New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2018-11-14 05:34:40

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,358

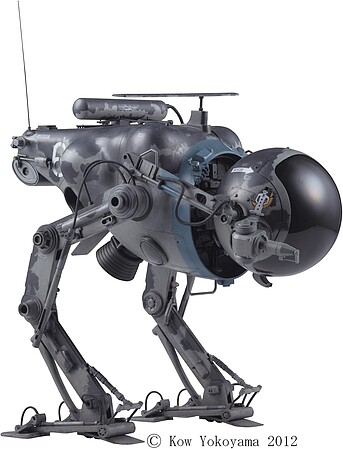

Robotic Camels for Mars Transportation

All,

I thought this would be a really fun way to see Mars if we could make it work (the bipedal vehicle part, but perhaps the rocket hopping functionality as well):

Edit (it appears that the link to the model no longer works):

Maschinen Krieger LUM-168 Camel

Model kits are still available from various model providers:

It's just a concept, but I think it's pretty cool.

Last edited by kbd512 (2023-10-02 14:16:53)

Offline

Like button can go here

#2 2018-11-14 07:50:41

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Robotic Camels for Mars Transportation

I guess the issue with a lot of these robots (like Boston Dynamics' impressive critters) is that so many joints, moving parts, wires and so on are exposed to the atmospheric temperature which on Mars is of course usually extremely cold. A simple rocket hopper would not face those disadvantages.

All,

I thought this would be a really fun way to see Mars if we could make it work (the bipedal vehicle part, but perhaps the rocket hopping functionality as well):

Maschinen Krieger LUM-168 Camel

It's just a concept, but I think it's pretty cool.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#4 2018-11-14 16:20:32

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,358

Re: Robotic Camels for Mars Transportation

Louis,

Well, this is a strange turnabout of events. In your honor, I almost feel obligated to argue the inarguable over an obvious technical problem. However, you're correct, sir. A wheeled chassis should be a more simplistic transportation solution and likely easier to use and maintain for people accustomed to driving and repairing wheeled vehicles on Earth.

That said, after NASA gets ahold of something, even the lowly wheel is subject to reinvention for novel uses. Nobody thought woven steel wire would make a great tire material before Goodyear and NASA did that, so far as I know. It turns out that it actually didn't since it was easily dented by rough terrain, so then they switched to using Nickel-Titanium Shape-Memory Metal Alloy wire. The new tires solve the permanent deformation problem, but still have fatigue life issues.

In defense of this idea, while accepting that it's a mechanically more complex solution to the transportation issue that entails the problems you so dutifully pointed out, it has some distinct advantages.

The first is that while locomotion is more complicated in the control sense, it's not significantly more complicated in the mechanical sense than the current six-wheeled rover designs that are all the rage. There are six pneumatic or hydraulic actuators and ten major points of articulation between the vehicle's two legs. Given the independent suspension and steering associated with the rovers, there are more bearing surfaces and an equivalent number of hydraulics or springs, or both, in a six-wheeled rover. However, the configuration of the rover's control mechanisms are simpler than the camel.

The second advantage is that it doesn't require a supply of replacement wheels to replace those that are damaged beyond serviceability. The surfaces in contact with the ground on the camel are just hardened steel pads not subject to severe abrasive wear from constantly sliding over rough ground.

The fatigue life of Ni-Ti SMMA is not well characterized, yet the dynamic loads placed upon these spring tires would be substantial for a crewed vehicle. It's true that only wire and hand tools are required to produce the spring tires, but that's specialty labor and very labor intensive, just like making a suit of chain mail. I'll concede that it's still very simple to do. The camel's replacement parts should be limited to joint bearings, seals for pneumatics or hydraulics. For all practical purposes, only the seals for the hydraulics would require routine maintenance.

The third advantage is mobility in rough terrain, especially terrain that would elevate one side of the vehicle and potentially lead to a rollover. It's more difficult, though certainly not impossible, to create a motor vehicle capable of travel across some of the very rugged terrain features on Mars. The camel also has the ground clearance of a monster truck. It won't as easily be stopped by a sloping debris field containing basketball-sized rocks, whereas a wheeled or even tracked vehicle would have considerable difficulty traversing such terrain features without sufficient articulation in the suspension and ground clearance.

