughts that fall out of my head, but directed at specific solutions. Let's hope that any would-be textbook editors proof-read what I wrote, since I went back and re-read what I wrote after I posted it and counted several spelling errors. There are probably numerous grammar errors or questionably-lengthy sentences as well, but I just don't care because I'm the one who has to type this. The editors can go nuts with it. However, what's more pertinent to the subject matter at hand is the difference between back-of-the-envelope calculation and engineering development of a fully functional electrical power subsystem with the requisite performance specifications. None of what I wrote should not be taken as gospel. It's still a very rough estimate, as I still need some critical missing information for determining the exact performance requirement from the SCCO2 gas turbine. Simply put, I need to know the efficiency of every major component in order to compute the oxidizer and fuel mass necessary to produce sufficient input thermal power to overcome all real-world downstream thermal and electrical inefficiencies between the oxidizer and fuel tanks and the electric generator, in order to produce 250kWe of continuous power output). To wit, heat exchanger thermal efficiency (PCHEs appear to have an average thermal power transfer capability of 5kWt/kg of heat exchanger mass, so ~25kg to remove 125kWt, but at what efficiency; Inconel 625 has demonstrated 4500 hours of operation at 750C with no notable material degradation in a mixed O2 / CO / CO2 / H2O environment, and apparently PCHEs are good at tolerating substantial thermal load changes, so that's good for us; Sandia expects TRL9 for 750C for Brayton cycle SCCO2 by FY25 *1), generator electrical efficiency, high speed switching equipment electrical efficiency to produce 400Hz 440V 3-Phase or 6-Phase AC power. I've calculated the radiator area necessary to radiate the excess thermal power, but made even more assumptions in so doing. I then made assumptions about the thickness of the Copper plate, therefore its mass, along with assumptions about the emissivity of the radiator's surface, based upon application of a white ceramic thermal barrier coating on the engine compartment-facing side and a very black ceramic coating on the atmosphere-facing side.

There are other equally important details we haven't even touched on yet, such as the weight and efficiency of the fresnel lens solar concentrators that collect CO2, split it into CO and O2, and the cryocoolers and cryogen storage tanks that must be included to liquefy both gases. I know that even relatively large lenses can be reasonably light and I know that here on Earth the electrical efficiency of mass produced photovoltaics is so poor that not even all the thermal efficiencies using solar thermal are enough to overcome the total operating cost differential between photovoltaics and solar thermal. In general, solar thermal plants have design service lives of 50 years or more, whereas after 25 years most photovoltaic operators are looking at completely replacing their panels. It's unreasonable to think that such panels would survive longer than that on a planet with high radiation affecting photoelectric cell and electronics service lives, nor that they could ever be as efficient as they are here on Earth. The main selling points for solar thermal are simplicity, reliability, longevity, and low maintenance. It's not a given that it would weigh less, up-front, but over time it will probably become increasingly attractive. It could easily turn out that the weight of these devices makes the initial delivered tonnage proposition unattractive or not substantially different than photovoltaics and batteries. The goal here is to get a second branch of human civilization up and running at full send, not to get lost in the minutia. However, we're operating in a severely resource-constrained environment that's not particularly amenable to low-efficiency or excessive weight, so we need to work out the details of a simple, but as-efficient-as-we-can-reasonably-make-it, system for powering land-based vehicles. Apart from arriving / departing rockets or weather balloons, I don't see aerial transportation as particularly promising. Unfortunately, there are no waterways available and no railways nor roadways. Absolutely everything has to be created from scratch, something that's never been done using solar panels and batteries. It's just magnificent desolation, same as the surface of the moon, but it's there for the taking.

Irrespective of the vehicle power system that makes the most sense, if we have to make rocket fuel, this is our power system:

Sandia’s NSTTF facilitates ground-breaking experiments this summer

Gen 3 Particle Pilot Plant (G3P3)

National Solar Thermal Test Facility

Advanced Energy Conversion - sCO2 Recompression Closed Brayton Cycle (RCBC)

Sandia's been working on CSP since 1978 (picture): Sandia Labs Concentrated Solar Power

Whether you know it or accept it or not, powering real construction equipment and making rocket fuel means operating a small scale power plant on another planet; and to be frank, you won't even have the seed corn power to get started without small nuclear reactors; any greater expansion plans will always be hampered by energy poverty without them, and technologically advanced human civilization didn't spring forth from a state of energy poverty; when the US military deploys a major weapon system, they consider every nut / bolt / screw / scrap of information about designing / fabricating / transporting / training to operate it- it's a head-to-tail logistical train that encompasses the sum total of human knowledge, from first principles to an end result that gives all sane and rational actors pause before they consider the likely outcome of attacking us, plus we have an institutionalized national policy of never allowing ourselves to be taken by technological surprise; long story short, this is the mentality you need to have when you consider living on another planet in a serious way:

Similarly, I don't know enough about how temperature affects Lithium-ion cell performance. Presumably, your "ask" for 8 hours of continuous power suitable for heavy construction equipment is so that a construction equipment operator can run a bulldozer / grader / steamroller / backhoe / trencher / tunnel boring machine / whatever from 9AM to 5PM, refuel or recharge it overnight, and then get up the next morning to repeat that process, until whatever construction task the base manager or corporate entity wanted completed, has been completed. That's how we normally run construction projects here on Earth, so I presume the same will apply on Mars. While we do perform some construction activities at night, that's not normative and it is inherently more dangerous, even if everyone is rolling around in an armored vehicle.

