New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2019-04-26 11:18:20

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,988

- Website

Lunar Nickel Mining

(Crossposted from Facebook from 38 weeks ago)

I've been trying to figure out how much nickel Luna should have accumulated over the last 4+ billion years of asteroid impacts, and the answer seems to be... a lot. Really a lot.

Lunar regolith contains, from what I've been able to find on the internet, 300g of nickel per cubic metre in the form of nickel-iron particles. If the top 20cm (out of a total depth of 3m) was processed by magnets, that would yield 60 tonnes of nickel per square kilometre - over half a million dollars worth at current prices. The lunar surface area is 38 million square kilometres, so processing the top 20cm would yield 2.3 billion tonnes of nickel, if the content is uniform across Luna. By comparison, Terran land resources are estimated at a paltry 130 million tonnes. At the current price of $9000/tonne, those 2.3 billion tonnes would be worth $20 trillion dollars. The total regolith would have about 35 billion tonnes, valued at $300 trillion.

That's before we get into potential "orebodies" formed from asteroid impactors in the resulting slowly cooling magma pool...

_____________________

I know Inconel is primarily Nickel. Are there other alloys we could use that wouldn't need as much chromium? Could we shape almost pure nickel into aeroshells and land them somewhere friendly like the Australian outback?

There would also be other meteoritic metals, which might actually dwarf the value of the nickel... until we crash the market with Lunar metals.

Use what is abundant and build to last

Offline

Like button can go here

#2 2019-04-26 12:16:09

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,390

Re: Lunar Nickel Mining

For Terraformer re #1 of new topic Lunar Nickel Mining

Please develop this topic further!

It seems to fit into the ambitions of the asteroid miners, without the distance to travel.

Assuming (without having read all your posts) that your skill set does NOT include ALL of those which would be required to carry out the steps needed to realize the gains you have identified, I am hoping you can recruit experts in the fields that apply.

The NewMars forum appears to have room for a few more highly qualified members, to complement the ones who are already here.

The constant appearance of scam sales people confirms that the registration system is working just fine for some folks.

(th)

Offline

Like button can go here

#3 2019-04-26 13:03:25

- knightdepaix

- Member

- Registered: 2014-07-07

- Posts: 239

Re: Lunar Nickel Mining

What is the composition of Martian regolith?

Relatedly, can Martian dust in the dust storm be collected and mined?

Can the hydrogen sulfide from Venus be exported to Lunar factories or Martian settlement that it reacts with mineral to release water. Sulfides usually are phosphorophores.

https://en.wikipedia.org/wiki/Pyrite#Crystallography

Pyrite FeS2 has similar band gap as Silicon and is a naturally n-type semiconductor. During the early years of the 20th century, pyrite was used as a mineral detector in radio receivers, and is still used by crystal radio hobbyists. Pyrite has been proposed as an abundant, non-toxic, inexpensive material in low-cost photovoltaic solar panels.[21] Synthetic iron sulfide was used with copper sulfide to create the photovoltaic material.[22]. More recent efforts are working toward thin-film solar cells made entirely of pyrite. [23]

Can nickel sulfide replace copper sulfide in the low cost photovoltaic solar panel? That is to say low cost photovoltaic solar material on Mars are made from iron and nickel sulfides?

Last edited by knightdepaix (2019-04-26 13:31:28)

Offline

Like button can go here

#4 2019-04-26 15:14:45

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,988

- Website

Re: Lunar Nickel Mining

knightdepaix,

Possibly, but I don't think building Solar Power Satellites is going to be the big thing that funds space colonisation. That said, Luna does have sulphur, I believe, since it's been proposed as a binder in Lunacrete.

If it can be efficiently sifted from the regolith, and is sufficiently abundant, Lunar meteoritic metals could provide the revenue needed to get the cis-Lunar economy booming. Once we have that built out, colonising the rest of the solar system becomes a lot easier. I want to go to Mars too, as well as the rest of the solar system, but Mars doesn't offer the same immediate return as Luna.

