New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#26 2017-07-22 09:32:43

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,765

Re: SpaceX drops plans for propulsive Dragon landings

https://en.wikipedia.org/wiki/Antares_(rocket)

Does NASA get its money's worth for Antares-Cygnus flights?

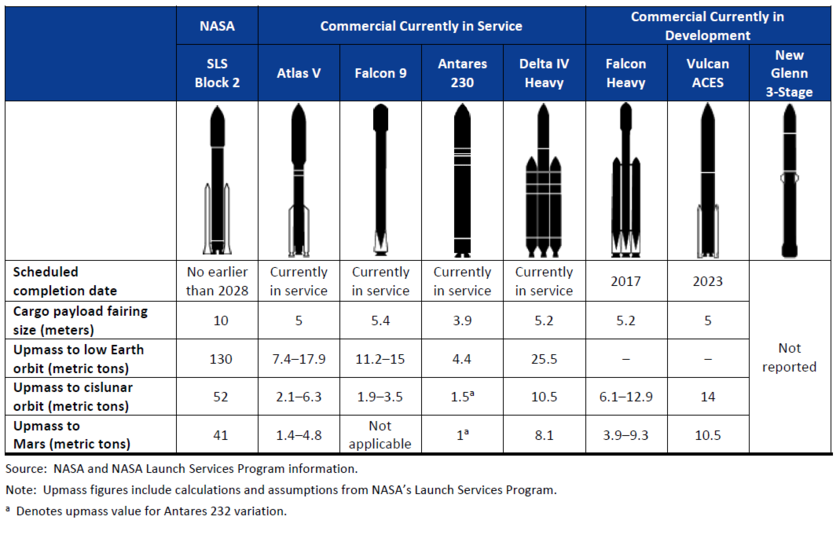

Say what to the SLS completion date no earlier than 2028????

Below this is the launch cost table....

Offline

Like button can go here

#27 2017-07-22 09:55:01

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,082

- Website

Re: SpaceX drops plans for propulsive Dragon landings

Every solid rocket motor ever made has at least one O-ring in it somewhere. One or the other end of the case has to be full-open to insert tooling and cast the propellant. That open end receives a closure (forward dome or nozzle end) held in place by pins or strip keys. The gas seal is one (and only one!!!) O-ring, leak-checked as a full motor low-pressure pressurization, before delivery to the customer.

The development process verifies the adequacy of the seal design in multiple tests. What is known about such motor seals is two-fold. (1) If the seal design is indeed adequate, then if it holds at low leak-check pressure, it will hold at full max motor pressure. (2) Solids, even non-metallized ones, are generators of dirty, solids-laden hot gases. These solids are chamber-temperature hot. You cannot use multiple O-ring seals with dirty gases, without inducing a cascade-failure mode of leak jets penetrating the next seal in line.

A single seal positively checked before delivery is far, far, far, far more reliable. THAT is what NASA could not bring itself to believe with the shuttle SRB O-ring designs: they insisted on 2, then 3, O-rings in accordance with their clean-gas experiences. And this disbelief killed one shuttle crew, and threatened all of them. That disbelief flies in the face of demonstrated one-seal effectiveness in millions upon millions of solid rocket motor-powered missiles since approximately 1940.

Yeah, a man-rated SRB is entirely feasible, is not expensive, is quite safe, and can even be segmented. Just don't let NASA tell you how to build it. Myself, I would add more powerful attitude thrusters to the core vehicle, and simple non-vectoring nozzles to the SRB. And, if you keep track of which grains came from which mixes, and carefully match grains from the same mixes into each SRB's stack, you can almost eliminate differences in thrust and burnout time between your SRB's.

Mix size is the ultimate limiting item, unless shipping intervenes. You want all of the segment to come from one mix, or it won't burn evenly. Burn rates vary a little, statistically, from mix to mix. Inherent.

There is a more neutral-burning grain design than the simple cylindrical segment, with a "best" L/D longer than the cylindrical segment, and a lower sensitivity to off-perfect L/D proportions. The cast tooling is almost as simple, too. Better characteristics, just as cheap. Why this wasn't in the shuttle SRB's is a mystery to me. It was available before the late 1970's.

The high costs of shuttle SRB's derive from the use of expensive vectoring nozzles which were not reusable, unanticipated damage loss rates from impact with the sea, and more-or-less monopolistic pricing with only 3 big-motor suppliers back then. Note that today all the major solid propellant factories are now owned by Orbital ATK. Now it really is a monopoly.

As with all the monopolies and near-monopolies whose prices we suffer from, the government lets them agglomerate without regulation of any kind, for no good reason, only ideology. But that is a different discussion.

