New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#151 2019-12-02 15:48:13

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: 3D Printers

I think they mean the following:

A thin gelatinous mixture, made from glue, clay, or wax, that is used as a sealer or filler on paper, cloth, or plaster surfaces (also known as size).

To size something is to treat or coat (a surface) with size (also known as sizing).

Following up on basalt mixture for 3D printing feedstock:

https://3dprint.com/246666/anisoprint-n … -printing/

According to Composites Manufacturing, basalt fiber is formed from melted and drawn basalt rock, which covers almost one-third of the earth’s surface. Basalt furnaces are heated to about 1,500° Celsius, and the rock is melted before being drawn through platinum/rhodium bushings to form fibers. While leaving the furnace, these fibers are treated with sizing, which prepares them to be used in downstream applications, and for binding with resin systems.

Basalt also has a unique feature: radio transparency. It’s a great option for non-conductive elements, as parts made with CBF don’t alter the amplitude and phase of radio-frequency electromagnetic waves that are transmitted through it too much.

I'm wondering about the English used in this report:

"treated with sizing" could mean there is a substance called "sizing" (which would be a new concept for me at least)

or, the expression could be an attempt by a non-English speaker to imply that the drawn threads are somehow "sized".

If anyone in the forum membership knows, I'd appreciate a clarification.

(th)

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#152 2019-12-02 19:07:15

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,264

Re: 3D Printers

Since you are making a buildings walls to which they would be sealed with many layers of plaster, epoxies ect... since the chances of bubbles and cracks under mars condition are very likely.

Offline

Like button can go here

#153 2019-12-12 06:37:06

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,894

Re: 3D Printers

This topic was restarted in 2012, apparently shortly after a crash. It was interesting to see JoshNH4H interacting with Glandu and others about the state of the art at that time.

Today, in recognition and appreciation of activity in the parallel topic, Power to Gas, I would like to offer a speculation that 3D printing might be capable of building blades for large wind generators. More than one extruder can be engaged in building the layers, and recent posts about large scale 3D printing for habitats shows that size of the object to be printed can be considerable.

And advantage of 3D printing of wind blades is that internal bracing of the structure can be built into the program. This would be a planned extension of the idea of extternal supports already used routinely in 3D printing.

The distinct advantage of use of this technology is that mass production of blades can be set in motion, so that even though fabrication of a blade might take months, there could be hundreds of blades under construction simultaneously.

(th)

Online

Like button can go here

#154 2019-12-12 22:05:09

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,264

Re: 3D Printers

The world's first 3D-printed neighborhood is being built in Mexico for families living on $3 a day

The printer is named Vulcan II

The 33-foot printer pipes out a concrete mix that hardens when it dries, building the walls one layer at a time. It takes 24 hours over several days to build two houses at the same time -- that's about two times faster than it takes New Story to build a home with regular construction. "We think part of what 3D printing allows us to do is to deliver a much higher-quality product to the housing market at a speed and price that's typically not available for people in" low-income housing,

About 1.6 billion people in the world don't have adequate housing, according to a 2015 Habitat for Humanity study.

Offline

Like button can go here

#155 2019-12-16 22:02:53

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,894

Re: 3D Printers

Because of interest in developments with 3D Printing, here is an update which appears to show that 3D Printing as a business activity has reached a stage of performance beyond anything I've heard or read about to date;

https://techcrunch.com/2019/12/16/carbo … ports-car/

Carbon today announced the expansion of its partnership with Lamborghini. The white-hot 3D-printing startup will manufacture central and lateral dashboard air vents for the carmaker’s Sián FKP hybrid sports car.

The move follows the deal announced earlier this year that found Carbon printing a fuel cap and an air duct clip for Lamborghini’s Urus SVU. Baby steps, honestly, but important ones nonetheless. Lamborghini follows in Ford’s footsteps with the Carbon partnership.

This is (apparently) production of ** very ** high end parts for the OEM market.

The brief reference to Ford implies that Ford may be contracting for parts from this vendor, which would imply a larger sales number.

(th)

Online

Like button can go here

#156 2019-12-16 22:14:12

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,894

Re: 3D Printers

For SpaceNut re #154

Today I ran across a story (video) about a Russian builder who created a machine large enough to build a decent sized house/apartment in 24 hours. I noted that the gaps in the 3D printed wall were filled by human workmen using two different insulation materials designed/selected to withstand Russian winters.

I also noted that the horizontal braces between 3D printed wall elements were plastic rods, which (I am deducing) would NOT conduct heat from the exterior wall to the interior wall.

