New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#26 2015-10-29 15:37:34

- Antius

- Member

- From: Cumbria, UK

- Registered: 2007-05-22

- Posts: 1,003

Re: An Island getaway on Mars

Antius wrote:I would suggest a semi-transparent masonry

Antius wrote:Nothing wrong with glass. I'm not sure about the transmittance of a sheet of glass 3m thick. Producing glass sheets of that thickness would also be energy intensive and therefore expensive. Dirt is dirt cheap.

What do you think glass is? Glass is just sand, melted.

You start with pure white silica sand, add caustic soda (sodium hydroxide) and lime (calcium oxide). Soda and lime add strength. Lime is formed by baking limestone, which is a mineral of calcite and dolomite. Calcite is calcium carbonate, dolomite is calcium magnesium carbonate. You can use calcite instead of limestone, although you will also need oxygen to combine with carbonate to form CO2. Sodium hydroxide is formed by dissolving salt in water, then electrolysis across a membrane. Hydrogen bubbles off the negative electrode, chlorine gas from the positive. Add salt water to the positive side, sodium hydroxide builds up on the negative side. Theoretically water becomes hydrogen gas and hydroxide, salt becomes chlorine gas and sodium, so nothing left. In practice there's always something else in the water or salt, so spent brine has to be removed or recycled.

If you don't find any white silica sand on Mars, you can use silica gel. That's a byproduct of making aluminum.

If you want to make a transparent block from dirt, isn't that just a less pure grade of glass? Most dirt won't form anything translucent (or semi-transparent). The only "dirt" that will is sand, or highly pure minerals such as plagioclase feldspar. Anorthite and bytownite are types of plagioclase feldspar that will dissolve in acid, the first step to extracting aluminum. Another mineral that will form something translucent is quartz, a crystal of silicon dioxide. That's the same thing as glass, just a crystal structure instead of amorphous. Sounds like you're just talking about grades of glass.

Excellent post. But I don't disagree that glass is a good material to use or that the materials exist to make it. Merely that it is much cheaper to build thin glass windows in a masonry structure than a solid glass structure 3m thick. And the transmittance of glass decreases with increasing thickness.

Offline

Like button can go here

#27 2015-10-29 15:50:00

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: An Island getaway on Mars

Don't lecture a professional aerodynamicist with 3 degrees

![]()

Offline

Like button can go here

#28 2015-10-29 16:10:48

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,168

- Website

Re: An Island getaway on Mars

RobertDyck:

I've never seen an emoticon like that! That's amazing! I stand/sit/lie totally flabbergasted! I bow humbly to someone who knows modern tech far better than myself! (No emoticon available, because I know little-to-zero about them).

GW -- who still uses a slide rule when the calculator craps out

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#29 2015-10-29 16:26:35

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: An Island getaway on Mars

I just used Google. Found this one in the list from Yahoo Messenger online. Their hidden emoticons...

https://ca.messenger.yahoo.com/features … emoticons/

A Canadian political website has different emoticons.

http://www.canadaka.net/forums/posting. … ilies&f=59

There are more. Just Google.

And the young generation think I'm an ancient fossil because I still use internet forums (fora). When I talked to Young Liberals in 2006-2011, they said they use Facebook. Now my niece thinks Facebook is passe; she now uses Twitter. I tried Facebook, comments scroll off in a matter of hours, never to be seen again. You can't hold meaningful conversations with that. And Twitter! Each message restricted to 140 characters, and only goes to those who have subscribed to your feed. Useless. This forum has discussions going back years. I still wish we had the original forum, with posts by Maggie Zubrin and members of the board of directors themselves. I know why that was taken down; I spoke to key individuals involved. Political. I won't repeat the person's name. But it's a shame. I've used bulletin board systems since the days of dial-up modem. My first computer had an external 300-baud modem. That was actually before TCP/IP was invented. I've given up on hair dye, how much for Rogaine?

Last edited by RobertDyck (2015-10-29 16:42:22)

Offline

Like button can go here

#30 2015-10-29 16:46:40

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,168

- Website

Re: An Island getaway on Mars

RobertDyck:

Well, I can't even cope with Google very well. Gray hair turning white. No need for Rogaine. I can barely cope with email and with a forum like this. Facebook and the rest, forget it.

1950-vintage. How 'bout you?

