New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#301 2014-12-01 09:20:06

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,378

- Website

Re: Reusable Rockets to Orbit

I don't know of any sorbents specific to CO. If there were, then they would have been used for safety long ago. After 9/11, NASA developed a safety system for fires in downtown tower buildings. It's a safety mask, to protect against smoke. It uses a catalyst that combines CO with O2 to produce CO2, operating at +24°C. It's a platinum group metal, I think rhodium. Note it doesn't remove CO2, only converts CO into more CO2. That's because CO is letal at in trace amounts, while CO2 requires high concentrations before it becomes dangerous. If there was a sorbent for CO, then that sort of thing wouldn't be necessary.

The only way I know to make CO on Mars, is that same thin wall catalyst that I talked about. You start with a freezer to concentrate CO2 from Mars atmosphere. Then run pure CO2 through the direct CO2 electrolysis device. That will give you at most 80% CO, 20% CO2. Then use a freezer to remove CO2, and a CO2 sorbent to remove remaining trace CO2. The result is CO.

Direct CO2 electrolysis requires heating the CO2 to +900°C. Between energy to heat plus electrolysis, total energy in terms of kilowatt-hours per kg of oxygen is three times water electrolysis. That's why most people don't think to use it for life support. I've argued several times to use this on ISS, and that system would be used on Mars. It can remove oxygen from remaining CO2 that is currently dumped in space. With the current system, the Sabatier reactor consumes 100% of the hydrogen from the water electrolysis tank, and half the CO2 from the cabin sorbent system. The other half is dumped in space. Direct CO2 electrolysis would convert 80% of that CO2 into CO, so that recovers only 40% of the oxygen, but that's better than 0%. This could be used to replenish recycling losses. It wouldn't replace the current system, just augment it. If the primary system is tight enough, this would eliminate the need to ship water up to ISS. And that system could be used for a human mission to Mars.

But now look at using CO for propellant. Production equipment isn't simple, and requires a lot of power. And the propellant has low Isp.

Offline

Like button can go here

#302 2014-12-05 09:23:44

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,137

- Website

Re: Reusable Rockets to Orbit

This was a press release recently from XCOR. The XR-5H25 engine is a subscale demonstrator for a full scale engine that could power the Centaur upper stage on Atlas-5. This subscale demonstrator has 2500 lb thrust. Previous releases indicated the full scale design is 25,000 lb thrust, with growth potential to twice that value.

This press release is about the very significant milestone of operating a LH2-LOX engine live-fire on a piston pump, not a turbopump assembly. (Orbital Sciences has “fingered” a turbopump failure as the prime suspect in their recent Antares launch loss.) This XCOR piston-pump approach is the same manned-aircraft-safe pumping design approach that was in the Rocket Racer rocket-powered airplane some years ago.

That was a very reusable rocket engine, and that's the title of this thread, essentially. I don't know of anybody else working on something truly innovative like this. More power to them. The sooner "everybody" does things like this, the sooner fully-reusable rockets safe enough to fly men will be a reality. -- GW

Mojave, CA, November 20, 2014 – XCOR Aerospace today announced it has completed the latest test series for the liquid hydrogen engine it is developing for United Launch Alliance (ULA). This is an important milestone in the long-running LH2 (liquid oxygen and liquid hydrogen) program. It is also a step toward running the engine in a fully closed cycle mode.

In its most recent milestone, XCOR successfully performed hot fire testing of the XR-5H25 engine’s regeneratively cooled thrust chamber, with both liquid oxygen and liquid hydrogen propellants supplied in pump-fed mode, using XCOR's proprietary piston pump technology.

“This test marks the first time liquid hydrogen and liquid oxygen have been supplied to a rocket engine with a piston pump,” says XCOR Chief Executive Officer Jeff Greason. “It is also the first time an American LH2 engine of this size has successfully fired liquid hydrogen and liquid oxygen together in pump-fed mode. We are happy to be making solid progress on the engines. This will also bring us to a new phase in our plans for orbital flight.”

"ULA has an ongoing effort to develop rocket engines for our next generation upper stage, and we are thrilled to see that progress continuing with XCOR," added ULA Vice President George Sowers.

Upcoming test series will fully integrate the nozzle with the engine and piston pumps. Fully closed cycle testing will follow soon afterwards and will complete the sub-scale demonstration engine program.

The XR-5H25 engines are being developed under contract to ULA as potential successors to the Delta and Atlas series upper stage engines currently used. These engines will also help power orbital launches.

