New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2014-01-10 03:49:20

- Quaoar

- Member

- Registered: 2013-12-13

- Posts: 665

Zero boil-off active cooling for LH2

I have read this work on a battlestar galactica 360 ton NASA NTR spaceship. To keep cool the huge amount of LH2 for almost 2 year, it proposes a Bryton cycle zero boil-off active cooling unit: it weight only 920 kg and needs almost 9 KW.

http://ntrs.nasa.gov/archive/nasa/casi. … 004085.pdf

If it's really possible to build such device, that can be easly feeded by solar panel on a chemical rocket propelled spaceship, LOX-LH2 may become the best propellant choiche for a manned Mars mission.

Last edited by Quaoar (2014-01-10 03:50:12)

Offline

Like button can go here

#2 2014-01-10 12:41:37

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,137

- Website

Re: Zero boil-off active cooling for LH2

I think LOX-LH2 is the best solution, yes. There are "cryocoolers" available already, and I think they're lighter and lower power requirement than the Brayton thing in the old NASA study. So, yes, we can prevent significant hydrogen boiloff over long times. If you add foil-and-foam layered meteor armor, it doubles as a very effective insulation and sunshade. That reduces boiloff further, and lets you use smaller cryocooler equipment.

I don't really think a 300-600 ton ship is an unaffordable "battlestar galactica", unless you choose to launch it in chunks that are too big, which forces you to develop a gigantic one-use rocket. That's really expensive. If you build it in many smaller chunks, you can use commercial rockets to launch these chunks far less expensively, and then just dock it all together in orbit. There is no reason at all that all the propellant for any one burn need be in one single tank. Just use a bunch of one single tank module design.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#3 2014-01-10 13:58:34

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,995

- Website

Re: Zero boil-off active cooling for LH2

Are we talking about a 500+ tonne drymass ship? Because if so, good. We can fuel up at L1 from Lunar fuel (after fueling up in LEO to get it there...), and go do a proper exploratory mission.

500+ tonnes, though, would be 10 Falcon Heavy launches. Perhaps we could combine the upper stage with it, and get engines and tankage included in the deal? Maybe even launch a small (well, huge, relative to most designs...) ship in one piece as an upper stage...

Use what is abundant and build to last

Offline

Like button can go here

#4 2014-01-10 15:28:26

- Quaoar

- Member

- Registered: 2013-12-13

- Posts: 665

Re: Zero boil-off active cooling for LH2

I think LOX-LH2 is the best solution, yes. There are "cryocoolers" available already, and I think they're lighter and lower power requirement than the Brayton thing in the old NASA study. So, yes, we can prevent significant hydrogen boiloff over long times. If you add foil-and-foam layered meteor armor, it doubles as a very effective insulation and sunshade. That reduces boiloff further, and lets you use smaller cryocooler equipment.

I don't really think a 300-600 ton ship is an unaffordable "battlestar galactica", unless you choose to launch it in chunks that are too big, which forces you to develop a gigantic one-use rocket. That's really expensive. If you build it in many smaller chunks, you can use commercial rockets to launch these chunks far less expensively, and then just dock it all together in orbit. There is no reason at all that all the propellant for any one burn need be in one single tank. Just use a bunch of one single tank module design.

GW

Thanks for the lesson!

I've seen your very interesting docked module rigid baton: you used LOX-LH2 with active cryocooling system, even for your landers. For safety, in the first mission you choosed to bring all the ascent propellant and utilize ISPP only for optional extended explorations, hopping in other sites. It makes sense.

If I have correctly understood, your ISPP devicie will melt water ice and produce propellant via electrolysis: will it produce both LOX and LH2 or only LOX, bringing the LH2 from Earth?

Last edited by Quaoar (2014-01-10 15:44:16)

Offline

Like button can go here

#5 2014-01-10 22:45:56

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,420

Re: Zero boil-off active cooling for LH2

One thing that we forget is that we should do what we can with the least amount of energy as we do have it as a limiting facture for the initial flights regardless of if its just one before moving into a full out assault on mars colonization or way more flights and decades which I do not hope for to actually trying to be a colony.