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#31 2015-10-29 17:45:42

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: An Island getaway on Mars

Born in 1962. I was bottle-fed in front of the TV during the last two missions of Mercury. Didn't see earlier missions because I wasn't borne yet. High school class of 1980. Addicted to internet forums, can find all sorts of useful information on the internet. Use the full version of Microsoft Outlook, not Outlook Express. But I stopped upgrading with Microsoft Office XP, also known as Office 2002. The place where I volunteer gave me a copy of Office 2003, together with the product key for their charitable volume license agreement. Never did install it because it's a full install, not an upgrade. Stopped upgrading Windows at ME. Upgraded to Windows XP Professional a few years ago. Microsoft announced they would stop support for XP the same year I broke down and upgraded to it. I'm in the computer business, so have to learn this stuff deeply, that's my job.

I don't like the "ribbon" of Office 2007/2010/2013. And now there's Office 2016. So I stick with 2002. I have learned and taught classes for OpenOffice and LibreOffice. They're written in Java, an interpreted language, so that means they consume too much memory, and run a little slow. But they're free. Can't beat free. I have written applications in VBA (Visual Basic for Applications) and integrated client/server applications using Office for the client, and enterprise database for the back-end. I can use the new version of Office. Doesn't mean I have one at home.

I started with CP/M, upgraded to MS-DOS 2.11. Followed the upgrades to MS-DOS 6.22. Used Windows 1.4, 2.0, 2.2, 3.0, 3.1, and Windows for Workgroups 3.1.1. The first version of Windows NT, called version 3.1 to confuse customers. Windows 95, 95 OSR2 (aka 95b), 98, 98SE, ME. Windows NT 3.5, 4.0, 4.1, 4.2, 4.3, 4.4, 4.5, 5.0. Microsoft had a problem selling NT 4.0, so they changed the name to Windows 2000. Then Windows NT version 5.1, aka Windows XP. I've supported/repaired Windows Vista, 7, 8, 8.1, and last Friday had the first customer bring a computer to me with Windows 10. Used Windows Server NT, 2000, 2003, 2003R2, 2008, 2008R2. And by "used" I mean installed, upgraded, configured, supported, and written software for. I could go on.

Have written applications that use TCP/IP sockets, etc. One employer in 2001 wrote the software for the manufacturer of an internet appliance: Netpliance made something called the i-Opener. Linux geeks would have given me big bucks for the secret to hack into it. Yup, I was one of the developers. The boss asked me to shrink memory requirements because they wanted a spelling checker for the email program. He had an open source free spelling checker, but it required 400kB of memory, and they didn't have that much left. The device used a cheap processor and much less memory than was common at that time. The manufacturer sold it basically at cost, but locked it so you had to subscribe to his internet service. That's how he made his money. I looked at what was taking the most memory, and suggest rewriting the internet browser to use one computer language instead of two. That would mean one run time library instead of two. I hadn't written HTML (web pages) before, but had to jump into the C and C++ source code of the browser. Talk about jumping in the deep end. Did add features for some of HTML 4, specifically features used by popular websites like CNN. The browser was written for HTML 3. But rewriting it took too much time, the client didn't want to pay for that much time. So I asked to look at the spell checker itself. I threw out the whole thing, only kept the dictionary, and started over from scratch. Got it down to 4kB of code memory, plus 4kB of index into the dictionary, and 0.4kB of scratchpad variables. Wrote it to mark changes parts, and only check spelling on a pause in typing. It worked so well I got the pause in typing down to 1/10th of a second. And the processor was a Pentium 1 clone running at 4MHz. Yes, that's 4 megahertz, not gigahertz. My boss was impressed. But the client chose to change to Windows Mobile. I had written software for Windows before, but the company I worked for at the time specialized in QNX, a variant of Unix. So we lost the contract. Since then Blackberry bought QNX; all Blackberries now use QNX. But their development is in Waterloo, Ontario. I'm tired of moving for a job. Refuse to move again.

My computer at home and typing on right now runs Windows XP professional, 32-bit. With all the upgrades. And I have installed that hack that lets me still get updates from Microsoft. That'll stop working in a couple years. Upgraded the hardware more times than I can count. Motherboard died last winter, last summer went to store that specializes in used computer equipment. They gave me a deal on a package with motherboard, processor, heat sink, fan, and memory. I now have an AMD Phenom quad-core running at 2.3GHz, with 4GB of DDR2 memory @ 800MHz. With 32-bit edition, total of main memory plus video memory cannot exceed 4GB, so only 3.25GB is usable. My video card plugs into the PCI-e x16 slot. It's an ATI Radeon HD 4300. My GeForce 8800 Ultra died. That model has a known heat problem, basically it de-soldered itself.