I do know from personal experience that operating Lithium-ion batteries on a cold day substantially diminishes available capacity and if you make a habit of discharging 100% of a Lithium-ion battery's available capacity, it won't last very long. The newest cells are remarkably better than the cells we had 10 years ago, but there are limits to every available technology. It would be unreasonable to believe that an environment as cold as Mars would have no effect on the usability of a battery pack stored outside, mounted within an off-road vehicle, for its entire service life.

I omitted some critical info that I don't have regarding the weight and thermal efficiency of the Printed Circuit Heat Exchanger (PCHE) and Variable Frequency Generator (VFG), along with the solid state switching equipment that VFGs require. For instance, going from, say, 90% thermal efficiency to 95% thermal efficiency can roughly double the mass / volume of the PCHE used. That's why I used such a generous mass estimate for the SCCO2 power pack. I'm also aware that VFG manufacturers often list the maximum output their equipment is capable of, rather than maximum continuous output. That may or may not be a severe issue in a land vehicle application, dependent upon how it's actually used. Maximum power may be demanded for a few seconds to get a vehicle moving, but moving an armored vehicle at maximum speed typically requires maximum power output. Even so, the T-55 example is grossly over-powered for a 0.38% Earth-gravity environment, relative to its Earth-bound diesel powered cousin. As always, caveat emptor.

In any event, none of that materially changes my overall point regarding the intractable issues related to the mass and volume of the Lithium-ion battery solution. The energy density is at least an order of magnitude lower than LOX/LCO. Overcoming that issue with much greater total efficiency is still nearly impossible. As it turns out, power laws are quite powerful. Similarly, on account of how energy dense nuclear fuel is, if it was ever practical to power a land-based vehicle using fission, over time it would be utterly impossible to overcome that advantage using a combustion engine of any kind, never mind solar-powered batteries, even though the nuclear reactor would undoubtedly be much heavier on account of shielding and radiator mass. If you must double your continuous output capability using batteries, then you must also double your battery weight and volume. While the same also applies to chemical and nuclear fuels, recall how those order of magnitude energy density improvements make the added weight far more tolerable. For every 1.5kg of LOX/LCO, you get 2.8kWh of thermal output. For every 1.5kg of Tesla 4680 battery pack, you get 450Wh of output. Even if you only receive 1.4kWe from that 2.8kWt worth of input power, you still get more than 3 times as much power output, so the battery energy density would have to improve to that of those impractical Aluminum-Air batteries in order to achieve mass parity. That's at the battery pack-level, BTW, so your individual cells must have an energy density greater than the 1,400Wh/kg provided by LOX/LCO. As the name suggests, Aluminum-Air actually requires O2 from the atmosphere, so you still need a LOX bottle to provide power, but humans need LOX as well, irrespective of the power provisioning solution. Anyway, consider this problem the "tyranny of the order of magnitude energy density improvement equation", which doesn't sound nearly as cool as the "tyranny of the rocket equation". If the requirement is to continuously produce a given amount of power output from a system with minimal weight and volume, then it won't be a current technology Lithium-ion battery.

While gravity and aerodynamic drag are clearly far less of an issue on Mars, the mass (weight of the batteries that must be shipped to Mars from Earth) and volume (vehicle interior space claim, if the battery is used to power a purpose-built tracked off-road transport or construction vehicle that provides generous interior volume "under armor"- in this case, it's radiation and thermal protection "armor" for the subsystems and occupants, rather than ballistic protection). I presumed that we won't be mounting Lithium-ion battery packs externally on the sides or top of the vehicle, exposed to the elements, where there is the potential to damage them from driving accidents, since we never do that here on Earth. For a given weight and interior volume while providing equivalent off-road mobility, the increased chassis and suspension weight of wheeled vehicles reduces the available payload weight ("volume under armor") allowance by about 28%. That's what the US Army studies indicate, and "fresh eyes" continually arrive at that same conclusion over and over again, every 5 to 10 years or so. It's a popular War College study subject for Army Officers. If we're still absolutely dead set on battery-powered off-road vehicles, then we absolutely must have that additional 28%, which is one reason that tracked vehicles are so much more practical on a planet with no roads and exceptionally rough and sandy terrain, the other reasons being traction / ground pressure / center-of-gravity / payload capability. To reiterate, it's less of a problem on Mars than on Earth, thanks to the dramatic gravity and aerodynamic drag reductions, but if you want two vehicles to perform equivalently at a given weight and volume, then even our LOX/LCO "poor man's AGT-1500" powered "main battle bulldozer" ![]() performs much better with a gas turbine engine and chemical fuels than batteries. If weight is not a problem, then the total "well-to-wheels" efficiency of batteries is much better

performs much better with a gas turbine engine and chemical fuels than batteries. If weight is not a problem, then the total "well-to-wheels" efficiency of batteries is much better ![]() . Thus far, the most significant problem seems to be delivering significant payload tonnage to Mars and the extreme cost of delivering anything to Mars.