These observations are reported here because a recent post in the forum (possibly by RobertDyck) pointed out the obvious unsuitability of a research demonstration 3D printed wall for a cold climate.

What the Russian video demonstrates is that a combination of insightful design engineering and judicious use of supplemental human participation can yield a 3D Printed accommodation that can (or at least ** should ** ) hold up to a Russian winter.

The video included cost comparisons showing that the 3D printed design is modestly less expensive than a comparable structure built with all traditional methods.

As another side note which may be of interest to forum members ... the 3D Printing was performed inside a canvas tent.

(th)

Last edited by tahanson43206 (2019-12-16 22:14:58)

Online

Like button can go here

#157 2019-12-17 16:24:40

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,264

Re: 3D Printers

tahanson43206,

I think I can tell you where a substantial portion of the requisite excess energy went- packaging. We should also call it marketing, since that's most of what anything that came from a store actually is. Note how much energy-intensive packaging material is simply being buried, year after year, decade after decade:

Glass and Aluminum are very energy-intensive to simply bury after a few days to weeks of use, at most, but even wood and plastic require considerable energy input. There's more than enough material to go around, but not if we toss half of what we make into a landfill each year.

Affordable resources are definitely not scarce here in America, but there are more wasted resources than you can shake a stick at. Industrialization and computerization of nearly everything have made production so fast and efficient that we've wildly over-produced disposable commodities with meaningless minor variations that do nothing to improve upon the function of a product. This comes at terrible expense to efficiency and therefore cost. Many Americans can't afford to purchase the nth meaningless variation of some product or the packaging that the product comes in, even though that clearly doesn't stop them from trying. The added expense in the form of the labor, machines, and materials that were used to package / market the product is too much for the customer to afford.

Do we really need hundreds of different types of toothbrushes, or do we just need manufacturers to figure out which ones do the best job of cleaning peoples' teeth at an affordable price and then produce nothing but what does the job most effectively? Why do we need to throw away or recycle an entire toothbrush after the bristles have been damaged? Why can't we just replace the head with a new one? Is it more expensive in terms of resources and energy to make a completely new toothbrush or just the head? The answer should be pretty obvious, shouldn't it? Now apply that same disposable commodity thinking to far more energy / resource / labor intensive artifacts of modern society, like cars, ships, aircraft, and buildings. Is it any wonder that we don't have enough energy and resources to keep pace with the increasing rate of consumption?

We now have an endless variety of meaningless choices that do not make our society more effective at progressing through our technological adolescence and it costs so much that a growing number of us simply can't afford it anymore. At some point, ultimate durability or the energy consumption associated with new manufacture or reuse has to be taken into account.

If it's faster and cheaper to 3D print small houses with concrete, do we really need to mess around with an endless variety of less cost-effective / more resource-intensive alternatives, or are our finite time and monetary resources better spent figuring out how to crank out as many as we can, as fast as we can, so that people aren't living outside when it's cold enough to turn them into ice cubes? We don't need ten different floor plans and thousands of different color variations to choose from. If white paint is cheaper than red paint, then we use white paint. If no painting at all is required, even better. If we could pre-fab the entire structure at a factory and plop it down wherever, that's probably the cheapest way. Fancy is for people with plenty of disposable income from long-term stable employment. I think effective is better than fancy in this case.

Here's a rather simple final closing thought. The American consumer has paid for the packaging costs associated with burying enough Aluminum each year to completely rebuild every commercial aircraft in our current fleet, and has done so every year since at least 1990. The fleet of commercial aircraft was estimated to be around 7,400 aircraft in 2018. From just the Aluminum that we've buried in landfills each and every year since 1990, that's enough material to source more than 324,000 pounds of Aluminum per airframe. The majority of commercial aircraft, by numbers, don't weigh that much when fully loaded with passengers or cargo and fuel. That is a staggering amount of waste. If we can actually afford to do that, although I opine that we can't, then there shouldn't be any issue with obtaining cheap resources because we've literally buried billions of tons of the wood, metal, and glass required to make houses.

Offline

Like button can go here

#158 2019-12-18 21:35:46

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,264

Re: 3D Printers

another area that Researchers create functional mini-liver by 3-D bioprinting techniques to combine cells, growth factors, and biomaterials to fabricate biomedical parts that maximally imitate natural tissue characteristics. Generally, 3D bioprinting utilizes the layer-by-layer method to deposit materials known as bioinks to create tissue-like structures that are later used in medical and tissue engineering fields. Bioprinting covers a broad range of biomaterials.