When I got involved with politics in Canada, the leader of the provincial Liberal party recommended I get on Facebook to connect with young people. Found I connected with other politicians, not many young people. Back then my two nieces were entering junior high, and they posted everything. It was a way to learn what was going on in their lives. But they're young adults now. One uses Facebook very rarely, the other not at all. And I found Facebook video annoying. It causes Flash player to crash. Firefox locks up entirely. I have to use Task Manager to "End Process" on a process called plugin-container. When it hangs, that process consumes 100% of CPU time of one processor core. That gets Firefox to resume running, but kills Flash. You need Flash to view internet video. Refreshing the web page will cause Flash to reload, but it's not long before Facebook causes it to hang again. And all these politicians produce copious drivel. And Facebook now inserts ads as a post, in addition to ads off to the side. I have an ad blocker, but Facebook does something to get past it.

Offline

Like button can go here

#32 2015-10-29 20:51:05

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: An Island getaway on Mars

RobertDyck I was born only 4 years ealier and while I remember Apollo there is little before that. I went to a vocational technical institute but failed out of the 2 year course after only a year and 2/3 of the second. I learned code writing with Fortran, Basic and machined coding based on instruction sets of the processors ( z80,8080 series and others) working in the days of vacumn tubes, FET, Diode, transistor logic cards. On magnetic tape drives and all favors of hard drives ect... where the input to the Nova 2 computer were flip switches and a paper tape reader to start the bootstrap loader (early version of a bios) learning the trouble shoot skills to fix power supplies and all parts that make up a product that relates to a complete computer system. Was in the R& D labs when CD Roms were in the developement stages of the media design, optical paths, servo motor control and home circuit designing.

These were followed by networking company circuit board trouble shooting, computer software loading/ configuring in Dos 5, 6.22 windows 3.0 ,3.11 and so on through each windows platform. Worked with engineering to provide on board debugging tools to aid in circuit diagnostics. I can not say where I work currently but it has many parallel conditions and instances that space represents to an astronauts ship systems as much as I can.

Offline

Like button can go here

#33 2015-10-29 22:13:10

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: An Island getaway on Mars

Long winded. One issue is that I'm not retired, I'm unemployed. I'm scraping by with a little home business doing computer repair.

Offline

Like button can go here

#34 2015-10-30 06:13:35

- Tom Kalbfus

- Banned

- Registered: 2006-08-16

- Posts: 4,401

Re: An Island getaway on Mars

Tom Kalbfus wrote:What's wrong with glass? It is transparent and fairly heavy, it works out to about 1 ton per cubic meter under Mars Gravity. I am sure there is plenty of material for making glass on Mars, and with modern production methods, you could make that glass crystal clear so that most of the light that you want gets through.

Nothing wrong with glass. I'm not sure about the transmittance of a sheet of glass 3m thick. Producing glass sheets of that thickness would also be energy intensive and therefore expensive. Dirt is dirt cheap.

There is no reason why you can't place thin sheets on top of each other until we reach the required thickness, so if each sheet of plate glass is 10 cm thick, you need 100 of those sheets to produce a layer that is 10 meters thick!

Offline

Like button can go here

#35 2015-10-30 09:54:33

- Antius

- Member

- From: Cumbria, UK

- Registered: 2007-05-22

- Posts: 1,003

Re: An Island getaway on Mars

Antius wrote:Tom Kalbfus wrote:What's wrong with glass? It is transparent and fairly heavy, it works out to about 1 ton per cubic meter under Mars Gravity. I am sure there is plenty of material for making glass on Mars, and with modern production methods, you could make that glass crystal clear so that most of the light that you want gets through.

Nothing wrong with glass. I'm not sure about the transmittance of a sheet of glass 3m thick. Producing glass sheets of that thickness would also be energy intensive and therefore expensive. Dirt is dirt cheap.

There is no reason why you can't place thin sheets on top of each other until we reach the required thickness, so if each sheet of plate glass is 10 cm thick, you need 100 of those sheets to produce a layer that is 10 meters thick!