. Thus far, the most significant problem seems to be delivering significant payload tonnage to Mars and the extreme cost of delivering anything to Mars.

I computed the gross thermal power requirement to produce 250kWe at 50% thermal-to-mechanical power conversion efficiency (there are other ways to increase this efficiency figure beyond 50% without dramatic weight gains, such as exhaust gas recirculation), which dictates 750C turbine inlet temperatures. That's running right at the edge of what Inconel alloys can tolerate without unacceptable oxidation rates. I didn't compute how much power would actually be required from this setup since I don't have the required manufacturer's data pertaining to the electrical efficiency of the Variable Frequency Generator, so more total stored chemical energy to produce thermal power would be required to produce the total mechanical output required for the VFG's to actually produce 250kWe. Even if it's only 75% as I've seen suggested, that still wouldn't alter the math in favor of batteries, nor would it even be reasonably close in terms of total power subsystem weight / volume. I don't have the data on the maximum continuous output rating for the Hamilton Sundstrand 250kVA generators, either. That might be proprietary information, but it really shouldn't be since plenty of Boeing 787s rely upon those devices to produce ship's electrical power. Often times the maximum output is not the same as the maximum continuous output, on account of excessive heating of the starter-generator or switching circuitry limitations. If I can find this information, then I will post corrected figures that illustrate as close an approximation to a realistic setup as I can. In the real world, everything consumes more power and weighs more than textbook math would suggest.

Regarding the Tesla 4680 Lithium-ion batteries, I was also overly-generous in that I only accounted for the weight and volume of the batteries themselves, and used battery pack level energy density that has yet to be achieved. The overall pack level energy density is sitting at 247Wh/kg, but Sandy Munro says Tesla can achieve 300Wh/kg at the pack level and I trust his math skills. The 4680 cells will, according to Tesla, hurt volumetric energy density at the pack level by about 9% over their 2170 cells (the 2170 cells used in the Model 3 are 711Wh/L, again, for the cells themselves), but gravimetric energy density is improved by about 16% at the pack level (because more of the battery weight is jelly roll, rather than stainless steel containment can) and the total number of cells in the battery pack is substantially reduced (Sandy made a full scale mockup of a Model 3 battery pack and there's a video on YouTube, so Google it for all the gory details), manufacture is substantially simplified and therefore cheaper, the use of expensive specialty metals such as Cobalt is reduced or eliminated entirely, and most importantly and germane to these discussions, cooling of the cell is drastically improved (you cool Lithium-ion batteries from their ends).

Going back to the idea of using thermal power and batteries, Aluminum-Air batteries have already demonstrated 1,300Wh/kg and some new Aluminum-Air flow battery in development at Ulsan National Institute of Technology is touting 2,500Wh/kg. The Aluminum is recycled after using it, meaning another 10kWh/kg to 12kWh/kg is required to remove the oxidation from the pure Aluminum metal, but it's essentially sheets of porous Aluminum in a box that O2 flows through and oxidizes to produce electricity. It very closely resembles a fuel cell stack- it's sealed and bolted together in the exact same way as a PEM fuel cell. The Aluminum sheets are replaced after oxidation / use with new ones, but in theory that can be done forever. So... What if we used the fresnel lens to smelt Aluminum that we bring with us. That way, we only need to collect and store LOX. We'd still need LOX/LCO for rocket propellant, though. Something tells me this is unlikely to be better than LOX/LCO, given how much input thermal power is required to produce Aluminum from Aluminum Oxide, but it would be far easier to work with than LCO and it has greater energy density than gasoline in a prototypical combustion engine. I don't know what the complete battery pack would weigh, but 800kg of Aluminum satisfies the electrical power requirement and only requires a LOX bottle that has to be onboard anyway. The UNIST flow battery uses a Silver-Manganese catalyst and their battery supposedly has 17 times the discharge capability of traditional Aluminum-Air batteries like the kind Alcoa and Israel developed, so providing bursts of power to rip boulders out of the ground would be no problem at all. Still, 800kg is a lot of Aluminum to smelt every day for 2MWh worth of power, plus whatever O2 is required. We would need a machine for automated assembly of the batteries.