The disadvantages are fairly obvious.

Most wheeled or tracked vehicles are simpler to design, construct, and operate, even if such vehicles use more moving parts. The much greater ride height introduces dynamic stability issues that computers must account for and overcome. While not impossible, as Boston Dynamics has more than adequately proven, it materially adds to the complexity of the vehicle. The camel's dynamic stability / motion control requires the use of gyros and sensors that detect movement. For all intents and purposes, the level of sophistication of the control software and computer hardware is no different than that of a modern fighter jet, which also uses instability to enhance maneuverability.

To exit the vehicle, the driver must be wearing a space suit. This is something that certain NASA vehicles, such as the wheeled version of MMSEV, contend with by using an airlock system. It's conceptually possible to integrate the same system into the camel, but at the expense of added mass and complexity. As a function of the ride height, the camel must also kneel to permit passengers to exit. Most of the larger NASA vehicles use simple runners or ladders for entry and exit.

In certain types of terrain, the camel would require articulating feet and/or claws to ensure that when the foot was lowered onto very rough terrain that it didn't slide off.

The camel would also exert higher ground pressure for a given weight. That's especially problematic for wheeled and tracked vehicles that generate motive force through friction or sliding contact with the terrain, though far less of a problem for the camel. It remains a real issue, nonetheless.

Offline

Like button can go here

#5 2018-11-14 16:46:11

- Quaoar

- Member

- Registered: 2013-12-13

- Posts: 665

Re: Robotic Camels for Mars Transportation

In case of falling, is this vehicle able to stand up again by itself without external aid?

If not, it may be better to switch to a more stable quadrupedal vehicle or, why not, a six legged vehicle, with one leg out capability.

Offline

Like button can go here

#6 2018-11-14 17:41:21

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,967

Re: Robotic Camels for Mars Transportation

There have been other quadraped robotic creators and while they are quite novel the real tests are planned in a war time senerio which then could lead to other uses.

We have also talked about tracks vs wheels as well and why they would be good in some senarios and not for others.

Offline

Like button can go here

#7 2018-11-15 14:54:28

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,358

Re: Robotic Camels for Mars Transportation

Quaoar,

I always have specific advantages in mind when I think about specific applications. I didn't propose this simply because it looked cool. There are some potential efficiency benefits to be had.

Would you move through a rock field at a dead run or drive through it at top speed? Either scenario could easily result in fatal injury. No person or vehicle is indestructible and being in a vehicle more suitable for rough terrain doesn't change that fact. Good judgement is still required to stay alive and remain in one piece.

A camel should be able to right itself if balance is lost and it ends up on its side. The robots from Boston Dynamics and other outfits do that already. A true rollover would be more problematic if the vehicle came to rest on its back, which is possible but improbable since the weight of the legs would tend to carry it over onto its side. A simple rope, pulley, and pitons could winch it over to its side using people power. It should be noted that ride height, therefore CG, is adjustable when moving slowly. It would be prudent to use your camel as a low rider when traversing a rocky field. Retractable carbide claws on the feet could provide additional traction and stability in rough terrain.

The vehicle I had in mind won't look exactly like the plastic model because it's a vehicle and not a piece of science fiction artwork.

Here's some ways that the robotic camel would differ from the "Maschinen Krieger Camel" science fiction model:

* materials and design techniques selected with the intent to emulate natural systems

* apart from high abrasive wear components such as the steel track pads on the feet, this design eschews the use of metal components wherever possible so as not to fling secondary particle showers from GCR impacts at the vehicle occupants

* subsequent track pad versions may use replaceable Thoraeus metallic rubber composite pads, which combine the flexibility and impact absorption of rubber with the toughness of metal and the abrasion resistance of aramid fibers in mildly cryogenic temperatures

* chassis is a rigid internal carbon composite subframe that everything else is attached to

* legs are a combination of carbon composite in the upper limbs for actuator attachment point rigidity and fiberglass composites in the lower limbs that provide shock absorption through limited deflection during movement to improve ride quality and decrease impact loading to the rest of the subframe / chassis (the tibia bone shown on the model appears to have a pneumatic shock absorber attached to the back of it)

* chassis and legs are wrapped in high density aerogel or polyethylene foam to absorb impacts from falls and collision

