New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2020-08-15 01:18:37

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

What Does "A Better Design" Actually Mean?

We were discussing the use of tracks vs wheels for heavy off-road vehicles in another topic in the "Planetary Transportation" section of the forum and we chanced upon a conversation about the benefits of specific designs for specific uses, when we started talking about the relative merits or lack thereof, as it relates to the designs of various weapon systems. Rather than stray further off-topic there, I've started a new topic here and will re-post what I posted there here instead.

People who make sweeping statements like "the F-35 sucks" have little to no concept of what modern air warfare actually looks like.

1. Modern IR weapons, irrespective of which nation made them, are so highly lethal that any aircraft caught in its "no escape" envelope is as good as dead, with or without stealth technology. All pilot skill is in vain at that point. There's no such thing as any modern fighter jet "out-turning" an AIM-9X or ASRAAM or "take your pick of modern short-range IR-guided missile", for example, for as long as the missile is under power. Our British allies actually "got this more correct than nearly anyone else", with respect to how they approached short-range air-to-air missile design with their modern take on an existing US design from the Cold War era that lacked the electronics sophistication to complete the kill chain. Incidentally, our own weapons designers (Raytheon and Lockheed-Martin) are now making facsimiles of these "under power all the way to the target" type missiles that fly a little slower, yet retain the energy to maneuver after they close the distance. The "super fast" missiles can be "out-maneuvered" in certain cases because they blow through all of their propellant very quickly to achieve those eye-watering speeds.

2. Stealth technology means "get a lot closer to your enemy without the enemy fixing your position with the precision required to achieve a targeting solution". Yes, a WWII radar can "detect" a stealth aircraft... to within about 10 cubic miles of its actual position. Can you afford to fire a missile at every 50 cubic yards of 10 cubic miles worth of airspace and manage to hit much of anything but air? Can you afford to do that hundreds of times to kill each stealth fighter you "detect" with your WWII radar? No? Then your WWII radar isn't worth a hill of beans and people who spout off this nonsense know so little that we can safely ignore what they're claiming without understanding what's coming out of their mouths. When we say "stealth", we don't just mean stealth against radars, either. The IR and other signatures have been drastically reduced. And no, there's nothing you can do about that gigantic glowing hot tailpipe (part of the reason why modern IR weapons are so lethal- you can drop flares all day long, but modern missiles will completely ignore them; this still works against older less-sophisticated shoulder-fired weapons).

The radars that actually fit in the noses of aircraft and radar-guided SAMs or AIMs are absurdly too small to stuff a WWII radar into, so they always suffer detection range reduction from properly designed stealth features that require them to get right on top of a stealth aircraft to achieve a radar lock of sufficient precision for a targeting solution. That interrupts the kill chain in a massive way.

Q: Why in the hell is every nation with the resources developing their own stealth technology if it doesn't actually work?

A: Because it obviously does work and it works so well it's keeping people up at night.

Red Flag proved that the F-35 could and did absolutely massacre its opposition using only a few of the features packed into it and it was intentionally handicapped in significant ways to prevent pilots and air defense crews fighting against it from throwing up their hands and completely giving up. They also put very low time pilots in those F-35s because they weren't interested in determining what a skilled combat veteran could accomplish. You can think of the F-35 as a way to keep novice fighter pilots alive long enough to be able to fly and fight with anything against anything. Red Air (includes IADS and fighters) was killing half the Gen 4 fighters per mission prior to the F-35. They killed 2 or 3 F-35s in the entire game (many dozens of missions) through plain dumb luck (visual acquisition of the jet). If you can have less than 500 total flying hours to your name, almost no experience in air combat tactics, and still only get yourself killed through rare chance visual engagements, that's utterly amazing.

3. Fighter jets close on each other at 1,200mph or more. Merely seeing an enemy jet in perfectly clear skies in broad daylight requires eagle eyes. The number of seconds you have to find, identify, and engage is very fleeting. This is perhaps the least understood aspect of combat using jet aircraft. If you have a shoulder-launched IR-guided SAM, your engagement window is measured in low single digit seconds, even if the jet is just loitering at low altitude. Smart pilots negate this entirely by flying right at the edge of the threat's engagement envelope, made feasible by using stealth technology to prevent radar locks from far more powerful and lethal SAMs until the jet is so close that a radar is no longer required (because it's so close that you can see the jet with your own eyes). In most actual modern and historic air combat resulting in a kill, the pilot who was shot down was never aware that they were being engaged. That's what all those sensors and computers are intended to prevent from happening.

The protracted turning engagements of WWII are a really good way to get yourself killed in virtually any jet. Imagine someone on a horse with a lance going 600mph. He or she gets one pass at the target, and the target gets one pass at the pilot, and then the chance for either to re-engage requires a lot of time and/or fuel due to the sheer speed of the engagement. The last time any US fighter made an air-to-air gun kill was 1981 (the same year that the Cessna 172 I fly was made).

A better question to ask yourself would be, what is the F-35 and therefore what was it actually designed to do?

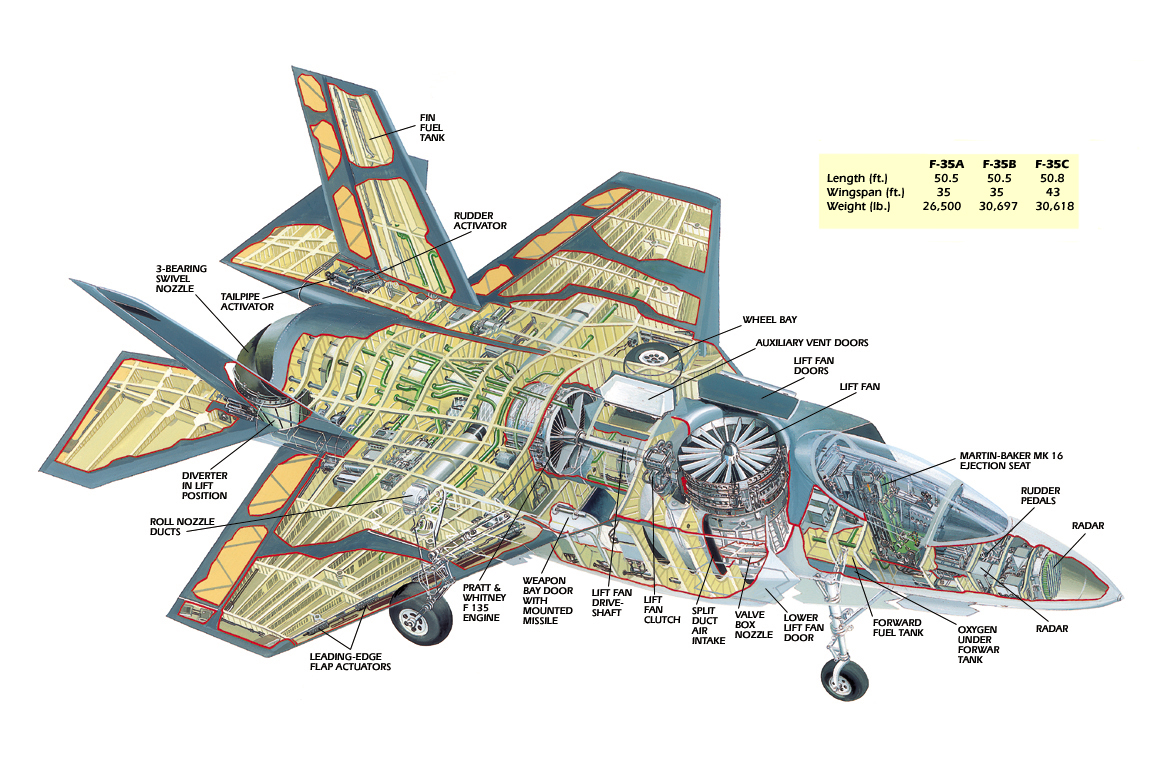

1. It's a flying super computer with extremely high resolution multi-spectral sensor fusion (overlay or correlation of IR / UV / radar / EW info and info from its data link to other friendly assets). It only tells the pilot what he or she needs to know in the next few seconds to minutes. In addition to being a radar, the radar itself is a powerful electronic warfare weapon that can be used to physically destroy enemy electronics. However, the plane doesn't even need to turn its radar on to advertise its position to the world when it can uses other radars from other platforms to locate targets, sneak up on them, and then kill them at point-blank range. The F-35's real supremacy is in the quality and quantity of its sensors and computers and software. It's real "trick" is only telling the pilot what's most pertinent. An enemy jet 100+ miles away is not a threat and can be ignored, whereas an enemy jet 2 miles away is far more likely to be a serious problem.