A novel catalyst for high-energy aluminum-air flow batteries

Merely thinking out loud here:

A Lithium-ion battery recharge requires 2MWh per day, but you need at least double the capacity for acceptable cell service life, plus night reserve power to keep the battery warm during recharging. You need another 4MWh stationary battery connected to the photovoltaic farm, in order to supply the power for recharging, so now we need a combined battery mass equal to at least half the weight of a equipment. The Aluminum smelting process would add another 9.6MWh. I've no clue what would be needed to reprocess the catalyst. We still need to figure out what the minimum thermodynamic requirement is to split CO2 into CO and O2, then add an inefficiency factor using known processes. If the mass of one or the other of these solutions happens to be substantially better than the others, then that's the solution until shipping things to Mars gets a lot cheaper and easier. There's an alternative to the Hall-Heroult process, carbothermic reduction of alumina, but that requires an electric arc furnace, very tight process control, and is NOT simple or easy to do.

Offline

Like button can go here

#56 2020-12-25 06:35:49

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,479

Re: Battery power construction equipment

For kbd512 re Post #55

Nice gift to the forum, to find "under the tree" this particular morning on Earth, for some folks!

SearchTerm:Electrical powered construction equipment - materials - practices - constraints

(th)

Offline

Like button can go here

#57 2020-12-25 18:29:54

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,924

Re: Battery power construction equipment

And with it what fuels to make use of in an ICE engine....and not really a battery powered piece of equipment as it requires a generator engine to make the battery power on the same vehicle like a hybrid....where when the load drive is required we are using the engines torque and when we are looking at economy we are using battery....

Offline

Like button can go here

#58 2020-12-29 07:21:31

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,479

Re: Battery power construction equipment

This post is a duplicate of one created in the Internal Combustion engines topic ...

There are arguments made in this topic that all-electric design is superior to an IC design for construction equipment on Mars.

I'd ** really ** like to see an all-electric version of the vehicle kbd512 described here:

For kbd512 re #83 of IC topic ...

I ** like ** it ... The system ** should ** work:

a) On Mars or the Moon, both of which are going to need plenty of regolith movment

b) With remote control by human operators or potentially by AI operators when the reach that stage of developmentSearchTerm:TankChassis Bulldozer design for Mars or Moon

http://newmars.com/forums/viewtopic.php … 70#p175370

Can I invite you to develop your ideas a bit further? What I'm looking for is an outline of how vehicles like this might be manufactured ON the Moon or Mars, using indigenous materials?

For quite some time, it seems to me humans are going to need to bring their own energy supplies, so for discussion, let's assume nuclear reactors are available to provide power.

A bootstrap operation to build vehicles like the one you've described in a continuous flow would need to arrive on site with some minimal set of equipment and capability.

I'm planning to create a post in the Electric topic, to see if I can encourage someone to take your concept and run with it there.

Nice work!

The volume that will be needed for fuel and oxidizer can be allocated to batteries in this topic.

What I'm looking for is details of motor size and power output needed for the application, which can be extended to battery sizing for a eight hour shift of typical bulldozer duty, which includes backing up and positioning without a load, as well as pushing regolith.

A battery powered bulldozer will be something to see! I'm inviting someone with passion for electric power to take this on.

(th)

Offline

Like button can go here

#59 2020-12-29 08:07:24

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Re: Battery power construction equipment

tahanson43206,

I have a better idea that still uses batteries, but not ones mounted in the bulldozer at all times. Many armored vehicles have swing-out rails that the engine is mounted to, so that field engine swaps can be accomplished in a relatively short period of time. Some of these systems are so slick that crew members can remove a power pack in 15 minutes or less using the swing-out rails and a hand crane mounted to the vehicle. The 500kWh battery would only occupy 1 cubic meter or so, provided we had some kind of quick-detach radiator panel and LCO2 coolant lines. The idea is that the battery comes straight out the back of the vehicle, LCO2 coolant lines are detached, and the empty battery merely sits on the ground, connected to a charging cable near the construction site, a very long extension cord back to the nuclear reactor farm.

We take the weight of batteries we really need to the construction site (14t or so), but then only have a single 500kWh (1,666kg) battery in the vehicle at one time?

We could skip LOX/LCO and most of the excess batteries by using a power cable that directly connects the construction equipment batteries (the ones that are not in the vehicle) to a stationary nuclear power source. That would drastically reduce the continuous power requirements. A bespoke KiloPower reactor could feasibly supply up to 20kWe, so 10 such reactors could recharge a battery every 2.5 hours. That would negate the extreme power production and storage requirements for a consumable O/F combo and the crushing weight and space claim of 4MWh worth of batteries. At 50% DoD, we could expect reasonably good service life from the batteries and they'd always be on the charger if they weren't in the vehicle, which takes care of keeping them warm at night. We can't really go too far from base to explore, but at least we can actually build a base with a practical piece of equipment, which is still fairly important if we want a million people to live there.

Offline

Like button can go here

#60 2020-12-29 08:36:43

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,479

Re: Battery power construction equipment

For kbd512 re #59

Thanks for adapting your idea for the tracked dozer to the Electric topic.

