New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#126 2020-02-17 20:56:09

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,715

Re: Running on Compressed Air?

The moxie process creates the possible fuel for land based crafts to be created and used early plus it requires no water mining for a trip with all that is required is to super cooling it to liquid. pg 50 shows the tracked verion of a vehicle using it.

http://www.niac.usra.edu/files/studies/ … 40Rice.pdf

ADVANCED SYSTEM CONCEPT FOR TOTAL ISRU BASED PROPULSION AND POWER SYSTEMS FOR UNMANNED AND MANNED EXPLORATION

The rover mission was defined as a 300 km one day trip. A system of gravel roads was assumed. Based on a trip distance of 300 km and a transit time of 10 hours, a velocity of 30 km/h was used. Turbine efficiency was assumed same for all fuels at 65% chemical potential to mechanical energy conversion efficiency.

For the initial iteration, the structural mass penalty for storing propellant was a 100 kg storage tank. The propellant mass penalty was ½ the mass of the propellant. For example, a 2000 kg rover that burns 200 kg of propellant and stores the byproducts has a mass of 2300 kg for the entire duration of the trip (with the tank mass penalty), while a 2000 kg venting rover has a mass of 2200 kg at the beginning of the trip and 2000 kg at the end. The mass used to calculate the propellant usage was therefore 2100 kg.

Offline

Like button can go here

#127 2020-09-22 19:38:37

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,715

Re: Running on Compressed Air?

Addressing post 207. Pneumatic transport, that is to say a vehicle pushed along by differential pressure, is definitely an option worth considering on Mars. The interesting thing about the idea is that the vehicle need not carry its own power supply. A rail based or wheeled vehicle propelled by differential pressure could simply be a set of carriages, equipped with brakes to control its speed.

On Earth, atmospheric railways have found niche applications, but were largely rendered obsolete following the application of electricity to railways. However, small pneumatic pipelines carrying wheeled vehicles could be very useful for transporting bulk materials on both Earth and Mars. A square conduit just 20cm wide, carrying wheeled vehicles at 10m/s, could move up to 1500 cubic metres per hour of freight or bulk materials between any two points. The vehicle would have a loose seal at its front and back, to minimise gas leakage past it.

The required differential pressure needed to drive the vehicle would be a function of its mass (weight), the friction coefficient of the wheels and the cross-sectional area of the vehicle.

The minimum force needed to move a vehicle is given by: F = W x C, where W is weight in N, and C is coefficient of rolling resistance, typically 0.002 for steel wheels on steel rails. A 1 tonne mass would weigh 3679N on Mars. To move this mass in a rail vehicle will take a minimum force of 7.4N on Mars. For a vehicle 20cm wide, this amounts to a required differential pressure of 184Pa per tonne. This of course assumes a perfectly flat surface.

Hydraulic capsule pipelines are a related concept in which neutrally buoyant capsules of material are carried through a water pipe. Typically, this carries capsules very slowly, about human walking speed. The concept is one of the most energy efficient transportation methods known to man, but it has the limitations of low speed and the need to load and unload the capsules with whatever is being transported and handle them at both ends. An added problem exists on Mars - low temperature. Operating hydraulic pipelines on Mars would require either heating the pipes or using brine as a carrying fluid. The first solution is an option if we have access to nuclear waste heat. The low thermal conductivity of Martian regolith would make it an excellent insulator. Using cold brine is problematic, because water at subzero temperatures becomes progressively more viscous, which pushes up pumping power.

One significant advantage of low speed pipelines on Mars is the extremely low vapour pressure of water at temperatures close to zero. The pipelines would barely need to be pressurised. They could be constructed from cast basalt, concrete, steel or polymer. We would lay them between our colony and numerous mine sites, allowing colonists to access materials from hundreds or even thousands of kilometres away. The water would carry the capsules along at speeds of no more than a few metres per second.

A pipe some 10cm in diameter, carrying capsules at a speed of 1m/s, could transport up to 250,000 tonnes of material per year. If the pipe is made from steel with a wall thickness of 1mm, it would weigh 2.5 tonnes per km. A 1000 km long pipe would therefore weigh 2500 tonnes. The pipe could therefore carry 100x its own weight in freight every year. Useful, if we wanted access to resources from a large area to support the needs of a growing city. We could for example, build a city under a polar ice filled crater. We could grow food in an agricultural colony closer to the equator. A pipeline would deliver water from the polar city to the agricultural colony during the spring and summer months. During the autumn and winter, the same pipeline would be used to transport food north in capsules.

Offline

Like button can go here

#128 2022-10-08 17:19:09

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,715

Offline

Like button can go here

#129 2022-10-09 11:05:21

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,201

Re: Running on Compressed Air?

Compressed air energy storage has always interested me. Despite it's excellent ESoEI, progress in expanding CAES has been slow. The problem is that pressure vessels are expensive and CAES projects therefore rely on underground air storage. This limits CAES to areas with suitable geology, like underground salt deposits, which tend to be few and far between.

Other options have been explored over the years. Subsea air storage in tanks or rubber bags. Prestressed concrete storage vessels. Even liquid air energy storage. But none of these concepts have caught on in a way that would allow CAES to expand as a mainstream solution.

As a local offgrid solution, it may be possible to store low-pressure compressed air in pits or covered trenches. This would work for storage of small quantities of energy at pressures <1 bar(g). Vacuum can be stored in entirely compressive vessels made from concrete. Again, this is not something that scales to large sizes, but may be a niche solution in situations where we need to store <1kWh and discharge it at high power.

Last edited by Calliban (2022-10-09 11:12:51)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#130 2022-10-12 19:40:02

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,715

Re: Running on Compressed Air?

Why yes you did see a topic

I remember seeing SpaceNut maybe post news and Calliban discussing Air Compression the other day, I might search again for the thread later.

'China turns on the world's largest compressed air energy storage plant'

https://newatlas.com/energy/china-100mw-compressed-air/

The Chinese Academy of Sciences says the Zhangjiakou plant is capable of supplying the local grid with more than 132 GWh of electricity annually, taking on the peak consumption of some 40-60,000 homes. It'll save around 42,000 tons of coal from being burned in power stations, and reduce annual carbon dioxide emissions by around 109,000 tons – the equivalent of taking about 23,700 average American cars off the road.

