New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2018-12-30 19:28:47

BFS becomes SSTO with altitude compensation.

The Raptor is expected to have quite high chamber pressure, ca. 200 to 300 bar. So the sea level version gets quite good sea level Isp, 330s, and vacuum ISP, 356s. Still the vacuum Raptor gets 382s Isp in vacuum. So I used the rocket equation to estimate the payload under these two vacuum Isp values.

LEO delta-v is 30,000 ft./sec, 9,150 m/s. The BFR upper stage has 85 ton dry mass, 1,100 propellant mass. The sea level Raptor gets barely more than 1 ton to orbit in payload:

356*9.81Ln(1 + 1,100/(85 + 1.3)) = 9,152.6 m/s.

But the vacuum Raptor with 382s vacuum Isp gets nearly 20(!) tons:

382*9.81Ln(1 + 1,100/(85 + 19.8)) = 9,151.2 m/s

So using alt.comp. on the sea level Raptors so they can launch from ground yet still get the full 382 Isp of the vacuum Raptors would have major advantages as an SSTO. Note that 20 tons payload would be enough for both 100 passengers and their cargo.

The key holdup is that retrofitting usual cylindrical combustion chamber engines to use annular chambers for aerospike nozzles is expensive and time-consuming. Cheaper, faster, and just as effective is to add nozzle extensions onto already existing engines. See the J-2X discussion here:

https://www.alternatewars.com/BBOW/Spac … ngines.htm

Bob Clark

Last edited by RGClark (2018-12-31 01:09:13)

Old Space rule of acquisition (with a nod to Star Trek - the Next Generation):

“Anything worth doing is worth doing for a billion dollars.”

Offline

Like button can go here

#2 2019-01-15 21:00:10

Re: BFS becomes SSTO with altitude compensation.

In the above I calculated the BFS could be SSTO with an expandable nozzle extension. I went the route of a nozzle extension because there was some doubt if a centrally placed aerospike nozzle could fit under the BFS due to the large size of the Raptor nozzles. But it turns out cutting down the size of the nozzles easily allows the fit of a central nozzle. In fact, it likely would work on the 31 engines of the BFR booster.

Additionally, using a new approach to the aerospike may allow the individual engines to each be fitted with an aerospike:

https://exoscientist.blogspot.com/2019/ … itude.html

Bob Clark

Old Space rule of acquisition (with a nod to Star Trek - the Next Generation):

“Anything worth doing is worth doing for a billion dollars.”

Offline

Like button can go here

#3 2019-01-16 07:49:14

- elderflower

- Member

- Registered: 2016-06-19

- Posts: 1,262

Re: BFS becomes SSTO with altitude compensation.

Use of aerospikes gives you an off axis component of the thrust vector. This reduces the effective Isp.

Offline

Like button can go here

#4 2019-01-16 10:55:52

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,144

- Website

Re: BFS becomes SSTO with altitude compensation.

It is a mistake to assume "vacuum Isp" as a model for self-compensating nozzles. You need to evaluate the fluid mechanics of the nozzle vs altitude, with due allowance for off-angle streamlines, and couple that with chamber pressure and c* via the resulting thrust coefficient. And, deduct some for bled-off massflow for your pumping "cycle".

If you compare self-compensating designs that feature long spikes or surfaces (not the short ones that are in vogue), with conventional nozzles designed to barely not-separate at sea level, you will find very comparable performance during the ascent. The self-compensating design is slightly (only slightly !!!) better in the vicinity of 100 kft, and at sea level, but actually substantially worse in real vacuum, because of the streamline divergence effect.

Not conferring "vacuum Isp" (and they don't) means your SSTO potential is not really there.

These nozzles are the better choice only if (1) they are lighter than a conventional bell (and they are not), and (2) you can adequately heat protect structures partially immersed in an incandescent gas flow at high supersonic speeds. That second item is made more difficult by the inability to radiate heat away as effectively, due to the geometry. The enhanced cooling and extra hardware are why they are heavier.

I already did those calculations and posted the results at exrocketman. Look at the Isp vs altitude curves I got. The best designs are in the update, near the bottom of the article.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#5 2019-01-23 11:12:48

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,499

Re: BFS becomes SSTO with altitude compensation.

GW,

Any possibility of using hot high pressure gas from the spike to help feed the engine to reduce the mass of the turbo machinery?