Use what is abundant and build to last

Offline

Like button can go here

#5 2019-04-26 18:37:23

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,872

Re: Lunar Nickel Mining

A lunar vaccumn was discussed many years ago where a cone with inlets of of any gas to allow for the fines to be sucked up within the diameter of the unit which has a street sweeper like vehicle to catch the fines for later processing.

Still not finding the truck stuff but this is sort of like it

Offline

Like button can go here

#6 2019-04-28 08:32:08

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,390

Re: Lunar Nickel Mining

For Terraformer ...

Please continue developing this topic ...

I think it has potential to attract qualified contributors to the NewMars forum.

So much work has been done already! Books have been written, and lectures offered at major conferences.

Your initiative here can draw upon all that earlier work, and build new knowledge as research continues, discoveries are made and reported, and as individuals acquire the financial resources to have a go at creating an income stream from what today seems like an unlikely source, but which (as you point out) has the potential to become a major part of economic flows as humans expand away from Earth.

Since your topic is focused on the Moon, I'd like to bring to everyone's attention an initiative to create a virtual simulation of a lunar community.

The work is reported on thespaceshow.com. Look for Moonwards as the subject.

The site where the work is under development is www.moonwards.com

I have tested the Linux version of the beta copy of the simulation, and can report that it does work, but it is excruciatingly slow.

I tried the Windows 10 version but numerous errors were reported during initialization, and the program did not work. It didn't fail, but it didn't do anything either.

In case RobertDyck catches this post, I'd like to mention that the simulation (as well as I understand it) plans to show terraced homes built on the walls of a crater. The intention is to insure that each home is protected by a large amount of regolith, while at the same time providing a nice view out over the crater, through windows tucked far enough under the overhand to protect occupants from radiation.

My impression is that this concept is certainly transferable to Mars, where the environment is slightly less hostile.

However, what is encouraging about this work is that I can imagine an Earth based version, funded by prospective home owners who are supportive of the idea of humans living on the Moon or Mars, and willing to support testing of architectural ideas, while at the same time enjoying the abundant advantages of living on Earth, and especially of living on Earth on the outskirts of an attractive urban location.

(th)

Offline

Like button can go here

#7 2019-05-13 15:30:12

Re: Lunar Nickel Mining

I did some quick research and I was able to provide an estimate for the amount of nickel in the upper level of lunar soil.

This article suggests that iron of meteoric origin is roughly 0.25% of the regolith by mass, and on pdf page 26 (page 252 as marked) of this paper nickel composes roughly 6% of the mass of meteoric metals. We can therefore surmise that lunar regolith is about 0.014% nickel by mass. Using an assumed bulk density of 1500 kg/m^3 for the upper layer of regolith (particle density is closer to 2900 kg/m^3 but there are substantial voids caused by micrometeoroid impact, etc.), this means there will be roughly 200 grams of nickel per cubic meter of regolith. Given the substantial uncertainty in this estimate I consider my estimate of 200 g/m^3 to be generally in agreement with Terraformer's estimate of 300 g/m^3.

I propose that the separation could proceed in two phases: First, separating native metals (Iron and nickel, mostly) from bulk loose regolith. Second, separating nickel from Iron.

The first paper I linked to notes that the actual size of iron particles (and consequently I would imagine also nickel particles which are probably admixed) is often quite small, substantially less than one micron across, and that they can be physically bonded onto (or inside of) oxide particles. Ideally you'd be able to use physical methods of separation. A sieve would be easiest, but I see no reason to believe that the size profile of metal particles (and the oxide particles they bond to) would be different enough from the overall size profile of the regolith to generate a substantial separation using these means.

Next you might look to separate them using the difference in their bulk densities. This method is often used on Earth and might work, depending how tightly bound the metal microparticles are to the silicate/oxide particles. You would probably want to agitate the mix using gas flow while spinning it in a centrifuge. You're going to want to use a low-value gas, because loss rates will probably be quite high compared to the amount of nickel you ultimately recover. There might be some value, once the metal has become somewhat concentrated, in running this procedure in a basic or acidic (hot?) slurry, which may cause the silicate/oxide particles to break up somewhat and free the metal particles to be separated.