Offline

Like button can go here

#159 2019-12-23 20:03:47

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,264

Re: 3D Printers

repost

It is hard to believe that the International Space Station has continuously been home to astronauts for more than nineteen years. Solving the challenges of long duration space flight with 3D Printing

The eat, sleep, relax and exercise as well as perform science in LEO.

To make all of this possible requires sending more than 7,000 pounds of spare parts to the station annually. Another 29,000 pounds of spaceflight hardware spares are stored aboard the station and another 39,000 on the ground, ready to fly if needed.

The 3D Printing in Zero G investigation produced dozens of parts, which researchers analyzed and compared with those made on the ground. Analysis revealed that microgravity had no engineering-significant effects on the process, demonstrating that a 3D printer works normally in space and paving the way to new logistics systems for long duration missions.

Using recycled material for printer feedstock could save future long-duration exploration missions from having to carry a large supply of material for 3D printing. Recycling also could make use of material that otherwise would represent a nuisance or a trash disposal issue on these missions.

As a step toward that capability, the ReFabricator investigation demonstrates technology developed by Tethers Unlimited to recycle waste plastic materials, including previously printed items, into high quality 3D-printer filament. It began operations on the space station in February of 2019.

Offline

Like button can go here

#160 2020-02-14 05:23:19

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,894

Re: 3D Printers

Here is a 3D printer report that looks encouraging for large scale implementation on Mars ...

https://www.yahoo.com/news/dubai-houses … 47043.html

The building, unveiled in October 2019 and registered by by the Guinness World Records, stands at 9.5 metres high and spans across 640 square metres. It could be the starting point of Dubai government's plans to turn the emirate into a hub for 3D printing technology.

The municipality says the building is 60 percent more sustainable than average buildings, using half of the number of construction workers.The reduction of the labour force needed to construct the building reduced the cost of production from 2.5 million dirhams (nearly $681,000) to 1 million dirhams ($272,000).

Developing 3D printing is part of a drive by the Gulf's main tourism and business hub to develop technology that cuts costs and saves time.

Online

Like button can go here

#161 2020-03-30 16:43:51

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,264

Re: 3D Printers

Here is the second time the active use of 3d printing has come to light in the fight against the corona virus. The first was to create a coupling tube to alter a scuba breathing mask to ventilator fileters for use.

How Stratasys is helping the COVID-19 medical crisis with 3D printing company, is creating needed healthcare equipment for hospitals during the COVID-19

Offline

Like button can go here

#162 2020-03-30 18:54:57

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: 3D Printers

Yes - I've noticed these reports.

It underlines how important 3D printers could be to a small human colony on Mars.

A colony of 10,000 would be well served if they had 100 or more industrial 3D printers.

Here is the second time the active use of 3d printing has come to light in the fight against the corona virus. The first was to create a coupling tube to alter a scuba breathing mask to ventilator fileters for use.

How Stratasys is helping the COVID-19 medical crisis with 3D printing company, is creating needed healthcare equipment for hospitals during the COVID-19

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#163 2020-03-31 17:55:13

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,894

Re: 3D Printers

Louis, your name is on this topic, so here is an update that I hope you will like:

https://www.yahoo.com/autos/flyin-miata … 00879.html

The article at the link above shows gradual conversion from milled steel tools to high end 3D printed ones by an automobile manufacturer.

It may turn out that developments along these lines will be helpful on Mars, where there is a supply of Carbon.

(th)

Online

Like button can go here

#164 2020-03-31 18:53:11

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,264

Re: 3D Printers

carbon-reinforced nylon tools are just as tough as the old pieces, but lighter, less likely to be damaged in the event of a drop

All very important from mass shipping stand point to mars for use but once there is insitu manufacturing energy possible.

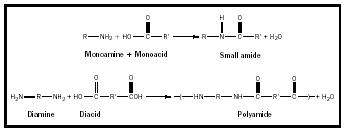

https://byjus.com/chemistry/nylon/

http://www.chemistryexplained.com/Ny-Pi/Nylon.html

The atmosphere of mars has CO2 but at low pressure so energy is with ver low nitrogen content. The regolith soils of mars have once processed the nitrogen and hydrogen.

The energy use during nylon manufacture was approximated as 85 MJ per kilogram here on Earth but would be higher on mars from insitu materials to be used to make the raw stock materials to be used by the printer.

.

Offline

Like button can go here

#165 2020-03-31 19:11:18

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: 3D Printers

Thanks TA, that was interesting. As with most technologies it takes people time to work out where best they can be applied...and of course 3D printing technology is improving all the time - getting faster and involving less after-finishing with each iteration.

I agree that 3D printing is a very good fit for Mars, especially using carbon-based materials.