You keep saying they're heavier, but how much heavier?

Forgive me, but the J-2 engine specifications I've seen from NASA said 3,480lbs for J-2 and the J2T-250 demonstrator was supposedly 3,950lbs. I'm not sure why the numbers on Wikipedia give weight figures around 3,100lbs for J-2 and J-2S. It is indeed heavier, albeit not absurdly heavier, but how fast would that mass differential be offset by a 25s+ higher specific impulse?

I noted that the XS-2200 managed to achieve specific impulse very similar to RS-25 using the gas generator cycle, whereas RS-25 is staged combustion.

Anyway, just curious about how significant the weight problem is.

Offline

Like button can go here

#6 2019-01-23 18:36:42

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,460

Re: BFS becomes SSTO with altitude compensation.

If I recall the boiloff fluids were used by Boeing for the fuel but sending in a very hot exhaust?

Offline

Like button can go here

#7 2019-01-23 19:35:53

Re: BFS becomes SSTO with altitude compensation.

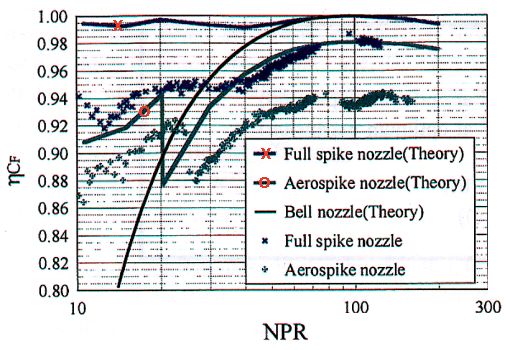

The aerospike won’t give the same performance as a fully optimized vacuum nozzle, but the performance curves I’ve seen show them to be close:

The dark x’s on the graph represent actual measured values for the full aerospike. The graph at high pressure ratios shows the performance difference from the theoretical vacuum bell nozzle of only 2 percentage points. Note this is compared to a theoretical bell nozzle so the full aerospike may be even closer to an actual bell nozzle.

The key fact is the vacuum performance of the full aerospike will be markedly higher than that of the sea level bell nozzle. As a point of comparison the current sea level Merlin gets a vacuum Isp of 312s, while the Merlin Vacuum gets a vacuum Isp of 348s. So if the full aerospike gets within 2% of the Merlin Vacuum that will be at 341s, compared to the 312s of the sea level Merlin.

Also, the new high temperature ceramics are also lightweight and may be only a third of the weight of the usual high temperature metals:

Sustainable Energy

A More Efficient Jet Engine Is Made from Lighter Parts, Some 3-D Printed.

Composite and 3-D-printed components will mean jet engines that use 15 percent less fuel.

by Kevin Bullis May 14, 2013

In the LEAP engine, the ceramic matrix composites will replace only some of the nickel alloy parts. But in the future, they could be used for more engine parts, further reducing losses from cooling. This change could also allow engines to run at higher temperatures, making it possible to get more thrust from a given amount of fuel. Furthermore, composites could make engines lighter—parts made from these materials weigh one-third as much as the equivalent nickel alloy parts.

https://www.technologyreview.com/s/5146 … d-printed/

What does need to be done though is full trajectory analysis of the aerospike SSTO compared to that of a sea level bell nozzle SSTO. The rocket equation is only an approximation and a valid argument could be made these estimates were only intended for fixed bell nozzle engines.

Bob Clark

Last edited by RGClark (2019-01-23 21:28:05)

Old Space rule of acquisition (with a nod to Star Trek - the Next Generation):

“Anything worth doing is worth doing for a billion dollars.”

Offline

Like button can go here

#8 2019-01-23 20:20:49

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,499

Re: BFS becomes SSTO with altitude compensation.

RGClark,

The point is that the nozzle for this specific rocket / upper stage has to be operable over the pressure range from Earth sea level to hard vacuum. It's not possible to optimize a conventional nozzle that must be operated at both sea level in order to land the rocket and vacuum in order to propel the upper stage into orbit. Furthermore, it's quite likely that whatever weight is added to the engines in the upper stage from a truncated annular aerospike design will be accounted for through lack of gimbal mass along with lower thrust structure, propellant feed, interstage, and landing gear masses associated with shorter engines. The mass allocations can be dead mass, design-driven mass, or functional mass, but either way you have to pay the piper. For a very large rocket, it's quite likely that higher specific impulse and a more highly integrated design will pay off. We're not simply stuck with using the materials from back in GW's heyday, either.