2. It's a flying gas can. It carries more internal fuel than any other fighter of a similar weight class, and many much heavier fighters. In air combat, missions are frequently cut short due to lack of fuel. The F-35 is absolutely numero uno in this department. Yes a handful of twin engined fighters carry more, but they also have to feed 2 big thirsty turbofans vs 1 big thirsty turbofan. Once you load up a Eurofighter or Rafale or Super Hornet or Falcon or Eagle or Sukhoi with enough drop tank gas to make it to the target and back, the kinematics are terrible and they no longer look nearly so impressive as the models they fly at airshow where absolutely everything non-essential to "putting on a good show" has been removed from the jet. From Red Flag, the wings of the Sukhoi jets were determined to function as giant air brakes in any type of protracted turning engagement with an Eagle or Rafale or F-22. They slowed down so fast that they were literally falling out of the sky. So yes, they're very impressive at low speeds at airshows when stripped of everything combat-related, but they also bleed energy like crazy at high subsonic speeds where all real air combat occurs. Still dangerous? You bet. It's still a good jet, but it's also a dated airframe design with limitations inherent to that design (same basic wing design as the Falcon and Hornet / Super Hornet). The Eurofighter and Rafale are much better designs for sustained turning performance, not that you ever want to rely on superior skill in dogfighting to kill your enemies. The net net of the situation is that air show performance is an idiotic way to judge combat performance. A Cessna 172 like the one I fly will out-turn a F-16 (and any other fighter jet for that matter) every single time, but that doesn't make them suitable for air combat with jets 10 times as fast that can carry individual pieces of ordnance that weigh more than the fully loaded Cessna does.

The notion that the F-35 doesn't "turn as well as other fighters" is pure unmitigated BS. Make the range equivalent by adding enough drop tank gas to the Gen 4 fighters and then see which one turns better (because that's how you actually fight in real life combat missions). In real combat, Eurofighters / Rafales / Super Hornets / Falcons / Eagles / Grippens / Sukhois carry drop tanks because they'd be all but useless without them for prototypical missions. The F-35 is a lifting body design, which is why the "wings can be tiny", yet it still delivers better kinematics than a F-16 with equivalent load out (turns every bit as tight with the prior software restrictions removed, but accelerates a lot faster / "gains energy back faster" when you come out of a turn). No, the kinematics aren't quite as good as a F-22, but they're still pretty darned close and the F-35 costs a lot less than the F-22, but with even better situational awareness than the F-22 and a lot less maintenance to remain stealthy. The F-22 is a single mission plane, though it does interceptions of 1950's era turboprop-powered Russian bombers with "more style" than anything else. The F-35 does everything else except CAS. Furthermore, it's not some WWI era man vs man aerial duel. It's the entire allied air combat apparatus against the entire enemy air combat apparatus and the allies always seem to win those wars.

3. It's a small to medium sized weapon dispenser that carries serious tonnage externally for Week #2 of the war. Yes, it can "only" carry a pair of 2,000 pound bombs internally. It doesn't matter how many weapons you can carry if the enemy air defenses can see you coming from hundreds of miles away- that's functionally a "suicide mission", not a major contribution to the war effort. However, it can carry a dozen or more smaller weapons. In modern combat, dropping 2,000 pounders is reserved for very large and well fortified fixed targets that are far away from civilians and friendly troops. There simply aren't many of those on a modern battlefield to attack. More often than not, allied troops or civilians are within a football field of your target. If there are lots of those targets, then a stealth bomber is a more appropriate weapon to use. That said, our bombs are so accurate we can literally "put warheads on foreheads", by which I mean a jet flying at 25,000 feet can drop a bomb the size of a 155mm artillery shell that can literally hit a moving human being in the face from 20+ miles away (if you put a basketball on the ground somewhere, it would physically strike the basketball before the warhead explodes). We now have missiles that have kitchen knives mounted on them instead of warheads because they're so accurate that they literally hit the single human being they're aimed at and yes, these have already been used to kill individual terrorists in crowds of people. Do you really need a "bigger bomb" to make the body parts fly a little further or do you need dozens of tiny weapons that can kill any mobile target short of a tank and "mission kill" a tank by destroying its optics and radio antenna or gun barrel?

On Week #2 of the war, whereupon there's nothing left to speak of in the way of enemy air defenses, the pylons are brought out and the F-35 can carry 18,000 pounds of ordnance. That's nearly identical to or more than any other heavy twin engined fighter jet except a Sukhoi or Strike Eagle (but remember that these will also be carrying 2 or 3 drop tanks to provide equivalent range) and 2,000 pounds more than the A-10.

4. It's a quarterback for the allied air combat team. It can direct other weapons and sensors onto targets so that other aircraft or artillery units can kill whatever it finds without ever directly using active radar sweeps or firing a shot at the target. If you found a large formation of troops in the open by chance, but lacked appropriate weapons, then if you could instantly send the target coordinates to an artillery unit, it doesn't matter to the enemy that you "only" had air-to-air weapons onboard. Sure, this same capability could also be retrofitted to Gen 4 jets, provided we completely revamp their entire avionics suites. Think that'd be cheap?

5. It's a means to hold enemy assets at risk, irrespective of how sophisticated their defensive measures are or where they're located in the world. Even a Russian military expert admitted on camera that the F-35 was an astoundingly good aircraft for what it was actually intended to do- meaning, everything that the F-22 and A-10 or other similar Cold War era jets can't do.

But yes, there's still such a thing as an appropriate weapon for the job and contrary to the opinion of former President Obama's Defense Secretary, a F-22 is NOT an appropriate weapon to use to go after Somali pirates.

We frequently pay tidy sums of money for capabilities we seldom use because we have to fight someone with our level of sophistication for the capability to actually be used to begin with. Apart from a country like Russia or China, it's physically impossible for any other potential adversary to have the requisite level of sophistication because they lack the money / people / industrial base to be any significant threat. I just wish an extra $20B from our defense budget could go to a worthy cause like space exploration and Mars colonization. The Defense Department probably has that kind of chump change (to them) rattling around in the seat cushions somewhere. We now have more than 600 stealth fighters and bombers. Russia and China have a whole 4 squadrons of stealth aircraft between them and they're not true stealth aircraft. Something doesn't quite add up there. The entire economy of Russia is less than that of California and China still can't produce a jet engine that lasts half as long as our fighter jet engines. My SWAG is that any conventional air war would be over in less than a month.

Last edited by kbd512 (2020-08-15 01:20:16)

Offline

Like button can go here

#2 2020-08-15 14:32:46

- SeaDragon

- Banned

- From: Merry Old England

- Registered: 2020-07-25

- Posts: 32

Re: What Does "A Better Design" Actually Mean?

What makes a better design?