Could be made to work I am sure. In fact this is probably the only way of building large transparent pressurised volumes where there isn't significant gravity (a shell world must be kilometres thick before self-gravity can balance internal pressure).

A multi-layered pressure vessel would appear to be much easier to maintain and replace damaged sections incrementally. But if you are interested in letting light in, transmittance would be a problem through that much glass. Pressure control would be important. You would need a set of cascading pressure relief valves between each section to ensure that it doesn't build an overpressure.

It ultimately comes down to which is the cheapest way of creating habitable volume for the situation at hand. What is cheapest invariably wins.

Offline

Like button can go here

#36 2015-10-30 10:18:05

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: An Island getaway on Mars

There is no reason why you can't place thin sheets on top of each other until we reach the required thickness, so if each sheet of plate glass is 10 cm thick, you need 100 of those sheets to produce a layer that is 10 meters thick!

Why do you want 10 metres thick?

Offline

Like button can go here

#37 2015-10-30 11:27:28

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 4,000

- Website

Re: An Island getaway on Mars

Because it allows 400mb pressure below the layer...

I think glass/plastic layers containing pure water will be the cheapest way of producing clear, pressurised volumes. My vision for a habitat involves an small dugout canyon with a water layer for pressurisation, with apartments built on the sides and gardens and parks on the canyon floor. Farming would be a separate section, at a lower pressure, with the exception of animals, who might be housed along the side as well (maybe in barns on the bottom level?). Though it wouldn't quite be like this.

When it comes to getaways, I don't think you need to have one big enough for the horizon to be closer than the walls. There are a lot of places where you can't see the horizon where people go on holiday. Build an artificial wooded valley, and include lakes, and islands in those lakes. The trees would obscure the walls.

Use what is abundant and build to last

Offline

Like button can go here

#38 2015-10-30 15:42:13

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: An Island getaway on Mars

How about rather than a dome we build a layered vertical structure that is pressurize such as in the vertical farming topic. Each floor as it rises from the surface has a reduction in pressure until we get to the top floor that has regolith spread across it to act as shielding to the floors below. The glass then is only there to allow the side wall for light and are made thick enough to hold the internal pressure in.

Offline

Like button can go here

#39 2015-10-30 17:36:39

- Tom Kalbfus

- Banned

- Registered: 2006-08-16

- Posts: 4,401

Re: An Island getaway on Mars

Tom Kalbfus wrote:There is no reason why you can't place thin sheets on top of each other until we reach the required thickness, so if each sheet of plate glass is 10 cm thick, you need 100 of those sheets to produce a layer that is 10 meters thick!

Why do you want 10 metres thick?

Because glass on Mar weighs 1 ton per square meter, so if you stack ten 1 meter glass cubes on top of each other, they have a foot print of 1 square meters on the surface of Mars, and the weight of a stack of ten one meter glass cubes is 10 tons per square meter, which is about the air pressure of Earth's atmosphere at sea level. So underneath a 10 meter thick layer of glass, you can have a 1 bar atmosphere. The airpressure underneath would balance out the weight of those ten 1 meter glass cubes.

Offline

Like button can go here

#40 2015-10-30 18:16:50

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: An Island getaway on Mars

The orbiter called Mars Odyssey included a radiation instrument called Marie. It measured radiation in low Mars orbit, and reflected from Mars. NASA and the military have developed detailed mathematical models to calculate radiation shielding; they calculated shielding effects of Mars atmosphere at various locations. One objective of the Mars 2001 lander was to measure surface radiation, to provide ground truth to these estimates. That lander was cancelled, recycled to become Mars Phoenix and the radiation instrument removed. However, Curiosity has a radiation instrument, so is providing ground truth. I kept papers published by the Marie team. I put them on the local chapter website. Here is one:

RADIATION CLIMATE MAP FOR ANALYZING RISKS TO ASTRONAUTS ON THE MARS SURFACE FROM GALACTIC COSMIC RAYS

The last page shows radiation at an altitude of 4km to 8km below the datum has 20 rem/year. The caption says 20 cSv/year. The difference between rem vs centi-Sievert is technical. An altitude of 2km to 4km below the datum has 22 rem/year. Those areas are easier to find at low latitude (close to the equator).

