New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#26 2015-04-16 17:40:17

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,548

Re: ISRU Polymers

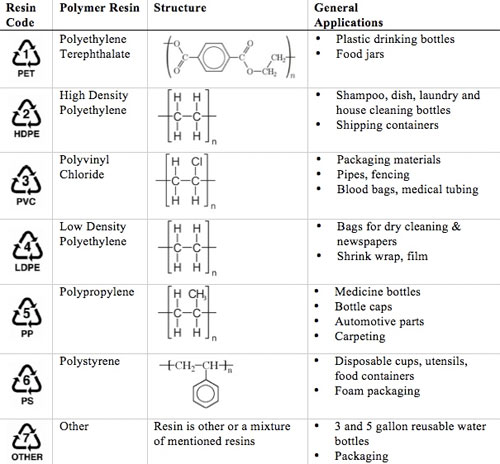

Typical chemical makeup:

Offline

Like button can go here

#27 2015-04-17 09:36:56

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,156

- Website

Re: ISRU Polymers

There will be lots of plastic to recycle if that coffee-maker technology they just shipped to the ISS catches on. One cup brewers inherently produce an enormous stream of plastic waste.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#28 2015-04-18 19:46:08

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,548

Re: ISRU Polymers

Here is a chance to make plastic trash into 3D filament....

Tethers Unlimited wins NASA contract to create 3D printer filament from plastic waste on ISS

It was only yesterday when we heard that Made In Space would be offering their “space grade”, NASA-approved ABS filament to the general public to use for creating their own space-ready product designs. Now, NASA has announced that their Small Business Innovation Research (SBIR) Program has awarded Tethers Unlimited, Inc. (TUI) a contract to further develop their "Positrusion™" recycling system for converting plastic waste into high-quality 3D printer filament for use in making tools, replacement parts and satellite components aboard the International Space Station. "Positrusion is a new approach to making 3D printer feedstock that produces filament with much more consistent diameter and density than traditional extrusion processes," said Jesse Cushing, TUI's Principal Investigator for the project. "That consistency will improve the quality of tools and other parts produced by 3D printers on the station."

In addition to using the technology in space, the company also sees it being used on Earth to help recycle plastic waste into high-quality filament using their patent-pending process.

"For a recycler to be useful on the ISS, it has to meet stringent safety requirements, and its design needs to minimize the amount of time an astronaut must spend operating it," said Jeffrey Slostad, TUI's Chief Engineer. "So we designed the Positrusion recycler to be as safe and simple to operate as a microwave oven, and we believe a consumer version of this machine will be ideal for recycling household and office waste."

This appears to be the company that supplied the printer to the station from this image....

Offline

Like button can go here

#29 2015-04-19 07:07:36

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 4,000

- Website

Re: ISRU Polymers

Oh. So they *are* planning to recycle plastic waste after all...

Use what is abundant and build to last

Offline

Like button can go here

#30 2017-01-14 12:25:15

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,548

Re: ISRU Polymers

Another reason to figure out how much plastic and other waste products there are for a mission to Mars to land with and for how much we will have for a long duration mission from a crews stay. Before a new mission starts and is restocked with more of the same to make use of in recycling.

Offline

Like button can go here

#31 2017-04-18 22:14:51

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,548

Re: ISRU Polymers

Ya I reported the possible suspect on the first post but before I got to remove this current efforts the admin did so.....I still think that we still have some sleepers with login capability but will need to wait until they cross the line....

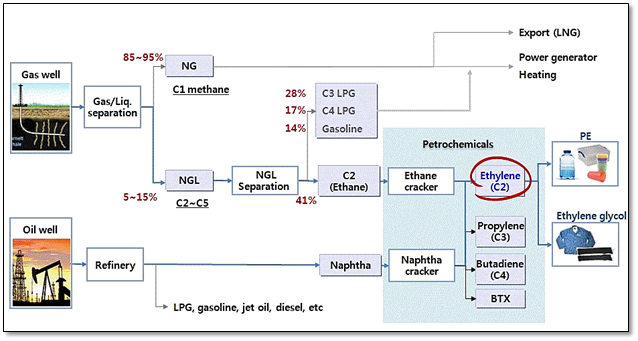

The formation of light hydro carbons to allow for Mars creation of plastics starts with the outputs of the Sabetier reactor with Methane, Ethane, Ethylene, Propane, Propylene, Butane, Butenes, Butadiene

Offline

Like button can go here

#32 2017-04-22 06:13:34

- elderflower

- Member

- Registered: 2016-06-19

- Posts: 1,262

Re: ISRU Polymers

The CO /Hydrogen/steam mixtures fed as syngas to reactors with different catalysts operating under different conditions can make methane, methanol, formaldehyde, formic acid, ethanol, ethylene and loads of others. Whether any of them is practical on Mars I couldn't say. I've only ever seen huge industrial units. They might scale down.

I particularly like methanol (storable fuel) and formaldehyde (cross linking agent).