* hide / skin is spectra fabric for abrasion and puncture resistance from falls or running into sharp rocks

* initial versions would use discrete pneumatic or hydraulic actuator for leg movement, but subsequent versions would use integrated hydraulics like the latest Boston Dynamics robots use, thanks to the "magic" of 3D printing, and finally bundles of carbon fibers (a 0.4mm diameter bundle of coiled carbon fiber was used to lift a half gallon of water 1.4" using .172V/cm^2, as researchers from University of Illinois at Urbana-Champaign did earlier this year; some of the common fishing line artificial "muscles" can lift 100 times more weight than natural muscle fiber and generate 100 times or more the specific power, meaning mechanical work output on par with a jet engine, but these use thermal power to temporarily deform the polymer and the carbon fiber muscles use electrical power)

* camel jockey is bungee suspended in a fabric seat within a single piece polycarbonate "fishbowl" cockpit for maximum visibility in all directions

* the place where the rocket engine is shown is the hatch to a pressurized passenger / cargo compartment (perhaps a NTO/MMH rocket engine equipped hopper variant with a reduced volume cargo compartment just for the driver could be developed for lunar and asteroid exploration purposes)

* the hatch can be mated to airlock structures at bases for shirt sleeve transfer by having the camel straddle the airlock from above

* despite shirt sleeve transfer capability, vehicle occupants should always wear pressure suits with umbilical connections to the vehicle's onboard life support systems as a prudent minimal precaution against accidental depressurization, meaning personal life support backpacks are not absolutely required for transit, but a pressure suit should be worn at all times

* the passenger compartment is protected from CME/SPE using a BNNT overwrap, but the fishbowl is unprotected, so the driver must halt and wait out any CME/SPE with the rest of the passengers

* pressure vessel is surrounded by spherical composite LOX/LCH4/H2O tanks, as depicted in the photos as bulbous areas on the chassis or body (the tanks are mounted to the subframe and sandwiched between the cargo compartment pressure vessel and the impact absorbing foam)

* the little popsicle stick propeller attached to the top of the vehicle body / chassis is replaced by a small Ka-band Satcom turret

* antenna attached to the rear of the chassis is a standard omnidirectional VHF whip aerial for voice communications between vehicles and bases, as depicted

* the tank situated atop the vehicle chassis is gone

* the cigarette lighter "muffler" on the underside of the very rear of the vehicle is gone, possibly replaced with a spectra straps that hold individual life support backpacks

* the little gun turret thing on the side of the fishbowl / cockpit is removed and replaced by a small FLIR and LIDAR turret on the top of the fishbowl

* the exposed hydraulic lines on the feet are replaced with internal routing of the hydraulic lines to avoid snags on rocks using the integrated hydraulic technology developed by Boston Dynamics

* primary power is Lithium-ion battery or LOX/LCH4 fuel cell, rather than the internal combustion engine seen at the very rear of the model

* thermal regulation for cold temperature operation provided by RHU's and heat exchange pipes, just like Curiosity

Anyway, I hope that helps to paint a picture of what I was thinking about doing with this concept.

Offline

Like button can go here

#8 2022-09-23 13:42:59

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Robotic Camels for Mars Transportation

Four-legged jumping robots LEAP to explore the Moon

https://www.spacedaily.com/reports/Four … n_999.html

A four-legged robot trained through artificial intelligence has learned the same lesson as the Apollo astronauts - that jumping can be the best way to move around on the surface the Moon. An update on LEAP (Legged Exploration of the Aristarchus Plateau), a mission concept study funded by ESA to explore some of the most challenging lunar terrains, has been presented at the Europlanet Science Congress (EPSC) 2022 in Granada by Patrick Bambach.

"LEAP's target is the Aristarchus plateau, a region of the Moon that is particularly rich in geologic features but highly challenging to access," said Patrick Bambach of the Max Planck Institute for Solar System Research in Germany. "With the robot, we can investigate key features to study the geologic history and evolution of the Moon, like the ejecta around craters, fresh impact sites, and collapsed lava tubes, where material may not have been altered by space weathering and other processes."

