New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#51 2018-03-10 18:48:13

Re: Construction technology for Mars?

You can use those other materials if you can ALWAYS prevent them from ever soaking out cold. That simply ain't gonna happen during construction on Mars, even if you specify insulation on the outside of the pressure vessel. Some of that practical, real-world stuff is certainly inconvenient, ain't it?

Sure is!

I disagree that it would be impossible to use those materials to the extent that it's possible to heat them continuously during construction (it's a waste of power but in principle is doable), but for the most part agree.

Looks like Aluminum 6061 has pretty good thermal response characteristics. You might modify my design so that the outside panels are Aluminium but might be able to get away with the interior cables being Carbon steel.

-Josh

Offline

Like button can go here

#52 2018-03-10 19:11:29

- Void

- Member

- Registered: 2011-12-29

- Posts: 9,073

Re: Construction technology for Mars?

Josh,

Quote:

Hey Void,

I am not going to say that the things you're suggesting are impossible or unworkable because they certainly are not, but they do require that a lot of attention be paid to the geology of your surroundings.

I am not intending to cause trouble, and I understand just how different our minds are. I have never intended to obstruct your efforts. And when I get a hint that it is time for me to step back I fully intend to step back. I just need clues of when.

But the stuff I add is intended to propose possible options, not to obstruct your work or replace it. Even with all our efforts Mars is incredibly hard.

Is it possible that the root of political science claims is to produce white collar jobs for people who paid for an education and do not want a real job?

Online

Like button can go here

#53 2018-03-10 19:15:22

- Antius

- Member

- From: Cumbria, UK

- Registered: 2007-05-22

- Posts: 1,003

Re: Construction technology for Mars?

Aluminium alloys have been used in cryogenic applications. They work, but have problems. Some problems with aluminium are it's generally poor fatigue life, it's high energy cost and high coefficient of thermal expansion.

Low temperature embrittlement will be a huge problem for any above ground pressurised structure on Mars and greenhouses need to be above ground. I suspect that any serious settlement on Mars will need to get cosy with the idea of nuclear heating. Every square metre of greenhouse will need 300W of heat energy to keep it above freezing at night. We are trying to colonize a planet that is as cold as Antarctica. On Earth, we would burn fossil fuels to keep non-pressurised structures warm and ship in food from elsewhere. On Mars, there are no fossil fuels. Food must be grown onsite in pressurised structures. That means nuclear heat, lots of nuclear heat. Each human being will need a continuous supply of about 30kW of nuclear heat just to supply him with food.

Last edited by Antius (2018-03-10 19:25:12)

Offline

Like button can go here

#54 2018-03-10 19:22:54

Re: Construction technology for Mars?

Josh,

I am not intending to cause trouble, and I understand just how different our minds are. I have never intended to obstruct your efforts. And when I get a hint that it is time for me to step back I fully intend to step back. I just need clues of when.

But the stuff I add is intended to propose possible options, not to obstruct your work or replace it. Even with all our efforts Mars is incredibly hard.

Not at all, you make good points.

I think I tend to have too strong a preference for my own designs. Probably too strong.

-Josh

Offline

Like button can go here

#55 2018-03-10 19:47:15

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,905

Re: Construction technology for Mars?

https://www.nrel.gov/docs/fy16osti/66071.pdf

Luxfer - Manufacturing of carbon composite cylinders

https://www.compositesworld.com/article … res-firsts

Taken from the BFR:

This would make a good start to making mars settled

Offline

Like button can go here

#56 2018-03-10 22:00:56

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,488

Re: Construction technology for Mars?

The properties of single polymers are well known, but this is also one of the reasons that various monomeric blends are made to give desired properties across a wide range of conditions. But this is also why I suggested that my polymers be used as a glue for regolith. For example, pure Portland Cement has different compressive properties from concrete composed of sand and gravel along with Portland Cement. This is an area for some innovation and research, and is also why various automotive companies spend big bucks on O-ring research. O-rings are primarily a combination of butadiene-styrene, and the ratios vary for maximum elasticity as opposed to rigidity and strength. Same holds with concrete mixes for the construction industry. For example a 3-bag mix (3 bags of Portland Cement per cubic yard of concrete) has pretty low compressive strength and is subsequently used for parking lot "logs." The ratio increases to a 6 bag mix for construction in Federal buildings. My point here isn't to bore everyone with the properties of concrete structures, but to illustrate that all the possible building materials aren't a single line in some table somewhere.