GW

Last edited by GW Johnson (2017-07-22 10:11:59)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#28 2017-07-22 10:39:57

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,488

Re: SpaceX drops plans for propulsive Dragon landings

From the industrial chemistry point of view, the hot gasses in the exhaust would be non homogeneous, simply based of the character of what is undergoing combustion: normally ammonium perchlorate and some type of butadiene polymer--either with or without powdered Aluminum. These components are not formed from a solution, but are a mixture of different substances. Every effort is no doubt made to make the mixture as uniform as possible, but it's still a mixture. As such, the dirty flame components are highly erosive. And everything GW said about batch manufacture is dead-on. I've worked with reactors up to 10,000 gallon capacity, and every effort to make batches identical is made. Still, there can be NO mixing of final batches whatsoever for the pharma industry; the only mixing allowed is by combining several lots as precursors for final reaction processing. I fully understand the problems involved in manufacturing identical burn booster motors, and the problems are NOT TRIVIAL.

Liquid propellants are probably an easier chemical problem to handle!

Offline

Like button can go here

#29 2017-07-22 14:02:53

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,082

- Website

Re: SpaceX drops plans for propulsive Dragon landings

I forgot the small-fry stuff. Every motor has pyrotechnic items and instrumentation items attached.

These are all installed in SAE O-ring fittings (called “MS ports”). Every one of these fittings has one single O-ring, and they always have. These get checked by the same low-pressure leak check test as the main case closure seal or seals (many are wide open at both ends).

Kinda makes the NASA insistence on 2 or 3 O-rings in a segment joint seem kinda silly, doesn't it? Especially when their SRB's had those same SAE O-ring fittings for this-and-that.

If your vehicle has two strap-ons, say, then you want to be making at least two grain segments from each mix, plus the small ballistic test motors and properties test samples. One grain goes in the stack of each SRB, and in the same location within that stack, so that they see identical conditions.

If you really understand solids, there is no mystery to doing these things to get very consistent and very reliable performance. You get that understanding by actually building them. No one at NASA ever actually built one.

The rocket-science fallacy was just too seductive to NASA managers: they thought they knew everything they needed by reading reports. The science is only what was written down, the art was never written down, but is also critical. "Rocket science" ain't science, it's only about 40% science, it’s 50% art, and it’s 10% blind dumb luck, and that's in production work. The art and luck factors are even higher in development work. This is not for the amateur, except as an apprentice.

The solids in the solid rocket gases are mostly actual solids and some molten liquids. Carbon soot grit exists even in non-metallized formulations, as does a little bit of iron and iron oxide particles from the burn rate catalyst. If aluminized, there is a mix of solid and liquid particles of various aluminum oxides, mostly Al2O3. The liquids mixing with the soot plate out all over everything as "slag".

There was usually around 2-3 tons of slag inside every fired shuttle SRB, because 20% of the propellant mass was aluminum powder. On the order of 1000 tons of Al2O3 gets formed by burning in a shuttle SRB. Most of it goes out the nozzle; that’s part of the dense, persistent white smoke. A lot of the rest of the white smoke is water condensation on HCl particles, with the chlorine coming from the AP oxidizer. That’s concentrated hydrochloric acid in cloud droplet form.

These condensed phases form at near-chamber temperatures. Being incompressible, these condensed phases do not cool by expansion in pressure drops the way the gas phases do. If you do get a leak with a gas jet, the condensed phase content is essentially a 5000-6000 F sandblast stream impacting at near-gas jet speed, on whatever is in the way.

See the futility of having second and third rubber O-rings? Not even the steel O-ring groove structures survive that.

NASA's case segment O-ring leak check procedure called for putting high air pressure into the space between two adjacent O-rings. This drives them to the sides of their grooves to seal. But the upstream O-ring nearest the motor chamber is inherently and always driven to the wrong side of its groove when you do that! Upon motor pressurization (around a 5-10 millisecond event, almost a shock wave), that ring has to slam across to the correct side of its groove before it will seal.

You do that to a cold ring, and you will break it, unless you are very, very, very careful that such a pressurization event is evenly spread all along the O-ring groove. NASA did not ensure that, instead putting uncured silicone "pooky" in the insulation joint gaps between segments. Such "pooky" does not hold pressure, but in a fast pressurization event, will "wormhole-through", to leak at one single point! This phenomenon is entirely repeatable, just not predictable as to exactly where.

That "pooky" mistake is why about 1/3 of the upstream O-rings in the SRB joints had half-moon-shaped holes cut in them. In all 135 flights. Doing that to a cold stiff O-ring in Challenger's last flight is why the second ring failed, too. Debris plugged the leak in the second ring for 73 seconds, until wind shear-induced shaking knocked it loose.

None of that would have ever have happened with a single O-ring design, no "pooky", and a whole-motor low-pressure leak check. The O-ring would have seen even pressurization while already seated and sealing to the correct side of its groove. It would have just sat there, already sealed, even cold. Simple as that. Same as the O-rings in the instrumentation fittings.