The Academy says this design's low capital costs, long lifetime, safety and efficiency, along with its green credentials, position it well as "one of the most promising technologies for large-scale energy storage."

Offline

Like button can go here

#131 2022-10-12 21:43:16

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,715

Re: Running on Compressed Air?

I just found a site that builds the metal shell for those old cars of the 60 - 70 if one was into restorations.

Offline

Like button can go here

#132 2023-11-18 17:54:52

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,715

Re: Running on Compressed Air?

This topic has come up again.

Offline

Like button can go here

#133 2023-11-18 19:12:43

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,201

Re: Running on Compressed Air?

Long term, I think L-CO2 could be a valuable resource on Mars and a convenient way of storing energy. It can be stored as liquid at 5.1 bar at -56°C. If exposed to a modest heat source above 304K, high pressure, dry CO2 gas is generated. This gas could be used to power tools and even short range vehicles. Nuclear waste heat could provide the heat. We could store almost endless amounts of L-CO2 in thin walled steel vessel, insulated with regolith. Natural circulation could cool the liquid CO2 using a surface radiator exposed to the cold of night. If we can subcool the CO2 in the tank during night, we can refill it using solar electricity during the day, by compressing atmospheric CO2 to 5.1 bar and pushing it into the tank. The gas that bleeds off will be enriched in non-CO2 atmospheric fractions.

Last edited by Calliban (2023-11-18 19:17:59)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#134 2023-11-18 20:20:41

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,301

Re: Running on Compressed Air?

Calliban,

The bleed-off could become our source of Argon (electric propulsion and welding) and Nitrogen (for a breathable atmosphere). There are other trace gases that will also prove useful, such as Carbon Monoxide and water vapor. There's very little Neon, Krypton, and Xenon, but those trace gases would also need to be collected. Neon is presently required to make CPUs, for example.

Offline

Like button can go here

#135 2023-12-19 17:51:32

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,201

Re: Running on Compressed Air?

I managed to find a copy of this article:

'Experimental Investigation of A Compressed Air Vehicle Prototype With Phase Change Materials for heat Recovery'

https://sci-hub.ru/10.1002/est2.159

This is a prototype compressed air powered vehicle, with an exergy efficiency of 61% and a range of 87 miles. The high exergy efficiency is achieved by storing compression heat in a paraffin phase change material onboard and then preheating the compressed air prior to expansion.

The range and efficiency allows the vehicle to compete with electric vehicles and will considerably outperform them when embodied energy is factored in. The thing I have always liked about the idea of compressed air vehicles is that exotic materials are largely avoided. We need fibre glass for the tanks, and paraffin wax as phase change material, but almost everything else is steel and plastic. That should make these cars cheaper to build at volume. Another positive attribute is the compressed air can be generated mechanically, without the prior need to generate electricity.

Whilst the prototype discussed here stores compression thermal energy onboard, another option would be to store cold energy from expansion and use it to precool air reducing the energy needed for compression. This may work better, because the heat of fusion of water is substantially greater than paraffin and a smaller volume is needed to store the same amount of heat.

Last edited by Calliban (2023-12-19 17:58:30)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#136 2023-12-19 20:42:19

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,810

Re: Running on Compressed Air?

For Calliban re #135 ...

Thank you for finding the link you showed us in #135

I followed the link (to Russia without incident) and discovered the email addresses are for authors in Canada.

The image of a hybrid car, with both electric driven wheels and air motor driven wheels is definitely interesting. I like the option of running on electric batteries to get home if the compressed air runs out. Nice!

(th)

Offline

Like button can go here

#137 2023-12-20 02:22:27

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,201

Re: Running on Compressed Air?

I hadn't noticed the link was from Russia. From Russia with Love, perhaps, though I doubt :-)

Integrating the compressed air into an electric hybrid drive train, dillutes a lot of the advantages. It means having all of the electric car components with just a smaller battery. Maybe more work can eliminate the need for this by using a hybrid hydraulic drive train. So long as the world remains fixated on a shiny electric future, progress will be slow unfortunately. It is an ironic turn around that people that green movements are actually pushing the world into less sustainable practices. Then again, being a Green is not the same as being an Environmentalist.

Last edited by Calliban (2023-12-20 02:25:41)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#138 2024-01-23 13:32:56

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,715

Re: Running on Compressed Air?

SpaceNut, I wonder if the situation would be better if we transition to compressed air vehicles instead of battery-electric?

https://en.m.wikipedia.org/wiki/Compressed-air_carBack in 2020, a prototype was able to achieve a 140km range and a roundtrip efficiency of 74%. We would need to scale up generating capacity just as much using compressed air. But the distribution pipework and charging infrastructure will be made from steel and synthetic rubber. The pressure tank in the vehicle would be glass fibre wound around a carbon steel liner. This idea at least does not present us with any unsustainable materials problems. If we corrosion protect the steel pipes and avoid heavy pressure cycles, they should last for a very long time. Same with the glass fibre tanks. They should last for the life of the vehicle.

Offline

Like button can go here

#139 2024-01-23 13:50:34

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,810

Re: Running on Compressed Air?

This topic certainly has legs, but after all the posts, we don't seem to be any closer to having a working system ...

I went back to Palomar's original post, and followed the discussion for a short distance ... Early in the series I found was I was looking for ... a proposal to store air (atmosphere in the case of Mars) as a liquid (Earth) or a solid (Mars).

I have two questions for Calliban (if you are willing to consider them and have the time)...

1) The vehicle in my garage can go 500 miles with a topped off tank using fossil fuel.

If air were liquefied and loaded into a suitable tank before a trip, could that charge carry the vehicle 500 miles?

I don't think the size of the gasoline tank is relevant, but it might turn out to be. The volume of the tank is (about) 10 US gallons.

2) If paraffin is used to heat the LOX, what size paraffin tank is needed?

I'm assuming some thermal energy can be collected from the air along the way, but the system should be able to operate in a cold climate as well as a hot one.

(th)

Offline

Like button can go here

#140 2024-03-11 17:17:34

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,715

Re: Running on Compressed Air?

For Calliban re air pressure energy storage ...

In the forum archive, there are posts between you and kbd512 (and perhaps others) about use of compressed air to store energy.