Offline

Like button can go here

#57 2018-08-30 17:18:43

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,905

Re: Construction technology for Mars?

Bump using concrete in a 3D printer but how will we get the mass to do so there as it will take mining for water, mining for minerals, moving equipment for both mining operations, heat energy source, electrical energy source......

Offline

Like button can go here

#58 2018-12-05 12:07:41

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,905

Re: Construction technology for Mars?

Along with the equipment to make the habitat we need the equipment to make the materials readily availble to be used by the tech that we bring

Another useful technology for Mars is rock wool. Same insulation as fibreglass but non-flammable, and perhaps more importantly easy to make. It's made by melting rock and extruding. No binder, the hot rock fibres stick together before they cool.

Comfort Batt

Offline

Like button can go here

#59 2018-12-05 17:25:28

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Construction technology for Mars?

There's going to be a balance to be struck. The chief problem on Mars will be shortage of (skilled) human labour for all the many tasks (coms, media, engineering, mining, agriculture etc etc). I am not sure it makes a lot of sense to devote a large proportion of labour time to construction if you can simply import inflatables and (virtually) self-assembly units.

I see a Mars ISRU construction capability as a matter of relatively slow growth, not because it's not feasible but because it uses a lot of labour time.

For Mars ISRU construction I favour:

1. Cut and cover technique. This technique was used to build the first line on the London Underground (subway). It's cheap and effective and of course provides plenty of radiation protection as you pile the spoil on top of the structure. Robotic diggers (with microwave attachments) should be able to work almost completely independently of humans digging the trenches.

2. Mars compressed bricks. Experiments on Earth show these are feasible.

3. Mars cement and concrete. We need a source of calcium or we will have to import it.

4. Basalt. This can be sawn into smooth rectangular panels that can be used for lining structures, and provide flooring. As Robert points out, it can also be used to create rockwool for insulation and more generally fibre glass.

5. Steel. Mars should be able to develop a steel industry quite early on.

6. Glass. Always useful, especially in agriculture.

I would recommend investing a lot of money in construction robotics on Mars, to substitute for labour. Keep everything simple and standardised. Electric conduits could simply be snap-clicked together. Same with all the plumbing. Robots should be ahble to handle these tasks.

Along with the equipment to make the habitat we need the equipment to make the materials readily availble to be used by the tech that we bring

RobertDyck wrote:Another useful technology for Mars is rock wool. Same insulation as fibreglass but non-flammable, and perhaps more importantly easy to make. It's made by melting rock and extruding. No binder, the hot rock fibres stick together before they cool.

Comfort Batt

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#60 2018-12-05 18:22:53

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,905

Re: Construction technology for Mars?

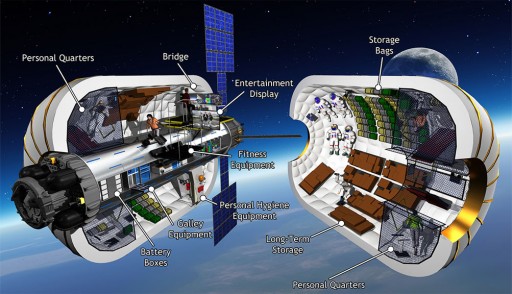

The test of Beam is an empty bag and no designs of larger with anything within them for structures have flow.

https://en.wikipedia.org/wiki/Bigelow_Aerospace

The dream of what they might look like for in space use:

Which is not for surface use.

While the Nasa unit has not flow but it is however closer to what a lander would look like with an airlock built in.

Automate equipment still needs men to set up and give it the commands to go do the work and to be monitored as it does.

Offline

Like button can go here

#61 2018-12-05 18:41:08

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Construction technology for Mars?

I've said before, I've been a bit disappointed by the slow development of the Bigelow habs. Did Musk spot a lack of urgency?

My thinking is that we can subsitute almost self-assembly habs, made of aerogel-infill panels that lock into place, and are also held in place with powerful magnets.

I'm just puzzling over whether dust would be a problem for self assembly. If so, it might the case that you would put the panels inside an inflatable plastic "bubble" which spacesuited pioneers could enter and aid final assembly of the seal unit. At that point the "bubble" can be broken or discarded.

Dust in the interior would be an annoyance that could likely be dealt with by cleaning with vaccuum cleaners and wipes prior to sealing. But my concern would be more with the seals themselves as dust might break the seal at a micro level.

http://spaceflight101.com/dragon-spx8/w … 12x295.jpg

The test of Beam is an empty bag and no designs of larger with anything within them for structures have flow.

https://en.wikipedia.org/wiki/Bigelow_AerospaceThe dream of what they might look like for in space use:

http://spaceflight101.com/dragon-spx8/w … 12x294.jpg

Which is not for surface use.