Offline

Like button can go here

#6 2021-12-12 06:56:21

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,065

Re: Zero boil-off active cooling for LH2

This topic showed up when I asked FluxBB if we had any topics on cooling ...

It has been quiet since 2014. I'd like to ask the question why there is a question about dealing with boil off.

Why do we continue to see posts expressing worry about boil off of cryogenic materials in space?

There must be a reason, or it wouldn't keep happening. In the conclusion of this post, I will show why worry about boil-off persists.

I bring this up because the most recent hybrid meeting of the North Houston chapter of the National Space Society included a 1 hour+ long talk on the James Webb Space Telescope.

Instead of a theoretical argument about how to maintain cryogenic temperatures, the Webb is a real-world demonstration of an attempt to maintain temperatures at extremely low levels in order to be able to detect faint infrared signals from the earliest moments of the Universe.

The presentation is now available for viewing at www.northhoustonnss.org

The Webb talk begins 1 hour in. The first hour includes an extensive review of space flight operations in the past month.

Per Google:

The sunshield will allow the telescope to cool down to a temperature below 50 Kelvin (-370°F, or -223°C) by passively radiating its heat into space.

The Sunshield Webb/NASA

www.jwst.nasa.gov › content › observatory › sunshield

Also per Google:

Hydrogen has the second lowest boiling point and melting points of all substances, second only to helium. Hydrogen is a liquid below its boiling point of 20 K (–423 ºF; –253 ºC) and a solid below its melting point of 14 K (–434 ºF; –259 ºC) and atmospheric pressure. Obviously, these temperatures are extremely low.

Module 1: Hydrogen Properties - gov.energy.eere.www1

www1.eere.energy.gov › hydrogenandfuelcells › tech_validation › pdfs

20 Kelvin is well below 50 Kelvin. If successful (which we will know a month after launch) the Webb will be a real-Universe demonstration of sustained cooling to 50 Kelvin.

I note that an active cooling system is (apparently) included in the Webb, to allow liquid Helium to participate in operation of a spectrograph.

A site that Google says may discuss design of the spectrograph is: https://jwst.nasa.gov/content/observato … rspec.html

I conclude that while the James Webb is going to demonstrate ability to sustain 50 Kelvin for it's operations, that is NOT cool enough to keep liquid hydrogen or liquid helium from gaining thermal energy from the deep space environment.

It would appear to me that the frontier of deep space cooling remains open for highly motivated, very bright people to explore.

The goal (that I see at least) is to find a shade solution that allows sustained temperature of 20 Kelvin for storage of LH2.

Per Google:

The primary reason to use liquid helium is that it is cold. Super cold. At normal atmospheric pressure, liquid helium boils at at temperature of just 4.2 Kelvins (-452.11 Fahrenheit).

Aug 17, 2012

Accordingly, the frontier of deep space shade cooling would appear to be 4.2 Kelvin.

In conclusion of this post .... it appears that the engineers working on Webb will have found a solution to keep Oxygen liquid!

The sunshield membrane is one of the enabling technologies that will allow the JWST to operate. To make observations in the near and mid infrared spectrum, the JWST must be kept very cold (under 50 K (−220 °C; −370 °F)), otherwise infrared radiation from the telescope itself would overwhelm its instruments.

Sunshield (JWST) - Wikipedia

en.wikipedia.org › wiki › Sunshield_(JWST)About Featured Snippets

The Sunshield Webb/NASA

www.jwst.nasa.gov › content › observatory › sunshield

The sunshield will allow the telescope to cool down to a temperature below 50 Kelvin (-370°F, or -223°C) by passively radiating its heat into space. The near- ...www.universetoday.com › james-webb-tests-its-sun-shield-so-far-so-good

Oct 23, 2019 · The James Webb Space Telescope successfully completed critical testing ... the shaded telescope side will be cold enough to freeze oxygen.

Thus, it would appear that a ship fueled at Earth departure with liquid methane and liquid oxygen could carry those materials to Mars with zero boiloff.