Offline

Like button can go here

#9 2019-01-24 06:41:58

Re: BFS becomes SSTO with altitude compensation.

GW,

Any possibility of using hot high pressure gas from the spike to help feed the engine to reduce the mass of the turbo machinery?

You keep saying they're heavier, but how much heavier?

Forgive me, but the J-2 engine specifications I've seen from NASA said 3,480lbs for J-2 and the J2T-250 demonstrator was supposedly 3,950lbs. I'm not sure why the numbers on Wikipedia give weight figures around 3,100lbs for J-2 and J-2S. It is indeed heavier, albeit not absurdly heavier, but how fast would that mass differential be offset by a 25s+ higher specific impulse?

I noted that the XS-2200 managed to achieve specific impulse very similar to RS-25 using the gas generator cycle, whereas RS-25 is staged combustion.

Anyway, just curious about how significant the weight problem is.

Don’t know about reducing turbomachinery weight, but using a small percentage of the exhaust flow to exit from the bottom of a truncated aerospike has been studied to improve the performance of the truncated version to near that of the full aerospike. Do a web search on “aerospike” and “base bleed”.

Bob Clark

Old Space rule of acquisition (with a nod to Star Trek - the Next Generation):

“Anything worth doing is worth doing for a billion dollars.”

Offline

Like button can go here

#10 2019-01-24 11:29:28

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,144

- Website

Re: BFS becomes SSTO with altitude compensation.

The “eta-CF” ordinate variable on the plot Bob provided is not the same as my “eta-KE” nozzle kinetic energy efficiency. If it were, it would show any conventional unseparated bell nozzle of 15 degree average half angle at a constant 98.3% nozzle KE efficiency from sea level to hard vacuum. (It does NOT show that for the bell nozzle.)

No free expansion design can possibly do that constant-kinetic-energy-efficiency thing, because their outer plume boundary shapes inherently change drastically as backpressure drops, to just about 90 degree half angle in hard vacuum. That’s due to basic physics, in this case Prandtl-Meyer expansion. That shape change of the plume outer boundary is EXACTLY how they adjust. You cannot have your cake, and eat it, too.

The “eta-CF” variable on the chart Bob provided includes the backpressure term in some way. That definition is not provided, so it is difficult to interpret the true meaning of the plot. My best guess is CF with backpressure term divided by CF with no backpressure term, or something like that, I just dunno. This kind of ambiguity is the effective lie by which marketeers sell gravy-train programs to government labs. Been there and done that. I know it when I see it. (That’s one benefit of being as old as I am, which is now pushing 70 pretty hard.)

The nozzle kinetic energy efficiency is THE multiplier upon the massflow x exhaust velocity term that dominates thrust from a nozzle. It does NOT multiply the exit area pressure-difference term. The bell nozzle equation to which I refer is F = eta-KE mdot Vexh + Aex (Pex – Pamb).

The “NPR” variable that is the abscissa on the plot Bob provided seems likely to be “nozzle pressure ratio”, which I would GUESS is defined as motor aft chamber pressure (right ahead of the nozzle contraction) divided by ambient static pressure. If so, for a chamber pressure on the order of 1000 psia and an ambient pressure on the order of 10 psia (sea level), this ratio is some few hundreds. For ambient pressure on the order of 1 psia, the ratio falls in the thousands. For 0.1 psia, 10’s of thousands. The chart shows high performances in the 100’s, so I presume my guess is correct.

I see ratios from 10’s to 100’s on the chart. Again, presuming my guess for the meaning of NPR is correct, the 10’s are meaningless as they relate to very low chamber pressures (vs sea level backpressure) that we are not interested in. The 100’s shown are sea level performance. There is NOTHING shown on that chart that refers to altitude backpressures, nothing at all.

If that chart were extended toward the 10’s and 100’s of thousands for NPR, you would see a falloff of whatever that eta-CF variable is, for ALL free-expansion designs, while the bell nozzle would stay fairly efficient. If the ordinate were my “eta-KE”, the bell would show a constant 98% out to NPR = infinity, while there would be some NPR where the free expansion “eta-KE” would drop to near 50%, or even lower.