The second last page expresses radiation as cell hits per type of radiation at different altitudes: p, a, l, m, h. These are proton, alpha, light ion, medium ion, heavy ion. There are two charts: solar minimum, solar maximum. Solar maximum produces more proton radiation from the Sun, but solar wind blows away more GCR. Notice heavy ion radiation at 0km altitude, at solar maximum. The bar is a pixel in height, the legend says 0.001 cell hit per year. This is why I keep talking about a base below the datum.

Tom, you are trying to calculate thick windows for radiation shielding. How much glass do you need to reduce radiation at your proposed location to equal that of a US nuclear reactor worker? Note: government regulations state no more than 5 rem/year. And remember radiation on Mars is mostly proton, there isn't any neutron radiation from space. The only neutron radiation is secondary from radiation impacting Mars soil. I asked one MIT student to calculate that; she came up with about 0.5 rem per year. And there's almost no gamma radiation. Most nuclear reactor shielding is designed to stop neutron and/or gamma. That will not be useful on Mars.

Offline

Like button can go here

#41 2015-10-31 05:52:32

- Tom Kalbfus

- Banned

- Registered: 2006-08-16

- Posts: 4,401

Re: An Island getaway on Mars

The glass is mostly useful for providing weight to hold down the air, and for being transparent to let in light. I was told that air pressure at sea level is ten tons per square meter, so we contain it with something that weighs ten tons per square meter, and a ten meter thick sheet of glass will do that. So we try to create a situation where the air pressure pushes up and the weight of the glass pushes down, if both of those forces cancel out, we have a stable situation. We probably will want to keep the temperature of the air below at a constant 72 degrees F. If you increase the air temperature without expanding the air, the air pressure will increase, seems the dome will rise and fall with air temperature unless something is done about it. The usual idea for domes is to have a very strong wall rather than rely on gravity to provide the counter force to air pressure.

Offline

Like button can go here

#42 2015-10-31 08:54:38

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: An Island getaway on Mars

Pressure has a way of getting out. Side walls will experience all the pressure anyway. The structure has to hold that pressure, adding weight doesn't really get away from that. A structure with heavy glass blocks will have all the pressure pushing blocks sideways away from each other, just to create a crack that pressure can escape from. Might as well design the structure for pressure, forget counter weight.

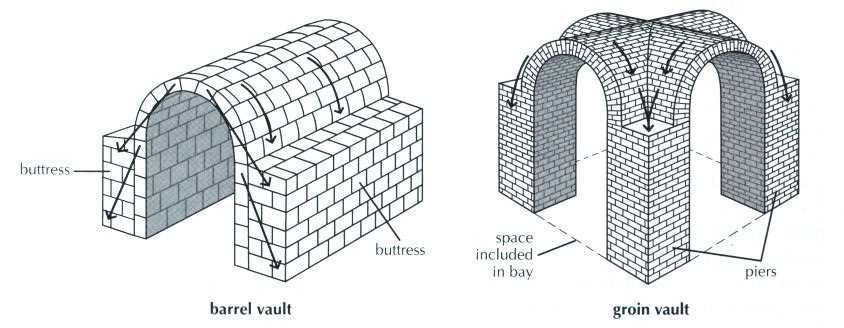

I went through this with Bruce MacKenzie. He's a friend, and his idea was Roman architecture. He wanted to use masonry: bricks. Take Mars regolith, add water, and bake. You'll get the water back when it boils off during baking. The result is brick. Then stack bricks to form barrel arches and groin arches. Pile regolith on top with more weight than the interior pressure. Sounds good, but I was worried pressure would find a way out through mortar, then create a channel through piled regolith (Mars soil). Pressure has a way of doing that. So he suggested using a spray-on polymer sealant on the inside of the brick structure. Ok, that works. And applied to the inside, pressure will push the polymer into the brick. But that sealant is something he hadn't counted on.

Offline

Like button can go here

#43 2015-10-31 10:04:45

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,168

- Website

Re: An Island getaway on Mars

Try doing a mushroom-shaped structure. It has to hold pressure even without deadweight, and it has to hold deadweight when depressurized (not to do that is really dumb from a safety standpoint). Build a masonry center column building (that does not hold pressure, only weight), with a ring of well-anchored columns around it. Build a flat roof sort of like a pre-stressed bridge deck out of the yet-to-be-developed Martian equivalent to concrete.

You pile regolith about a meter or two deep on the roof for both insulation and radiation protection. You install triple-glazing transparencies between all the columns. Seal the inside (deep beneath, ice can serve, since that's permafrost down there).