Edit per Google:

Liquid methane also has a temperature range (91–112 K) nearly compatible with liquid oxygen (54–90 K).

Methane - Wikipedia

en.wikipedia.org › wiki › Methane

A much more reasonable way to carry supplies of Hydrogen to Mars is as frozen water. Solar power can deliver hydrogen and oxygen as needed en route.

SearchTerm:boiloff this post attempts to answer the persistent worry about boiloff that keeps showing up in NewMars forum posts

I conclude (subject to correction) that the target of 50 Kelvin was chosen for James Webb because of an operational requirement. The 50 Kelvin figure appears to meet the needs of the instruments which will be capturing photons of infrared and near-infrared light. The shaded side of the Webb may in fact reach colder temperatures than 50 Kelvin, so I hope (and trust) that temperature readings will be returned from the instrument.

(th)

Offline

Like button can go here

#7 2021-12-12 13:58:25

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,420

Re: Zero boil-off active cooling for LH2

If we are talking tanks the boiloff is an increase of internal pressure that is caused by the heat and its that build up that would rupture the tank.

So venting is the relief for that pressure and that means a loss of fuels.

For the telescope its the lose of the cooling agent typically helium.

So for active cooling of the would would be the contents of the tank or of what we would have vented we must bring its temperature back down. This is where the radiator in the shade aids in that process. For space that means mass and tubing and such to keep from losing the precious commodity.

Since its an unmanned ship until a crew is boarded the means to erect a sun shield means building a design that can be automated for deployment. That same shield would block any means to make use of solar energy to power the ship while in a waiting on orbit status during refueling operations.

As you noted the telescope is for the IR bands of information that will be concentrated by the segmentation of the large mirror system in this design to the common focal point. The sun shield is a reflective surface to keep heat from reaching the telescope. Its what was done with skylab. Even with the shield it still will see some loss over time of cooling agents.

Offline

Like button can go here

#8 2021-12-12 16:21:17

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,065

Re: Zero boil-off active cooling for LH2

For SpaceNut re #7

The telescope is not yet launched, so we don't have on site proof that the radiation cooling method will work.

However, if it ** does ** work, then all the worries that some folks have about boil off of liquid oxygen will have been resolved.

I am certainly hoping this radiative cooling method works as planned, because it solves a ** lot ** of problems for space travelers.

Thanks for tracking these developments closely!

Remember, if this ** does ** work, you will NOT need mechanical cooling systems for your liquid oxygen supply.

On the other hand, as you point out, liquid helium will (and does) require mechanical cooling.

That is why I am challenging our younger readers to develop radiative solutions for Hydrogen and ultimately, for Helium.

(th)