I was inspired by the discussion to invest in a generator/alternator that is designed for the golf cart market. The machine is brand new and ready to go into service. My test plan was to drive the device from an air motor, to produce current to light a string of 12 volt DC bulbs.

The automobile marketplace appears to include a few attempts at production of air pressure powered automobiles, and the tanks designed for that market would surely serve as energy reservoirs for my test. I found an air motor that would be suitable for the experiment, but the Critical Path items is the air tank. Commercially available air tanks for air tools do not appear to have the capacity needed for the experiment, which was intended to produce 20 amps at 12 volts for some period of time (which I've forgotten but it might have been an hour).

I'd like to see the air stored energy discussion continue, if possible.

The cost of a suitable air tank may be out of reach for my budget, but at this point, I have no idea where to find one, let alone ask for price.

In the automobile application, I assume the engineers must have provided a regulator to deliver air to an air motor, so that would need to be part of the apparatus.

Follow up 2024/03/11 ... in a quick review of the compressed air automobile industry, I found hints that the air pressure in tanks may reach into the hundreds of atmospheres. Safety would be a concern if air pressure driven equipment is supported by a store of that magnitude. However, safety issues must have been addressed, if working automobiles have been developed and placed on the market. I am interested in the application of this technology for on site power generation, whether for an electric generator via an air motor, or standard pneumatic tools.

(th)

Offline

Like button can go here

#141 2024-03-12 03:51:03

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,301

Re: Running on Compressed Air?

SpaceNut,

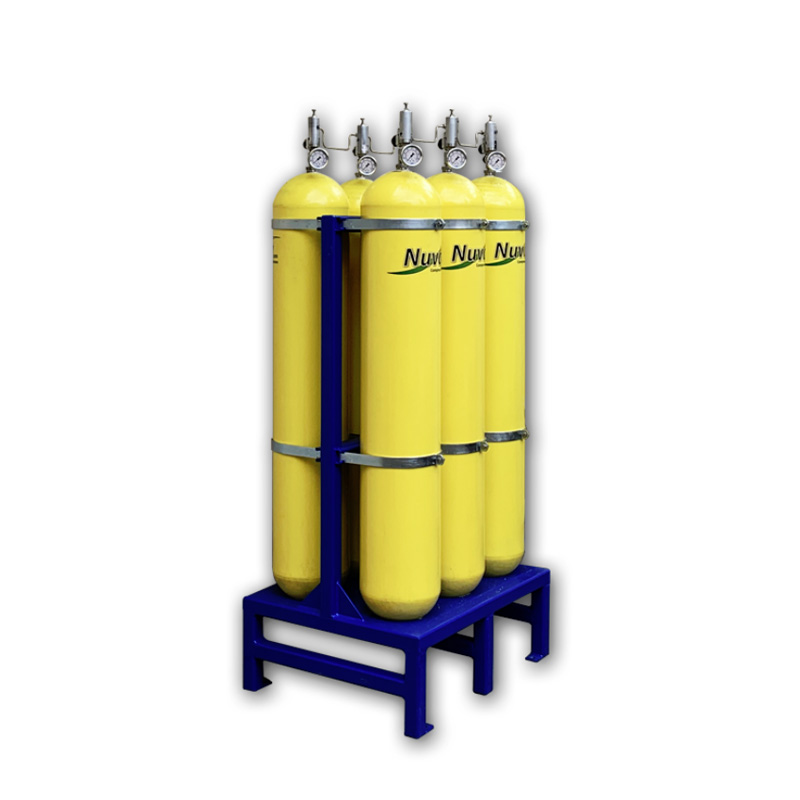

Practical air powered vehicles will use scuba diving tank or Hydrogen gas storage technology, either high strength corrosion protected (galvanized) steel or CFRP high pressure air cylinders with HDPE liners (Type IV H2 storage tanks). CFRP is the safest and lightest and least affected by water vapor in the compressed air, but also the most costly by a considerable amount. This is not the sort of equipment you can pick up at a home improvement store. It must be ordered online or through a dive shop or from a company that makes H2 storage tanks, and then hydrostatic tested periodically by placing the high pressure air tanks underwater, taking them up to test pressure, holding for a specified period of time to assure no leaks, reinstallation in the vehicle, followed by leak testing. This is also an ideal time to inspect the material condition of air feed lines and valves.

Hydrostatic testing is required every 5 to 10 years as a rule of thumb. If you live near the coast, then retest every 2 years. Ignore the 5 year requalification requirement and retest every 2 years. Cylinder service life is normally 10 to 15 years, but this is something to ask the manufacturer of your particular air cylinders. There is steel, Aluminum, and GFRP or CFRP with various types of liners. CFRP overwrap tanks are designed to resist a set number of pressure cycles. Going beyond that is a bad idea. The steel is typically good until unacceptably corroded, damaged, or a service life or calendar life limit is reached. Type IV CFRP H2 tanks can legally go to higher pressures, in accordance with US DOT regulations, as they were designed and intended to do when storing compressed H2. Legal is important here, but not getting seriously injured or killed is infinitely more important.

You also need a much thinner / lighter hot water tank to contain hot water heated to just below its normal boiling point. This tank can be corrosion protected steel (a standard water heater tank) or plastic, with an insulating foam used to retain heat. A vacuum jacketed vessel such as a LN2 dewar is theoretically ideal, but again, more cost. At some point, you have to give up on total optimization and aim for the most practical and cost effective solution. Hot water tanks are pretty cost effective. Anyway, the hot water tank goes inside your engine compartment, along with the air motor or turbine.

The entire system consists of one or more high pressure compressed air cylinders mounted below the passenger cabin or in / under a truck bed, a hot water tank to add thermal energy back to the "cold" expanding air to both maintain flow volume and preclude freezing from residual water vapor, plus an automotive air conditioning refrigerant loop with the radiator mounted inside the hot water tank standard location for a car, and the other side of the loop wrapped around the high pressure air line feeding expanding compressed air into the vehicle's air motor. The refrigerant loop and pump attached to your air motor are using heat from the hot water to "gain efficiency" or "get extra air volume" to provide more power, however you wish to think about it. In theory, your air motor could be a refurbished air cooled motorcycle engine. A purpose-built air motor will be more efficient, but again... money. A turbine is even more efficient for cruising at relatively constant speed, but not required, and the torque output from a stop will not be as good as a piston-driven air motor.