I'll focus here on the related question "what makes good design?", the distinction being purely that the former presupposes comparison while the latter also concerns those traits not including direct comparison found in the process of making something new. This is a question very deeply linked to everything we're trying to do with the Mars Colonisation movement. The traps that are commonly fallen into on this subject have previously led to the waste of enormous resources and life on technologies that gave the appearance of effectiveness while failing to deliver in practice. After the fact the distinction between good and bad design is obvious - my post here is intended to share my personal thoughts on the difficult and unforgiving task of identifying good design before the machine has been tested in its actual intended environment of use, hopefully even before construction begins. That's all it is though: "the F-35 sucks" was an unprofessionally colloquial and pejorative statement meant in jest, I appreciate that it's possible to have different opinions about anything so complicated, I hope my opinions here can help our efforts but I mean no offense by any of them. With that said:

The fallacy of system capability

Not only is it very possible to have very high performance technology appearing in bad designs I think it's a tell-tale sign of them. The Space Shuttle had a contender for the most sophisticated rocket engines in history by many metrics including number of components, excellent thrust to weight ratio and exhaust velocity. It is a notoriously bad design. The intended goal of the Shuttle (as originally sold) was easy access to space not to provide a high engine exhaust velocity. The bid to make the Shuttle reusable and as close to single stage as possible was to make it cheaper rather than having reusability as an end goal in itself. Low cost was the intended goal but the Shuttle's many cutting edge features served to massively increase the unit cost and refurbishment cost after each launch. It's my position that arguments working along the line of "The Shuttle is a good design because it uses state-of-the-art materials" or "because it has the best avionics" etc. is missing the point even if it's true that those things are useful on a rocket. It's easy to get good performance compared to alternatives when you have a resource and technology advantage over your competitors. With a hundred times my budget I'm sure anyone could colonise Mars quicker and more effectively than me. Commissioner Gordon in the popular movie The Dark Knight says it best:

"I'm not paid to be an idealist; I do the best I can with what I have."

In that vein, good design requires making the best use of what you have available to achieve your actual goals.

Good design is about sacrifice

When you have superfluous capabilities to trade it's suddenly possible to purchase more of what you want for costs you can afford: the A-10 doesn't need a high top speed or high thrust-to-weight ratio. The designers happily traded those capabilities for low speed maneuverability and durability, making it an excellent CAS and a terrible dog fighter. That's a feature rather than a flaw. Similarly, the Concorde engines have a terrible thrust to weight ratio but excellent efficiency across a wide range of speeds. Since it has long runways anyway and needs very little agility this is a good trade in the context of what it's trying to do. If the F-35 is an excellent warplane because of its stealth and avionics (which I don't doubt) this doesn't necessarily make it a good design. Is that huge air intake and the giant frontal fan necessary for stealth or avionics capabilities?

I hold that when you have the biggest aircraft carriers in the world and your aircraft has a large combat radius anyway, VTOL, STOVL etc. is unnecessary. A thinner, lighter aircraft means a higher top speed and lower radar cross-section. After burners can provide the necessary extra thrust for take-off (as many carrier launched planes already do) at a tiny percentage of the mass and complexity of that huge low bipass turbofan engine. They needn't even add much volume either - afterburners are hollow cylinders after all, having them fold away over the outside of the main engine manifold when not engaged in take-off and landing might be a simple way to lower runway requirements at little cost to the vehicle in what you care about (total volume, mass etc.) and is a far simpler engineering problem than the VTOL the F-35 intended to achieve.

Besides this, it's touted as a "multirole" aircraft. If you need a bomb truck when the scenario you write about has come to pass and the enemy air defence is destroyed you can make those at a fraction of the unit cost, better fuel economy and far easier maintenance by cherry picking the appropriate technologies in the F-35 for the job (like those wonderful modern electromagnetic actuators, way better than hydraulics, that really is a leap forward from my poor beautiful F-16). If you want air superiority and first strike ground attack that's still possible for a fraction of the cost by giving up VTOL with the added benefit of speed and perhaps even maximum altitude. Unnecessary complexity has had notorious bad consequences in the vein of reliability for the F-22 (famously grounded for a long period because of carbon monoxide poisoning its pilots), Space Shuttle (tragic and infamous crashes) and other such projects. Simplicity offers so many advantages that I'm tempted to conclude that deliberately cutting out complexity is a feature of all good design with the single exception of situations where a deliberately complicated machine achieves some other objective (making it impossible for an opponent to usefully reverse engineer your design for example). The F-35, like the F-22, is immensely complicated. What's more, given the perverse incentives of the cost plus funding process and the inherent difficulty in trying to figure out which parts are there to waste money and which are actually necessary if some funding body tried to look (how could anyone possibly keep track of something like this?) I'm inclined towards suspicion that this plane is deliberately complicated, though I have no easy evidence to point to. At least for the F-22 I can say that if the very people who made it could scramble for months trying to figure out what was causing a simple carbon monoxide leak in what should have been a simple and isolated component of the vehicle (the pilot's air, for goodness sake) and not be able to find anything despite billion dollar contracts going up in smoke because of their failure that the F-22 is overcomplicated in the extreme. I'm forced to give the F-35 the benefit of the doubt.

Beyond all this, there is great danger in comparing finished machines rather than thinking from first principles. For one thing, nobody on this forum has the expertise required to design something like the F-35 from scratch (I'm not convinced any human on Earth could do every part, even Elon) so that sharing links and studies serves to prove one position over another but doesn't tell us much about how to design things for ourselves. On top of this the data we can get is usually terrible compared to first principles. The energy release by methane combustion is 55.6 MJ/kg and the process of finding a temperature for your combustion products and using the De Laval equation to get an estimate (all the means to do this are available to any of us just with a few web searches), a prediction within 10% can be made for engine performance compared to results from actual machines. Talking about the relative effectiveness of modern missiles, by contrast, (and hence whether or not the Fighter Mafia still has or ever had a point) relies on sketchy information from a scant few hundreds of engagements over decades, each time with huge disparities in pilot training and vehicle age, numbers, who has the initiative, relative mission priorities etc. Even trying to compare apples with apples using official figures is a nightmare - the F/A-18 Super Hornets's range and internal fuel capacity vs gross weight suggests a comparable fuel economy to the F-35 (not bad for 43 year old engines) but it's not clear how that translates to combat. With what weapons and at what altitude should such a system be designed to operate? If the needed missions aren't the same (even though they're both supposed to be versatile), the comparison quickly becomes unfair. I don't trust such figures to the extent I can live without them. I appreciate that practical experience has a lot to teach us and it's dangerous to go without but real machines, like real nations, are so complicated and the data collected from their performance frequently so narrow as to make it hard to learn the correct lessons from them even with the benefit of totally unclassified information and perfect hindsight.

By contrast, the freedom that comes from doing things ourselves lets us make entirely new designs and get a feel for what really makes a design good. Never mind the fancier stuff, could it be done in principle with the cheapest of materials and the lowest tolerances? A coaxial compressor certainly does have flow rate advantage over a zeolite in a tube but if all you care about is the cheapest total liquid CO2 produced you might be able to buy equivalent production capacity from the second option ten times over without reaching the costs of the first (initial or maintenance). It's harder to work this way of course but it can really genuinely count for something.

In any case, I've never flown a plane or worked with military aviation in practice so outside of these opinions or in receipt of better facts I'll defer to the experience of others (including the original poster if these categories apply). In addition, the values of Western civilisation need to be defended and I'm grateful that I can live without fear of external threats to my country (the UK) in large part because of the presence of United States Military capability on the world stage. Irrespective of arguments about what should be done and how (which is politics and banned on this forum) I have great thanks and respect for service personnel and hope that the Space Force can keep Mars safe long enough for us to safely get started there too.

Last edited by SeaDragon (2020-08-15 16:21:47)

Offline

Like button can go here

#3 2020-08-15 17:40:37

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: What Does "A Better Design" Actually Mean?

SeaDragon,

As it pertains to the STS Program... I'll defer to GW and RobertDyck for why that machine was so costly to use in actual practice since they either did design work on the Shuttle or worked with the people who made it fly. However, the entire reason the design became so costly to use in actual practice was an attempt to satisfy the military requirement that it ascend to orbit, deliver a satellite to a polar orbit, and land within a single orbit. That specific requirement had a drastic impact on the weight, design, and performance of the vehicle. The second drastic impact was dictating to NASA that they would use solid rocket motors instead of the existing F1 engines. Between those two mandates from on high, made by people who were not engineers, the Space Shuttle because something quite unlike what it was originally intended to be. The two lost orbiters were the inevitable result of management ignoring actual problems, rather than solving them. NASA was told not to launch Challenger, yet it did so anyway. The engineers suspected Columbia had a serious problem, yet didn't conduct a space walk or re-task a satellite to take images of the wing. Columbia's fatal accident was the direct result of a management reaction to a non-issue (thermal environment around the propellant feed lines) that actually caused an accident. Hindsight's always 20/20 and that may seem utterly idiotic now, yet precisely what the management of an organization supposedly filled with "smart people" did anyway.