Last edited by GW Johnson (2014-12-05 09:28:50)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#303 2014-12-05 16:43:53

- Impaler

- Member

- From: South Hill, Virginia

- Registered: 2012-05-14

- Posts: 286

Re: Reusable Rockets to Orbit

Interesting, I take it that piston-pumps because they do not depend on numerous small thin blades are fundamentally more robust and thus a rocket engine based on piston-pumps would be fundamentally more reusable, provided it could avoid fouling from soot deposits and other such things. But I would imagine that the piston is a bit less efficient on mass then the turbine, back when we had shitty impulse we had to go with the high throughput device to keep the rockets thrust to weight high. With broader improvement in performance across the whole rocket their may be sufficient margin to utilize a less efficient but more robust pumping mechanism and to make other broad trade-offs between performance and durability.

Also I assume piston-pumps need some outside power-source to start, but do they then like our standard internal-combustion engines run off of the combustion process? Do they offer any advantage is being able to throttle over a wider range of flow or are they able to cut on and off faster?

Offline

Like button can go here

#304 2014-12-06 10:06:57

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,137

- Website

Re: Reusable Rockets to Orbit

I don't know the details of the pump drive process, they keep that very proprietary. But in broad outlines, it's a piston heat engine driving piston pumps with a common crankshaft. The heat engine derives its heat from the rocket's waste heat. It's tied into the regenerative cooling somehow, I believe. But the details are unknown to me. They say they avoid the gas tap-off losses that some turbo-pumped designs suffer.

The piston pump assembly and heat engine are actually quite lightweight. More or less comparable to the turbo-pump assemblies on more conventional rocket engines. A lot of the casing is aluminum, kind of like an air-cooled VW motor. If there's an inert weight penalty, it's not very much at all. There's some photos on their website.

Besides the physical robustness of piston/cylinder hardware vs spinning turbomachinery in thin pressure vessel shells, there is another very distinct advantage: extremely-rapid "spool-up" and "spool-down" times. Almost all liquid engines have to be ignited at low thrust/low propellant flowrate conditions to avoid explosion upon ignition. Then they have to "spool-up" to full thrust for launch, which takes a time usually measured in seconds. The piston-pumped engines also have to light at low flow rate, but the spool-up only requires 1's-to-10's of microseconds. Throttle-up/throttle-down response is similarly fast.

That's about all I know, really. I've seen their hardware up close and personal. It's very impressive, what they do and how they do it. Their smaller engines, like the ones that went in the airplanes, have containment built into the thrust chamber assembly, so that a burst chamber won't down the airplane. That does cost some inert weight, but for utter safety, it's well worth it, in my opinion.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#305 2014-12-06 13:07:54

- Impaler

- Member

- From: South Hill, Virginia

- Registered: 2012-05-14

- Posts: 286

Re: Reusable Rockets to Orbit

Reading on other sites I was someone basically summarizing it as a Sterling-Engine that runs on the heat differential of the combustion chamber and the cryogenic propellent. If that is the case then the HUGE temperature range it would have access to means it could have excellent Carnot efficiency and would explain how it can compete with a turbo-pump, it also means your using a working-gas to drive the piston and the propellent is driven BY the piston. That how they can avoid wasting any propellent in a side reaction like a standard gas-generator, it's got the benefits of full-flow without actually having a second pre-combustion chamber. A very clever design and a real new addition to rocket technology.

Last edited by Impaler (2014-12-06 13:09:16)

Offline

Like button can go here

#306 2014-12-06 13:43:24

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,137

- Website

Re: Reusable Rockets to Orbit

Yep, I think it's a real handsome contribution to the technology. I do recall seeing a free-piston version among some of their early feasibility demo hardware.

One of the things they noticed with their earlier pumps was that there was plenty of increased crank rpm capability to handle much larger flow rates. That is exactly where they went the higher-thrust applications, like their LOX-RP1 Lynx.

The "biggie" with the ULA engine project is two-fold: (1) handling LH2, and (2) scaling to much larger sizes (25,000 to 50,000 lb thrust). So far, they've demo'd the hydrogen.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#307 2014-12-06 14:33:51

- Impaler

- Member

- From: South Hill, Virginia

- Registered: 2012-05-14

- Posts: 286

Re: Reusable Rockets to Orbit

Hydrogen is impressive, if it can handle everything from hydro-carbons to LH2 then their is really nothing it can't do. I wonder how much this opens the possibility of rockets with wider ranges of fuels, just being able to run on a range of hydro-carbons would be a big improvement as the ISPP concepts for Mars have not completely nailed down what the ideal hydro-carbon to produce is yet and their is a good change that the simplest easiest to produce ISPP device will produce a mix of several hydro-carbons as making any chemical output pure is generally energy intensive and capitol intensive.