As for the "pooky" in the insulation joints serving as "necessary insulation" against hot gas exposure to the joint seals, nothing at all ever beats a static gas column as good insulation! Check the thermal conductivities for yourself. The only design "trick" is the bent pressurization path so that thermal radiation from the flame (and there is far more in a solid than in a liquid engine) cannot shine directly on the O-ring. And even in the shuttle SRB, this bent path was there.

I made that statement about flame radiation quantities in solid rockets because the typical thermal emissivity of a solid material is between 0.1 and 1.0, while most gases have effective emissivities under 0.01. There’s just a whole lot more soot in the solid, at 0.95+ emissivity, plus the aluminum oxides at 0.1 to 0.2.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#30 2017-07-22 15:35:28

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,488

Re: SpaceX drops plans for propulsive Dragon landings

I read this to mean that NASA arrogance and the failure to understand that they didn't know what they were doing resulted in the deaths of 7 Americans.

Last edited by Oldfart1939 (2017-07-22 20:28:44)

Offline

Like button can go here

#31 2017-07-22 15:57:16

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,082

- Website

Re: SpaceX drops plans for propulsive Dragon landings

That's exactly right. NASA management arrogance and ignorance killed that crew, and Columbia's crew, too, by a different route. And presented quite a hazard to the other 133 crews that flew.

Challenger's crew actually had 7 aboard, if you count the civilian teacher Christa McAuliffe. My sister was not selected to go, but came close.

Not suffering fools gladly makes me a real irritant, I know, but no one was ever killed or hurt on my watch in an explosives plant, or in dealing with hazardous materials in any scenario. Not in two different careers over 4 decades, one in defense contracting, the other in civilian works. The key thing to succeeding in that is learning how to be a professional coward.

One of the civilian jobs was teaching at a university where I taught students how to run the Reid vapor pressure test on gasoline. Imagine: a lab of 30-ish total-amateur students, confining gasoline in tubes with air, and heating it with electric hot plates. Takes real sharp eyes to watch all that. And I had no lab assistant.

GW

Last edited by GW Johnson (2017-07-22 16:06:10)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#32 2017-07-22 16:25:06

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,488

Re: SpaceX drops plans for propulsive Dragon landings

Well, you're still alive to tell the tales!

Meanwhile, back to the suggestion I made earlier of a Falcon 9 "Semi Heavy," or Enhanced Falcon 9 using the Aerojet-Rocketdyne AJ-60A strap-on boosters? Using either 2 or 4 of these could really give a vehicle with some enhanced LEO performance.

Here are the numbers: Weight of each fully loaded booster: 46,697 kg; Thrust: 1,688.4 kN; Burn time: 94 seconds.

Falcon 9 v1.2 (full thrust) vehicle mass: 549,054 kg; thrust: 7,607 kN; burn time: 162 seconds.

Empty mass of first stage: NA.

Offline

Like button can go here

#33 2017-07-22 18:34:07

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,488

Re: SpaceX drops plans for propulsive Dragon landings

Back to the original topic of the original post: Musk reveals that NASA insisted on elimination of the landing legs protruding through the heat shield! So...GW was indeed correct; NASA overruled the engineering geniuses at SpaceX.

http://www.spaceflightinsider.com/organ … moon-base/ See paragraph 14 for the statement.

Last edited by Oldfart1939 (2017-07-22 18:35:21)

Offline

Like button can go here

#34 2017-07-22 18:58:36

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,765

Re: SpaceX drops plans for propulsive Dragon landings

Maybe Nasa was worried that if it came in to hot for landing that the legs would damage the internals of the capsule such that its landed cargo would be made inoperative.

So change the design and do not drive the landing so hard that its got not enough fuel or engine thrust to do the job....

Offline

Like button can go here

#35 2017-07-22 19:00:42

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,765

Re: SpaceX drops plans for propulsive Dragon landings

The strap on srb's are simular to the approach for the cores used on Boeing Delta and lockheed Atlas products, to me that means its a no brainer to make small upgrade changes for higher mass to orbit.

Offline

Like button can go here

#36 2017-07-22 20:12:13

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,321

Re: SpaceX drops plans for propulsive Dragon landings

SpaceNut,

Maybe NASA was worried that SpaceX actually hit upon a design concept that would actually work and remove another excuse from their list of excuses for not going to Mars. In any event, an all-propulsive landing is not mass-favorable on Earth or Mars. That is why NASA is working on HIAD and supersonic parachutes. There's no reason why Red Dragon or crewed Dragon could not use a HIAD heat shield for Mars landings. Heat shield mass goes down, the HIAD's materials list are COTS items requiring some hand assembly, ballistic coefficient goes down, and delivered tonnage goes up.

From the content of the talks Mr. Musk was party to from the link provided by Oldfart1939, it appears as though SpaceX is shelving their 2020 Mars colonization plans. Louis should take note of Mr. Musk walking back what he said about all-propulsive landings on Mars and the loss of the precursor missions required to demonstrate LOX/LCH4 production from local water sources. I wonder how long it'll be before Mr. Musk "discovers" that Mars is not a particularly amenable environment for using high-power solar arrays and batteries, either.