When the air is compressed using your onsite air compression pump, presumably solar or wind turbine powered, at least until hot water is provided as a grid service, the waste heat from the compression process is used to reheat the water in your vehicle's hot water tank. If you have extra hot water or the water gets too hot, then some of that water goes back into your home's potable water heater tank or kitchen sink or bath or whatever else you use boiling hot water for. That means the air compression piston cylinders of your stationary air compressor are surrounded by a water jacket, sort of like a normal combustion engine, to collect the waste heat.

For that burst of energy required for brisk acceleration, you're using a much larger turbine at low-speed, or a simpler / lower cost piston pump air motor which has greater friction losses than a turbine.

With 8X 45L 310bar compressed air tanks, you have 4.273hp-hr / 3.186kWh of energy from the compressed air alone, to work with. 100kg of hot water, cooled from 99C to 20C by adding heat / volume to the compressed air adds 9.186kWh, so 12.372kWh, maximum. In other words, not a lot of energy. That would give you about 35 miles of driving range at 350W/mile. The vehicle will weigh about as much as a Tesla Model 3. At this point, you probably understand why the engineers went for Lithium-ion batteries, 677kg / 18.275Wh/kg of weight for this setup, excluding the motor, for 35 miles of range vs 300+ miles of range.

The real difference, of course, is cost-over-time, of pay-as-you-drive energy consumption, vs lots of high energy materials. If you have CFRP tanks, then your energy density looks much better, with 309kg of weight, or 40Wh/kg at the same 310bar operating pressure, which is about the same as Lead-acid batteries, but without the batteries. The CFRP tanks are rated at 25,000 cycles. At 720bar pressure of the Type IV CFRP H2 tanks, you get 80Wh/kg. That's about half as good as Lithium-ion at the pack level. Your battery, of whatever type, will never give you the same total Wh/kg after 25,000 cycles, yet simple heat and pressure will. In reality, your system doesn't work at zero pressure, so you don't get quite as good as what's described here, but you can see how we rapidly achieve a meaningfully "more renewable" energy system that will last dramatically longer than electro-chemical batteries will.

If someone figures out battery and photovoltaic cell recycling, and we come up with 4 billion tons of conductor wiring, then we can go gangbusters on all-electric. Until then, combustion where required plus a much more "natural energy system" anywhere we can, looks like a winner. It doesn't catch fire or combust, because it's non-electric and non-combustion. Anyone can figure this out, because it's so simple, even if it requires real engineered systems. People who balk at natural energy due to the limitations are essentially asserting that natural energy doesn't work. For "green energy" to be truly environmentally friendly, it has to. Let's try something we haven't meaningfully tried before, and see where that leads us. I'm tired of dead-ends. There has to be something to serve as an adjunct to combustion or wild computerization, or normal folks are never going to switch, because they can't afford it.

Offline

Like button can go here

#142 2024-03-12 03:58:59

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,301

Re: Running on Compressed Air?

I did a poor job of explaining the refrigerant loop concept, but you're piping "cold" expanding air through your "hot water refrigerant loop", to pick up heat energy from the water to increase the volume of air through the air motor, so that by the time it's finished expanding, you get a multiple of the total stored compressed air volume to use to push / drive / pump your non-combustion air-pump. You can do fancier stuff with primary and secondary loops to increase or temporarily store "hot air" for acceleration, but you don't need to. You regulate pressure down at the compressed air tank outlet to something a standard car AC radiator core can work with, you increase the volume or force with the energy in the hot water, the hot air goes into the air motor to expand and drive the piston(s) to produce mechanical pony power output, and then you exhaust the "colder" air.

Offline

Like button can go here

#143 2024-03-12 11:47:04

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,201

Re: Running on Compressed Air?

Kbd512, many thanks for an excellent description of an air powered car.

I wonder how much the compressor needed to charge the car will actually weigh? Would it make sense to integrate a compressor into the vehicle? One thing that does interest me about this concept is that charging an air vehicle can be accomplished using mechanical energy. This could be in the form of pressurised water, LP compressed air or even direct shaft power from a mechanical windmill. The systems involved can be simple and don't rely on any exotic resources.

We can build machines like that out of brick, stone, wood and welded steel. If someone told me today that I had to build a photovoltaic powerplant from scratch with only basic materials that I could find, I would be lost. But I am confident that I could build a mechanical windmill that pumps water. I think a lot of people could do that. And if we have a supply of pumped water at a pressure of 5-10bar, then we have a hydraulic power source for a compressor that can charge our vehicles.

Last edited by Calliban (2024-03-12 11:50:37)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#144 2024-03-12 11:59:53

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 22,810

Re: Running on Compressed Air?

Is there any chance at all this interesting topic could be tweaked to yield a practical recommendation?

I remain interested in finding a compressed air solution that can deliver 7 CFM for 20 minutes. This would be a solution for a remote location, without electrical supply to refill the traditional steel tank.

The energy storage capacity of tanks designed and build for the automotive market appear to have the capability of meeting this requirement. So far I have not seen any down-to-earth practical information moving through this topic or ** any ** similar topic.

***

In order to advance this initiative, I just ordered a V-Belt for the drill press I have on a nearby work bench. My plan is to mount the 12 volt generator/motor purchased earlier, on a frame so that motion from the drill press will drive the generator. The purpose of the exercise is to confirm that the generator works and that it can light a string of 12 volt bulbs.

An air motor is available but I'll hold off on making that investment until a solution to hold compressed air for the required time period is available.

(th)

Offline

Like button can go here

#145 2024-03-13 01:13:15

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,301

Re: Running on Compressed Air?

Calliban,

A 300-350 bar compressor is reasonably small, light, affordable, and typically water-cooled to get rid of waste heat (heat we want to store for later use in the car). Perhaps $500 to $1,000. Some individuals own these if they do a lot of diving or paintball or air rifle practice. A 700 bar compressor is not small, light, or affordable, at least several thousand dollars, but more like $5K to $10K for a machine that can get the job done in a reasonable amount of time. A gasoline pump at a gas station costs a lot more than that, so it's a machine that a gas station can pay for by charging customers to refill their car.

I don't see the point to owning potentially very dangerous charging equipment at home, whether it's a high power battery charger or 700 bar air / H2 compressor. Knowing how to charge or refuel a car is one thing. Knowing how to service the charging or fueling equipment is different. Yes, some people do it. It's not something I want my wife or children messing with. As I said before, it belongs at a gas station / service station / servo.