Louis, your name is on this topic, so here is an update that I hope you will like:

https://www.yahoo.com/autos/flyin-miata … 00879.html

The article at the link above shows gradual conversion from milled steel tools to high end 3D printed ones by an automobile manufacturer.

It may turn out that developments along these lines will be helpful on Mars, where there is a supply of Carbon.

(th)

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#166 2020-03-31 19:23:32

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: 3D Printers

We will need to split carbon from carbon oxide in order to produce methane to fuel Starships for return to Mars, so the infrastructure will be there for producing carbon. If we are using solar power as our main energy source we will need to over-design the propellant plant facility to cope with major dust storms - so I suspect there will be a lot of spare capacity there 90% of the time...so that might provide a good starting point for nylon production.

carbon-reinforced nylon tools are just as tough as the old pieces, but lighter, less likely to be damaged in the event of a drop

All very important from mass shipping stand point to mars for use but once there is insitu manufacturing energy possible.

https://byjus.com/chemistry/nylon/

http://www.chemistryexplained.com/Ny-Pi/Nylon.htmlhttp://www.chemistryexplained.com/image … mg0647.jpg

The atmosphere of mars has CO2 but at low pressure so energy is with ver low nitrogen content. The regolith soils of mars have once processed the nitrogen and hydrogen.

The energy use during nylon manufacture was approximated as 85 MJ per kilogram here on Earth but would be higher on mars from insitu materials to be used to make the raw stock materials to be used by the printer.

.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#167 2020-04-07 10:43:09

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,894

Re: 3D Printers

For Louis re topic ...

It is time to bring this topic back into view...

There is an article behind the blurb that came in today with an industry newsletter ... if anyone is interested in the article, I'll see if I can retrieve it.

Will 3D printing shift into high gear in the Covid-19 fight?

German automaker Volkswagen has created a task force to explore how to use its more than 125 industrial 3D printers to help manufacture ventilators in the fight against coronavirus.

More from Manufacturing Technology…

Those 3D printers are (most likely) at the very high end of current 3D Printer technology.

For SpaceNut ... this item could go in the COVID-19 topic as well, and perhaps others.

(th)

Last edited by tahanson43206 (2020-04-07 10:43:59)

Online

Like button can go here

#168 2020-04-07 11:48:33

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: 3D Printers

Yes, I think we've had similar in the UK - I forget which company...one associated with Formula One I think -F1 teams all have state of the art 3D printers because they are perfect for their very low volume business!

That's how I would think of the early Mars colony. They will be high spec but low volume like F1 car manufacturers...I don't know how many cars they produce each year but it's probably something like 10! But of course, in terms of auto tech, for what they can achieve, they are at the absolute top of the range.

For Louis re topic ...

It is time to bring this topic back into view...

There is an article behind the blurb that came in today with an industry newsletter ... if anyone is interested in the article, I'll see if I can retrieve it.

Will 3D printing shift into high gear in the Covid-19 fight?

German automaker Volkswagen has created a task force to explore how to use its more than 125 industrial 3D printers to help manufacture ventilators in the fight against coronavirus.

More from Manufacturing Technology…

Those 3D printers are (most likely) at the very high end of current 3D Printer technology.

For SpaceNut ... this item could go in the COVID-19 topic as well, and perhaps others.

(th)

Last edited by louis (2020-04-07 11:48:56)

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#169 2020-04-09 18:56:04

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,894

Re: 3D Printers

The local 3D Printer group met virtually last night. The technology used was Zoom. This was my first encounter with Zoom, and the experience was flawless.

This was a meeting without an agenda. The highlight of the gathering was provided by a young woman who co-owns a 3D Printing facility with a local dentist. She provides dental devices for the dentist and for a wider client base.

However, what was special about this evening was that the lady had received an order for specially designed 3D printer capable probes for use by medical technicians needed to test for the Corona Virus. The printer behind her was hard at work during the meeting, making the first test batch of probes. The end result was a display of a small forest of devices that looked a little bit like tooth brushes, all standing on end. The ends were bristly, as seems appropriate for something to be scraped inside a human to collect specimens.

However, the reason for this post is to report a new 3D Printing filament I'd not heard of before: Glass fiber nylon filament.

https://www.3dxtech.com/glass-fiber-reinforced/

It appears this material is well along in development and apparently in commercial use. One member of the group reported intentions to try this material, although it may require more than a consumer grade 3D Printer.

The 3D Printer used to make the test probes was most definitely NOT consumer grade. The lady said she'd checked with the manufacturer, and there are 130 of these available around the United States, in case she wanted to splurge on enough to make a large order. I'm ** pretty ** sure this was a laser bath type of printer.