Offline

Like button can go here

#37 2017-07-22 20:31:59

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,488

Re: SpaceX drops plans for propulsive Dragon landings

Another case of NIH! (Not Invented Here).

Offline

Like button can go here

#38 2017-07-24 00:08:39

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,321

Re: SpaceX drops plans for propulsive Dragon landings

Oldfart1939,

I actually think NASA has co-opted some of the good concepts that others have come up with, especially ISRU propellant production and deployable heat shield technologies like ADEPT and HIAD. An all-propulsive landing is a good way to maximize propellant consumption and minimize landed tonnage. The ballistic coefficient of the capsule style landers is too high for effective aerodynamic braking.

Offline

Like button can go here

#39 2017-07-24 08:18:53

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,488

Re: SpaceX drops plans for propulsive Dragon landings

kbd512-

Very true. SpaceX and Blue Origin really showed up the NASA/ULA/Lockhheed Martin/Boeing engineers by being the first to successfully execute vertical propulsive landings and recover flown spacecraft.

I would wonder whether some of the side panels of the reentry capsules couldn't be extended in a manner similar to the grid fins as additional heat shield area with resulting higher drag? I would also speculate that they haven't abandoned the concept, but might incorporate the extensible landing legs from the sides, especially if they lengthen the entry vehicle with a cylindrical extension for additional cargo or crew return.

Last edited by Oldfart1939 (2017-07-24 08:20:21)

Offline

Like button can go here

#40 2017-07-24 10:42:09

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,082

- Website

Re: SpaceX drops plans for propulsive Dragon landings

From AIAA’s “Daily Launch” email newsletter for 7-24-17:

SpaceX Changes Mars Mission Plan Causing Speculation Of Their Mars Mission Being Canceled.

The Los Angeles (CA) Times (7/21) reports that there is speculation that the Mars Mission by SpaceX may be canceled because the Dragon approach to landing on Mars has changed. SpaceX CEO Elon Musk stated that the Dragon approach to landing on Mars was “no longer in line with what we were confident was the optimal way of landing on Mars.” Musk later tweeted that, “Plan is to do powered landings on Mars for sure, but with vastly bigger ship.”

--- end quote

I take this to mean the change is not whether to do powered landings, the change is whether to do Red Dragon at all, since they are no longer looking at powered landings with crew Dragon. Note the last sentence in the quote from Musk. The headline itself is entirely misleading, as so many are.

Given the work on powered landings with Dragon, I would presume there is quite a bit of turmoil in Spacex’s engineering function right now. If the powered Dragon landings are to be done at all, Musk would have to pay for that himself. He would rather do what NASA will pay him to do, perfectly understandable.

As for landing legs through the heat shield as an excuse not to do powered landings with crew Dragon (and Red Dragon), that is total and complete BS. If the space behind the leak in the heat shield is sealed to completely (and reliably!) prevent throughflow, you can have any sort of opening you want. Including wide-open holes through which to fire rocket engines.

That sealing behind a leak-in-the-heat-shield was flight-proven in 1969 with a re-flown Gemini capsule, one with a hatch cut through its heat shield. This was USAF on its MOL program, which got cancelled after its one and only (successful) test flight. Not NASA, USAF.

So “not invented here” at NASA strikes yet again! Very bad management.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#41 2017-07-24 11:23:15

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,263

- Website

Re: SpaceX drops plans for propulsive Dragon landings

I've posted this before, but will again. The ADEPT team calculated requirements to land a 40 metric tonne landed mass payload on the surface of Mars, using several different systems.

#1: 23 metre diameter heat shield during aerocapture, expand to 44 metre diameter for hypersonic and supersonic entry, propulsive landing starts mid-subsonic. Total launch mass 90 metric tonnes

#2: 33 metre diameter heat shield during all phases of atmospheric entry, propulsive landing starts high-subsonic. Total launch mass 87 metric tonnes

#3: 23 metre diameter heat shield during all phases of atmospheric entry, propulsive landing starts supersonic. Total launch mass 81 metric tonnes

#4: 23 metre diameter heat shield during aerocapture and hypersonic entry, supersonic parachute, propulsive landing only for terminal descend and landing. Total launch mass 78 metric tonnes

The last one has the lowest launch mass. This is the entry sequence used for Viking landers, Mars Phoenix, and Curiosity rover. Yes, there is a limit how much mass this can safely land on Mars. Notice this exercise is for 40 metric tonne payload landed on Mars. The Mars Direct surface habitat massed 28 metric tonnes.

Mars Colonial Transport (MCT) is much greater than 40 metric tonnes; I believe it's so massive that you must use propulsive landing. GW Johnson has said there's a limit to how much mass can be landed on Mars using the current sequence, that propulsive landing must be used for large masses. That is true, but that limit is much greater than Mars Direct.