To your point, the F-35 is little different in that regard. Lockheed-Martin received a litany of design requirement changes from the services and foreign nations after the basic design was tested and proven to work. The end result was a 20 year development program. They won the contract, so they were obligated to service the contract requests, irrespective of the cost or practicality of the additional capability. The few engineers who questioned the requests were fired for daring to push back against customer requests. A very significant chunk of the costs were directly related to the software, avionics, and sensors development programs. The basic engine technology was a development of the existing F-119 engine program. The airframe had a few problems that were identified and corrected through limited operational experience. As expensive as it's been for the tax payer, the development program very nearly bankrupted LM because the Air Force demanded fixes or changes they refused to pay for. LM had to seek governments loans to cover production and development costs.

The mishaps with the F-22 program were related to what happens with early versions of the mature technologies incorporated into the F-35. The military is always trying to implement newer / faster / better before it's actually ready for prime time. This is always a problem with new and highly complex systems. However, the F-22 and F-35 were created to counter the incredible lethality of modern IADS and fighter weapon systems against Cold War era aircraft. More than a few A-10s and F-16s were shot down over Iraq during the first Gulf War using air defense weapons that were at least as old as they were, if not older. Stealth was the obvious counter to that, but it has a real price tag attached to it. The alternative to that price tag is that a competent peer or near-peer level adversary with IADS and training could potentially shoot down half of your strike package on every major strike mission you conduct. Those kinds of losses are not sustainable, even if we use turboprop powered attack aircraft. We'll run out of pilots long before the enemy runs out of missiles.

The "giant frontal fan" was necessary for the Rolls Royce lift system to fit within the fuselage to provide sufficient thrust for stable hovering. That system is only installed in the B models. The other models carry more fuel. The giant turbofan that provides tremendous thrust also requires a giant fuel tank to achieve a respectable combat radius. Other aircraft of its same general size and weight carry far less internal fuel and are incessantly range-limited without lugging around gigantic gas tanks on the wing pylons, so they definitely had the right idea with making the fuselage wide enough to store all that fuel and weapons. The idea behind this, admittedly seldom achieved in practice, is that amphibious or forward deployed forces operate very close to the enemy and therefore don't need nearly so much range or speed because they're almost on top of their objective from the time they launch. The aircraft carriers can be much cheaper to build and operate as a result and you can operate more of them to ensure there's more available or nearby in time of war. There are a variety of reasons that this ideation about how amphibious combat works is so rarely achieved in practice. It can be done and has been done numerous times in the past but may not continue to work in the future as a function of being so close to hypersonic anti-ship missiles.

America may have a dozen nuclear powered super carriers, but nobody else does. I will readily admit that CATOBAR is a much better system than STOVL if range and payload matter at all, and in point of fact I served aboard two Nimitz class CATOBAR-equipped aircraft carriers in a squadron- a lot of 16 hour days in the ready room. The Hornets and replacement Super Hornets were and are good aircraft, but to claim that they're comparable to the F-35 on a single performance metric is a bridge too far. Ye Olde Hornets were chronically in need of fuel, even with 3 drop tanks and buddy stores. They could best be described as the replacement hangar queens for the retiring hangar queens, the Tomcats. The Super Hornets were a little bit better on that metric, though little better on maintenance, and mostly because they carried more internal fuel and modernized engines (even if the basic Hornet design is 43 years old, the engines certainly are not, nor the avionics, nor the Super series airframes- you get where this is going right; all that stuff costs a truck load of money). Better than the Hornet, sure, but not to the same level as the F-35 and the airframes are now very comparable in terms of cost, which means there's little merit to the cost argument. The operational costs of maintaining 2 vs 1 engine will quickly make up the difference.

You're paying about $29M more for the bigger engine and stealth and sensor fusion and other capabilities. Fuel economy is the same, thrust is the same, top speed is the same, acceleration is better for the F-35C according to the actual users who have flown both types, and MTOW is higher for the F-35C. There's no way in hell maintaining two turbofans with twice as many parts is cheaper than one. Most of that money comes down to software / sensors / avionics, believe it or not, so you'd be paying for a healthy chunk of that additional cost either way if you wanted all the other capabilities without stealth. The F-15EX carries a price tag of $138M as a point of comparison- more expensive than a F-35B, but no stealth. So what does all that extra money actually buy? All those other capabilities except for stealth.

The "multi-role" buzzword is DoD-speak for "primarily drops bombs on fixed or mobile targets or goes after enemy air defenses, but can engage other aircraft, too". In most cases, as I previously stated, modern air-to-air engagements consist of one jet firing one or two missiles at one other jet to shoot it down, with the adversary having never been aware that they were engaged. No US air-to-air gun kill since 1981. Sure, purpose-built interceptors like the F-22 will always be better at interception than a "multi-role" aircraft, but that's the extent of the added capability. Quite frankly, the F-22's technology is so dated today and total deployed assets so limited that the F-35 would still be a more practical and readily available interceptor against enemy bombers and strike aircraft (other "multi-role" fighters, for the most part, since only Russia and China have bombers of any kind). To be perfectly honest, "purpose built" bombers are probably replaceable with interceptors like the F-22 with more internal fuel. The YF-23 was the correct general concept for a long range interceptor and nuclear strike aircraft that the new Lockheed-Martin Gen 6 fighter design concept closely resembles.

In permissive environments, the US can continue to operate A-10s, so there's no reason to retire or replace them with cheaper but less capable platforms that will incur even more cost through establishment of entirely new programs of record. In non-permissive environments, only aircraft like the F-22 and F-35 will survive IADS (Integrated Air Defense Systems) and similar tactical fighters.

I would argue that a long range interceptor / nuclear strike airframe is required (YF-23-like F-22 replacement), a general purpose assault airframe is required (F-35), a close air support airframe is required (A-10), and a stealthy tanker airframe is required (B-21 Raider). Since we're already developing the B-21 Raider, that could also serve as a stealthy tanker for nuclear strike missions performed by much faster and more capable airframes (F-22 replacement) or drones. In the next decade or two, the long range nuclear strike missions will be performed by stealthy drones like the XQ-58 by obtaining "tanker gas" from B-21s, so now we've removed the requirement for the F-22s and its replacement. If someone had F-22s or similar airframes, then we'd just kill them with short range missiles anyway since engagements would be much closer due to stealth negating radar targeting solutions and at that point, maneuverability doesn't matter much because you're never going to out-maneuver the IR-guided weapon launched at you, so the platform that sees first and shoots first typically wins (stealth or no stealth). The "fighter mafia" had a point in an era when IR-guided missiles could be out-maneuvered or fooled with flares. That era is gone now, never to return.

My SWAG at an optimal future combat force:

F-35 - general purpose assault (hitting pre-selected or opportunistic ground targets and chance enemy aircraft encounters)

A-10 - close air support in permissive environments (the only type of environment in which A-10s don't get killed by IADS)

XQ-58 or MQ-25 - long range strike or nuclear strike and non-permissive environment tankers for naval aircraft

B-21 - long range nuclear strike bombers (interim solution) and non-permissive environment tankers (optimal solution with drones)

KC-46 - permissive environment tankers (the only type of environment in which KC-46s don't get killed by IADS)

That's what we're ultimately left with that makes good tactical and strategic sense in the face of increasingly lethal IADS and stealthy aircraft and typical wars fought in more permissive environments. The Cold War is over and the threats are staggeringly more sophisticated than what technology permitted during that bygone era. The technology of that era was suitable for that type of threat environment, but needs to be replaced with something fundamentally better.