Offline

Like button can go here

#9 2023-09-21 07:41:43

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Robotic Camels for Mars Transportation

It walks like a Crab or Spider but it is also a Rover

Very interesting lunar cave probe prototype for ILRS.

https://twitter.com/CNSAWatcher/status/ … 4437766340

International Lunar Research Station (ILRS) Chinese

,

https://m.weibo.cn/status/4946275700312138

Last edited by Mars_B4_Moon (2023-09-21 07:42:11)

Offline

Like button can go here

#10 2023-10-02 09:28:51

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,277

Re: Robotic Camels for Mars Transportation

I rather like this idea. Whilst a robotic walker has moving parts like any vehicle, the simple linear joints can be wrapped in a flexible cover material that will keep dust and detritus out of the moving parts. That is obviously impossible for any kind of wheeled vehicle. Some of that dust is as fine as talcum powder. So keeping it out of moving parts is going to be a real issue. It is even worse on the moon, which has no atmosphere and even weaker gravity. There, the dust has static charge. It wrecked astronaut space suits in hours. It is just as well the Apollo missions didn't last any longer than a couple of days.

A walker needs replacable shoes that will stand up to the wear of constant abbresion from regolith. These can be cast iron and can be moulded on Mars. Rather like horse shoes. The constant wear from Martian regolith wore out Curiosity's rover wheels after ten's km of low speed driving. I think those wheels were aluminium alloy, but don't qoute me. An iron shoe that can easily be replaced using ISRU would allow durability. We need that sort of durability if we want vehicles that can treck across the planet.

Last edited by Calliban (2023-10-02 09:31:28)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#11 2023-10-02 14:00:26

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,556

Re: Robotic Camels for Mars Transportation

For kbd512 re link below ...

Just FYI ... I tried the link today, and got a 404 ... perhaps the article is just moved?

(th)

I guess the issue with a lot of these robots (like Boston Dynamics' impressive critters) is that so many joints, moving parts, wires and so on are exposed to the atmospheric temperature which on Mars is of course usually extremely cold. A simple rocket hopper would not face those disadvantages.

kbd512 wrote:All,

I thought this would be a really fun way to see Mars if we could make it work (the bipedal vehicle part, but perhaps the rocket hopping functionality as well):

Maschinen Krieger LUM-168 Camel

It's just a concept, but I think it's pretty cool.

Offline

Like button can go here

#12 2023-10-09 06:34:26

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Robotic Camels for Mars Transportation

New AI models are training cheap robot dogs costing only hundreds of dollars, to succeed on tough Parkour obstacle course challenges.

Offline

Like button can go here

#13 2024-03-05 04:13:15

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Robotic Camels for Mars Transportation

Researchers taught a robot dog to open a door with its leg

https://www.popsci.com/technology/robot … -with-leg/

Xiaomi’s latest robot dog does backflips off skateboards, costs $3,000

https://uk.news.yahoo.com/xiaomi-latest … 54297.html

Tiny robotic crab is smallest-ever remote-controlled walking robot

https://news.northwestern.edu/stories/2 … ing-robot/

Smaller than a flea, robot can walk, bend, twist, turn and jump

Elon Musk welcomes competition from humanoid robot rivals: 'Bring it on'

https://www.yahoo.com/news/tech/elon-mu … 27403.html

For kbd512 re link below ...

Just FYI ... I tried the link today, and got a 404 ... perhaps the article is just moved?

(th)

captured in archive but no images

https://web.archive.org/web/20140929203 … ger-camel/

Last edited by Mars_B4_Moon (2024-03-05 04:16:14)

Offline

Like button can go here

#14 2024-04-12 11:34:50

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Robotic Camels for Mars Transportation

Robot dogs drill to train for moon rescue missions, navigating craters - Spirit was field tested by a team comprising engineers, cognitive scientists, geoscientists, and planetary scientists as part of the LASSIE Project.

https://interestingengineering.com/inno … expedition

A multidisciplinary team is teaching dog-like robots to navigate the moon’s craters and other challenging planetary surfaces.

As part of the research funded by NASA, researchers from various universities and NASA Johnson Space Center tested a quadruped named Spirit at Palmer Glacier on Oregon’s Mount Hood.

During five days of testing in the summer of 2023, Spirit traversed various terrains, ambling over, across, and over around shifting earth, mushy snow, and stones with his spindly metal legs.

Offline

Like button can go here