While the Nasa unit has not flow but it is however closer to what a lander would look like with an airlock built in.

http://media1.s-nbcnews.com/j/msnbc/Com … id-6x2.jpg

Automate equipment still needs men to set up and give it the commands to go do the work and to be monitored as it does.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#62 2018-12-08 04:48:55

- elderflower

- Member

- Registered: 2016-06-19

- Posts: 1,262

Re: Construction technology for Mars?

Louis. You aren't going to run a vacuum cleaner on Mars before you seal your hab. Mars atmospheric density is much too low so mass flow is tiny. Once you have sealed and pressurised your hab you can have a vacuum cleaner.

Offline

Like button can go here

#63 2018-12-31 09:28:23

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,427

Re: Construction technology for Mars?

There's going to be a balance to be struck. The chief problem on Mars will be shortage of (skilled) human labour for all the many tasks (coms, media, engineering, mining, agriculture etc etc). I am not sure it makes a lot of sense to devote a large proportion of labour time to construction if you can simply import inflatables and (virtually) self-assembly units.

6. Glass. Always useful, especially in agriculture.

3D Printing continues to advance. The work done at MIT reported here seems promising for application in Mars, since population will be small in early years, but the needs for sophisticated structures will be high in order to maintain a reasonable level of technology.

https://techcrunch.com/2018/12/31/mit-r … ing-glass/

I would add to Louis' observation above that glass utensils will be welcome for daily home use, in the health professions, as well as in a variety of industrial applications.

Edit: Here is a short YouTube video showing that the new 3D printer uses a continuous feed of hot glass.

Per kdb512's observation, the new system uses a heated lower bay to allow for slow cooling.

https://www.youtube.com/watch?v=IvcpbtpWpGY

This invention appears (to me at least) to be capable of commercial levels of output.

(th)

Last edited by tahanson43206 (2019-01-02 11:32:40)

Offline

Like button can go here

#64 2018-12-31 13:05:38

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Construction technology for Mars?

Yes, glass could have a lot of uses. Glass could be used as receptacles for food and drink. A lot easier to produce than plastics.

louis wrote:There's going to be a balance to be struck. The chief problem on Mars will be shortage of (skilled) human labour for all the many tasks (coms, media, engineering, mining, agriculture etc etc). I am not sure it makes a lot of sense to devote a large proportion of labour time to construction if you can simply import inflatables and (virtually) self-assembly units.

6. Glass. Always useful, especially in agriculture.

3D Printing continues to advance. The work done at MIT reported here seems promising for application in Mars, since population will be small in early years, but the needs for sophisticated structures will be high in order to maintain a reasonable level of technology.

https://techcrunch.com/2018/12/31/mit-r … ing-glass/

I would add to Louis' observation above that glass utensils will be welcome for daily home use, in the health professions, as well as in a variety of industrial applications.

(th)

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#65 2018-12-31 16:55:03

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,905

Re: Construction technology for Mars?

The 3d process is more inline with melting a tiny beads of glass materials with laser feed stock fed into the printer.

I know that the glass 3d printing was discussed.

Here is some of the glass topics...

Glass

Transparent Alumina - When Science fiction meet Science fact!

There might be one more but did not find it as of yet.

Offline

Like button can go here

#66 2019-01-01 05:17:07

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,988

- Website

Re: Construction technology for Mars?

Where did you get the idea that glass is easier to produce than plastics, louis?

Use what is abundant and build to last

Offline

Like button can go here

#67 2019-01-01 06:31:19

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Construction technology for Mars?

Previous debates, plus historically glass was produced millennia before plastics.

One of the early debates I had here was regarding extrusion. Some people were arguing you couldn't scale down plastic making because extrusion could only take place in large facilities. I never bought that. I think you could create scaled down machines.

I should perhaps clarify "easier" as meaning in this context easier, or simpler, to produce using ISRU materials and machinery. My understanding is that plastics manufacture involves a much wider range of chemicals not all of which could easily be produced on Mars, which has no naturally occurring oil as far as we know.

Where did you get the idea that glass is easier to produce than plastics, louis?

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#68 2019-01-01 08:19:15

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Re: Construction technology for Mars?