If this is not successful, you could look to exploit the electrical and/or magnetic properties of metals vs. oxides. Iron and nickel are attracted to electric and magnetic fields, while silicates are generally neutral towards them. In the hard vacuum and low gravity of the lunar surface (enabling tall structures to be built easily) it's easy to imagine a number of different possibilities for the separation of metal containing particles from non-metal containing particles, not just their different responses to electric/magnetic fields but also their different affinities for static electricity and their ability to become magnetically polarized.

If even this is found to be unsuccessful (for example, if it is typical for oxide minerals to have single atoms or small collections of native metal material distributed throughout) you need to look to more aggressive techniques: Separating out metals with the rock in the liquid state, for example, or trying to use a carbonyl process (which will certainly result in the loss of tons and tons of carbon monoxide, given the low proportion of metal materials, the ability of finely ground dust to physically and chemically absorb volatiles, and the impossibility of pumping anything down to perfect vacuum).

It will likely be the case that some mixture of the above procedures is used (in many different stages) to enrich metal levels to a usable concentration (75% would be 300x).

Once you have obtained the nickel/iron mixture in relatively pure form, I propose that the nickel be separated from the iron by a process of selective oxidation. This is a tried-and-true method (although perhaps not often used specifically for these two metals) and here's how it works: In a bath of liquid metal, introduce some oxygen. The more reactive element will oxidize while the less reactive will not. Being less dense than the metal mixture and insoluble, the oxide will float to the top as slag where it can be removed using various physical means. This process is very widely used to pull the carbon out of smelter iron to make usable steel, but I believe similar chemistry applies to the iron/nickel system. Solidus/liquidus behavior in the nickel/iron system may also allow you to concentrate it further, I'm not sure.

Launch methods are a topic for another thread. As far as entry vehicles, I favor woven basalt fiber as a thermal protective material.

-Josh

Offline

Like button can go here

#8 2019-05-13 20:11:38

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,872

Offline

Like button can go here

#10 2019-05-14 16:14:36

Re: Lunar Nickel Mining

Went back and had a look at what I said last time, and it turns out I'm nothing if not consistent.

Well firstly, global nickel consumption is around 2,250,000 tonnes per year for an annual market value of around $20 billion. That's good news for a prospective mining company because you can make several billion without harming the market. More good news: Stainless steel goes for $2000-3000/tonne and contains roughly 20% Ni. If these numbers are to be believed a huge component of the cost of stainless steel is Nickel. I don't think it's credible to say that it's 90% of the cost, as these numbers might imply, but I would absolutely say it's more than 25%. The bulk of the nickel produced in the world goes towards stainless steel. This matters because it means that the market is not only large, but likely to respond to decreases in cost with increasing demand. For comparison, Aluminium (the other major corrosion-resistant metal in common use) goes for around $2000/tonne.

As far as processing, I think you'd want to throw regolith straight into an agitating hopper with a magnet on the bottom. You'll likely recover Fe, Ni, various trace elements (probably valuable ones) and some slag that they're physically bonded to. You can remove the slag by melting and treating with CaO, and then probably just let the mix harden into a block (solidus/liquidus behavior will probably allow you to further concentrate, although I'm not sure what the solidus and liquidus will look like for any particular mixture) then ship it back to Earth for further processing.

[...]

I don't think the carbonyl process can easily be used to separate nickel from iron, because they both form volatile carbonyls. An oxidative process in the liquid state might be better because iron oxidizes much more readily than nickel.

As far as returning the objects to Earth, rocket launch is probably out of the question for cost reasons. But you might try either a tether through L1 or a launch-catch-redirect maneuver, probably involving L4/5.

-Josh

Offline

Like button can go here

#11 2019-05-14 17:05:23

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,872

Re: Lunar Nickel Mining

Sorry for the hit and run....

The shrinking of the moon means a cooling of the inner of the moons core area is seperating the molten metals into depositing layers. These would be easy to get in drilling and coring operations as we dig deep into the moons surface layers for higher concentrations of any ore on the surface. In other woods mining....

Melting temperatures of some common metals and alloys

Offline

Like button can go here

#13 2019-05-14 18:00:40

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,390

Re: Lunar Nickel Mining

Drilling down 1000+ km to the metal core of the Moon seems, er, challenging.