Offline

Like button can go here

#4 2020-08-15 19:40:09

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,346

Re: What Does "A Better Design" Actually Mean?

Expertise for sts was in the standing army costs which were not just those that did the in between flight refurbs but for engineers as well.

Poorly written cost plus contracts did not need to be completed to be paid in its entirety.

Flight rate due to duration of refurbishment kept operation costs high.

These three were across the board on all parts and facilities operations.

I forgot many system upgrades and the 2 stand downs after each ship and crew loss.

Offline

Like button can go here

#5 2020-08-16 03:49:50

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: What Does "A Better Design" Actually Mean?

SeaDragon,

I feel as though one of the greatest potential contributions to continued air supremacy would be made by investing in a micro fighter program that would permit the US and allied nations to maintain a pipeline of trained pilots to eventually fly / fight with incredibly sophisticated and costly war machines like the F-35. I actually have a thread on this already that's related to concrete actions that the US military could take to lower its CO2 emissions, but I've refined the concept in my mind over time and this discussion brought up some good points about how high cost and complexity and low production rates can detract from overall mission readiness when taken to extremes.

My revised micro fighter concept calls for a 6,000 pound MTOW and is designed around the Williams International FJ-44-4M engine (a 3,800 pound thrust class very light jet engine that powers a number of training airframes) and a carbon fiber composite airframe. I originally envisioned miniature F-16s, but a scaled-up Boeing X-36 airframe clone with some stealth features for greater survivability in modern air combat are probably worthy of consideration. These micro fighters would have 2 small weapons bays for carrying small munitions, either 6 of the new Raytheon Pyros, 2 Hellfire, or 2 M260 7-shot lightweight rocket pods containing guided air-to-ground or air-to-air weapons. After careful consideration of how infrequently gun kills are achieved at high subsonic speeds, I don't think an internal cannon adds much capability. Ultimately, 14 Stinger type missiles carried in rocket pods would deliver greater probability of kill against small drones and other light aircraft.

The primary purpose of these jets would be to provide a cost-effective yet modern supplemental multi-role light fighter specifically to equip new pilots with an affordable combat-relevant airframe to build significant flight hours. The cost of a single F-35 would cover the purchase of an entire squadron of these jets. If there are not enough new pilots being fed into the fighter program, then there's little chance of sustaining a force of thousands of advanced multi-role heavy fighters like the F-35.

This might seem crazy at first, but I think pilot flight hours are deteriorating to the point that if we don't do something about it relatively quickly, then there simply won't be enough pilots to fill the cockpits of these sleek new F-35s. Cost kinda doesn't matter at this point because we can't seem to retain enough qualified pilots. This would give prospective candidates a real Gen 5 fighter to learn to use that doesn't bankrupt the tax payers footing the bill. Yes, capabilities are somewhat limited by the tiny airframe and weight restrictions, but that also means cost per flight hour is sustainable. This would fall somewhere in the $2,000 range, which is doable. The engines are $2M per copy. There'd be 1 pilot and 3 maintainers (1 avionics tech, 1 engine tech, 1 ordnance tech) per airframe- we're talking about something similar in physical size to the Cessna 172. That's approximately 1/4 of the human resource requirements for a typical fast jet squadron. If we had 1,200 of these aircraft, then that's only $12B in initial purchase costs and a total of 4,800 personnel. If our allies also purchase these more affordable jets, then they could bolster the number of available pilots and maintainers without going broke.

The primary combat mission of these jets would be neutralizing less capable opponents in a war with a peer-level adversary and supplementing existing CAS assets in wars fought in permissive environments to ensure that fast jets are always available for tasking in remote theaters of war. Any ground unit would be able to call for CAS and swiftly receive assets to get them out of a jam.

We're already re-thinking the use of 155mm artillery and large air-dropped ordnance as a result of experiences in Iraq / Afghanistan / Syria with ground forces in close proximity to hostiles. The end result of that thought process seems to be that smaller weapons are less likely to cause unacceptable collateral damage and greater numbers of cost-effective sensor-shooter platforms are better than smaller numbers of more sophisticated assets that are in chronically short supply, especially if they may be unavailable altogether due to higher priority tasking.

Edit:

I think the engine cost differential illustrates my point fairly aptly. The Williams International FJ-44-4 series cost is about 1/10th that of the Pratt & Whitney F-135 ($2M vs $20M) and should be less than that with mass production. The time between cold and hot section overhaul is also very comparable for both engines, between 3,000 and 4,000 hours of operation. Hot section overhauls average $350K for the FJ-44 and occur at 3,500hours.

The Czech Aero L-39NG weighs 12,787 pounds, has an endurance of 4h 30m at an avg. speed of 358mph (10mph faster than A-10 cruise speeds), range of 1,610 miles on internal fuel only, a total internal fuel capacity of 3,196lbs. That means the fuel burn for this 2 seater is 11.837 pounds per minute at cruise. I want an endurance of 4 hours on internal fuel using my design, so 2,841 pounds of fuel. I suspect that this airframe would cruise somewhere between 400mph and 450mph, given it's half the weight and has less frontal area than the L-39NG, so range would be at least as good if not slightly better.

The FJ-44-4 weighs 658 pounds, so 3499 for engine and fuel. Max stores weight would be 560lbs for the APKWS guided rockets and 7 shot M260 lightweight launchers. The empty M260 7-shot rocket launchers weigh 35lbs/ea and APKWS rockets weigh 35lbs/ea. That leaves 1,941 pounds for the airframe structures / landing gear / avionics / sensors, which seems quite doable for a tailless lifting body design using all CFRP and GFRP construction and short trailing link landing gear. Modern radars and avionics can be incredibly light, with some AESA radars weighing a 30 to 50 pounds and sophisticated EO systems capable of seeing targets a dozen miles or more while being hand-portable.

The majority of both combat and training missions are 2 to 4 hours in length. Sometimes combat missions last longer, but that's not typical and would be rare for forward-deployed assets. I would expect takeoff in 1,500 feet or so and a landing roll of 2,000 feet using the canards for braking. In any event, a half mile runway should be more than sufficient. If the canards and stub wings fold, it should be perfectly feasible to store them in revetments or hardened aircraft shelters provided by the Army Corps of Engineers. At least 4 airframes could be stored in the same physical space as a single F-35 and towing would be easy to accomplish using a battery-powered aircraft tug. No special equipment would be required to enter / exit the jet and all ordnance is light enough to be pinned by hand.

In most actual combat missions over Afghanistan, 1 to 2 pieces of precision ordnance were carried and perhaps dropped or, more likely, brought back to the carrier or airfield if there were no enemy or the enemy was intimidated into leaving the area by the presence of fast jets overhead. This type of airframe would ensure that fast jets are always overhead and can be summoned at will by the infantry fighting below.

I envision a single F-35 acting as the quarterback for a mission while providing top cover for 6 micro fighters tasked with providing close air support or target interdiction for the mission. The F-35 will be equipped with Peregrine missiles and a 200kW laser to ward off MiGs or Sukhois or larger and more sophisticated drones. The micros will be equipped with a mix of Hellfire or Griffin anti-armor missiles for attacking tanks and field fortifications or APKWS for use against drones and light vehicles or Pyros if only infantry and light vehicles are expected. There's technically enough room in the weapons bays I had in mind to shoehorn in a pair of StormBreaker guided bombs if light precision strike weapons are required, but it would be a squeeze for sure.

Edit #2:

Based upon DLA (Defense Logistics Agency) FY20 standard fuel prices, fuel cost per barrel is set at $124.32/bbl, or $2.96/gal. The micro fighter fuel consumption rate is 105 gallons per hour at cruise, so fuel cost per flight hour is $310.80. Engine overhaul costs would be pro-rated at $100 per flight hour. For such a small light jet, I would guess ~$1,000 per flight hour in terms of spare parts and diagnostics services (engine oil analysis, electronics replacement, fuel system parts replacement, etc). If each pilot flies 10 hours per week, that's a very respectable 520 hours per year. Although it's possible to fly a mission per day or every other day, that kind of schedule is mentally and physically exhausting. My rule of thumb from experience is that for each mission hour, 2 to 3 hours of mission planning are required. It's not practical to do a brief in less than 1 hour unless everyone is already familiar with the mission, for example. Even after the maintenance activities are done, filling out the paperwork is a headache unto itself, there's squadron PT, squadron cleaning, FOD walk-down, etc. Let's say $1,500 per flight hour. That puts operational costs at $9.36M per squadron per year, so 100 squadrons would run DoD a mere $936M per year. That's peanuts compared to what we spend on much larger jets that typically only carry and drop 1 to 2 pieces of ordnance in an actual combat mission.