Louis,

Plastic extrusion doesn't require large facilities. There are plastic extrusion heads that can be mounted on robotic arms. The smallest ones I've seen require around 1kWe and probably weigh 25 pounds or so with their power supplies and extension cords. There's no reason to create scaled down machines since they already exist. Maybe NASA could figure out how to make it weigh 5 pounds for a few tens of millions of dollars. A much smaller and less power hungry machine could create beads / shreds / strips of source material for recycling. All the food packaging material needs to be recycled into something useful, for example.

Offline

Like button can go here

#69 2019-01-01 08:26:15

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Re: Construction technology for Mars?

Louis,

Glass extrusion doesn't require large facilities, either, but the 3D printed glass object must be thermally soaked to prevent it from cracking during the printing process. That's normally done with Propane, but Methane would work just fine. Various trinkets, vases, cups, and other glassware have been produced using that method. It works for one-off type stuff, but requires a lot of energy. It probably can't produce glass for a pressure vessel, though. I think ALON is more appropriate for things that must take impacts or withstand pressurization.

Offline

Like button can go here

#70 2019-01-02 11:34:19

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,427

Re: Construction technology for Mars?

Following up on kdb512's post #69, here is a short video showing that the MIT process uses a heated lower bay to permit gradual cooling.

https://www.youtube.com/watch?v=IvcpbtpWpGY

(th)

Offline

Like button can go here

#71 2019-06-22 20:45:00

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,905

Re: Construction technology for Mars?

Radiation and regolith piling onto of a habitat or created from building tunnels or other underground means controlling the amount of exposure. The more the thickness is one would feel that the lower the obsorbed dosage would be.

The journey to mars accounts for a great deal of what one might recieve and the trip back just compounds it even more.

http://www.mars-one.com/faq/health-and- … exposed-to

https://phys.org/news/2012-09-regolith-humans-mars.html

https://www.universetoday.com/107093/ho … s-mission/

http://www.marsjournal.org/contents/200 … 6_0004.pdf

Technology Radiation Effects and Shielding Requirements

https://spaceradiation.larc.nasa.gov/na … 217983.pdf

Radiation Shielding Optimization on Mars

Offline

Like button can go here

#72 2019-08-10 12:14:05

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,905

Re: Construction technology for Mars?

One of the early question is what will we bring and what can we do with it?

Are we planning to build from mars resources?

This question comes from the fact that a flag foot print mission to mars is 500 days long on its surface. Remembering the moon mission was in hrs to days long on the surface what will we do with all of that time?

Mars is unique that once we look locally its now a question of what science do we need to rush to do?

How far must we go to gather that scientific data?

Cramped living spaces are not for man so when do we start to build to give more leg and foot room?

Offline

Like button can go here

#73 2019-10-30 14:28:09

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,427

Re: Construction technology for Mars?

This article is about construction technology on the Moon.

I'm hoping it can be read with an eye for application of the concepts on Mars.

https://www.yahoo.com/news/construction … 00938.html

(th)

Offline

Like button can go here

#74 2019-10-30 17:09:00

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,905

Re: Construction technology for Mars?

The catapillar corporation has been working on telerobotic machines as they have a need even here on earth to reduce hazards for the men that work with them.

Its not the first time they have been meantioned for lunar missions and if our site still contains that posts it should turn up.

NASA previously collaborated with Caterpillar between 2004 and 2013 on a project pairing construction and robotics,

https://mars.nasa.gov/insight/weather/

Mars with temperatures from -160'F to -13'F is reason enough to want to reduce rik to crew....

Offline

Like button can go here

#75 2019-12-12 10:32:33

Re: Construction technology for Mars?

Hey All,

Much of the articles should be familiar if you follow this thread, but I'm doing a series on my blog about construction architectures on Mars. So far parts one and two are up:

Construction on Mars, Part One: General Principles and Design Assessment Criteria: In this post I give a broad overview of design constraints and produce the following six criteria for evaluation:

The structure sustains a pressurized atmosphere

The structure provides protection from radiation

The structure is failure resistant

The structure is failure tolerant

The structure can be constructed in an affordable way

The structure is useful as such

Construction on Mars, Part Two: Design, Details, and Evaluation: In this post I go into the details of my design (familiar to you all from this thread) and discuss how it meets the criteria described in Part One.

The next posts are going to discuss materials and specifications (IE dimensions), Construction technology and methods, setups for different functions, building entire settlements using these structures as units, and more!

Interested in hearing your comments and thoughts.

-Josh

Offline

Like button can go here