A rocket that can burn any fuel along the spectrum from Hydrogen to the most carbon rich fuel that might be used Acetylene C2H2 would be quite incredible, the fuel-oxidizer ratios would need to adjust across a very wide range and the fuel side pumping would need to operate with fuel coming in at even larger temperature ranges. It may be beyond the current materials science but it sure would be an amazing piece of operational flexibility to run both of the two dominant fuels through one engine.

Last edited by Impaler (2014-12-06 14:34:42)

Offline

Like button can go here

#308 2014-12-25 10:19:23

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,137

- Website

Re: Reusable Rockets to Orbit

Merry Christmas, guys!

I found a news release on Spacex's website about the upcoming attempt to recover a Falcon-9 first stage on their next launch to ISS, the one rescheduled for January.

They're using supersonic retro-propulsion (multi-engine but without any cant angle) successfully already. That's a topic we have discussed before for reusable Mars landers. It works. So it would work in those other applications.

What they've added is 4 "grid fins" up near the front end of the first stage to act as steerable tail fins while it is descending rear end first. They needed the extra stability and control, and that's what they added to achieve it. That's the same grid fin idea as is on the Russian AA-12 "Amraamski". So they knew it worked before they adopted it. Smart!

The news release gave me the impression that the biggest remaining problems to solve have to do with circular error probable for their touchdown point. The barge they want to land on is only 300 x 170 feet, and it's not exactly stationary: wave action, currents, winds, etc.

Once they start launching out of Brownsville, TX, there's lots of islands out in the Gulf/Caribbean that are much larger than any barge. Better start watching the real estate transactions out there. Normalizing relations with Cuba might be an unexpected bonus for them.

The January launch is going to be a very interesting show! I hope they make a successful recovery. What an industry shake-up that would be!

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#309 2014-12-25 11:15:44

Re: Reusable Rockets to Orbit

It seems to me I saw somewhere that their stages were coming down up to 10 kilometers from where they want them to land, so clearly they need steering fins! There was some sort of reference to them possibly negotiating landing rights on a Pacific island down range of Vandenberg, too. This information was probably on nasaspaceflight.com. That's a really great website and the guy who runs it has a lot of contacts, so he has "unnamed insider sources."

Offline

Like button can go here

#310 2015-01-05 23:57:13

Re: Reusable Rockets to Orbit

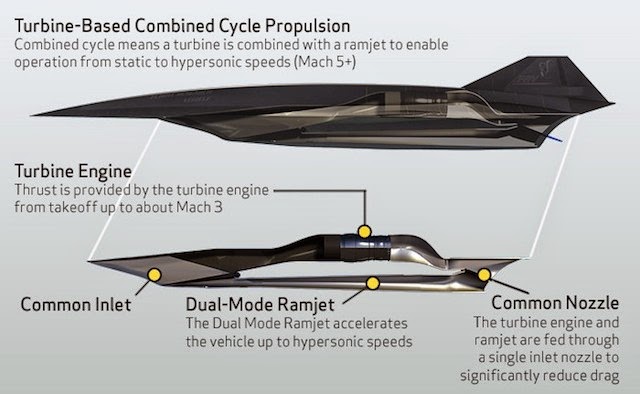

For a different reason, I had to rough out essentially the same plane circa 1985. Mine was turbojet/ramjet parallel-burn propulsion, a similar layout, and designed for M5 at 100-150 kft. I did it from all open sources.

It was so close "to reality" the FBI confiscated all my design notes, but not my sources or my slide rule, because I did not possess the clearances "to know about such a craft". I have often wondered if such a thing ever got built.

It appears in hindsight apparently not. Although it could have been. The delta-wing pulse detonation experimental craft (seen above Groom Lake) of about 1995 apparently led nowhere.

GW

December 25, 2014

NASA seed funds SR 72 hypersonic drones as other countries race for hypersonic missiles.

http://nextbigfuture.com/2014/12/nasa-s … rones.html

I like that it is using both turbojets and ramjets. But my preferred system would have the turbo/ram jets integrated into one by having a single combustion chamber as with the SR-71's engine.