Can you (would you?) develop your ideas for the LCO2 coolant a bit? I'm presuming the CO2 will become a gas while it is cooling the batteries. How would the life cycle of a CO2 molecule look in this situation. I was planning to ask SpaceNut a similar question in the IC topic. He had proposed saving CO2 after it is exhaust from the IC engine.

In this case, I'm assuming you've loaded up the LCO2 tanks at the same time as you've replaced the battery, and the vehicle goes back to work.

What happens to the LCO2 ? One option is that it is simply exhausted to the atmosphere after it becomes a gas, but perhaps not?

(th)

Offline

Like button can go here

#61 2020-12-29 10:12:02

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,924

Re: Battery power construction equipment

If you vehicle is unmanned just use a larger RTG....

What we have determined for mobile equipment is a hybrid is required for use. One to generate power for torque and the other for life support functions as well as lower torque required movement. Like all hybrids we start with electrical until we need movement or recharging of the power system.

(th) Battery cooling is bad for the batteries they need to be kept warm...with no large temperature variances with any cooling needed is to lower temperatures due to over heating as its more like a vent to allow cold mars air inside.

Offline

Like button can go here

#62 2020-12-29 12:01:47

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,479

Re: Battery power construction equipment

For SpaceNut re #61

Thanks for giving the Battery topic a boost .... you've raised an interesting question, that I hope kbd512 will take up.

Kbd512's design features liquid CO2 for cooling, but it may have been for cooling the electrical motors? I'm not sure.

On the other hand, perhaps heavy current draw heats up batteries so them must be cooled!

Hopefully kbd512 will clarify that point!

(th)

Offline

Like button can go here

#63 2020-12-29 14:51:16

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Re: Battery power construction equipment

tahanson43206,

LCO2 won't become a gas if it's suitably pressurized. We store LCO2 at room temperature on Earth all the time. Anyway, we would have quick-detach coolant lines that connect the battery to a large radiator integrated into the deck of the vehicle. A small amount of CO2 would escape whenever the lines were detached for battery swaps, but the LCO2 would either stay inside cooling channels in the battery housing or inside the radiator, with a small tank carried in the vehicle to top-up the system immediately after a battery swap. I'm reasonably sure this can be done since A/C technicians do this every day when recharging refrigerant lines. This is a closed-loop system with a small coolant pump, in case the point isn't clear. It's a more sturdily constructed Tesla battery pack that uses a coolant that doesn't freeze and shouldn't corrode the metal. CO2 is in common use as a refrigerant here on Earth and should work equally well on Mars.

All the batteries are arranged into this proposed "battery block", an Aluminum cube with LCO2 coolant bores and stud holes gun drilled through individual plates that comprise the interior of the block. The shell for this block would be carved out of 5083 and the cell holder plates arranged inside the shell. That way, there's a single large sealing surface on one side of the cube. The 80mm thick Aluminum plates (same height as the 4680 batteries, mostly empty space with 46mm holes drilled into it for inserting the batteries at that, kinda like a super-sized metal version of the plastic cartridge holder that shooters use on a range to neatly arrange their cartridges) are then bolted together internally using a series of ~1m long studs that permit proper sealing of the device. The plates are both electrically and thermally conductive, so additional electrical connections are not required. LCO2 will be the coolant of choice for the SCCO2 gas turbines connected to our "bespoke" KiloPower nuclear reactors, batteries, electric motors, power conversion electronics, as well as a pneumatic gas for vehicle suspension systems. The reactors will replenish the LCO2 from atmospheric CO2, as required.

CO2 exhaust from an ICE can be collected in a zeolite bed and recompressed to feed it back into the engine, which requires more power, but does not represent a major impact on vehicle weight. In fact, CO2 could be recirculated into the engine to provide the requisite O2 diluent gas / working fluid for combustion to expand, negating the requirement for most of the onboard CO2 storage.

Offline

Like button can go here

#64 2020-12-29 15:01:11

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Re: Battery power construction equipment

SpaceNut,

This is a crewed vehicle intended to be a durable bulldozer, meaning a piece of construction equipment with a 25 year service life.

The cold Mars air is nearly useless for providing adequate cooling at 6mb of pressure at Mars sea level, as compared to 1013mb at Earth sea level. In the summer, it can reach room temperature near the equator. Radiative cooling at very low speeds still dominates at such atmospheric pressures. Achieving significant cooling through convection would require very high fan speeds and/or very large fans.

Offline

Like button can go here

#65 2020-12-30 13:38:12

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Re: Battery power construction equipment

tahanson43206,

I have a second thought on the batteries. A few models of Saft's space-rated Lithium-ion batteries are similar to Tesla / Panasonic 4680 cells (46mm D x 80mm L), but they're much longer (54mm D x 222mm L). Saft also achieved greater energy density by increasing the size of the jelly roll. Anyway, instead of having multiple Aluminum plates, we would have a single block of 5083 with gun drilled CO2 passages to transport heat from the batteries to the end plates. Perhaps we could provide enough radiator plate surface area to negate the requirement for a separate radiator panel on the top deck of the vehicle. That would make removal a simple matter of rolling the depleted battery off the vehicle rails, dropping it onto the ground, no cranes or tools required.