Where that happens, depends upon the detailed free expansion geometry approach, and for what high-altitude backpressure it was actually designed.

The bell nozzle, if designed at sea level, will show slightly higher sea level thrust and slightly lower altitude thrust, than one designed at about 25 or 30 thousand-foot altitude backpressures. This is due to negative values for the backpressure term in the modest-altitude-design when operated at sea level.

The modest altitude backpressure design has a longer bell and higher exhaust velocity than the sea level design. The modest backpressure design altitude is that for which sea level operation does not cause the nozzle flow to separate, which is why it MUST be modest. The higher the chamber pressure, the higher that design altitude can be.

The free expansion design does better at very high altitudes when it is designed for roughly a 15 degree plume boundary expansion angle, at something like 100 kft. The plume boundary will actually contract at sea level, but the average streamline angle off axial is inherently low. The plume boundary expands to much higher angles off axial at 200 kft, and even higher at 300 kft. That is why performance falls as you ride such a design into hard vacuum.

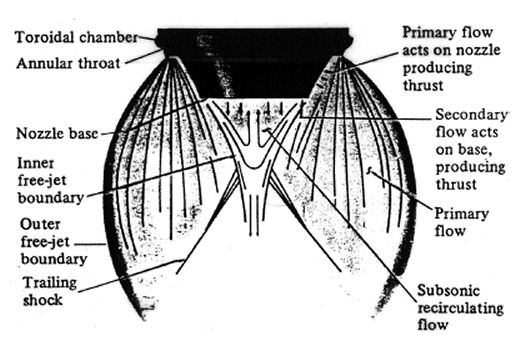

By the way, the flow pattern illustration Bob provided is a sea level or very low-altitude pattern. As you ascend, the flow pattern DOES NOT maintain that appearance. The inner boundary he shows is maintained, but the outer boundary approximates an ever-wider half-angle cone as you ascend. In hard vacuum, it is just past 90 degrees out to the side.

It’s just physics; you cannot avoid it. This really has been known for decades. There’s nothing new here. And it hasn’t changed, either. (Having literally seen this stuff for decades is another advantage of being as old as I am.)

Whether new materials can make free expansion designs lighter for the same average performance than a conventional bell, well, that remains to be seen.

There are some new “super-ceramics” that don’t melt at temperatures higher than we have ever seen before. They are high-density, and therefore inherently high thermal conductivity. Thus a compact part will tend to be isothermal. If it is that hot, then just how do you hang onto it? And with what? Now THERE’s an interesting design problem! And I have seen no solutions for it, not in all my long decades.

Plus, all dense ceramics are inherently brittle, and many are very, very vulnerable to thermal shock as well. What good is a 3-D-printed super-ceramic rocket engine-and-nozzle, if it shatters upon ignition, or shatters the first time a bit of combustion instability occurs (and it will, by the way)? And just how do you connect your propellant feed plumbing to something that hot? And if your propellant is cryogenic, just how do you stop thermal shock in your super-ceramic injector plate, when it is likely to thermal shock just exposed to ordinary-temperature fluids?

There really is quite-a-ways between some new material from a lab, and a material you can really rely on to do its job. The beta-phase titanium alloys still aren’t in Mil Handbook 5, precisely because of room-temperature aging effects. Been there and done that, too. As did the SR-71 designers. (I may be quite old, but that huge difference between a lab result and a practical “something” hasn’t changed either; and I literally spent those decades taking new “somethings:” and making them into practical “somethings”.)

GW

Last edited by GW Johnson (2019-01-24 15:16:26)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#11 2019-01-25 01:33:40

Re: BFS becomes SSTO with altitude compensation.

The drop off for the full aerospike would depend on it’s length. So how long would an aerospike have to be to be efficient at, say, 300 kft?

Even with a truncated aerospike we might be able to maintain performance with base bleed.