You could then potentially produce a SSTO by having a rocket engine also use the same combustion chamber.

Bob Clark

Last edited by RGClark (2015-01-05 23:59:10)

Old Space rule of acquisition (with a nod to Star Trek - the Next Generation):

“Anything worth doing is worth doing for a billion dollars.”

Offline

Like button can go here

#311 2015-01-06 10:01:40

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,137

- Website

Re: Reusable Rockets to Orbit

The only geometrically similar items between an (afterburning) turbojet and a ramjet are the afterburner duct and the supersonic inlet components. Yet even these are suboptimal shapes if you try to switch roles. Neither of these has anything geometrically in common with a rocket engine.

That's why no combined-cycle engines have actually flown in all these decades. Getting around those incompatibilities is just too heavy, and penalizes the component engine performances too greatly. You are quite literally better off in terms of weight, performance, and complexity to just put the two engine types separately in the airframe.

Myself, for the drone (or piloted) hypersonic plane that folks call "SR-72", I'd use the ramjet in the fuselage of D-21 drone shape, and mount two small rocket engines in the aft ends of the wing fillets. The ramjet can take this plane as fast as Mach 5 or 6 in combat at high altitudes, and cruises for long range at Mach 3. Take off on simple rocket using large propellant mass in drop tanks, accelerate to Mach 2-ish for ramjet takeover, and climb at about Mach 2.5 to 3 into the thin air where ramjet is range-efficient. Then go do your thing. Glide landing with on-board rocket propellant residuals for go-around capability.

The D-21 shape has better L/D ratios BY FAR than any of these airframe-integrated scramjet things. Once you reach about Mach 3.5 at 80+ kfeet, you're pretty well beyond the reach of air defenses. What's the point of incurring all that trouble with an unready-to-apply scramjet technology and poor L/D cutting your range, just to fly Mach 8, when Mach 5-6 is good enough, and with a mature and reliable propulsion technology?

Do you really intend to fly, or do you want a technology development gravy train?

These things (press releases for big contractor SR-72 programs) are gravy-train "sops" for the two gigantic favorite oligopoly contractors. Government's favorite, that is. None of these wet dreams will ever really fly.

Somebody else, likely overseas first, is going to do exactly what I outlined above, and stun the world with it just like Sputnik 1.

GW

edit same day: further thoughts --- the other thing that comes to mind regarding "hypersonic" is aeroheating. If you do something other than a brief ablative or heat-sinked transient, you must solve the steady-state hypersonic thermal protection problem. This gets really severe above Mach 4. By the time you reach Mach 6, even your captured inlet air is flame-hot.

Go to Mach 8 or 10, and it just gets ridiculous to the point of serious stupidity: you are simply much better off leaving the atmosphere entirely if you really want to go that fast. Reentry is only 3 minutes long from LEO, after all.

From about Mach 4 or 5 on up, you must protect skins, leading edges, and nose tips, PLUS all your combustor, nozzle, and inlet surfaces inside. There is no such thing as "cooling air" above Mach 3. And the new ultra-high-temperature-ceramic nose tip and leading edge materials are simply not suitable for those other jobs.

Last edited by GW Johnson (2015-01-06 12:26:18)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#312 2015-01-06 17:16:04

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,378

- Website

Re: Reusable Rockets to Orbit

Brilliant! Separate air flow for SCRAM jet and turbine, yet common inlet and exhaust nozzles. This solves a few problems. The article says mach 5+, but a linked article says top speed should be mach 6. It also says

The SR-72’s design incorporates lessons learned from the HTV-2, which flew to a top speed of Mach 20, or 13,000 mph, with a surface temperature of 3500°F.

Woo hoo! Getting to what we need. Boeing's Rocket Based Combined Cycle (RBCC) engine used a rectangular cross-section for the internal air path. That allowed floor and ceiling sections to raise and lower to change internal geometry. And multiple fuel injectors, so it could inject fuel at different locations at different speeds.

Imagine going from wheel-stop sitting on a runway, to mach 20 in the upper stratosphere. Air breathing all the way. Of course +3,500°F skin temperature is severe, requiring better heat shield than Shuttle. Reinforced Carbon-Carbon was rated to 2,750°F. The craft couldn't sustain that. But briefly? Just long enough to get to mach 20 at high altitude? Then ignite a rocket engine for the final push into space.

Yes, I keep thinking of SSTO shuttle. Not combat drone.