Heat to keep the battery packs warm at night could be supplied by sealed molten salt cells inside a few of the battery block bore holes. Each molten salt thermal power storage cell would contain an integrated Tungsten electrode to re-heat the salt and a pass-through tube to transfer thermal energy into the battery pack using simple thermostat-operated check valves that begin circulating the CO2 through the thermal power transfer cells whenever the temperature drops below a critical level. Similarly, another series of check valves would stop circulating CO2 through that portion of the block when the temperature rises above a critical level. The temperature delta should be enough to circulate warmer CO2 through the block. This is not a fully developed idea, but essentially the flow path of the CO2 would be changed using the check valves to push more LCO2 through the core of the block and less through the end plates that radiate excess heat into the surrounding environment. I know these features will weigh more than simple heating electrodes, but the objective is to retain as much electrical energy as practical for the vehicle to use, not to simultaneously discharge the battery while trying to recharge it at night. Either way, the general idea is to implement a completely passive thermal regulation system system that does not require electronic temperature sensors, pumping power supplied by electric motors, or more control electronics.

I would much rather have purpose-built charge / discharge control electronics that are not built into the battery pack itself. Actually, I'm not describing this the right way. Every cell needs a current limiter and voltage regulator, but I don't want a bunch of cheap tack-welded circuit boards inside the pack, because that's an invitation to failure. In short, the power electronics for individual cell regulation are going to be sealed replaceable units (hockey pucks) held in place with spring pressure over the top of one of the battery terminals, in order that individual battery cells and individual voltage regulation electronics can be replaced through simple pack disassembly. The pressurized LCO2 will be contained inside sealed channels within the battery block using a charging port to replenish any LCO2 lost over time. You'll have to purge the LCO2 to service the battery cells / voltage and current regulation pucks / thermal heater cells inside the block, but that shouldn't happen very often. The radiator plates will be bolted to the ends of the block and Viton O-rings will seal the LCO2 channels passing through the radiator plates and block core.

The sides of the block will have rows of roller rails mounted to them to, to assist with inserting the battery pack into the front end (personnel carriers) or rear end (construction equipment) of the vehicle. As the pack is removed from the vehicle, the spring-loaded lower rail arms swing down so the pack can simply be dumped on the ground, at the correct height for re-insertion into the vehicle after it's recharged. When a pack is removed from the vehicle, the power supply cable from the KiloPower reactor will be removed from the battery pack it's charging, plugged into a service port on the vehicle, and used to maneuver the vehicle towards the replacement battery pack.

So, picture a construction site wherein there's a piece of construction equipment with a depleted battery pack and a power cable / extension cord run from the reactor farm to 3 other identical 500kWh battery packs per vehicle, laying on the ground. The depleted pack is removed from the vehicle, it sits exactly where you left it, the power cable is removed from one of the other three packs with the highest state of charge, the power cable is plugged into the vehicle to supply power to maneuver the vehicle into place to load the recharged battery pack into the rear end of the vehicle, after the fresh pack is loaded into place the operator removes the power cable, places the cable into the charge port for the depleted battery, and then drives away with the new battery pack. Basically, the entire front or rear end of these tracked vehicles is a giant slot for the 500kWh batter pack to occupy, between the vehicle's tracks and electric drive motors, where that spring-loaded rail-equipped battery pack can slide up and onto the rollers so it can be locked into place. Otherwise, you need additional tools like cranes to insert or remove the batter packs, so rails and rollers seemed like a better option. I've seen this system used to remove very heavy servers from server racks, as well as safe drawers or file cabinet drawers that would otherwise require multiple people to pick up. Granted, it generally works best on firm and level ground. Perhaps we'll need charging pads for the batteries to facilitate replacement, but a simple block of 5083 Aluminum plate should suffice. We can mill it out on the bottom in order to minimize its weight. If each 500kWh pack weighs 1,750kg on Earth, but only 665kg on Mars, which approximates the weight of a heavy commercial grade gun safe. Alternatively, I guess we could mount the rollers on the battery pack and leave the rails inside the vehicle. Maybe that would work better.

Offline

Like button can go here

#66 2020-12-30 14:46:28

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,924

Re: Battery power construction equipment

You have described a 3 contact battery where at the plus end we have an isolated contact to charge which is at a minimum 5 volts give or take to the charging circuit with a current controller that limits the output to 4.2volts to make contact to the plus connection of the battery with the battery output plus being the nominal volt of 3.7v per cell. with a either a dual contact ground pad for the support interface for charging and for tying them together in series or parallels depending on configuration. The circuit in the battery charging section would have a FET or other device set to disconnect the terminal from output when charging.

Here is such a device with a standard mini usb connection for charging but it lacks the internal disconnect and must be removed from the intended use product.

Even a battery pack for a laptop contains balancing cell circuitry with in the unit....