Offline

Like button can go here

#42 2017-07-24 12:54:37

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,321

Re: SpaceX drops plans for propulsive Dragon landings

Oldfart1939,

The idea that you can't have any heat shield penetrations is just silly. The Space Shuttle had landing gear doors to protect the landing gear and NASA didn't force themselves to come up with some sort of weird landing gear that deployed from the side of the orbiter. There are people who have ideas in their heads that don't mesh with what happens in the real world. That was a major factor in the loss of Challenger and Columbia. People in management thought they knew things they clearly didn't because they made assumptions counter to the experience of the people who actually knew things. Sadly, that's pretty common occurrence for government organizations and defense contractors.

Similarly, some people at SpaceX thought that cracks in the turbine blades of their turbopumps wasn't a big deal, but NASA forced them to redesign those components. Oddly enough, I agree with the agency on this requirement before SpaceX flies humans aboard Falcon 9. "Derp" goes on everywhere. It's not just a NASA thing.

Ruptured helium tanks, cracked turbopump blades, non-rad-hardened avionics for the launch vehicle, and clean stage separation (until recently) would keep me up at night. The heat shield is either intact and built properly or it's not and the crew stands a better than average chance of missing their ticker tape parade if it's not. The moral of the story should be "inspect before use", but somehow that point has been lost (repeatedly).

I guess the thinking now is that if you don't have to expose yourself to a risk, then don't do it. Like I said before. The moral of the story should be "inspect before use". If something doesn't look or feel right, then it probably isn't. Stop what you're doing and reevaluate before you put someone's life in jeopardy (especially your own). I still don't understand why crews didn't demand thorough visual inspections prior to irreversible events. I would've thought that was basic flying 101 type stuff. I'm sure there's a method to the madness, but I'd love to know what it is.

Offline

Like button can go here

#43 2017-07-24 13:26:28

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,082

- Website

Re: SpaceX drops plans for propulsive Dragon landings

I notice in RobertDyck's post 41 above that there is hardly any difference between scenarios #3 (all-retro-propulsive) and #4 (supersonic chute and terminal retro-propulsion). It was 81 vs 78 tons at entry to land a 40 ton item, with a 23 m dia heat shield (presumed extendible in some way). Even for all 4 scenarios including very-widely expandable heat shields, the range of masses at entry was only 78 to 90 tons to land that 40 ton item.

Supersonic retro-propulsion is just not the mass-killer it is made out to be. If it was, then landing stages by Spacex and Blue Origin simply wouldn't work. The simplification it introduces confers a reliability benefit that may well be worth the extra mass at entry. Which is about 3 tons out of 78, for 3.8% increase for the study RobertDyck quotes. Probably somewhat more if no extendible heat shield is used at all, only a conventional one.

Don't know where the limits will lead, but it is clear that the options and combinations are wide open. Red Dragon might not have had the highest-possible delivered payload fraction, but it definitely would have worked, and at useful levels. And very simply, with associated reliability benefits. Supersonic chutes do still sometimes burst instead of opening. Cannot happen if you don't use one.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#44 2017-07-24 14:48:06

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,321

Re: SpaceX drops plans for propulsive Dragon landings

GW,

The use of aerodynamic deceleration was the primary reason why 3 of the 4 proposed designs "only" have entry masses of about 80t. Without the use of deployables, those reentry masses using pure retro-propulsion would have been greater still. The Falcon 9 first stage requires 7% to 10% of the initial propellant mass to achieve a soft landing at a substantially lower velocity in a substantially thicker atmosphere. If you didn't have the deployable, then how would you protect the craft from reentry heating without a heavier heat shield or bring it to a dead top without larger propellant tanks holding more propellant?

The staging velocity of Falcon boosters is less than 2km/s. The reentry at Mars will be between 7km/s and 9km/s. Did I miss something here?

Offline

Like button can go here

#45 2017-07-24 19:58:52

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,082

- Website

Re: SpaceX drops plans for propulsive Dragon landings

Mars low orbit velocity is about 3.5 km/s. Mars escape velocity is about 5 km/s. If you make a direct entry from an interplanetary trajectory, then your interface speed can be 7 to 9 km/s, with the higher value associated with short-period interplanetary trajectories near 6 months or shorter.

The kind of heat shields used for LEO entries here at home are good for 8+ km/s. Coming back from the moon during Apollo, the entry interface speed was 11 km/s, and that heat shield was only a bit thicker. Those entry speeds are just not all that challenging from an entry heating viewpoint, and Mars is even less challenging, for even the fastest direct-entry trajectories.

The problem isn't heat protection, it is simple ballistics.

At high ballistic coefficients (over 1 ton at CD ~ 1.4 to 1.7), the dynamics result in too-deep a penetration before the hypersonics are over at ~ Mach 3, even at fractional-degree path angles relative to local horizontal. The "air" on Mars is just too damned thin to effectively slow you down before you are too low to open a chute. And, terminal velocity with your chute is high-subsonic to transonic, not 20-30 mph.