Arrange reflective surfaces outside it to bounce sunlight inside through the transparencies. If the floor is paved, it is a people space. If the floor is dirt, add organics to create soil, and start farming.

I sketched this up and described it a few years ago over at http://exrocketman.blogspot.com, scroll down using the by-date navigation tool to 2013, and look for January 26, titled "Aboveground Mars Houses".

If we had an equivalent to concrete, plus some rebar and transparencies and the sealant sent from Earth, we could build smaller ones on the first trip with nothing more sophisticated than the equivalents of a front-end loader and a backhoe.

These things will have a maximum size set by achievable material strengths and the square-cube scaling law. So will dome structures for which the necessary material does not yet really exist ("exrocketman" site, 6-9-12 "Pressurized Domed Habitat Structures". The only technique not limited this way by the square-cube thing is the ice-covered body of water ("exrocketman" site, 3-18-12, "Aquaculture Habitat Lake on Mars"). Those can be either freshwater or saltwater, and as big as you care to invest the effort to construct.

GW

Last edited by GW Johnson (2015-10-31 10:08:31)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#44 2015-10-31 11:47:20

- Antius

- Member

- From: Cumbria, UK

- Registered: 2007-05-22

- Posts: 1,003

Re: An Island getaway on Mars

Pressure has a way of getting out. Side walls will experience all the pressure anyway. The structure has to hold that pressure, adding weight doesn't really get away from that. A structure with heavy glass blocks will have all the pressure pushing blocks sideways away from each other, just to create a crack that pressure can escape from. Might as well design the structure for pressure, forget counter weight.

I went through this with Bruce MacKenzie. He's a friend, and his idea was Roman architecture. He wanted to use masonry: bricks. Take Mars regolith, add water, and bake. You'll get the water back when it boils off during baking. The result is brick. Then stack bricks to form barrel arches and groin arches. Pile regolith on top with more weight than the interior pressure. Sounds good, but I was worried pressure would find a way out through mortar, then create a channel through piled regolith (Mars soil). Pressure has a way of doing that. So he suggested using a spray-on polymer sealant on the inside of the brick structure. Ok, that works. And applied to the inside, pressure will push the polymer into the brick. But that sealant is something he hadn't counted on.

Linings as you suggest can seal leaks, but there will invariably remain small leaks. Water vapour will seal many of these by freezing within the cracks. On Mars leaks would be more tolerable than on the moon, as you can provide make-up from the atmosphere so long as leaks are not excessive. What you can or can't tolerate comes down to economics. I think MacKenzies' idea is a good one. There is actually no need to bake the bricks, as the Martian environment is dry. Adobe or rammed earth will do fine for relatively small structures.

The cost of any pressure vessel increases with size. On this basis it would make sense to utilise the space inside as efficiently as possible. I also anticipate that on Mars structures will tend to be more multi-functional. That is work space, industry, agriculture, leisure and accommodation will tend to share the same buildings and will attempt to fill volume efficiently. This reduces the need for interfaces between structures, reduces heat loss and allows outputs from one function to serve as inputs to another.

Offline

Like button can go here

#45 2015-10-31 19:47:19

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: An Island getaway on Mars

Depending on the materials and the methods for manufacturing it might be possible to weld the seams with microwave or by other methods Acrylic windows e.g. aquarium panels http://www.hydrosight.com/technology/ac … ckness.php

http://www.plasticgenius.com/2009/05/ca … kness.html

Here is a calculator for the wall thickness question.

http://www.momentive.com/quartz-tools.aspx

Offline

Like button can go here

#46 2015-11-01 22:19:35

- Tom Kalbfus

- Banned

- Registered: 2006-08-16

- Posts: 4,401

Re: An Island getaway on Mars

Pressure has a way of getting out. Side walls will experience all the pressure anyway. The structure has to hold that pressure, adding weight doesn't really get away from that. A structure with heavy glass blocks will have all the pressure pushing blocks sideways away from each other, just to create a crack that pressure can escape from. Might as well design the structure for pressure, forget counter weight.

I went through this with Bruce MacKenzie. He's a friend, and his idea was Roman architecture. He wanted to use masonry: bricks. Take Mars regolith, add water, and bake. You'll get the water back when it boils off during baking. The result is brick. Then stack bricks to form barrel arches and groin arches. Pile regolith on top with more weight than the interior pressure. Sounds good, but I was worried pressure would find a way out through mortar, then create a channel through piled regolith (Mars soil). Pressure has a way of doing that. So he suggested using a spray-on polymer sealant on the inside of the brick structure. Ok, that works. And applied to the inside, pressure will push the polymer into the brick. But that sealant is something he hadn't counted on.