Offline

Like button can go here

#9 2021-12-12 17:12:08

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,420

Re: Zero boil-off active cooling for LH2

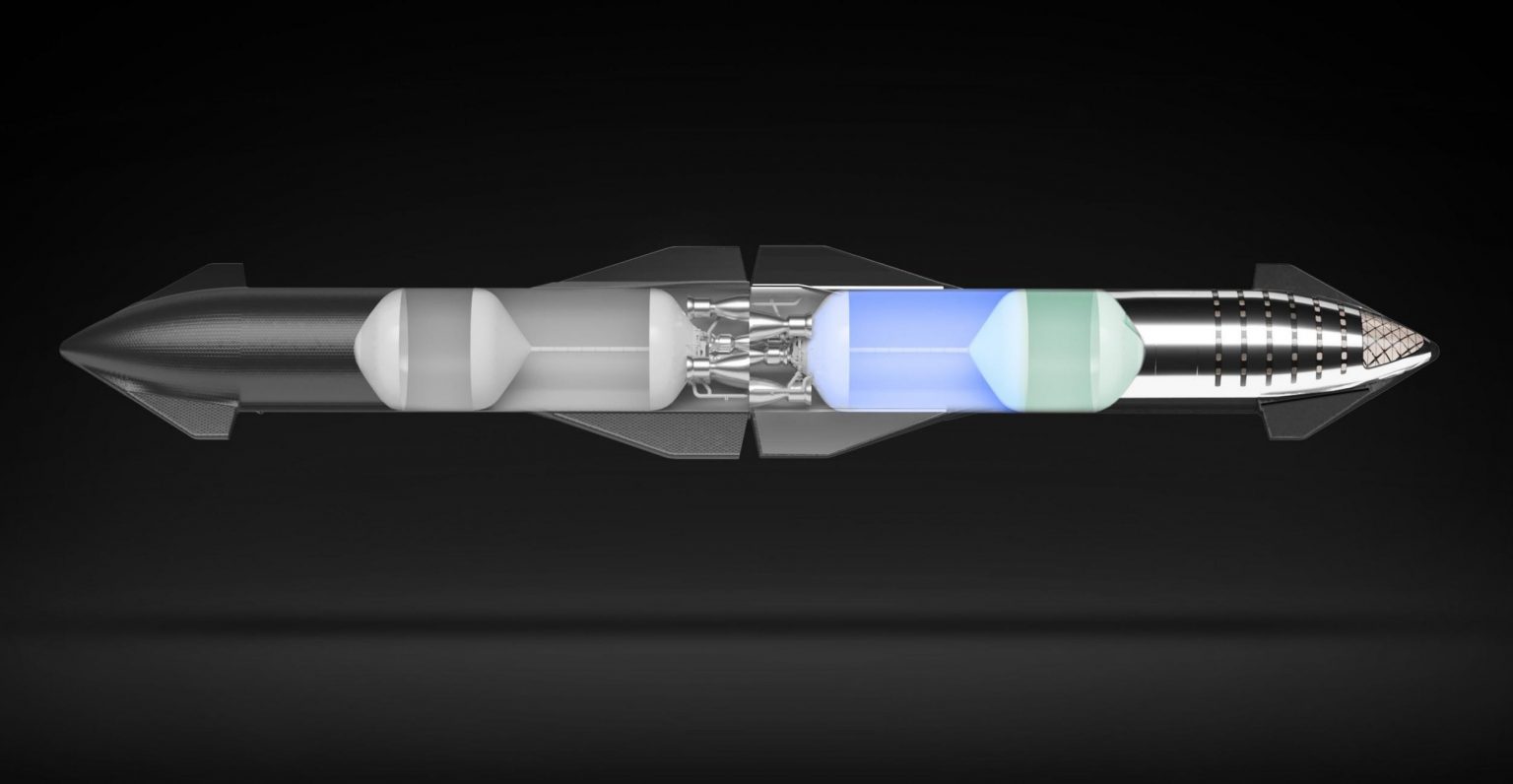

Boil off occurs as you noted as a result of heat from the sun and space x has no sun shade and its not part of there design. Its not just the shade to the tank as the heat is coming from all around it. So while we may be able to reduce the boil off rate its still present and all that hand waving on repetition rate of starship fuel flights are wishful thinking at this time since we have not move any cryogenic fuels in orbit.

We also do not know the transfer rate of a starship with no pumping of those fuels to the waiting starship that's going to any destination.

This is the thruster refueling in milli-G SpaceX’s path to refueling Starships in space is clearer than it seems

Currently, the turnaround record (time between two flights) for Falcon boosters is two launches in less than four weeks (27 days).

Impacts boiloff

In orbit, under microgravity conditions, the propellant inside a spacecraft’s tanks is effectively detached from the structure. If a spacecraft applies thrust, that propellant will stay still until it splashes against its tank walls – the most basic Newtonian principle that objects at rest tend to stay at rest. If, say, a spacecraft thrusts in one direction and opens a hatch or valve on the tank in the opposite direction of that thrust, the propellant inside it – attempting to stay at rest – will naturally escape out of that opening. Thus, if a spacecraft in need of fuel docks with a tanker, their tanks are connected and opened, and the tanker attempts to accelerate away from the receiving ship, the propellant in the tanker’s tanks will effectively be pushed into the second ship as it tries to stay at rest.