For SpaceNut ... this item could certainly go in the COVID-19 topic because of the product manufactured while we watched.

(th)

Online

Like button can go here

#170 2020-04-19 14:02:51

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,894

Re: 3D Printers

Here is an update for Louis' 3D Printer topic ... Very High Strength 3D printed Carbon Steel parts!

Any guesses as to how it was done, before you read the article? I didn't guess it, for sure!

https://www.yahoo.com/news/scientists-l … 00632.html

(th)

Online

Like button can go here

#171 2020-04-28 17:13:39

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,894

Re: 3D Printers

Here's an update for Louis ...

First, it's about 3D Printing

Second, a focus is on SpaceX (as prime customer)

Third, this is an article about economics, and the functioning of the market, even in difficult times

Finally, if SpaceNut were here, this would be about the new jobs being created as this industry grows...

https://www.yahoo.com/finance/news/velo … 30713.html

(th)

Online

Like button can go here

#172 2020-04-28 19:34:17

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: 3D Printers

Thanks for that TA - a very interesting article.

Of particular note:

- Space X are using the 3D printers for part of the rocket production process, it appears.

- The manufacturer claims the printers can be used to ramp up to "industrial scale" production.

3D printers will be invaluable on Mars. With this technology the Mars settlement will be able to manufacture the machines that manufacture PV panels (largely automated). They will be able to produce small scale rockets and rocket hoppers from an early stage.

They will be able to manufacture the trays, containers, tools and other equipment for farm habs. They can probably be used to begin manufacturing life support processing equipment as well.

I'm imagining some large habs containing maybe 50 plus industrial 3D printers.

I think a large industrial 3D printer uses about 6Kwes of power. So a super-hab with 50 would need about 300 Kwes of power to service it. You'd need a few CNC automatic lathes as well for finishing work.

Here's an update for Louis ...

First, it's about 3D Printing

Second, a focus is on SpaceX (as prime customer)

Third, this is an article about economics, and the functioning of the market, even in difficult times

Finally, if SpaceNut were here, this would be about the new jobs being created as this industry grows...https://www.yahoo.com/finance/news/velo … 30713.html

(th)

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#173 2020-04-28 20:25:57

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,435

Re: 3D Printers

Louis,

Do you have any idea what the printing machines that make thin film panels weigh or what their power requirements happen to be?

It may be easier to ship the first machines from Earth if they don't weigh too much.

Online

Like button can go here

#174 2020-04-29 11:03:51

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: 3D Printers

I agree that initially it makes sense to deliver a full PV production line to Mars via the Starships.

It's not easy to get all that info. I have looked into that before. There are several steps in the process in PV manufacture and each has its dedicated machine. Not sure if you get significant mass savings on the machines for a printing process.

Haven't got time to re-do the research for the whole production line but just to get a feel of the mass requirements, here's a machine that is part of a 90MW per annum production line that weighs in at 3 tons:

http://www.mondragon-assembly.com/solar … /mts-2500/

I'm thinking you could get a production line for say 35 MW per annum going at under 30 tons using machines especially designed for Mars.

Just a guess on my part. But if doable, then that might make sense for Mission 2. Or you might build up the production line over time. Initially you might send out pure silicon blocks (so they don't need to be made on Mars), and then later perhaps just pure silicon, before the Mars base takes over that role as well and puts in place processes for purification of silicon from local material.

But ultimately you want the Mars settlement to build its own PV panel or film manufacturing equipment using full ISRU. That, I imagine will take a few years, at least 10 I would think.

Here's an interesting video showing the various steps and machines - largely automated. This is for a 250 MW production line.

https://www.youtube.com/watch?v=_KTrq63Q2u4

Louis,

Do you have any idea what the printing machines that make thin film panels weigh or what their power requirements happen to be?

It may be easier to ship the first machines from Earth if they don't weigh too much.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#175 2020-05-30 18:02:49

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,894

Re: 3D Printers

The article at the link below is part of a series on "dirt".

The series concludes with consideration of building habitats on Mars and other off-Earth locations.

The 3D printer connection is via the winning entry in NASA's habitat competition, but the article considers a number of other options well known to readers of this forum.

The article would appear to have been written for a general audience, so I doubt there's anything forum readers would find new.

It ** does ** have the potential to serve as a vehicle for explaining the challenges of building a habitat on Mars or the Moon, if a forum reader knows of someone who might be interested in an introduction to the subject.

https://www.yahoo.com/regolith-cities-141549899.html

(th)

Online

Like button can go here