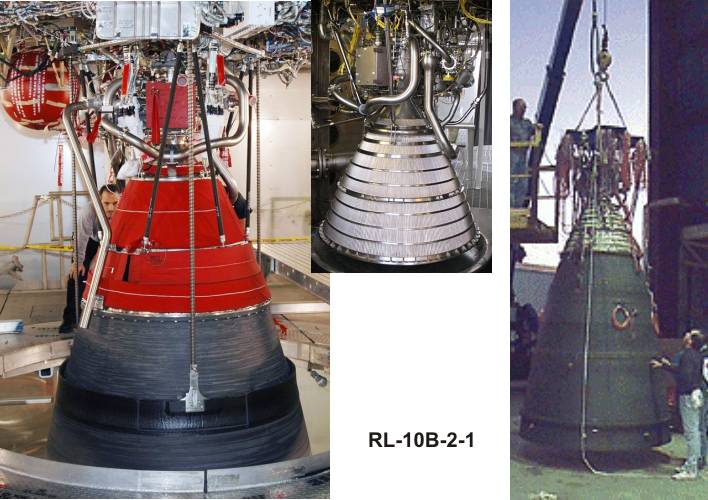

Also, note that a vacuum optimized bell nozzle engine also has a long nozzle. For instance the 20,000 lb thrust RL-10-B2 engine has an expansion ratio of 285:1 and a nozzle length of close to 12 feet:

The nozzle extension used there to get that high expansion ratio is also quite heavy. It doubles the weight of the conventional RL-10 engine from 150 kg to 300 kg.

Also, keep in mind the relevant comparison is to a sea level bell nozzle since we’re trying to get an engine for an SSTO.

Bob Clark

Last edited by RGClark (2019-01-25 01:59:56)

Old Space rule of acquisition (with a nod to Star Trek - the Next Generation):

“Anything worth doing is worth doing for a billion dollars.”

Offline

Like button can go here

#12 2019-01-25 09:41:12

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,499

Re: BFS becomes SSTO with altitude compensation.

GW,

Why can't you hang onto the "hot part" pneumatically using exhaust from the gas generators? As a function of the stagnation point created, let's say that the "hot part" is just the tip of the plug / truncated spike. What prevents you from using gas to pneumatically transfix the hottest part in place without it touching anything, sort of like an air bearing that's also bleeding a bit of gas to make up for the truncated spike?

Apart from the plug, which we already know will get very hot in operation and be difficult to cool using coolant channels (clearly not impossible since that's how J2-T-200 / J2-T-250 did it), how much more heat are we talking about for the rest of the annulus, in comparison to a conventional de Laval nozzle?

Offline

Like button can go here

#13 2019-01-25 11:56:01

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,144

- Website

Re: BFS becomes SSTO with altitude compensation.

I don't know of any pneumatic retention designs that were ever tried. Seems like any little disturbance would knock the thing loose, but I just don't know. Even if it works, there is a very hot surface in very close proximity to something a lot cooler. There will be very significant radiation from the hot part to the cooler one, if the hot part is incandescent. Which the super-ceramics will be: yellow to white hot.

An extended-dimension part that is partly in the high-convection environment, and partly is in a less stressful environment, will equilibriate at a cooler average temperature. For a wing leading edge, think a single ceramic part that extends significantly along the top and bottom surfaces away from that leading edge. Conduction through the ceramic runs from the hotter stagnation-line environment to those portions that are lateral surfaces, where the environment is milder. For high thermal conductivity, there is little temperature drop.

For a center-spike nozzle, the regenerative cooling effectiveness also depends upon how radiationally-opaque the plume is. For really clean plumes, the spike can radiationally-cool in addition to regenerative-cooling, just like a conventional bell. If the plume is clouded with incandescent particulates like soot, radiational cooling is reduced or eliminated, increasing the requirement for regenerative cooling.

The parts themselves must run incandescent, if there is to be significant radiation cooling. It's just not in the ballpark, if surfaces aren't red to yellow hot. Regenerative cooling is generally not feasible with liquids at such temperatures. It can be done with gases, but is less effective.

So, it gets down to what part of the structure can be allowed to run red hot and do radiation cooling, and what part must be kept cooler with a really large liquid coolant flow? That's how current vacuum bell nozzles work: the extension is not liquid cooled, it is radiation-cooled.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#14 2025-07-05 06:57:40

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,073

Re: BFS becomes SSTO with altitude compensation.

For all...

GW's work posted in the exrocketman.blogspot.com site is now available by a single click.

https://exrocketman.blogspot.com/search?q=ssto

The paper is detailed, with plenty of graphs to illustrate the text.

I am guessing here, but it is possible that anyone offering an opinion without reading the paper is indeed likely to be missing something important.

(th)

Offline

Like button can go here