Physics at work

The principles behind such a ‘settled propellant transfer’ are fairly simple and intuitive. The crucial question is how much acceleration the process requires and how expensive that continuous acceleration ends up being. According to Kutter et al’s 2006 paper, the answer is surprising: assuming a 100 metric ton (~220,000 lb) spacecraft pair accelerates at 0.0001G (one ten-thousandth of Earth gravity) to transfer propellant, they would need to consume just 45 kg (100 lb) of hydrogen and oxygen propellant per hour to maintain that acceleration.

100,000 kg / 45 kghr = 2,222.22 hrs / 24 hrs = 92.59 days to transfer the fuel

https://www.nasa.gov/pdf/62474main_Micr … _Guide.pdf

Nasa is working on a similar concept SpaceX begins work on Starship orbital propellant transfer test for NASA

Here is the sunshade work concepts

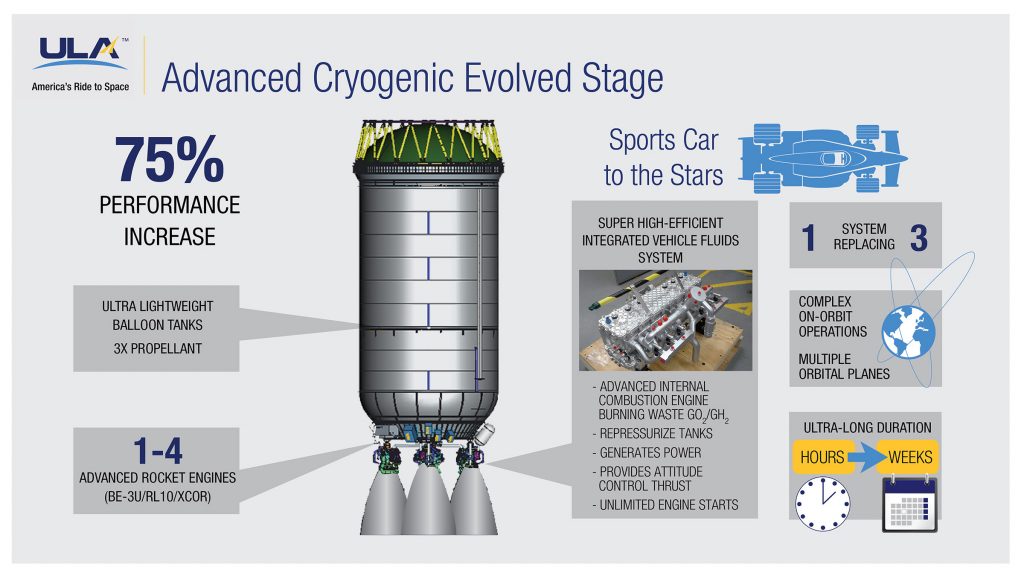

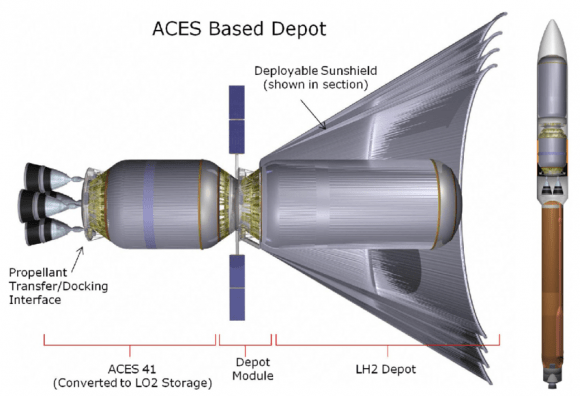

United Launch Alliance proposed the Advanced Common Evolved Stage, or ACES based on technology developed a few years earlier by Boeing and Lockheed Martin.

Each ACES upper stage would contain twice the propellant of a traditional Centaur upper stage booster – 41 metric tonnes of fuel. And a stretched version would have 73 tonnes on board.