Offline

Like button can go here

#33 2018-06-20 18:19:56

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,548

Re: ISRU Polymers

Bump

Moisture of any amount in the sodium Nickle Chloride battery compartment is its enemy.

Battery types and current curves pg8 and on 9 is li-poly from MIAAION THt did not happen yet.

MARVIN- Near Surface Methane Detection on MarsContains mass power for levels of water and processing on pg7

An ISRU Propellant Production System to Fully Fuel a Mars Ascent VehicleSomething I have indicated before with a waste truck for the journey to mars to be sent down to the surface for recycling pg2 gives content numbers but that may be even higher for some mission plans

Creating Methane from Plastic: Recycling at a Lunar Outpost

Offline

Like button can go here

#34 2018-06-25 04:26:23

- elderflower

- Member

- Registered: 2016-06-19

- Posts: 1,262

Re: ISRU Polymers

One item that will be needed is rope, string, cord. The best materials for these, for most purposes, are plastics based. Particularly High Density Polyethylene (as in Dyneema). We should therefore have available an extruder with filament dies and rope braiding equipment so that the plastic pellets, however produced, can be converted. Alternatively film blowing and slitting equipment could be used to produce fibres, but this route involves rather large machines.

For high temperature operations you need to use something else, such as steel wire. Unfortunately steel wire also needs some fancy termination and running hardware. You can't just tie a knot in it as you can with polymer cordage.

Offline

Like button can go here

#35 2018-06-25 19:26:32

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,548

Re: ISRU Polymers

Well a quick google for plastics used to make ropes found recycling to be a choice ingredient.

https://www.recycleyourplastics.org/con … an-become/

http://www.dailymail.co.uk/sciencetech/ … tring.html

Offline

Like button can go here

#36 2019-12-17 16:21:53

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,548

Re: ISRU Polymers

tahanson43206,

I think I can tell you where a substantial portion of the requisite excess energy went- packaging. We should also call it marketing, since that's most of what anything that came from a store actually is. Note how much energy-intensive packaging material is simply being buried, year after year, decade after decade:

Glass and Aluminum are very energy-intensive to simply bury after a few days to weeks of use, at most, but even wood and plastic require considerable energy input. There's more than enough material to go around, but not if we toss half of what we make into a landfill each year.

Affordable resources are definitely not scarce here in America, but there are more wasted resources than you can shake a stick at. Industrialization and computerization of nearly everything have made production so fast and efficient that we've wildly over-produced disposable commodities with meaningless minor variations that do nothing to improve upon the function of a product. This comes at terrible expense to efficiency and therefore cost. Many Americans can't afford to purchase the nth meaningless variation of some product or the packaging that the product comes in, even though that clearly doesn't stop them from trying. The added expense in the form of the labor, machines, and materials that were used to package / market the product is too much for the customer to afford.

Do we really need hundreds of different types of toothbrushes, or do we just need manufacturers to figure out which ones do the best job of cleaning peoples' teeth at an affordable price and then produce nothing but what does the job most effectively? Why do we need to throw away or recycle an entire toothbrush after the bristles have been damaged? Why can't we just replace the head with a new one? Is it more expensive in terms of resources and energy to make a completely new toothbrush or just the head? The answer should be pretty obvious, shouldn't it? Now apply that same disposable commodity thinking to far more energy / resource / labor intensive artifacts of modern society, like cars, ships, aircraft, and buildings. Is it any wonder that we don't have enough energy and resources to keep pace with the increasing rate of consumption?

We now have an endless variety of meaningless choices that do not make our society more effective at progressing through our technological adolescence and it costs so much that a growing number of us simply can't afford it anymore. At some point, ultimate durability or the energy consumption associated with new manufacture or reuse has to be taken into account.

If it's faster and cheaper to 3D print small houses with concrete, do we really need to mess around with an endless variety of less cost-effective / more resource-intensive alternatives, or are our finite time and monetary resources better spent figuring out how to crank out as many as we can, as fast as we can, so that people aren't living outside when it's cold enough to turn them into ice cubes? We don't need ten different floor plans and thousands of different color variations to choose from. If white paint is cheaper than red paint, then we use white paint. If no painting at all is required, even better. If we could pre-fab the entire structure at a factory and plop it down wherever, that's probably the cheapest way. Fancy is for people with plenty of disposable income from long-term stable employment. I think effective is better than fancy in this case.

Here's a rather simple final closing thought. The American consumer has paid for the packaging costs associated with burying enough Aluminum each year to completely rebuild every commercial aircraft in our current fleet, and has done so every year since at least 1990. The fleet of commercial aircraft was estimated to be around 7,400 aircraft in 2018. From just the Aluminum that we've buried in landfills each and every year since 1990, that's enough material to source more than 324,000 pounds of Aluminum per airframe. The majority of commercial aircraft, by numbers, don't weigh that much when fully loaded with passengers or cargo and fuel. That is a staggering amount of waste. If we can actually afford to do that, although I opine that we can't, then there shouldn't be any issue with obtaining cheap resources because we've literally buried billions of tons of the wood, metal, and glass required to make houses.

Offline

Like button can go here