Two factors that would make drilling this shaft (much) less difficult than would be true on Earth are:

1) There is no atmosphere to impose pressure on workers, or equipment

2) Heat build up is less likely to be a concern than is true on Earth, with its molten core

I admit that #2 is at best speculative, because (to the best of my knowledge) no direct measurement of lunar internal temperatures have been taken.

Another factor is that removing excavated material would be less costly in energy terms, due to the lower gravity.

Can anyone else think of factors that would make this drilling operation more or less difficult than on Earth?

(th)

Offline

Like button can go here

#14 2019-05-14 18:13:46

Re: Lunar Nickel Mining

The world's current deepest mine is under 4 km deep.

While there may be some factors that make digging a 1000 km deep hole on the Moon easier than a hole of corresponding depth on Earth, it remains the case that a 1000 km mine would be 250 times deeper than the deepest operating today.

More importantly, while this may be possible (emphasis on "may" as it may not be) I can't come up with any good reason to when there are much more easily accessible sources of iron and nickel out there, starting with the surface-level sources this thread was created to think about.

-Josh

Offline

Like button can go here

#15 2019-05-14 19:22:17

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,872

Re: Lunar Nickel Mining

Not to keep it going but here a reference

https://www.popularmechanics.com/techno … ade-holes/

https://link.springer.com/content/pdf/1 … 9-0_10.pdf

https://www.iflscience.com/space/why-we … mine-moon/

Back to the surface stuff which should be easy to gather and process as its not hard. The thickness of the regolith varies from about 5 m on mare surfaces to about 10 m on highland surfaces. Lumps smaller than 1 cm are called " lunar soil ". The stuff you're probably after is the fraction fine enough to be called "dust".

Offline

Like button can go here

#16 2019-05-15 03:58:33

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,988

- Website

Re: Lunar Nickel Mining

I was inspired to think about Lunar nickel from your post about Lunar aluminium smelting. I figured that Nickel might be easier to get at (since the regolith is composed of a mix of meteorite dust and fractured crust), whilst being more valuable - and without much worry of crashing the market, unlike certain metals.

A lot depends, of course, on what form the metal is found in. I am hoping we'll be able to enrich it using magnets to separate metal-rich dust from metal-poor dust, and then use other methods to get the metal.

Use what is abundant and build to last

Offline

Like button can go here

#17 2019-05-15 09:15:31

Re: Lunar Nickel Mining

At a high level my take is generally positive, with the usual caveats of ground truth measurement and technological development/investment to actually enable this sort of production.

One point of concern for me is the low concentration of nickel compared to terran ores. I calculated a concentration of 0.014% above, while 1-3% is more common in terran ores. Having said that, in Terran ores the material typically exists as an oxide rather than a native metal so it should be substantially easier to separate. The more I think about it the more I like the electrostatic (or magnetic) tower bulk separation method, probably with some leaching process once the native metals get above a certain level.

-Josh

Offline

Like button can go here

#19 2019-05-15 10:36:47

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,988

- Website

Re: Lunar Nickel Mining

It'll be useful once we locate actual orebodies. Large Nickel-Iron impactors would have lead to magma pools, which may have led to Pentlandite forming.

Use what is abundant and build to last

Offline

Like button can go here

#20 2019-05-15 12:21:25

Re: Lunar Nickel Mining

I've got no issue with open pit mining the moon, but even the biggest, deepest open pit mine imaginable wouldn't qualify as the sort of shaft-to-hell that mining the lunar core would be.

A more interesting question might be if it would make more sense to look for meteoric orebodies (meteorebodies?) and do a more traditional type of mining or if it would be better to process the regolith like we were talking about above.

-Josh

Offline

Like button can go here

#21 2019-05-15 14:11:54

- elderflower

- Member

- Registered: 2016-06-19

- Posts: 1,262

Re: Lunar Nickel Mining

Well an impactor was the source of the orebody at Sudbury, Ontario. The same may well apply on many other solar system bodies, provided they are massive enough to give a high impact energy and cohesive enough not to fall apart.