Offline

Like button can go here

#313 2015-01-07 09:49:32

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,137

- Website

Re: Reusable Rockets to Orbit

The separate flow paths make the turbine feasible as long as it can be isolated when speeds exceed about Mach 3.3. But, I'm very skeptical of the "dual-mode ramjet-scramjet" that share inlets and nozzles. The internal inlet geometries are very incompatible, and scramjet requires a slightly divergent combustor to a strongly divergent nozzle, with no throat convergence. Ramjet on the other hand requires 65% throat convergence on area before you pass into the expansion bell, or it performs quite miserably, if at all. Since scramjet min takeover is about Mach 4, and turbine's max is Mach 3.3, you must have a ramjet.

And then there's the service ceiling effect with any airbreather. Thrust is made with airflow. If the air massflow is low due to low density, so is the thrust. As is the drag. But weight is independent of air density. Your thrust margin over drag is what you may use to accelerate or to climb, or a little of both. Multiplied by flight velocity, this is the "specific excess power" that relates directly to increases in potential or kinetic energy, or both: Ps = (T-D)*V/W. In the thin air above 100,000 feet, T-D is a number approaching zero, W is not. It won't climb, and it will have a max speed that is more driven by airframe L/D than by engine characteristics.

Why not just do a turbine-plus ramjet, and use a much cleaner (higher L/D) airframe to reach Mach 6 at about 100,000 feet? Then go rocket from there. Or, do simple rocket plus ramjet, and delete the heavy turbomachinery core at high altitude where the service ceiling effect is so bad?

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#314 2015-01-07 14:48:44

- Antius

- Member

- From: Cumbria, UK

- Registered: 2007-05-22

- Posts: 1,003

Re: Reusable Rockets to Orbit

NASA had looked at converting Mars atmosphere in to CO & O2 bi-propellant for fuel. The problem is burning liquid CO with liquid O2 is very poor fuel. Specific impulse is very low. To use a rude expression: it sucks.

It was after NASA did that study that Dr. Robert Zubrin and Dr. David Baker came up with their idea for Mars Direct: bring hydrogen from Earth, use a Sabatier reactor to convert Mars CO2 + H2 into methane and water. Run water through electrolysis to convert to H2 and O2, store O2, recycle H2. Paul Sabatier invented the Sabatier reactor; it was used in the 1910s to generate methane for natural gas lighting. It was this idea from Mars Direct that brought the Sabatier reactor to NASA's attention; they have already used it to improve life support. But for In-Situ Propellant Production, the described system is not complete. The ratio of methane to oxygen is not correct for a rocket engine, more oxygen is needed. So Mars Direct includes a system that uses a thin wall tube that is a catalyst to convert CO2 into CO and O2. The O2 passes through the thin wall, CO2 and CO do not. It's carbon dioxide electrolysis. This only converts 80% of CO2 into CO and O2, but there's lots of CO2 on Mars. So this can generate the extra O2 for balanced rocket fuel.

The point is going back to CO & O2 is a major step backward. And it was already looked at.

I seem to remember the Viking soil tests released non-trivial volumes of water from the heated samples. And they were not polar sites. With this in mind, why not use a small rover equipped with an electric oven, to gather water by heating Martian regolith. The rover does not need to go more than a dozen metres from the ERV, so could presumably remain attached by umbilical. This would deliver the neccesary power to the rover, and a thin polymer tube would convey the water vapour back to the ERV.

Offline

Like button can go here

#315 2015-01-07 18:13:43

- Impaler

- Member

- From: South Hill, Virginia

- Registered: 2012-05-14

- Posts: 286

Re: Reusable Rockets to Orbit

I think Viking had to basically Bake the soil at oven temperatures to get ~1% moisture out, that would be be a tremendous energy expenditure for a very scant amount of moisture, I can't see it being practical unless it is at very large scale like a cement-plant AND your processing the Regolith secondarily for some other purpose like construction material, ore, growing medium etc etc.

For all resource extraction purposes SOLID MATER SUCKS, if it were not for the fact that we can get metal from it here on Earth we would never touch the stuff, and I don't think we will use Mars regolith or crust until that same point, and only after we have scavenged all the nickel-iron meteorites from 100 km radius too. Atmosphere beats solids for every element that is in the atmosphere even in tiny amounts like water.

