New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2017-04-28 14:45:09

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Introducing the Construction Hab...

I think it would make a lot of sense for construction work to be undertaken within a specially designed construction hab that would be anchored and sealed into a trench cut around the construction site. Obviously in the early colony we're not talking about huge construction sites.

1. Construction site is cleared and marked out exactly by robot rover. Standard accommodation hab will measure about 10 metres by 3 metres. (Several such cut and cover trenches can be connected if desired, to create larger living spaces.)

2. Separate robot rover lays out PV panel system to provide power for the site. Robots dig small service tunnels for cabling.

https://www.youtube.com/watch?v=w-5YbTZLLr8

3. Robotic construction machinery is put in place around the construction site, together with materials.

4. Construction Hab is erected and installed over the construction site (anchored and sealed in trench).

5. Construction Hab is pressurised and heated above freezing.

6. Robotic digger (with integral microwave beam to warm regolith) cuts a large trench to the dimensions of the hab.

https://www.asirobots.com/mining/excavator/.

7. Construction robots puts in place steel supports and lays Mars bricks as arch over the trench. Glass bricks may also be incorporated to allow through some natural light.

https://www.youtube.com/watch?v=G_Pj2GI6-xc

http://www.popsci.com/mars-soil-bricks

8. Robotic digger lays regolith over the roof.

9. Interior is cemented over and plastered (with ISRU Mars materials).

https://www.youtube.com/watch?v=ZuRzlbG4XJ4

10. Airlock is installed under human supervision at the exit/entry point. I am still looking into that. Can we get a large airlock for a mini Rover in place?

11. Under human supervision, the new hab is fitted out with electric cabling, communication cable and life support units (including emergency battery). The life support units will intially still be imported from Earth, ready to go. Water will not be piped in. Rather, it is delivered in the equivalent of jerry cans. Farm and industrial habs will of course be laid out differently.

12. The airlock is locked before the construction hab is removed.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#2 2017-05-20 15:44:37

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Introducing the Construction Hab...

Another approach to automated construction -

http://fortune.com/2017/04/27/mit-robot … -building/

I think it would make a lot of sense for construction work to be undertaken within a specially designed construction hab that would be anchored and sealed into a trench cut around the construction site. Obviously in the early colony we're not talking about huge construction sites.

1. Construction site is cleared and marked out exactly by robot rover. Standard accommodation hab will measure about 10 metres by 3 metres. (Several such cut and cover trenches can be connected if desired, to create larger living spaces.)

2. Separate robot rover lays out PV panel system to provide power for the site. Robots dig small service tunnels for cabling.

https://www.youtube.com/watch?v=w-5YbTZLLr8

3. Robotic construction machinery is put in place around the construction site, together with materials.

4. Construction Hab is erected and installed over the construction site (anchored and sealed in trench).

5. Construction Hab is pressurised and heated above freezing.

6. Robotic digger (with integral microwave beam to warm regolith) cuts a large trench to the dimensions of the hab.

https://www.asirobots.com/mining/excavator/.

7. Construction robots puts in place steel supports and lays Mars bricks as arch over the trench. Glass bricks may also be incorporated to allow through some natural light.

https://www.youtube.com/watch?v=G_Pj2GI6-xc

http://www.popsci.com/mars-soil-bricks

8. Robotic digger lays regolith over the roof.

9. Interior is cemented over and plastered (with ISRU Mars materials).

https://www.youtube.com/watch?v=ZuRzlbG4XJ4

10. Airlock is installed under human supervision at the exit/entry point. I am still looking into that. Can we get a large airlock for a mini Rover in place?

11. Under human supervision, the new hab is fitted out with electric cabling, communication cable and life support units (including emergency battery). The life support units will intially still be imported from Earth, ready to go. Water will not be piped in. Rather, it is delivered in the equivalent of jerry cans. Farm and industrial habs will of course be laid out differently.

12. The airlock is locked before the construction hab is removed.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#3 2017-05-20 19:15:14

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,730

Re: Introducing the Construction Hab...

I am sure in time we will if we keep going have such a place to build with in but in the interum we can use any empty cargo lander to start the process if we have the tools.. Correction 3D printers with excess media to make use of with more coming on the next flight for resupply unit we can make the feed stock for them from mars insitu resources....

Offline

Like button can go here

#4 2017-05-21 03:47:08

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Introducing the Construction Hab...

"Portland cement is the basic ingredient of concrete. Concrete is formed when portland cement creates a paste with water that binds with sand and rock to harden.

Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients"

http://www.cement.org/cement-concrete-b … nt-is-made

Sand and rock for the concrete are easily sourced on Mars.

Silicon and iron for the cement are widely available.

Calcium and aluminium are more problematic but can eventually be identified and surface mined.

Maybe we'll take along some calcium and canniablise some lander craft for the aluminium?

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#5 2017-05-21 07:24:28

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,730

Re: Introducing the Construction Hab...

Building materials will come as there seems be enough hints that we will be able to come by them with some effort.

Such things as Boron for radiation protection.. Boron Enrichment in Martian Clay

silicon and oxygen, the most abundant elements in the martian crust are iron, magnesium, aluminum, calcium, and potassium.

fluorine on Mars: Implications for Gale Crater’s geochemistry Readily available phosphate from minerals in early aqueous environments on Mars Discrimination of clinically significant calcium salts using MARS Spectral CT

Offline

Like button can go here

#6 2017-05-21 16:34:25

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Introducing the Construction Hab...

Spacenut, I was pleased to find that Chrysie Planitia has calcium oxide at 6% as CP is my favoured landing site for Mission One.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#7 2017-05-24 03:25:57

- elderflower

- Member

- Registered: 2016-06-19

- Posts: 1,262

Re: Introducing the Construction Hab...

Please work out for yourselves, the upward thrust on a large half sphere anchored to the ground and pressurised to even a modest internal pressure within the limits of human surviveability. Then develop your anchor design. I think you will find that the construction of your construction dome and its anchor system will be pretty much as big a job as whatever you were going to construct inside it.

Offline

Like button can go here

#8 2017-05-24 03:42:58

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Introducing the Construction Hab...

I was envisaging a pre-constructed hab with anchoring through piled and compacted regolith perhaps in a trench either side of the construction hab edge anchor line/edge.

Please work out for yourselves, the upward thrust on a large half sphere anchored to the ground and pressurised to even a modest internal pressure within the limits of human surviveability. Then develop your anchor design. I think you will find that the construction of your construction dome and its anchor system will be pretty much as big a job as whatever you were going to construct inside it.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#9 2017-05-24 04:03:58

- elderflower

- Member

- Registered: 2016-06-19

- Posts: 1,262

Re: Introducing the Construction Hab...

Piling and trenching, then back filling requires a lot of heavy equipment, maybe blasting as well, and somewhere to store a lot of excavated spoil. This has to be done without benefit of the construction hab. You might just as well construct whatever it was you want to end up with straight away.

Your piles are in tension so just driving them to depth or to refusal is not sufficient. You have to show that they won't be pulled out, by testing them. Usual method for tension piles involves three test piles in a row. The outer two are bridged and then the middle one is pulled upwards. Because of variable geology and soil conditions this procedure is quite common on earth. Ultimate resistance of piles is quite unpredictable, but compression piles are easier.

Offline

Like button can go here

#10 2017-05-24 04:37:17

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Introducing the Construction Hab...

An ordinary mini digger comes in at about 1.5 tonnes. I think our basic 2 person human passenger rover at maybe 3 tonnes could handle that work with a digger attachment. I am not talking about a huge structure for the construction hab - probably 15 metres by 10 metres and perhaps 3 metres tall.

So we are talking about digging a trench 50 metres long and 2 metres wide to create the curtilage anchor. Maybe 1.5 metres deep. 150 cubic metres in total. If we were digging out 20 cubic metres a sol (let's say about 5 cubic metres an hour, or 1.25 cubic metres every 15 minutes), that would be an 8 sol job. The regolith you dig up provides most of the anchor, but can be further butressed outside with additional regolith. Maybe a 20 sol job to get it all up and ready, then construction of the hab itself might take another 30-50 sols.

I am thinking that the real time saving is when you come to construct the hab itself. That's where you need a lot of detailed work and that is going to be difficult either robotically or in space suits. I feel that people can work to a high standard when they can breathe freely and see up close with their own eyes.

Piling and trenching, then back filling requires a lot of heavy equipment, maybe blasting as well, and somewhere to store a lot of excavated spoil. This has to be done without benefit of the construction hab. You might just as well construct whatever it was you want to end up with straight away.

Your piles are in tension so just driving them to depth or to refusal is not sufficient. You have to show that they won't be pulled out, by testing them. Usual method for tension piles involves three test piles in a row. The outer two are bridged and then the middle one is pulled upwards. Because of variable geology and soil conditions this procedure is quite common on earth. Ultimate resistance of piles is quite unpredictable, but compression piles are easier.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#11 2017-05-24 16:39:44

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,730

Re: Introducing the Construction Hab...