You're looking at 35kg to 55kg for a good 300 to 350 bar unit, commonly used by SCUBA and paintball shops. I don't know about a 700 bar unit, but I know it's not going in a car. 700 bar paintball and air rifle units are not at all suitable for filling 360L of tank volume with 700 bar compressed air, because they're not intended for extended duration / continuous duty use. Most of those recreational compressors have a 30 to 45 minute operating time cutoff.

45L 300 bar steel compressed air cylinders weigh 65kg to 75kg each. The industrial compressed air tanks I looked at were about 68kg each, less fittings and hardware, so 544kg for 8 tanks. It's a two man lift, and you need to be reasonably strong to do it. It has the benefit of being cheap, because it's steel. Let's call it $1,200 worth of steel.

I would skip Aluminum tanks entirely, even though they're a good "in-between" CFRP and steel. Salt water dive shops near the equator use Aluminum instead of steel because scratched or unprotected steel corrodes way too fast. They won't pay to shot blast and repaint the steel tanks, so they get scratched being dragged back into the boat or along concrete piers, but mostly accumulate water vapor inside during filling, so then they rust, and then they're junk in a year or two. The inside rust is way more problematic than the outside, though. Someone could invent a machine to shot blast inside the tank and that would solve the rust problem. Aluminum has a strict service life limit, but is essentially zero maintenance, which is why dive shops like them. Aluminum is also very easy to recycle. Someone else can make the case for Aluminum, but I view the most realistic options as CFRP (maximum performance) or hot-dipped galvanized steel (maximum economy to the consumer for very short-range vehicles).

Type IV (high modulus fiber with a HDPE liner) 700 bar / 10,000psi CFRP is less than half as heavy as 350 bar steel, about a quarter the weight of steel in an optimal configuration. As the images below indicate, this is why you really want Hydrogen or Methane or Propane, rather than Lithium-ion batteries or compressed air and hot water.

360L of volume for 350 bar steel is 544kg.

360L of volume with 700 bar Type IV CFRP / HDPE is 143kg in a mass-inefficient configuration, so 3.79X lighter.

360L of volume with 700 bar CNT would be about 75kg or less, same mass-inefficient configuration (using a bunch of little tanks).

CNT tanks buy 160Wh/kg.

What does 160Wh/kg represent?

A 100kWh Tesla Lithium-ion battery pack weighs 625kg, so 160Wh/kg.

CNT 700 bar compressed air tanks achieve Tesla battery pack performance without a battery. CNT fiber doesn't have a functional service life limit. The plastic liner and resin will eventually degrade, but the fiber will not. NASA gave up on breaking the fiber after bending it back and forth over 1,000,000 times. At the point at which we achieve Lithium-ion battery pack level performance without any Lithium-ion batteries, nor power-robbing performance degradation, we have to question the reason to use Lithium-ion or Sodium-ion batteries for vehicle applications, because it won't make any economic or environmental sense.

Offline

Like button can go here

#146 2024-06-25 19:02:44

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,715

Re: Running on Compressed Air?

Part of post

Hot water, salt, or rock could potentially damage the road surface or vehicles or burn people involved in the accident, but compressed air becomes cold air during an accidental release. 700bar H2 tanks struck by bullets will release their stored H2, but they don't burn or explode, so compressed air stored in the same manner would result in a lot of nothing happening.

The CFRP Type IV (HDPE liner or liner-less) H2 tank that US DoE is evaluating at has a 253L water storage capacity, operates at 700bar, and weighs 182kg. That would provide 177.1m^3 of compressed air (0.253 * 700 = 177.1m^3 or 6254.2275ft^3).

A 1hp air motor regulated at 90psi is equal to a volumetric flow rate of 12scfm to 15scfm. Actual flow rate depends upon the type of air motor involved. Turbines tend to be more efficient than pistons and gerotors, because pistons have more friction and starting torque to overcome. They provide more torque, but not more power per volume of air flowed through them.

6,254ft^3 / 12ft^3 per minute = 521 minutes of operation at 1hp, or 8.68hp-hrs

6,254ft^3 / 15ft^3 per minute = 417 minutes of operation at 1hp, or 6.95hp-hrsThat's not very much, but the horsepower required to move a vehicle at a given speed is a function of aerodynamic drag and rolling resistance. As speed increases, aerodynamic drag force becomes the limiting factor.

Force(drag) = 0.5 * Density(air) * velocity^2 * Area * Cd (drag force coefficient)

F = 0.5 * rho * V^2 * A * Cd

rho = 0.07647lbs/ft^3 (sea level "standard atmospheric density")

V = 55mph

A = 8ft^2 (standard full size passenger car frontal area)

Cd = 0.31 (Toyota Corolla drag coefficient used, most passenger cars fall between 0.25 and 0.3, 0.35 to 0.45 for most trucks and SUVs)F = 0.5 * 0.07647 * 3,025 * 8 * 0.31

F = 286.84ft-lbsThat means aerodynamic drag requires 0.522hp to overcome at 55mph.

Coefficient of rolling resistance (Crr) is mass, gravity, and surface-dependent. On a concrete roadway, which is what we have here in Houston and in many other major cities, the following is what your rolling resistance looks like for a 1,000kg total vehicle weight and "grippy" tires rather than absolute minimum coefficient of friction tires:

F = mass * gravitational acceleration * Crr

F = 1,000kg × 9.81m/s^2 × 0.015 = 147.15N

F = 108.54ft-lbsIn total, 395.38ft-lbs of force needs to be produced by the drive system to maintain 55mph, or 641.92ft-lbs to maintain 75mph.

Offline

Like button can go here

#147 2024-06-30 09:59:46

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,715

Re: Running on Compressed Air?

In response in the other topic.

tahanson43206,

1. Immediately going out and buying an electric motor, with the idea of turning it into an air compressor, runs directly counter to the use of basic engineering principles to first work out what to build and then how to build it. Do you recall how we were still debating whether the compressed air or hot fluid power source would work best? I admire your enthusiasm for the idea, but I never asked anyone to do such a thing.

2. The equipment to make an air powered car does exist, but much like the tech to make an internal combustion engine or a battery for a road car, it's not something you're likely to fabricate in your garage, absent a substantive investment in time and money.