I presume the aviators will predominantly be O-2s, so $3,800/month. I presume the mix of E-2 to E-9 will average out to E-5 pay rate of $3,200/month. For 3 maintainers and 1 pilot, that works out to $18.63 in direct labor costs. I don't know off the top of my head what the services pay in terms of health care for families and whatnot, but I don't think it would more than double the labor costs. I would think $40 per hour would cover labor / health care / housing for all officers and enlisted plus families.

Anyway, instead of 2,500+ F-35s, I would like to have a force of 1,200 F-35s and 1,200 micro fighters. However, given those costs we could feasibly operate several hundred squadrons to build flight hours for smoother transitions to far more costly machines during the second or third enlistment, yet still retain enough happy pilots who get to fly frequently and happy maintainers who aren't over-worked trying to keep so many super weapons in the air to provide capabilities that we typically never use.

Last edited by kbd512 (2020-08-16 20:20:39)

Offline

Like button can go here

#6 2020-08-18 13:53:22

- SeaDragon

- Banned

- From: Merry Old England

- Registered: 2020-07-25

- Posts: 32

Re: What Does "A Better Design" Actually Mean?

kbd512,

Now this is very intriguing!

I've been thinking along very similar lines for a long time. It's not just a lack of pilot experience that comes as a negative consequence of planes too expensive to fly except for actual missions. Without a large mass of experience, not just from pilots but mechanics and technicians and so on, critical lessons not obvious during development on a supercomputer might need to be learned in battle. Aside from this, a fleet of hyper expensive war machines is vulnerable to economic disruptions prior to its need in a warzone. If the US goes bankrupt it's not obvious that Western Civilisation will be able to continue to protect itself from external threats. In addition I'd like to propose a similar concept for the Army/Marines in the form of gyrocopters. Being something like a tenth the cost of a helicopter per unit mass lifted and with better top speed and fuel economy (at the cost of requiring a short runway instead of VTOL) these might enable exceptional mobility in a serious conventional war. Using basalt fibre composite construction and magnesium alloy engine components with supercharging for a reciprocating engine designed to work with standard petrol (to power back mounted propellers) might make for something high performance but easy enough to manufacture that its parts can be made in bulk for car prices rather than attack helicopter prices. With the ability to rapidly move troops and equipment/dominate enemy ground forces once their AAA/SAM etc are suppressed by stealth aerial strike packages this might greatly enhance maneuverability but be cheap and compact enough that everyone gets to fly with them in exercises and during training. As for Martian self defence I'm not even sure it's a good idea to talk about it at all: strategically speaking our greatest defence might be that we're a peaceful group popular with international opinion and uninvolved with Earth politics so that aggression against us would gain support from a much stronger ally like the US on Earth. Even having an armed force or thinking up space based military theory might well aid the enemies of space industrialisation by making us look militaristic. This is a shame in some ways since it's the easiest way to make aerospace engineering discussions cool and get views.

I've long wanted to do a YouTube series where me and a group of other contestants choose a place in the solar system to colonise, are given starting resources, a population and a timeline predating game start in which to set up and then have to compete with each other to control the solar system. A previously agreed referee would preside over battles and review technology etc. so that outcomes of events can be decided. I could see that bringing thousands of people back into the technical sciences but perhaps at the cost of damaging our reputation to outsiders. I've been torn about trying to organise something like this for years.

Last edited by SeaDragon (2020-08-18 13:58:37)

Offline

Like button can go here

#7 2020-08-18 22:18:43

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: What Does "A Better Design" Actually Mean?

SeaDragon,

Note on the definition of "IADS" (Integrated Air Defense Systems):

This type of protection system prevents opposing aircraft or drones and some air-to-ground weapons such as cruise missiles from operating in contested air space without significant protective measures taken to prevent networked radar / IR / EO sensors from providing targeting solutions to surface-to-air cannons and missiles for the express purpose of shooting down opposing aircraft.

IADS are typically expensive to field and require dedicated and highly-trained crews who constantly monitor the sensor returns to determine whether or not the sensor return in question is a potentially hostile aircraft. The most sophisticated IADS also work with friendly fighter / interceptor aircraft to vector them to intercept inbound hostile aircraft. Modern IADS are highly lethal to aircraft and all but require any opposing aircraft operating in airspace protected by IADS to implement at least some stealth characteristics to avoid being detected at significant ranges, tracked, locked (targeting solution achieved), and subsequently shot down. The majority of IADS currently in use employ radar-based sensors and radar-guided missiles since radar is not significantly affected by weather conditions that might obscure IR and EO type sensors. However, an increasing number of IADS also slave IR and/or other EO sensors to radar system to use radar returns to direct those sensors onto potential targets to positively identify them.

The proliferation of these types of systems with the advent of modern computer-controlled sensors means that even relatively poor nations are likely operating some limited form of IADS. Wealthier nations are almost exclusively and often extensively protected by hundreds or even thousands of such systems. The widespread procurement and deployment of fighter weapons has seen radar and IR guided air-to-air missiles normally employed by fighters for shooting down other aircraft to also be deployed as ground-based surface-to-air missiles incorporated into short and medium range IADS. Many of the wealthiest nations, especially US / Russia / China can also afford to operate purpose-built surface-to-air cannons and missiles as part of their IADS, typically with the aim of achieving greater intercept range or speed / accuracy / lethality against opposing aircraft. In a nutshell, opposing interceptors / fighters and IADS are the greatest threats to fighter jets. Any sort of less sophisticated system, while still potentially lethal, is not nearly so problematic to deal with.

My primary concern is reigning in the ever-increasing cost of operating a myriad of different aircraft types that, while potentially truly excellent for a specific mission, don't get used as-envisioned during actual combat missions and dictate an incomprehensibly complicated logistics chain to support globally deployable tactical fighter units. In nearly all real combat missions, you typically carry and drop 1 or 2 pieces of ordnance on specific targets that are either pre-designated during the mission brief (tactical or strategic strike) or found during the course of the mission by chance (target interdiction). To do that efficiently, you need to execute many missions per day. The most practical and cost effective way to do that on a technologically advanced battlefield with targets spread far and wide and potentially protected by IADS is with entire squadrons of miniature stealth fighters that fly at moderate to high subsonic speeds (the speed range over which the overwhelming majority of air combat actually takes place). 300mph to 600mph perfect for engaging targets of opportunity, as they are found, while remaining relevant in both permissive (no IADS) and non-permissive (IADS) environments.

If I can realistically deploy half a squadron per mission due to the sheer weight of numbers of jets I can afford to operate, then you're not going to win a war against me with a handful of super weapons. The super weapons will either be down for maintenance, the crews won't be sufficiently well-trained and experienced, or they won't be where you need them when you need them there. That's just part of the reality of war. Every situation both you and the enemy find yourselves in is far from ideal. Making second and third passes at defended ground targets is generally a bad idea, so if you could afford to have multiple aircraft make single passes at targets with accurate weapons and attacking from multiple directions, then chances are pretty good that more targets will be destroyed and more pilots will gain experience making attack runs without succumbing to enemy air defenses.