Offline

Like button can go here

#67 2021-01-07 19:02:09

- Void

- Member

- Registered: 2011-12-29

- Posts: 9,084

Re: Battery power construction equipment

I have a small concern about the soil of Mars. The mole of the insight lander does not appear to be able to dig. Instead it appears to pack the soil below it.

It is said by some that the iron oxide in the soil can allow a sort of brick to be made just by compressing it.

So, I have no answers, but thought it might be mentioned that any earth moving equipment may need to be able to deal with that situation if it really exists.

Done.

Is it possible that the root of political science claims is to produce white collar jobs for people who paid for an education and do not want a real job?

Offline

Like button can go here

#68 2021-01-07 19:50:48

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,924

Re: Battery power construction equipment

I think that what Void has brought up needs to be explored more with a shovel backhoe device larger than the one used on the Polar lander Phoenix to be assured that we will not have a compacting problem as the Insight mole has seemed to have run into.

The lab experiments with simulant had indicated that a compressed brick was possible with a mixed soil that contained quite a bit of sulfur as a binding agent but thats in another topic.

Offline

Like button can go here

#69 2021-01-08 12:15:27

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Re: Battery power construction equipment

A piece of construction equipment with a 250kW motor will have no issue digging through the ground, however compacted it happens to be. At best, compacted regolith can slow the rate of overburden removal. I have no idea what the point was, regarding that goofy "mole" apparatus that NASA came up with.

Offline

Like button can go here

#70 2021-01-09 18:47:38

- Void

- Member

- Registered: 2011-12-29

- Posts: 9,084

Re: Battery power construction equipment

------

Well, lets see if I can get my head bit off ![]()

In a recent video, Dr. Robert Zubrin indicated that he though that Elon Musk would like to build 1 starship a day. Z, thinks that 1 a week might be the deal.

In any case he thinks that 9 out of 10 Starships should stay on Mars. In his vision, the cabins would be used for housing, and the rest of the ship might be canabalized for Stainless Steel.

And that left me wondering what about the Tesla Electric motors, and Battery packs?

I myself would think of sending 1 back to Earth, and modifying one as a sub-orbital hopper, or just keep it to go to orbit around Mars.

I also learned some useful things. If the heat shield problem from LEO is 8, then entering the Martian atmosphere from interplanetary space would be 6.5. Entering the Martian atmosphere from Martian orbit might be 4.0, on a scale of stress. That helps me see why perhaps going to Martian orbit prior to landing might not be the way to go.

If SpaceX does have one or more production lines on Earth for Starships, then I see the possibility that some might be used for lifting materials to LEO, a number of times, and then when it was felt that they were getting on in age, perhaps they would go on a one way trip to Mars with cargo. This might be cost effective, provided that the crash rate on Mars arrival was not too high.

I think that the above argues well for the notion that in the beginning Insitu would only be done where it pays off. Propellants, and perhaps construction materials.

I am satisfied that engines and battery packs from some of the starships could be placed into Tesla vehicles, and this would very likely delay the production of Insitu engines on Mars.

------

I will try for spell checking later.

Is it possible that the root of political science claims is to produce white collar jobs for people who paid for an education and do not want a real job?

Offline

Like button can go here

#71 2021-02-25 12:42:50

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,924

Re: Battery power construction equipment

To build a landing pad for starship we will need to have one of these due to time to build and volume of materials that need to be manufacture to create it.

My suggestion is to modify it into what we send as the carrier and make it part of the pieces to create it.

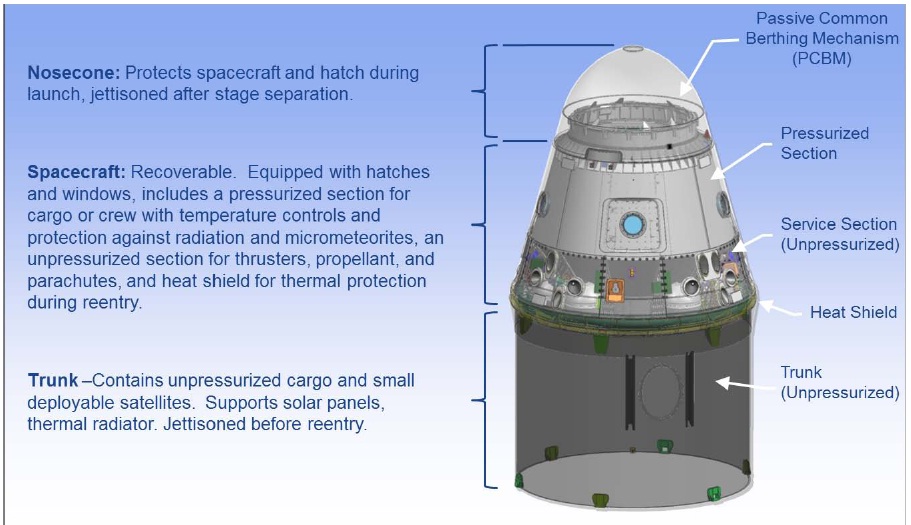

typical dragon layout of the internal diagram:

Use the pressure vessel as the mixer

Use the outer shell to make the cab for a crewman to operate it from

Make use of the payload to deliver the wheels like the rovers only larger but hatch-able, in hub electric motors, chasis pieces for the frame and a battery that will be needed to power it as the payload.