That's why at least subsonic retro-propulsion is mandatory, no matter what.

For an entry from low Mars orbit, the total delta-vee is only 3.5 km/s. Entry hypersonic dynamics kill that to about local Mach 3, or 0.7 km/s, without any propulsion at all, even at high ballistic coefficient. Which means your retro-propulsion delta-vee has nothing to do with 3.5+ km/s, and everything to do with that final 0.7 km/s, almost regardless of your ballistic coefficient. The shorter timeline at lower starting altitude just means you must design to higher thrust and deceleration gees.

The real problem is only that last 0.7 km/s delta-vee, which for low ballistic coefficient, begins at 25-30 km altitudes. For high ballistic coefficient, this is around 2-5 km/s, mere seconds from impact. With a margin to cover steering and a final hover allowance, you need to design to around 1-1.5 km/s. And that's all you need. Your entry speed has almost no effect on this delta-vee whatsoever. Your entry speed affects only the thrust level at which you must deliver this 1-1.5 km/s, and how many peak entry gees your crew must endure.

At high ballistic coefficient, there is just no time available to deploy a chute, and there is no time for it to actually decelerate anything significantly below its maximum opening speed of Mach 2 to 3. The only effect of an extendible heat shield is to lower your ballistic coefficient, and thus raise the altitude at which you come out of hypersonics at Mach 3. It makes your job easier. It is not a make-or-break, go/no-go item.

THAT is why supersonic retro-propulsion is absolutely required for massive payloads on Mars. This has little to do with landing things on Earth, whether by retro-propulsion, or otherwise. Adding an extendible heat shield lowers ballistic coefficient, which merely raises that end-of-hypersonics altitude, and thus extends that final touchdown timeline. Somewhat. Only a little bit. The answer still lies between the extremes I described: 25-ish km at fractional-ton, and 5-ish km at 10+ ton.

GW

Last edited by GW Johnson (2017-07-24 20:13:37)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#46 2017-07-24 22:42:49

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,263

- Website

Re: SpaceX drops plans for propulsive Dragon landings

GW, your argument makes sense until your conclusion. Ballistic coefficient is atmospheric drag vs mass. High ballistic coefficient is good for a bullet, because it means low drag. For an entry vehicle you want low ballistic coefficient, which means high drag. The point with a deployable is to increase surface area: ADEPT unfolds like an umbrella or HIAD that inflates. Increasing surface area will increase drag.

This is what I meant by cube-square rule. The volume of a object such as an aeroshell increases as the cube of the diameter or radius. If you double radius, that means you double the width, double the length, and double the depth. That means 2 x 2 x 2 or 2³. That's because we live in a 3-Dimensional universe. And mass is directly proportional to volume, so that means mass increases as the cube of radius. However, surface area of the heat shield increases as the square of radius. Surface area of a circle is π·R². (That's supposed to be the Greek letter Pi. It doesn't show well in my browser. How about yours?) So that means "ballistic coefficient" increases with size of an aeroshell. But that's only true if you stick with the same design aeroshell that we've used for Mars Pathfinder, Spirit, Opportunity, Mars Phoenix, and now Curiosity. The whole point of a "deployable" is it dramatically increases surface area of the heat shield, so that drops "ballistic coefficient" back to equal aeroshells of past missions.

Again, there's a limit how far you can push this. However, the study I quoted above uses ADEPT in all cases. That means a heat shield made of carbon fibre fabric that unfolds like an umbrella. It does allow ballistic coefficient to drop so that a 40t landed mass payload can enter using the same supersonic parachute as Curiosity. And again, the Mars Direct ERV has a landed mass of 28.6t while the Hab has a landed mass of 25.2t. So they're well within the mass where a deployable could work.

I keep arguing for ADEPT, because that's actually what Robert Zubrin himself selected in 1990 for Mars Direct. If you want to change to HIAD, then I'll call for a competition.

However, your continuing argument that only retro-propulsion can land a large mass on Mars only applies to extremely large craft such as MCT. Yes, all your arguments are valid for MCT. No, they aren't for Mars Direct.

Last edited by RobertDyck (2017-07-24 22:50:42)

Offline

Like button can go here

#47 2017-07-25 04:24:10

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,321

Re: SpaceX drops plans for propulsive Dragon landings

GW,

The idea behind HIAD and ADEPT is to ensure your ship is subsonic at a meaningful altitude so you can use subsonic retro-propulsion rather than still being supersonic at impact. Subsonic flight should begin between 20km and 30km. That should be enough altitude to complete deceleration using the little bit of lift you get from the heat shield CG-shifting lifting body and retro-propulsion. It's no different than lining up an orbiter for landing. That bird is coming down, no matter what, and you'd better have a good landing spot picked out ahead of time.