Offline

Like button can go here

#10 2021-12-12 17:12:46

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,420

Re: Zero boil-off active cooling for LH2

This is the only issue for use of starship to over come and that is the refueling operation

Shading from the sun to lower boiloff: Don't forget the real purpose of the small "header" tanks inside the propellant tanks. For a Starship going to Mars, most of the propellant is burned departing from LEO. What is needed for course correction and for landing is in the header tanks. These are shaded by the empty main tanks, being inside like that. Same is true for any refilled Starship returning to Earth from Mars: most of the propellant is burned departing Mars. Propellant for course corrections and the landing are in the header tanks.

This is even true of Starships operating as LEO transports: most of the propellant is burned from the staging point to orbital entry. Propellant for orbital maneuvers, deorbit, and landing is in the header tanks, shaded from the sun by their location inside the empty main tanks. That way, a long orbital mission is feasible without a lot of boiloff.

The unresolved problem is for the tankers that refill a Starship on-orbit before it can go to the moon or Mars or anywhere else outside LEO. These are either another Starship flown at zero payload so as to arrive on orbit with a one to two hundred tons unused propellant, or a dedicated tanker design carrying one to two hundred tons propellant in tanks added as the cargo section. Those will be unshaded, and will need to be drained into the waiting vessel on a time scale of days, not weeks or months. (Likewise the receiving vessel needs to use its refill on a scale of days, not weeks or months.)

There is an alternative to using attitude thrusters continuously for ullage thrust to make the transfer by microgravity. That's going to take a lot of time and use a lot of thruster propellant. A whopping lot of boiloff will occur over a long transfer time. There is no way to avoid that.

Settle the tanks with ullage thrust or by rifle bullet spin, and use pumps to move the propellant quickly. Either should work fine. You do need the stored energy aboard to run the pumps. But you lose a whole lot less propellant to boiloff, by drastically shortening the time the main tanks are exposed to the sun with propellant in them.

The stored energy and/or the extra thruster propellant are just the mass penalty you must pay to do this. But the huge boiloff loss over a long time interval is a penalty you need not pay, if you just do the transfer quickly. On a time scale of an hour or so. More like loading and unloading on the launch pad.

GW

Offline

Like button can go here

#11 2021-12-12 17:17:01

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,420

Re: Zero boil-off active cooling for LH2

Looking at the staging time and boiloff for a mars window of opportunity to launch. Since we want 2 cargo ships to land a full mars cycle ahead of another pair with a crewed ship ignoring the crew size thats quite a total number of launches to make it happen.

First off, boiloff is a lot lower in interplanetary space than in planetary orbit, as there is no nearby warm body radiating IR, so for most of the trip you will see a much lower boiloff rates. Secondly, the boiloff figures you quote are for hydrogen in LEO.

For LOX and LM there are ways to reduce boil off maybe to near zero. By orientating the craft so the engines or crew capsule faces the sun the boil off rate could be dramatically reduced because the amount of solar radiation absorbed would be greatly reduced and the heat radiated to space would be maximized.

But by default liquid methane is very close in temperature to liquid oxygen since it’s boiling point is -161.5 °C and it becomes a solid at -182 °C. Cryogenic Propellant Temperatures Due to the closeness in boiling points, we’ll likely see SpaceX chill their methane down closer to -180 degrees Celsius as they continue to squeeze performance out of that beast.

We don't want the CH4 to freeze, so the LOX should be allowed to rise to the freezing point of CH4 -182.5°C =90.65K .

http://www.unece.org/fileadmin/DAM/tran … 02-06e.pdf

The measure for the boil-off is the amount of vapours per unit time. It can be an absolute measure – kg/h, kg/day or a relative measure – % vaporized from total amount per unit time.

https://space.stackexchange.com/questio … ip-to-mars

The atmospheric boiling points of the chosen propellants are as follows: Oxygen 90K (-183C, -287F) Methane 111K (-161C, -258F) Compare Hydrogen 20K (-253C, -423F) Space is a place of temperature extremes: roasting in the sun, but pretty cold in the shade.

https://www.reddit.com/r/SpaceXLounge/c … ions_uses/

Note that simply painting Starship with the right white paint could reduce the solar absorptance from 0.39 to 0.09, which would reduce boiloff by a factor of 0.23, to 0.62 percent/day for LOx and 0.72 percent/day for methane, even if Starship is oriented in the worst possible way.

https://cryocooler.org/resources/Documents/C17/056.pdf

So since the star ship is going to have tile its got to spend its time facing away from the sun. If its got solar wings its got to be able face them towards the sun. The other side of the ship needs to be white to reflect heat. Since its seems that we are going to launch no quicker than a month appart that leaves days between refueling for it to boil off even with all of the above being taken into account.