Offline

Like button can go here

#72 2021-05-19 18:08:41

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,924

Re: Battery power construction equipment

I was reminded of the construction needs for mars to have a heavy duty battery powered system for use. Such system in fork lifts are quite commonly in use https://www.hyster.com/en-us/north-america/ which have many offerings that would be quite useable.

They most likely have charger units as well for the electrical units that they have but a universal supply might be better for all of the battery powered equipment that we will want.

Offline

Like button can go here

#73 2021-05-28 13:07:07

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,924

Re: Battery power construction equipment

Keeping topics up to date with posts that occur elsewhere is a challenge at times but its worth doing so that we have more information to pool from.

Oldfart1939 wrote:I did a bit of research on the Bobcat website last night, and perhaps we should include 2 excavators (tracked backhoes). They're heavier and more bulky than the front loader Bobcat skid-steer units, but these would allow excavation of habitat shelter trenches more rapidly and effectively than front-loader units.

I see you're doing construction. Not just the first exploration/science mission, but construction. The Mars Homestead project assumed 12 crew to construct the first permanent human base. Yes, we believed a construction vehicle was required. I would like to make a suggestion.

This is a typical Bobcat skid-steer loader. There are various sizes. This one is S450. ("S" for skid) Rated Operating Capacity: 1,370lb. Operating weight: 5,370lb

The thing that makes it "skid-steer" is it's wheels. It's wheels don't turn, to steer the vehicle you turn the wheels on one side while wheels on the other do not turn. Or to pivot in place, turn wheels on the other side backward. This means the wheels literally "skid" across the ground as it's steering. Be advised: operating this on grass will tear up the grass. This works very well on pavement or hard or very firm ground. It doesn't work so well on loose soil/dirt/sand/gravel at an incline.

This is a typical Bobcat compact track loader. This one is T450. ("T" for track) ROC: 1,490lb. Operating weight: 6,424lb

Track vehicles work better on loose ground and inclines. The track provides more traction. I'm suggesting a compact track loader would be more appropriate for Mars.

An excavator can be compact. The first is E10, Rated Lift Capacity 527lb, Operating weight 2,593lb. The second is E20, RLC 1,098lb, Operating weight 4,306lb.

https://assets.bobcat.com/excavators/misc/r-series/bobcat-e10-nav_pm_list.jpg

Bobcat has become known for compact construction vehicles. Other brands manufacture competing vehicles: John Deere, Case, Caterpillar, New Holland, others.

Heavy Equipment Guide: Companies by Skid-Steer Loaders

Any vehicle would have to be customized for Mars. One suggestion I made was to manufacture the vehicle with titanium alloy instead of steel. Titanium has the same weight (mass), but greater strength. That allows making structural members like arms to lift the bucket thinner, so lighter. Hydraulics will have to be adjusted for extreme cold of Mars. And the engine can't breathe air, Mars has no oxygen. Well, practically none; not enough for combustion. When Robert Zubrin and David Baker proposed Mars Direct in 1990, they suggested using methane/oxygen because the ERV would need that for propellant anyway. Just make a bit more for the rover. But rather than using electricity to run ISPP, you could just operate the vehicle with electricity. At least one company specializes in electric conversion of Bobcat vehicles. And Bobcat themselves is working on all electric vehicles using lithium-ion batteries. They're even working on all electric actuators instead of hydraulics; intended for cold climates like Alaska.

Offline

Like button can go here

#74 2021-05-28 13:09:38

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,924

Re: Battery power construction equipment

Construction vehicles: battery electric makes good sense on Mars. You have choices of nuclear and solar for recharge. Hydraulic actuators generate more force for the weight than electric actuators, even today. You use an electric motor instead of shaft power to run the hydraulic pump, so that the rest is the same as here. As for hydraulic fluid in the cold of Mars, delete the hydrocarbon oil in favor of silicone oil. It goes a lot lower without gelling up.

Choice of materials: densities of aluminum are 0.10 lb/cu.in, titanium 0.17 lb/cu.in, and steel 0.28 lb/cu.in. Aluminum has the lowest strength range, titanium is similar in strength range to aluminum, and steel is much higher in its strength range, particularly the heat-treatable forms. You can work-form aluminum and steel, you cannot work-form alpha-phase titanium (and there is no stable beta-phase form). All these metals fatally embrittle in the cold, except 300-series stainless steel. The 300 series austenitic stainlesses are nonmagnetic, and non-heat-treatable (except to anneal-out work hardening).

GW

Protecting the battery since we will not have a garage will be the challenge to keep them from getting to cold when not in use...

Offline

Like button can go here