When no blasting is required then the simple angled or stepped sidewalled trench is easy enough to do....

This can be done slowly so as to not put the crew at risk, angled down the blade a few inches at a time until shape is created for desired measurements. Pushing soil removed far enough away to allow for easy access to get back out to using the rover as intended.

Next step is to either install what we bring or make it in that trench. Making a mars concrete should be possible by keeping the center walls to the hieght desires and then step out at the first step a wing to use as a hole down for the structure. Back fill once complete on the sides and create a sealing top for the structure.

If desired leave one end angled for rover access with drive in enclosure area, followed by crew air lock internal to the structure.

Offline

Like button can go here

#12 2017-05-26 02:47:21

- elderflower

- Member

- Registered: 2016-06-19

- Posts: 1,262

Re: Introducing the Construction Hab...

You need to withstand huge upward thrust if you are going to do this, due to gas pressure in your dome. On earth this would be done by attaching huge masses (deadmen) or by installing tension piles.

You need to seal the bottom of your dome to prevent gas losses through the soil, which is likely to be porous, and to control the nature of the internal soil.

If the regolith isn't porous it is likely to be sealed by ice admixture or be permafrost. Either way you have to stop it from melting to avoid destabilising your foundations. Your dome will isolate the underlying soil from the natural atmosphere under which it has formed.

Offline

Like button can go here

#13 2017-05-26 05:12:25

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Introducing the Construction Hab...

I'd like to see some experiments done on porosity of Mars analogue regolith. I accept it will be porous but if it is compacted, I wonder what would happen in reality. If you have an air flow, won't all the microscopic air channels very quckly fill up with nanoparticles of dust that will then slow down the air flow? Clearly it is not an outrageous idea that gas can be kept under pressure in suitable natural environments...

http://www.hse.gov.uk/research/rrpdf/rr671.pdf

You need to withstand huge upward thrust if you are going to do this, due to gas pressure in your dome. On earth this would be done by attaching huge masses (deadmen) or by installing tension piles.

You need to seal the bottom of your dome to prevent gas losses through the soil, which is likely to be porous, and to control the nature of the internal soil.

If the regolith isn't porous it is likely to be sealed by ice admixture or be permafrost. Either way you have to stop it from melting to avoid destabilising your foundations. Your dome will isolate the underlying soil from the natural atmosphere under which it has formed.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#14 2017-05-26 16:43:12

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,730

Re: Introducing the Construction Hab...

No dome unless we need glass on the roof for natural lighting as its more like a concrete bunker or we are burying something....

Offline

Like button can go here

#15 2017-05-27 03:21:24

- elderflower

- Member

- Registered: 2016-06-19

- Posts: 1,262

Re: Introducing the Construction Hab...

Whether its a dome or a barrel vault in masonry or cement sprayed on a former, my post still applies. There will be huge gas loads which must be resisted and the soil beneath must be sealed and protected.

Offline

Like button can go here

#16 2017-05-27 09:58:53

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,487

Re: Introducing the Construction Hab...

If we can make cement, just pour a floor joined to the rest of the structure. The lifting loads will be reduced.

Offline

Like button can go here

#17 2017-05-28 06:44:41

- elderflower

- Member

- Registered: 2016-06-19

- Posts: 1,262

Re: Introducing the Construction Hab...

Oldfart, Louis wants to construct something inside it then, maybe, take it down and reassemble it somewhere else for the next construction, as I understand his proposal.

Offline

Like button can go here

#18 2017-05-28 07:29:47

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,487

Re: Introducing the Construction Hab...

Any structure sufficiently voluminous will generate huge lifting forces, unless it's a completely enclosed structure, and that includes the floor. It's simply a matter of coming to grips with the engineering realities--not a matter of "wants to."

Offline

Like button can go here

#19 2017-05-28 08:12:48

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,730

Re: Introducing the Construction Hab...

Oldfart, Louis wants to construct something inside it then, maybe, take it down and reassemble it somewhere else for the next construction, as I understand his proposal.

I think it would make a lot of sense for construction work to be undertaken within a specially designed construction hab that would be anchored and sealed into a trench cut around the construction site. Obviously in the early colony we're not talking about huge construction sites.

12. The airlock is locked before the construction hab is removed.

The real indication of a temporary structure or inflateable is indicated in first post only as a construction habitat as is removed in step 12. of the posts. Which would mean a mega structure is being created and not some sort of initial building as the opening would seem to be about a 10 m if its a solid can and something down to possibly 5 m to be able to pull it out the air lock system.