Are the bricks transparent, do they let light through? Why not use glass bricks?

Offline

Like button can go here

#47 2015-11-01 22:21:48

- Tom Kalbfus

- Banned

- Registered: 2006-08-16

- Posts: 4,401

Re: An Island getaway on Mars

Try doing a mushroom-shaped structure.

Oh you mean like these?

It has to hold pressure even without deadweight, and it has to hold deadweight when depressurized (not to do that is really dumb from a safety standpoint). Build a masonry center column building (that does not hold pressure, only weight), with a ring of well-anchored columns around it. Build a flat roof sort of like a pre-stressed bridge deck out of the yet-to-be-developed Martian equivalent to concrete.

You pile regolith about a meter or two deep on the roof for both insulation and radiation protection. You install triple-glazing transparencies between all the columns. Seal the inside (deep beneath, ice can serve, since that's permafrost down there).

Arrange reflective surfaces outside it to bounce sunlight inside through the transparencies. If the floor is paved, it is a people space. If the floor is dirt, add organics to create soil, and start farming.

I sketched this up and described it a few years ago over at http://exrocketman.blogspot.com, scroll down using the by-date navigation tool to 2013, and look for January 26, titled "Aboveground Mars Houses".

If we had an equivalent to concrete, plus some rebar and transparencies and the sealant sent from Earth, we could build smaller ones on the first trip with nothing more sophisticated than the equivalents of a front-end loader and a backhoe.

These things will have a maximum size set by achievable material strengths and the square-cube scaling law. So will dome structures for which the necessary material does not yet really exist ("exrocketman" site, 6-9-12 "Pressurized Domed Habitat Structures". The only technique not limited this way by the square-cube thing is the ice-covered body of water ("exrocketman" site, 3-18-12, "Aquaculture Habitat Lake on Mars"). Those can be either freshwater or saltwater, and as big as you care to invest the effort to construct.

GW

Offline

Like button can go here

#48 2015-11-02 01:01:29

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: An Island getaway on Mars

Are the bricks transparent, do they let light through? Why not use glass bricks?

Nope

Bricks on Mars (Background)

Bricks on Mars (Activity)

To support 6.5psi air pressure inside, you need at least 6.5psi weight (not mass) of regolith piled on top of the brick arch. Otherwise air pressure will blow out the arch. Remember bricks are held by gravity. Mortar helps, but it's mostly gravity. Yes, that weight includes the bricks themselves. But air pressure will push out from the centre of the arch, not up. That means 6.5pis lateral pressure where the arch meets the buttress or pier. How much pressure does the brick+regolith exert? Completely burying the arch can address that, but how does an exposed glass brick arch?

Our solution:

Last edited by RobertDyck (2015-11-02 01:06:26)

Offline

Like button can go here

#49 2015-11-02 05:49:06

- Antius

- Member

- From: Cumbria, UK

- Registered: 2007-05-22

- Posts: 1,003

Re: An Island getaway on Mars

Wonderful! A picture is more effective than any number of words. If crater walls provide lateral resistance to pressure, you could presumably expand this concept to cover very large areas.

Offline

Like button can go here

#50 2015-11-02 06:08:17

- Antius

- Member

- From: Cumbria, UK

- Registered: 2007-05-22

- Posts: 1,003

Re: An Island getaway on Mars

EVA time needed for construction of brick structures may be a problem. The difficulty of trying to lay bricks in astronaut gloves would also slow the process down.

Another technique that has a long history in Europe is cob construction. This is a mixture of wetted sand and clay mixed in with straw and cast in layers about a foot deep to gradually build up walls. This allows structures to be built very quickly, with far less labour cost than adobe. The compressive strength of the dried structure is ~1MPa (10bar). Damp is a constant problem in England, but wouldn't be any problem on Mars.

Unfortunately, the process is quite water intensive and needs to dry without freezing, which would shatter the wall. Both of these could be problematic on Mars if we attempt to carry out construction in situ. A likely solution would be to cast sections in heated moulds and then bolt the dried modular earth components together. This could be done from pressurised cranes without the need for space-suited labourers.

Offline

Like button can go here