Auto-gyros are significantly better on cost than helicopters, but only slightly less complicated in terms of gearbox parts. A piston engine of any kind would suffer even greater drive system torsional vibration issues than gas turbine powered variants, though it could still be more economical to operate on account of fuel consumption and engine costs, up to a certain weight class. All modern militaries run on jet fuel, so the reciprocating engine used would have to employ compression ignition and all diesels have the most severe vibration issues, which is why there are so few successful diesel engine designs used in light aircraft, though this is slowly beginning to change as 100LL AVGAS becomes increasingly scarce outside of America. All certified diesel aircraft engines are significantly more expensive to build and overhaul than equivalent power output gasoline engines, yet TBOs are very comparable, so only commercial operators and militaries could afford to use them.

A good example of a practical automotive diesel engine converted for aircraft use is the Red A03 500hp V12. That's a $170K engine, so considerably more expensive than a turbocharged all-Aluminum 500hp 632 cubic inch V8 Big Block Chevy. The Red A03 turbo diesel is about 5X the cost of a marine applications / high duty cycle BBC with the best of everything in terms of components, but remarkably similar in weight and only slightly better on fuel economy since a BBC is sitting on its fuel island at the RPM required to make 500hp. You can have billet everything in your BBC for $170K and it will tolerate 500hp for quite some time, especially with EI / EFI. However, the electronics to ensure reliability are quite expensive and difficult to program for reliability without extensive expertise that only an OEM could provide. At the end of the day, an equivalent gas turbine is still at least 10X more expensive than a 500hp class gas or diesel piston engine, but only half the weight.

I6s and V12s are typically smoother in operation than I4s and V8s, but heavy for the power output compared to gas turbines. The most simplistic and performant 500hp class ICE would be a 2-rotor turbocharged 13b Mazda Wankel, but those are easily $25K engines and pretty thirsty, just not as thirsty as a small gas turbine. The benefits of Wankel engines are far fewer small components to break, vastly simpler than any V8s or V12s or gas turbine for that matter, the components could be cheaper to produce if mass manufactured again, and there are fewer vibration-related issues since everything is moving in one direction (no torque reversals as with traditional reciprocating engines), much like a gas turbine (but you still have torque pulses to contend with, unlike a gas turbine), at all times. When the eccentric shaft is spinning at 9,000rpm, the rotors are only spinning at 3,000rpm. I would make the rotor housings and side irons out of CGI for durability and boost the crap out of it since Wankels handle boost better than piston engines. Wankels have chronic uneven heating issues, though the British have mostly solved that problem using exhaust gas recirculation to keep all sides of the rotor housing the same temperature.

If it was up to me, I would cease operating most helicopters larger than the Little Birds. They're simply too expensive for the capabilities provided. I'd keep the V-22s since they fly at fixed wing turboprop-powered aircraft speeds, but that's about it. The AH-64s and AH-1s would be replaced with small fixed wing general purpose tactical fighters like the micro fighter concept. Flying 50mph to 100mph faster than a traditional helicopter is not an acceptable substitute for a real attack jet that's small, light, highly maneuverable, and hard to hit. The CH-47s and CH-53s would be replaced with VTOL C-130s. The UH-60s would be replaced with STOL DHC-3s.

If I need troop transports, then turboprop-powered STOL aircraft are much more practical solutions than helicopters in most cases and far less likely to take effective fire on account of their greater flight speeds. No, they can't land on a 50 square foot plateau, but the numbers of troops who could feasibly be emplaced somewhere like that is quite small anyway and therefore the MH-6s make more sense than using much larger and more expensive machines like the CH-47s that guzzle fuel and are every bit as vulnerable as the much smaller machines but are far easier to connect with using a HMG or RPG or MANPADS as a result of their considerable size. Put another way, you can kill 20 to 40 people if a CH-47 goes down in a LZ, as the Navy SEALs have proven in Afghanistan, but if a MH-6 goes down the maximum number of people you could kill is 4. Given the cost differential between purchasing and operating both machines, you can easily afford to purchase and operate far more MH-6s than CH-47s or CH-53s. Each new USMC CH-53K costs as much or more than a F-35B, for example. Maybe you can afford to concentrate fire on 1 or 2 machines, but if I have an entire squadron of MH-6s landing troops, then you're not going to get them all and the MH-6s can carry sufficient armament to adequately suppress enemy fires.

The utility of a subsonic 1950s era bomber for penetration runs into enemy territory is practically nonexistent. Yes, the B52s are good cruise missile carriers, but then we're still stuck operating a very limited number of bombers that are still quite vulnerable to enemy air defenses. In reality, these bombers are only operated in the most permissive of environments. The B1s are slightly better in that regard, but operating them in contested airspace is still a non-starter. Like it or not, stealth is here to stay. Since the nuclear strike mission has been retired for both types, I can only surmise that they're not survivable in a shooting war with peer level adversaries, nor any adversary with IADS, for that matter. Basically, they're museum pieces with some modern electronics upgrades. Yes, we actually used B52s and B1s in Afghanistan to provide CAS to troops, but only because the enemy had no effective means to fight back and only because we didn't have any other assets in the area, quite possibly because we simply couldn't afford to put more appropriate jets into the air. Even at that, they weren't very helpful, apart from scaring the crap out of the Taliban.

We have a real problems with accepting the limitations of technology, designing and operating reasonably good systems within their limitations, and sometimes the customer, the DoD, isn't "always right".

Key Technology Programs for Affordable Future Warfare

US Air Force

F-35 development and sustainment by halving production and focusing on constant software and sensor upgrades

XQ-58 development for deep penetration tactical and strategic strike missions in non-permissive environments

X-36 style stealth micro fighters for affordable general purpose use in permissive and non-permissive environments

STOL / VTOL C-130 development to replace heavy lift helicopters and provide true heavy lift

B-21 stealth bomber / tanker / arsenal ship development

B-2 upgrades using

C-17 sustainment

Retirement of all previous generation fighters and bombers and badly aging transports like the C-5

US Army

M1 Abrams upgrades

M113 upgrades and repurposing as off-road fuel tankers in lieu of more vulnerable heavy trucks

Common chassis for heavy MBT / SPG / APC vehicles for urban or open field combat

Retirement of all previous generations of unsurvivable attack and transport helicopters in favor of cheaper fixed-wing solutions and limited vertical lift where absolutely required

Retirement of all cost-ineffective heavy wheeled combat vehicles like the M1126 / Stryker

US Marine Corps

To their credit, the Corps is already abandoning most of their old, heavy, and difficult-to-deploy systems that are making them logistics-intensive and slow to get into action

I want to read more about their latest initiatives before passing judgement on their new / old direction (the expeditionary amphibious fighting force that they're supposed to be)

Their major ongoing programs are F-35B, MV-22, CH-53K, and the new wheeled ACV replacement for the tracked AAV-7, another step in the wrong direction after the cancelled EFV program (at some point civilian service secretaries needs to put their foot down on new machines that don't do anything at all materially better than the old machines they were intended to replace; the point to spending money is to do useful things, not to spend money for sake of spending money)

US Navy

Refurbishment rather than retirement or replacement of the existing Ticonderoga class cruisers

Continued build-out of the Arleigh Burke class destroyers

Cancellation of the Independence class and Freedom class frigate programs that have thus far utterly failed to replace the retired O.H. Perry class frigates

Removal of the Zumwalt class stealth destroyers from fleet service to continue experimenting with new technologies as they become available

Continued build-out of the Virginia class attack submarines to replace the aging Los Angeles class

Continued build-out of the Columbia class ballistic missile submarines to replace the Ohio class

Repurpose the Ohio class ballistic missile submarines to cruise missile launchers instead of retirement

I have an entirely separate critique of what the US Navy and Marine Corps have done with their limited funding. Mostly, their procurement decisions exhibit a lot of the same poor decision making ("I'm a General / Admiral / officer looking to get promoted by spending a lot of tax payer money and I refuse to acknowledge the limits of technology and the applicability of basic physics to everything we do") of the US Air Force and US Army.