I still think the RCC composite X-Wing concept I thought of awhile back would make a decent lander. It's a simple lifting body with four all-moving airfoils. That configuration should provide some lift, given a wing area approximately the same as a 737 and a landed tonnage of around 8t to 10t on Mars. The airfoils should have a mass of about 5t. I figure another 5t or so for the rest of the airframe, 1.5t for a composite pressure vessel, 3.5t of mono-propellant for landing, and a 5t to 7t max. Four flexible solar panels could be draped over the wings after landing to provide electrical power. It's somewhat heavy and expensive, but relatively durable. Prior to touchdown, it'd perform a flare maneuver just like the Space Shuttle to kill forward velocity and then use retro-propulsion to achieve a soft landing.

Offline

Like button can go here

#48 2017-07-25 09:43:34

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,488

Re: SpaceX drops plans for propulsive Dragon landings

This is, in reality, a multi-part problem, or set of problems. One concept offered is a form of aero-capture into a LMO, followed by a landing. That essentially breaks this into a 3-part problem, each requiring different architectures. The other possibility suggested is a direct Mars atmospheric entry and immediately coupled landing. Overall, the problem is conversion of kinetic energy into heat, it's dissipation without structural disintegration, and coming to rest without destruction of the landed system.

Musk stated that his latest iteration would be revealed later this year with a MUCH LARGER SPACECRAFT. In my mind, I immediately ask "bigger than what?" Bigger than the Dragon 2 or Red Dragon capsule? Sort of a meaningless statement, one simply fueling speculation. Whatever happens will undoubtedly require propulsive landings, but I'm betting on a Mars orbit insertion via aerobraking, followed by some sort of enhanced spaceship drag during atmospheric entry, and a low supersonic retro-propulsion. At this point we haven't a clue.

Offline

Like button can go here

#49 2017-07-25 12:45:19

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,082

- Website

Re: SpaceX drops plans for propulsive Dragon landings

So many persistently misinterpret what I say about landing on Mars. What I said in post 45 above, including my "conclusions" in the last 2 paragraphs, is in accord with everything RobertDyck and Kbd512 say in their commenting posts, except that they take me to task for somehow being wrong. No, I am not wrong. Neither are they. There are just too many filters blinding vision here.

Almost no matter how you do it, if your ballistic coefficient is high, you will come out of entry hypersonics at roughly Mach 3 and at most 5-ish km altitude, unless you slant too steep and smack the surface instead. If your ballistic coefficient is low, you reach that Mach 3 point at a much higher altitude in the 20-30 km range.

Square-cube scaling is the way to understand why heavier objects of the same shape inherently have higher ballistic coefficients. It's just math and physics. Adding an extendible low-mass heat shield (whether it is ADEPT or HIAD makes no difference) is a way to lower that ballistic coefficient by changing the shape (mostly reference area increase for the drag coefficient, that being frontal blockage area; some impact on drag coefficient itself). It really is that simple, and yet it also is really that hard to do (or it would have already been done).

Parachutes require significant time to deploy, and more significant time to actually decelerate a supersonic object to subsonic speed. They also are limited by opening-shock destruction to Mach 2-to-2.5 deployments (at max) with a ringsail, and about Mach 1.5 to 2 with a ribbon chute. Because of the venting, these chute designs are less effective at producing slow terminal velocities than other kinds of chutes, but they are the only types that survive supersonic deployment.

On Mars there is barely enough time to deploy a ringsail at about 20 km and Mach 2.5, and get the payload down to high subsonic as it nears impact. From there, it's either retropropulsion or impact airbags. We've already seen it. Square-cube rules out airbags for anything much larger and heavier than a kitchen microwave.

If the altitude is lower than 20 km at Mach 2.5, there simply isn't enough time to get a ringsail deployed, much less use it to decelerate subsonic. THAT is why the lower altitude limit is about 20 km. And with conventional shapes and their drag, you are down that low at about 1 ton landed mass. We've already seen it. It happens at about a ballistic coefficient of 100 kg/sq.m, that being mass/(blockage area*drag coefficient).

If you want to land larger objects (and we do), you can do one of two things, given the choices we have today. Those are:

(1) You can fit your object with a low-mass extendible heat shield, and lower its ballistic coefficient. If you can lower it under 100 kg/sq.m, then you will come out at about Mach 2.5 and 20 km or even higher (if lower than 100 kg/sq.m). That gives you time to use a ringsail chute and subsonic terminal retropropulsion to land, with a terminal landing delta-vee close to the theoretical 0.2 km/s from high subsonic.

You don't want to dispense with chutes and do retropropulsion from high altitude, because the time to land is inherently longer from the higher altitude, greatly driving up propellant requirements. It has exactly the same effect as requiring a long hover time, even though the theoretical delta-vee is only about 0.2 km/s. You'll really need closer to 0.7-to-1 km/s real delta-vee to land. So, go with the chute.