Offline

Like button can go here

#20 2017-05-28 08:37:32

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,730

Re: Introducing the Construction Hab...

Any structure sufficiently voluminous will generate huge lifting forces, unless it's a completely enclosed structure, and that includes the floor. It's simply a matter of coming to grips with the engineering realities--not a matter of "wants to."

Rereading the first post the structure could be rectangular,square or round in shape to which forming a continous top to bottom is not possible as you suggest as we will need to pour in forms the floor, walls and roof within them. I am suggesting a hold down rings for the regolith to weigh the structure down at each piece is poured....

Offline

Like button can go here

#21 2017-05-28 09:06:09

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Introducing the Construction Hab...

Just to clarify - it is intended to be a temporary surround for the construction site that can be pressurised (and heated) and so allow humans to work in relative comfort. It could then be moved to a new construction site in due course. I was thinking it would probably be either an inflatable or something like a concertina structure.

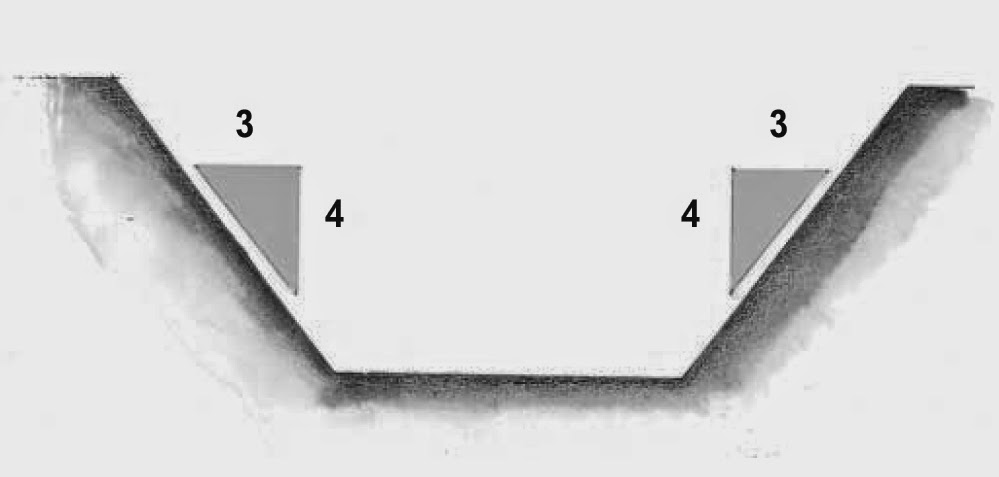

I imagined the point where the structure meets the regolith would be something like an inverted T or maybe like a W to aid the anchoring by compacted regolith.

Does anyone know what sort of anchoring requirement we are talking about?

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#22 2017-05-28 09:50:31

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,487

Re: Introducing the Construction Hab...

I question the validity of the concept of a mobile construction hab, as being a case of "bringing the Mountain to Mohammed," instead of the reverse. Once a construction facility is built, incorporation of tools and equipment subsequently accumulated will certainly limit mobility.

Offline

Like button can go here

#23 2017-05-28 11:33:04

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Introducing the Construction Hab...

I don't really see that problem. You erect the construction hab. You bring in everything you need for the construction (perhaps in phases, but maybe all in one go) and you get to work. The hab will have lighting and be temperature controlled. The construction workers can work in light MCP suits with emergency air supply at the ready and with a pressurised rover parked up should they need to access it at any time.

With trench style construction, there will be far fewer building materials than would otherwise be the case. Mars bricks, steel supports and so on can be laid at at appropriate locations within the construction hab.

I question the validity of the concept of a mobile construction hab, as being a case of "bringing the Mountain to Mohammed," instead of the reverse. Once a construction facility is built, incorporation of tools and equipment subsequently accumulated will certainly limit mobility.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#24 2017-05-28 13:05:10

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,730

Re: Introducing the Construction Hab...

So we are making some sort of large temporary structure to be able to build the permanent structure within?

Which when we pressurize to be able to build within and without space suits is that what is trying to be accomplished?

Is this really what the intended purpose is?

Offline

Like button can go here

#25 2017-05-28 13:33:18

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,985

- Website

Re: Introducing the Construction Hab...

Why pressurise it? We can just use MCP suits.

Use what is abundant and build to last

Offline

Like button can go here