Optimally, I'd like to see a force structure like this:

12 CATOBAR-equipped nuclear powered aircraft carriers

72 cruisers or destroyers to protect the aircraft carriers

12 ballistic missile submarines

12 cruise missile submarines

48 attack submarines

24 amphibious ships

36 fast oilers / resupply ships

That's a 216 ship Navy and entirely adequate to fight any existing adversary nation's Navy, none of which can realistically muster half of that kind of force structure in a surge capacity. The current 355 ship Navy is unsustainable and the Navy is trying too hard to take on more missions than it should. We need allied naval forces to come up to adequate strength for that to happen, though. However, that is right-sized for protecting American interests abroad and maintaining freedom of navigation of the world's oceans. The force reduction will provide budgetary margin for major systems upgrades, as required.

Offline

Like button can go here

#8 2020-08-19 13:28:37

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,989

- Website

Re: What Does "A Better Design" Actually Mean?

How do quad- and octo-copters compare to helicopters? As I understand it, they are far easier to control and are mechanically simpler, but sacrifice speed. Still, maybe they would have an advantage in terms of quickly moving people around the battlespace?

I'm particularly thinking about the hoverbike designs, in an urban context. Quickly hop between levels of buildings, for example.

Use what is abundant and build to last

Offline

Like button can go here

#9 2020-08-19 22:25:37

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: What Does "A Better Design" Actually Mean?

Terraformer,

Quad-copters that are large enough to carry a significant payload are objectively NOT easier to control than single rotor machines, which is why they require sophisticated control algorithms to make them fly to begin with, often with sophisticated yet vulnerable power transfer mechanisms like gearboxes and shafts to ensure a failure in one engine doesn't make the machine uncontrollable- because losing 1/4 of your power on one corner of your machine is difficult to overcome without a power transfer mechanism and/or computer control to instantly take remedial action. People who think computer software complexity is not real complexity are either unaware of what's involved or not being honest about the way in which the machine actually works.

Similarly, multi-engine machines are objectively more complicated to properly design and operate than single engine machines. There are still valid reasons for having multiple engines and helicopters and multi-engined helicopters. Since you don't get much in the way of usable auto-rotation from a quad-copter on account of the smaller rotors / oversized-propellers, and progressively less as the rotor count increases, a total loss of power, while unlikely to occur given proper fuel management, assuming you have 4 or more engines to work with, would be difficult to survive. Most crashes are attributable to pilot error of some kind making a bad situation worse. Fuel starvation from mis-management is a fairly frequent cause of crashes in light aircraft, for example, but generally avoidable by taking off with adequate fuel and switching to the correct tanks in flight, as required.

In theory, a twin engined machine should suffer fewer accidents than a single engine machine and save those onboard in instances where a single would crash or suffer a forced landing. In reality, twins kill more people than singles due to pilot error or marginal controllability while only under power using one engine following a loss of power from the other, to the point that it's difficult for a private pilot to get reasonable insurance rates on a twin. Most twins also takeoff and land faster than most singles. As the old saying goes, speed kills. A pilot with less experience and skill is generally better off with a single than a twin, even in military aviation. If you only have one engine, then lightweight armor around the engine can prevent shell fragments or small arms bullets from penetrating.

The companies spending money on electric multi-rotor designs put lots of engineering effort into making electronics failures as graceful as they feasibly can be, for example, and from what they say about the development process, it's not obvious to me that the design is any less complicated than a traditional helicopter. The principle advantages are less rotor clearance to account for the larger main rotor diameter of a traditional helicopter, better cross-wind controllability when the attitude hold software functions properly, and quieter operation, mostly due to blade design and electric motors vs combustion engines. Speed is less of a factor since the distances are quite short and, hopefully, nobody is shooting at you.

We could make the argument that computer control programs can be more reliable than mechanical devices and there's actual evidence to support the assertion that an engine control unit (a special-purpose computer with sensors attached to an engine) is far more reliable than a magneto for providing proper spark to a gasoline powered aviation engine, but we can't hand wave the very real complexity of that computer control system, nor the fact that it can and sometimes will fail completely, causing the engine to lose all power as a result, unless a backup ECU can restore ECU function in about a second or less, whereas one bad contact point on a magneto may cause spark not to be sent to a single cylinder, making the engine run rough and lose some power, but power won't be lost entirely. Issues such as proper sensor location, vibration dampening and proper sensor attachment, and software to gracefully deal with input failures become critical in the extreme. If the crank position sensor fails, then engine stops working. It's mathematically provable that the simplest form of computer program can't merely run in a loop and continue to produce output, for any given input. So, the software and sensor quality and reliability are of utmost importance.

Decades of evidence collected from running Continental and Lycoming aircraft engines indicate that aircraft magnetos can fail in about 500 hours or so without maintenance. Sometimes units will go many more hours prior to failure, but some won't. Proper maintenance on the mags conducted at the appropriate intervals, in conjunction with mag checks performed during run-up, reduces the likelihood of an in-flight failure. Over seven decades of continuous use of the same basic magneto designs, our magneto manufacturers have determined just how many operating hours can be extracted from their products before failures begin to occur, so that maintenance schedule is not really a suggestion. ECUs, on the other hand, have MTBFs measured in many thousands of hours using the latest solid state electronics. As such, it's objectively true that the electrical components can be and frequently are substantially more reliable in operation than mechanical components.

Offline

Like button can go here

#10 2020-08-20 06:53:47

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,046

Re: What Does "A Better Design" Actually Mean?

For kbd512 re #9

SearchTerm:MagnetoReliability

SearchTerm:ECUEngineControlUnit

(th)

Offline

Like button can go here

#11 2020-08-25 06:53:49

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,046

Re: What Does "A Better Design" Actually Mean?

For kbd512 re (to me very) interesting discussion in Housekeeping ...

The two of you bring a lot of experience and insight to bear on the problem of design of machinery for the Mars environment.

I am of the opinion that anything transported to Mars for use beyond the first moments after landing should be designed to be maintained there.

The advantages of digital technology to support analog mechanisms are documented in your posts. SpaceNut's reports on failure mode of digital systems installed in an automobile are cautionary. GW Johnson's reports of successful extension of the life of all analog machines are an example of what is possible.

It should be possible to design for the long life you have described in your posts, ** and ** for maintainability GW Johnson has described.

This topic (I note) was created under your flag.

It could become a repository of discussions of specific designs for specific elements of the Mars adventure, over time.

General discussions of principles are an important part of the mix, but in the end it is a specific design for a hammer that hits a specific design for a nail.

While I'm here, I'd like to invite you to start a topic for design of your contra-rotating habitat vehicle. We would then have the magic number of ** three ** initiatives underway to describe a large scale passenger vessel for the Earth-Mars trade.

I'm not including Elon's concept for the Starship, because it is in development by paid employees with far greater resources than this volunteer group can bring to bear.

The specific feature that RobertDyck, your concept and the Big Wheel all have in common is serving 1 g of simulated gravity to passengers and crew.

However, the approaches are sufficiently different to make the parallel development interesting for forum readers to watch.

RobertDyck is offering a design with the habitat fixed to the cylinder of the propulsion unit, and rotation about the longitudinal axis of the propulsion unit.

Your design features contra-rotating disks arranged in a manner similar to Star Trek Enterprise.

Big Wheel is a single wheel arranged in the form of a gyroscope.

These concepts will ALL work, and they are ALL worth further investment of time and (some) energy to develop.

(th)

Offline

Like button can go here

#12 2020-08-25 10:58:30

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,346

Re: What Does "A Better Design" Actually Mean?

Analog was around for centuries before the age of the semiconductor and is a K.I.S.S. design that is robust other than mechanical wear.

The computer as well can be made in that same manner and each is a separate unit not a combination of feeding the other one chained to the next with digital communications.

Offline

Like button can go here

#13 2020-08-27 19:45:06

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: What Does "A Better Design" Actually Mean?

tahanson43206,

Ford, the make of vehicle that SpaceNut owns, is very enamored with new technology. They're a leader in innovation, but all new innovations come with developmental problems. It took them awhile to make Aluminum pickup truck beds reasonably durable and they still have limitations. However, the Aluminum is easy to recycle and repair or replace and it does significantly reduce the weight of the truck. Much like our military, Ford will implement new technology before it's truly ready for prime time.