Lets ignore the ration and difference of fuel boiloff and use the lower 0.62 %

At month 1 we are basically zero in the main tank with the header tank holding 100Mt and at the next

1 month launch that fuel load will have boiled off to become 80Mt in the header tank.

We fill the main tank with 100Mt and wait for the next flight to happen.

Of course the header tank will drop to 68Mt and the main tank will be at 80Mt of fuel due to the boil off staying consistent.

This is why we need to fill faster and having the extra ships of cargo makes the refueling levels even higher to achieve.

So at that time of 2 months end you have a ship that has been in orbit and has just 150Mt for the ship to use.

Offline

Like button can go here

#12 2024-03-16 17:40:10

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,420

Re: Zero boil-off active cooling for LH2

Zero-boil-off tank experiments to enable long-duration space exploration

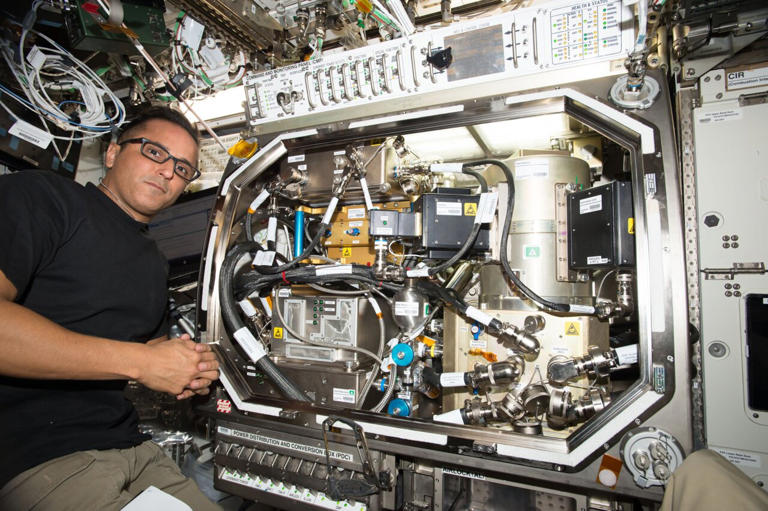

Astronaut Joseph M. Acaba installing ZBOT Hardware in the Microgravity Science Glovebox aboard the International Space Station

At the heart of the ZBO pressure control system are two proposed active mixing and cooling mechanisms to counter tank self-pressurization. The first is based on intermittent, forced, subcooled jet mixing of the propellant and involves complex, dynamic, gravity-dependent interaction between the jet and the ullage (vapor volume) to control the condensation and evaporation phase change at the liquid-vapor interface.

The second mechanism uses subcooled droplet injection via a spraybar in the ullage to control tank pressure and temperature. While the latter option is promising and gaining prominence, it is more complex and has never been tested in microgravity where the phase change and transport behavior of droplet populations can be very different and nonintuitive compared to those on Earth.

Although the dynamic ZBO approach is technologically complex, it promises an impressive advantage over the currently used passive methods. An assessment of one nuclear propulsion concept for Mars transport estimated that the passive boil-off losses for a large liquid hydrogen tank carrying 38 tons of fuel for a three-year mission to Mars would be approximately 16 tons/year.

The proposed ZBO system would provide a 42% saving of propellant mass per year. These numbers also imply that with a passive system, all the fuel carried for a three-year Mars mission would be lost to boil-off, rendering such a mission infeasible without resorting to the transformative ZBO technology.

Offline

Like button can go here