Hydrogen Type 4 Cylinder 700 bar 103L

You have to buy at least 3 of these, or they're not interested in selling to you. They're not cheap.

3. I wouldn't waste my time and money or anyone else's on ideas that I wasn't already quite certain would actually work. I would hope that anyone investing their own money has the attention span and level of understanding required to fully comprehend what we're proposing and why, before they ever spend one cent of their money. I would insist that they show some baseline level of comprehension before taking their money. I'm not a salesman for climate change or any other religion, so I don't offer up "solutions" that are not actually solving real problems for most people in practical ways.

I'm not the least bit interested in selling more disposable appliances to rich people. There's an endless variety of novelties for rich people to spend their money. I'm not enamored with novelties. If I never see my customers again, unless they wreck their car or their kids need cars, too, then I will consider that an actual worthwhile achievement. There are plenty of other ways to make money. After I solve one problem, I move on to the next. That's why Elon Musk went from payment software, to rockets, to cars, to tunnel boring, to AI machines. If a prospective investor has a problem with conducting business that way, then I don't want their money. If that means none of these ideas ever see the light of day, I really don't care.

I guess the kind of investor I'd be after is someone who genuinely cares about both people and the environment, and does not look down their nose at their fellow man merely because he has more money than they do. There aren't many Henry Fords left in this world, but there have to be some, and all it takes is one.

As I see it, the EV market is presently floundering due to intractable material scarcity issues that no amount of climate religion or happy talk will ever resolve, technical issues related to the fact that current battery technology is now well past any step-change performance improvements, and because the world's supply of snobbish wealthy leftists wishing to tell everyone else how green and clean they are, merely because they went out and bought a fancier disposable appliance than most other people could afford, has mostly dried up. Very few people who actually require a reliable car are buying EVs. They're status symbols for city-dwelling hipsters and middle-aged tech and finance guys with no wives or children- the kind of people who have plenty of disposable income, but would never get their hands dirty working on a car, because that's something they pay someone else to do for them. For the rest of the driving public, which is most people, buying a car with an internal combustion engine remains their only realistic option. The people who mow lawns, turn wrenches, or weld pipes are my target customers, regardless of how much disdain our snobs have for them. The major automotive manufacturers, at least those not presently firing all of their employees, are collectively returning to making more combustion engine vehicles, because they don't have any other workable solutions.

Yes, GM could've sold EVs to our Hollyweirdos back in the 1990s. They'd be the only people buying that product, and there simply weren't enough of them to justify the many billions spent trying to make EVs work at the scale required.

In the 1960s, Ford sold a million Mustangs in about 18 months. Tesla sold their millionth vehicle after 92 months of operations- almost 8 years of losing billions of dollars, every single year. Investors and governments wanted to force the technology into existence, so they kept dumping money into it, continued the PR campaign, and then they mostly sold them to people overseas who wanted to be "green and trendy". Your pizza delivery driver doesn't care about being trendy. He's not trying to keep up with the cool kids. He's busting his rear end to try and make ends meet. China now has acre after acre of EVs rusting in scrap yards, never to be sold to anyone. They keep their local firefighters gainfully employed, but that's about it. Nobody is buying the product because they can't afford to and they're not getting any cheaper than they already are. Most people need a reliable car that doesn't require factory disassembly because one battery cell out of thousands quit working. Putting a minor dent in the battery pack casing is grounds for the insurance company to total the entire car. I'm not sure how ridiculous the results have to become in order to convince people to try a different plan.

EVs remain an utterly impractical solution to personal mobility for most people, unless we're talking about a bicycle or moped. The people who buy those don't care at all about the clean green electrification religion. Transportation is purely a practical proposition for them. They either get a reliable vehicle, of whatever variety, or they don't get to work to make their money and pay their bills. EVs were sold to the general public as being a lot of things they're clearly not. 10 years from now our illustrious "scientists" will suddenly "discover", much the same way they did with corn-based Ethanol production, that in point of fact, the EV is no cleaner or greener, it merely shifts when and where the CO2 emissions occur to some place that nobody is presently fixated on measuring. EVs are not more reliable. I had an oil exec coworker who told me how reliable his Tesla had been, while it was sitting in the shop for 3 months, after asking him where his car was. EVs are not cheaper than gasoline powered cars, unless you get one that performs very differently than a normal gasoline powered car. They're not any less polluting until you drive the thing longer than most people keep a car and you power it using an energy mix that doesn't presently exist in most countries on planet Earth, and won't exist for lack of all that Copper and Lithium that we don't have and flatly refuse to invest more money into. They're nearly impossible to service, and the dealership won't even sell the parts to you to make your own repairs, if they even had parts to sell, because most of them don't.

4. It doesn't matter to an engineer if you know you're wrong, or not. All those people who swore up and down that the Earth was flat were still wrong. Valid math and therefore science is not consensus-based. If 97% of "scientists" agree that the Earth is flat, that only means 97% of them have no business attempting to apply the principles of valid science, never mind engineering, because they prioritize their ideological / philosophical / religious beliefs over observational evidence, or whatever makes money, which means what they're doing is no longer science. It's like a doctor selling pills he knows is killing his patients. Wearing that white lab coat is the most meaningless part of what makes you a medical doctor.

I can use simple historical observational evidence to "know" that at no point in time in all of human history has production of a metal that we already mine expanded by 50% in 10 years time. The probability that Copper and Lithium become the only exceptions to that rule is statistically zero or near-zero. That is precisely what any real engineer would tell you, because he doesn't care about his ideology, your ideology, or that of anyone else's while he's making math-based decisions about what will or won't work at the scale required, in the time frame required, and at the cost required to implement the new tech. Someone who is simply collecting a paycheck while not telling the truth to his employer about the practicality of what they're attempting to do is likewise, an engineer in name only.

5. I would like to see a practical application of these ideas as well, if only to finally realize the otherwise "impossible dream" of this cleaner and greener energy that we're thus far not getting, but maybe that won't happen until we run out of oil and specialty metals. I already see the engineers coming to the realization that in the future centralized power plants using dramatically simpler and cheaper energy production and storage methods than those involving power electronics will be required, else there will not be any energy transition.