(2) Alternatively, you can just bring the shape in at high ballistic coefficient, which then comes out of hypersonics at Mach 3 and very low altitude (3-5 km). No way around that. Start supersonic retropropulsion and dispense with chutes entirely, because there simply isn't time to use them. Your descent time is inherently short, so you don't have to increase propellant to cover a long burn; your real delta-vee will be much closer to the theoretical delta-vee of 0.7 km/s from about Mach 3.

You'll likely need about 0.7-to-1 km/s delta-vee for safety. Call it 0.85 km/sec. But you do need a large and deeply-throttleable thrust level. You're gonna pull some gees: something like 2-4 gees in my calculations, about the same as peak hypersonic deceleration, just seconds earlier.

Now, what's the weight addition incurred to add an extendible heat shield and something like 0.2 to 0.3 km/sec delta-vee capability? Compare that with no extendible heat shield, and about 0.85 km/sec worth of propellant. It's just not all that different. Propellant weight, while significant, is just not the driver here.

If you cannot get your ballistic coefficient down under 100 kg/sq.m with the extendible heat shield, then you will inevitably come out too low to use a chute. That drives you to a long retropropulsion burn if you are still fairly high up. Thus you incur both the weight penalty of the extendible heat shield and the weight penalty of 1 km/sec worth of propellant. The only savings is ~100 kg for the chute system that you cannot make use of. Not worth it.

So, if you cannot get your ballistic coefficient down enough with the extendible heat shield, then the smart thing to do is the low altitude retropropulsion landing at high ballistic coefficient. Otherwise, go low ballistic coefficient and use the chutes with a little rocket thrust at last second. In-between is the worst of all worlds.

That choice is what I have been trying to say all along. The criterion is ballistic coefficient 100 kg/sq.m. If you can get under that, go with extendible heat shields and chutes, and budget about 0.2-0.3 km/sec worth of touchdown propellant. If you cannot get under that criterion, then forget about the extendible heat shields and chutes, and just bite the bullet and budget 0.85+ km/sec worth of propellant to land using supersonic retropropulsion. It really is that simple a judgement.

A 40 ton "tuna can" 10 m in diameter with a hypersonic CD ~ 1.6 is a ballistic coefficient of 318 kg/sq.m. You would need about 0.85 km/sec worth of propellant, tankage, and engine hardware to land that from 3-to-5 km end of hypersonics. That in turn raises your ballistic coefficient further. The only risk if your ballistic coefficient is too high, is coming out under 3 km (or even smacking the surface while hypersonic). Flying a lifting entry helps offset this risk, so that is no excuse not to do this. But it likely is a tad heavier than the chute path. Not enough to provide an excuse, but heavier.

If instead you add a 23 m dia extendible heat shield with the same CD to your “tuna can”, ballistic coefficient is grossly 60 kg/sq.m, not counting the extendible heat shield mass. You'll come out of hypersonics 20+ km above the surface because you meet the criterion. You have "room" in your ballistic coefficient to add the mass of extendible heat shield, some chutes and 0.2-0.3 km/sec worth of propellant, tankage, and engines. But you cannot exceed 100 kg/sq.m, or your chutes become unusable. This is the slightly lighter-weight option. If you can meet the criterion with an extendible heat shield proven reliable, then do it. It is the better way.

For really large things, in the hundreds of tons, it is very unlikely you can add an extendible heat shield that is strong enough to hold the air loads reliably. That’s just square-cube law effects on strength (area) versus mass (volume). Materials are only so strong. I don’t know where that limit really is, but once past it, your only choice is the retropropulsive landing from end-of-hypersonics.

It really is that simple, and it really is that sort of rather stark either/or choice, depending upon what ballistic coefficient you can achieve.

There never was an argument or an error here, on my part or anyone else's. There is only a stark choice for landing. And your achievable ballistic coefficient picks it for you. It ain’t about optimizing thrown mass (both choices are acceptable). It’s about how much time you have to do what must be done.

GW

Last edited by GW Johnson (2017-07-25 12:48:31)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#50 2017-07-25 16:27:37

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,765

Re: SpaceX drops plans for propulsive Dragon landings

https://en.wikipedia.org/wiki/Atmospheric_entry

Mars Entry, Descent, and Landing Trajectory and Atmosphere Reconstruction

http://www.ssdl.gatech.edu/sites/defaul … 0-1210.pdf

http://spacecraft.ssl.umd.edu/academics … ntry_2.pdf

http://spacecraft.ssl.umd.edu/academics … entryx.pdf

Mars Entry, Descent, and Landing Trajectory and Atmosphere Reconstruction The Atmosphere of Mars

The Analysis of Mars Atmospheric Entry Dynamics of Atmospheric Entry

The Analysis of Mars Atmospheric Entry Analysis of Deceleration

The Analysis of Mars Atmospheric Entry Exponential Atmospheric Model

It looks like we need to stay in the thicker portion of the atmospher longer to reduce speed and use less fuel as the speed of entry at the top of the path can not be changed but the time in the slope can be if we can spiral down to a landing site.

Offline

Like button can go here