Offline

Like button can go here

#316 2015-11-30 11:00:42

Re: Reusable Rockets to Orbit

Elon Musk has confirmed the F9 first stage can reach orbit as an SSTO:

Elon Musk Verified account @elonmusk @TobiasVdb

The F9 booster can reach low orbit as a single stage if not carrying the upper stage and a heavy satellite.

https://twitter.com/elonmusk/status/669132749500887040

Thank you very much, Mr. Musk. See:

The Coming SSTO's: Falcon 9 v1.1 first stage as SSTO, Page 2.

http://exoscientist.blogspot.com/2013/1 … first.html

Bob Clark

Old Space rule of acquisition (with a nod to Star Trek - the Next Generation):

“Anything worth doing is worth doing for a billion dollars.”

Offline

Like button can go here

#317 2016-01-24 10:18:50

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,420

Re: Reusable Rockets to Orbit

While space x has been proving in its attempts to reuse the first stage on its Falcon its almost there but the specifics of what they are doing after a first flight for refurbishment is still being kept under wraps.

The Blue Origin conduct successful reuse test with New Shepard of its completely reuseable rocket.

The turnaround of the booster for the test was relatively easy, according to the company, with the team only having to replace the crew capsule parachutes, the pyro igniters, conduct functional and avionics checkouts, and made several software improvements ahead of Friday’s flight.

True the two of them are not quite the same as the Space X is a degree of difficulty higher due to return temperature, distance traveled and return location on the water barge.

My question is where is the line for sub orbital space travel and how far does it go....

Offline

Like button can go here

#318 2016-01-24 10:49:55

Re: Reusable Rockets to Orbit

"Space" is defined as crossing the "Karman Line" which is 100 kilometers altitude. If you go above 100 kilometers you are in "space" and are an "astronaut." Nothing can orbit at that altitude, however. There is too much air below about 100 or 110 miles (160-175 km) for something to stay up more than a few orbits.

Crossing the Karman line takes a delta-v of something like 3000-5000 mph, but orbit takes 17,500 mph (plus a bit more to overcome air friction and gravity losses to get there).

Offline

Like button can go here

#319 2019-11-09 12:15:50

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,420

Re: Reusable Rockets to Orbit

The success of Faclon 9 and of the Heavy has lead to the birth of BFR the much larger version of the first stages of the earlier models.

Nasa and its contractors are still late to this party and seems to not care at all.

Offline

Like button can go here

#320 2022-08-26 07:07:17

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Reusable Rockets to Orbit

Not SSTO but VTHL

X-43 Sänger Spaceplane?

https://twitter.com/CNSAWatcher/status/ … 9503716360

CASC’s sub-orbital VTHL vehicle completed another test flight on Aug. 26, taking off at Jiuquan, Inner Mongolia, and landing at Alxa Right Banner Airport.

Last edited by Mars_B4_Moon (2022-08-26 07:08:53)

Offline

Like button can go here

#321 2023-11-02 12:30:13

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Reusable Rockets to Orbit

China’s iSpace launches and lands rocket test stage

Offline

Like button can go here

#322 2023-11-02 13:16:05

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,065

Re: Reusable Rockets to Orbit

For Mars_B4_Moon ... thanks for bringing this old topic back into view ... I went back and read from the top for the first 25 posts or so.... the topic was opened by JoshNH4H .... Hop was present at the time, and there was a lively back-and-forth between the two.... Terraformer had just acquired a Blackberry at the time, and it seemed to work well, despite the small screen size.

Finally, thanks for news of Chinese progress toward reusability!

(th)

Offline

Like button can go here

#323 2023-11-03 10:40:35

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,137

- Website

Re: Reusable Rockets to Orbit

This was a good one to bring back, I agree. This is the conversation that got me to look at possibilities for ramjet assisted launch to orbit. I didn't find a lot of merit to that concept, for either horizontal or vertical takeoff. But it was fun to explore the possibility for its feasibility.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#324 2024-03-02 07:57:32

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Reusable Rockets to Orbit

Chinese start-up Galactic Energy plans reusable rocket debut this year

https://www.scmp.com/news/china/science … debut-year

China reusable rocket

https://thediplomat.com/tag/china-reusable-rocket/

China’s plan for a super heavy, reusable rocket has gotten far less attention than SpaceX’s Starship, but will be equally important over the long run.

CASC has a new rocket named Long March 12 this year!

D3.8m

4 YF-100K kerolox engines in 1st stage

2 YF-115 kerolox engines in 2nd stage

10 tonne capacity to LEO

6 tonnes to 700km SSO

This will also be the debut launch of YF-100K, which will power the moon rocket Long March 10

Offline

Like button can go here