Favoured mining targets might be Ni/Fe asteroids whose metals are not diluted with large amounts of melted rocks.

Offline

Like button can go here

#22 2019-10-23 09:27:35

- knightdepaix

- Member

- Registered: 2014-07-07

- Posts: 239

Re: Lunar Nickel Mining

(Crossposted from Facebook from 38 weeks ago)

Lunar regolith contains, from what I've been able to find on the internet, 300g of nickel per cubic metre in the form of nickel-iron particles,

Do you have that source or other that show the chemical, mineral and/or metal composition of lunar regolith. My idea for Mars is that collecting and sending nuclear waste on Earth, junk on LEO and processed mineral waste from the Moon facilitates raw material processing on Mars. Settlements on Mars on realistic terms is going to be large than those on the Moon, would they?

Offline

Like button can go here

#23 2019-10-23 15:25:15

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,988

- Website

Re: Lunar Nickel Mining

knightdepaix,

Josh' first post on the thread has some links. I think I read the figure in a Moon Society paper originally.

The important thing for space colonisation is having something that can generate a lot of revenue *and can scale*. If we can get at the Lunar nickel cheaply enough, then we can get bucks, and so get Buck Rogers.

Use what is abundant and build to last

Offline

Like button can go here

#24 2019-10-23 19:17:11

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,872

Re: Lunar Nickel Mining

Mining the Moon dreams of making use of the 7.3 x 1022kg of material circling the Earth that make up the Moon

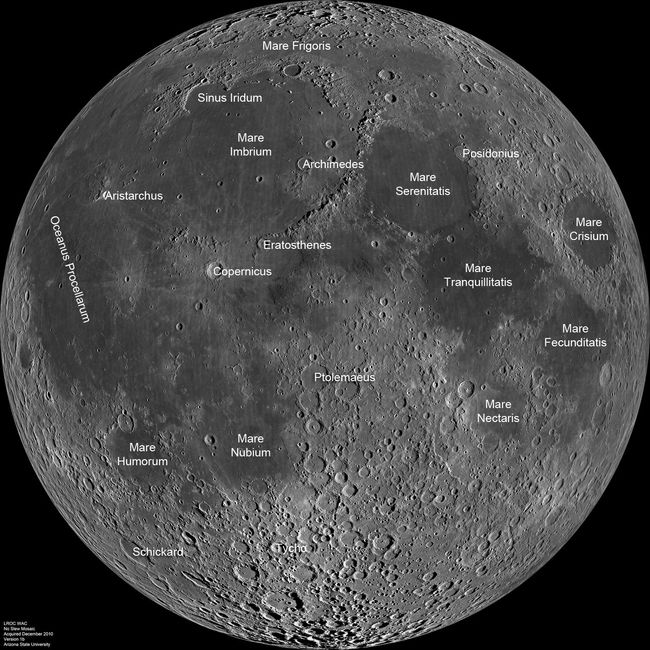

Apollo samples returned table of mineral percentages for each location

But the question Is Moon Mining Economically Feasible?

With only 2 places to go if we are solar dependant for missions we will not be making much for profit for a long time. Its with nuclear kilowat that we will have the best shot in being able to go to stay.

Offline

Like button can go here

#25 2019-10-24 20:37:29

- knightdepaix

- Member

- Registered: 2014-07-07

- Posts: 239

Re: Lunar Nickel Mining

On pdf pages 11, 39 (pages 237, 265 as marked) of this paper

aluminium, calcium are more available in lunar highland soil, iron in mare area. A good news is that average soil has more sodium, potassium and phosphorus oxides. All based on that paer, three sections of mining sites on extracting iron in mare area, aluminium and calcium in highland area and helium-3, sodium, potassium, phosphorus, stable nuclear fission elements and LEO junk processing near the transportation hub in and out of the Moon.

Nuclear waste from Earth could first be sent to the Moon as energy source. The energy is used to mining those metals and recovering stable isotopes from the waste. Useful elements would be sent to Mars.

Last edited by knightdepaix (2019-10-25 17:36:33)

Offline

Like button can go here