Everyone seems to want to live the Jetsons lifestyle, which demands more and more energy, while they also demand that energy consumption to somehow be less impactful to Earth's environment. Those are opposing engineering requirements. Pick one or the other. If you want cleaner and greener, that requires using more abundant materials, simpler and longer lasting machines that are easier to recycle, thus fewer of them, and people who broadly accept that you can't randomly throw money every which way with the expectation of a desirable outcome. In short, learn how to prioritize in a way most people can live with.

Offline

Like button can go here

#148 2024-06-30 10:00:50

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,715

Re: Running on Compressed Air?

was a desire to do direct power from the compressed air.

For kbd512 re Post #364

Thanks for a thoughtful review of the comparison between technology options.

Your observation about not buying equipment before a complete system is designed is certainly valid, as experience has shown. I was trying to create a psychological framework for members of this group to solve the problems of creating a small scale compressed air energy storage system. No one asked me to do anything! Calliban specifically asked that no one spend any money on anything.

Had my gambit been successfully we would now have a working compressed air energy storage system able to light a set of 12 volt bulbs.

Now we will remain as we were, just a forum with ideas and plenty of interesting information, but there will be no demonstration of capability in our archives.

The resources available to throw at a problem are certainly a factor in success vs failure.

If you look at Calliban's member text, you'll see a mantra that argues against thinking about how to do something, vs acting to make it happen.

My guess is that you'd find that most entrepreneurs do NOT know how to do something that is new, and many fail, but a few succeed, and our vibrant civilization thrives because of their willingness to take the risk.

Elon Musk is a reasonably good example of an entrepreneur who has the risk tolerance to address an opportunity, whether it is business or a technology or a combination. Losses go with that boldness, and by observation, I deduce that he has the ability to accept the early failures as the price for eventual success.

In any case, the inspiration you and Calliban have provided to forum readers remains available, and it may yet inspire someone to attempt to create a viable compress air energy storage system beyond known capabilities.

(th)

Offline

Like button can go here

#149 2024-06-30 10:01:44

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,715

Re: Running on Compressed Air?

My own history of tanks of composite materials.

I have seen 5,000 psi scuba style takes used for self-contained breathing equipment that are composite that do not explode when ruptured.

https://wilcoxind.com/backend/wp-conten … ochure.pdf

Offline

Like button can go here

#150 2024-06-30 10:02:27

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,715

Re: Running on Compressed Air?

SpaceNut,

450bar to 850bar Type IV CFRP high-pressure H2 tanks are quite real, even if most people don't normally see them in their daily lives. A Type IV pressure vessel is a very specific US Department of Transportation H2 / CNG storage container rating that comes with safety and testing requirements attached to it, because rated pressure vessels are used for transportation of compressed gases. Type IV works equally well for air and most other high pressure gases. There are highly acidic or basic chemicals for which CFRP is not a good storage container, but they are typically compatible with air, Oxygen, Hydrogen, Methane, Helium, Nitrogen, Argon, and other common gases. For gases such as Chlorine and Fluorine, you're better off using stainless steel, potentially with a fluoropolymer liner, and accepting reduced storage pressures. Composite tanks with fluoropolymer liners can store Chlorine and Fluorine gases, but that's not how it's typically done. I assume there are good engineering and economic reasons for continuing to use stainless steels and reduced pressures for such aggressively oxidizing chemicals.

A 450bar tank with a water storage capacity of 250L / 0.25m^3 can safely contain 112.5m^3 of air, while an 850bar tank can be charged with 212.5m^3 of compressed air. The 850bar tank will be heavier than the 450bar tank, but not in terms of equivalent storage capacity. For example, a pair of 450bar tanks can hold about the same amount of air as a single 850bar tank, but the weight of both tanks will exceed the weight of the single 850bar tank by a considerable amount. If you double the capacity of a singular 450bar tank, then it still ends up weighing a little bit more than the smaller 850bar tank. More importantly, 0.5m^3 is nearing the limit of what a vehicle with the same exterior dimensions as a standard compact car can reasonably carry, which is why the 850bar tank makes more sense for this application. If volume was not as constrained, then it might be possible to make that 450bar 0.5m^3 tank for less money than the 850bar tank because the processing steps are less costly, but it still requires more fiber and resin, so the materials cost will likely remain similar to that of the 850bar tank.

I see the chassis materials and design as 4 major types with various cost, durability, and recyclability trade-offs:

1. CFRP monocoque

A. lightest possible total vehicle weight

B. highest possible specific strength

C. highest possible cost (purely based upon structural materials cost, not cosmetics; apart from CNT and BNNT fibers, Carbon Fiber is the highest energy input fiber, which is reflected in its cost, followed closely by S2 Glass Fiber and Aramid fibers such as Kevlar, followed by the much more commonly used but much weaker E Glass Fiber and Basalt Fiber, which can be quite close to common grades of Carbon Fiber on tensile strength, and the various natural fibers- flax, hemp, cotton, etc)

D. greatest absolute performance (greatest "fuel economy", due to lightest possible weight, which implies less power required, lighter powerplant, etc)

E. most difficult to repair and recycleSpecialty grades of Glass Fiber, Basalt Fiber, and Kevlar can all come remarkably close to Carbon Fiber on specific strength, but not stiffness, so all other composites will be significantly heavier to achieve the same mix of material properties. No natural or synthetic fiber replicates all the mechanical properties of the others, which is why all of them have their own unique roles as structural materials.

As GW pointed out, accurately evaluating potential impact-related structural damage to CFRP and GFRP is exceptionally difficult. All impact damage is cumulative, and structural degradation is not linear in nature. If you beat on Aluminum, applying a given amount of force with each impact (below the point at which it yields, obviously), then its ability to resist future impacts without failure is linear up to a point. This has never been the case with CFRP and GFRP composites. One heavy impact might reduce structural integrity by 50%, while successive impacts might do very little additional damage, or the composite may fail completely. As a general purpose fabrication material, it's a significant compromise compared to steel or Aluminum. It will never corrode the way a metal would, and won't suffer from stress-corrosion cracking the way Aluminum does, but if you ever impact it in any serious way, the entire structure is probably trash, structurally-speaking. It may not outwardly look like it's junk, but appearances can be deceiving. The fibers can and will crack within the resin matrix. As far as absorbing a singular hard impact, CFRP does that better than almost any other material, for a given weight. However, accidents will leave razor-sharp shards of composite on the roadway that will puncture tires and injure occupants or bystanders unless Kevlar liners are applied to the interior and exterior of the parts. It's a mess to clean up, but would allow people to walk away from otherwise unsurvivable accidents.

2. Steel or plastic sandwich cored steel monocoque

A. lightest possible weight amongst metal options using high strength steel

B. lowest total cost

C. least durable due to corrosion and denting

D. simplest and cheapest to repair and recycle, but still high energySteel crumple zones do a fantastic job of absorbing hard impacts. Modern FEA has allowed automotive engineers to deliberately design sacrificial vehicle structures to fold up like an accordian, absorbing most of the force of the impact in the process, while a structural "strong box" prevents intrusion into the cabin of the vehicle. Steel is very easy to work with, and modern hydroforming allows incredibly complex shapes to be formed into a single sheet of metal, work-hardening the metal to the degree of hardness required in the process. The latest sandwich core steels use thermoplastic cores so that very thin sheets with a flexible plastic core can be formed into the desired shapes, and then electrically welded together without affecting the core material.

3. Aluminum monocoque

A. Strength comparable to lower grades of mild steel, but not high-strength steel, ease of fabrication is part geometry-dependent

B. highest cost amongst metal options, similar materials cost to GFRP

C. more durable than steel if modest corrosion protection is applied, less prone to denting for the same weight as steel, but fatigue life strictly limits ultimate durability

D. Repair is possible and no more labor-intensive than steel, but not stress-corrosion damage is non-repairable, easiest and cheapest to recycle of all available optionsGiant pressure casting machines such as Tesla's GigaPress allow automotive manufacturers to press Aluminum into very complex near-net shapes, with very little subsequent machining required.

4. Flax composite monocoque

A. Strength comparable to lower grades of CFRP, especially CFRP cloth / fabrics commonly used in automotive applications, about 5X better than CFRP at noise and vibration dampening

B. Fabrication and materials cost comparable to much less costly GFRP- easier to work with than GFRP and CFRP, less of a health hazard, doesn't shatter in quite the same way as CFRP in a high-speed impact, so less of a cleanup hazard and won't puncture tires

C. Overall performance comparable to a high grade GFRP, total cost is on-par with GFRP, meaning similar to Aluminum

D. FFRP repair options are as limited as CFRP and GFRP, but markedly easier to recycle into fiber boards, so less total environmental impact, and flax crops absorb CO2A passenger vehicle for the masses is going to be of monocoque or semi-monocoque construction. It won't be a body-on-frame design, which always costs more to produce, is markedly heavier since two different crash energy absorbing structures must be designed and fabricated, less passenger-friendly (reduced ride quality and overall handling), typically doesn't protect occupants as well in a major crash, despite what people "feel" about the protection offered by a truck or SUV vs a car (personal belief or marketing and salesmanship vs actual NHTSA testing results which don't paint a pretty picture of large truck and SUV survivability, especially in rollover accidents), and always requires more power to move down the road. In practice, trucks and SUVs are typically body-on-frame designs, and they're great for towing / hauling, but not-so-great for passenger transport safety. Body-on-frame is almost necessary for off-road applications, because monocoques tend to beat themselves to death, or rather, inadequate suspension systems beat monocoques to death.

All that said, those are the practical body designs. Steel will probably be cheapest and easiest to work with, because we already do. Aluminum will be or at least could be exceptionally easy and energy-favorable to recycle. Composites will provide the most efficiency and performance.

What trades are we willing to make?

This WILL work, and it won't burn a single drop of hydrocarbon fuel. That's not even a question mark, at least in my mind. They will not accelerate any faster than economy cars, and EVs will always easily beat them in acceleration performance, but they will run down the road at 75mph and they will take you from Point A to Point B with efficiency similar to an electro-chemical battery after all infrastructure and operational costs are factored in. Air powered cars will be cheaper to operate than electro-chemical batteries or combustion engines.

We had compressed air locomotives which powered ore hauling trains used in coal mines 100 years ago, because there was no danger of fuel-air explosions without coal-fired steam engines. It worked using the tech of 100 years ago, and they only quit using compressed air after they shut the mines down. The modern replacements in new mines were either diesel engines with special modifications to suppress open flame or external electrically powered.

A YouTube video of a compressed air locomotive in action, from 2015:

Lea Bailey Light Railway Running on Air Part 1, May 2015These devices exist, they're real, if they didn't work we wouldn't have had our industrial revolution since they powered coal mines and iron foundries, and we can achieve excellent overall energy utilization efficiency by consuming the heat from air compression as hot water or steam, perhaps to power locomotives or power plants, so that we get two or even three different uses out of the energy consumption process. A solar thermal or geothermal power plant can drive the air compressors. While we're pulling heat out, from deep beneath the Earth, we can use solar thermal to inject heat back into the rock so we don't cause any problems for the mantle or core. That is what a real circular energy system and economy looks like. It's simple, it uses natural processes, it's far more cost-effective than short-lived electronics, and the materials and manufacturing processes to make that happen are all in abundant supply and it doesn't take any advanced education to use or maintain them.

The compressed air locomotive is an ancient device using 110psi compressed air stored in an Iron cylinder. A modern air powered car is storing its air at 10,290psi in a linerless or HDPE-lined CFRP cylinder. That means it contains 93.5X more air per unit of cylinder volume. A 250L tank weighs about 182kg. If the tank was made from high strength steel, it would weigh somewhere between 910kg using 250ksi steel and 1,820kg using 125ksi steel. Modern materials therefore have an outsized effect on the practicality of air powered vehicles. Put another way, that air powered locomotive would have 93.5X greater range on a single tank of compressed air, with approximately 1/5th to 1/10th of the weight devoted to its compressed air cylinder for the same volume of compressed air.

We can validly assert that a rubber tire motor vehicle, irrespective of weight, consumes 9X to 10X more power than steel wheels on steel rails due to rolling resistance, but that still means we can go at least 10X further than that old 110psi locomotive if both vehicles required the same amount of power to move their respective payloads. It's hard to do a complete apples-to-apples comparison of two very different vehicle designs and different weights, but that's accurate enough to illustrate how drastically modern materials technology has evolved from 150 years ago.

Offline

Like button can go here