New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2020-01-19 13:04:15

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

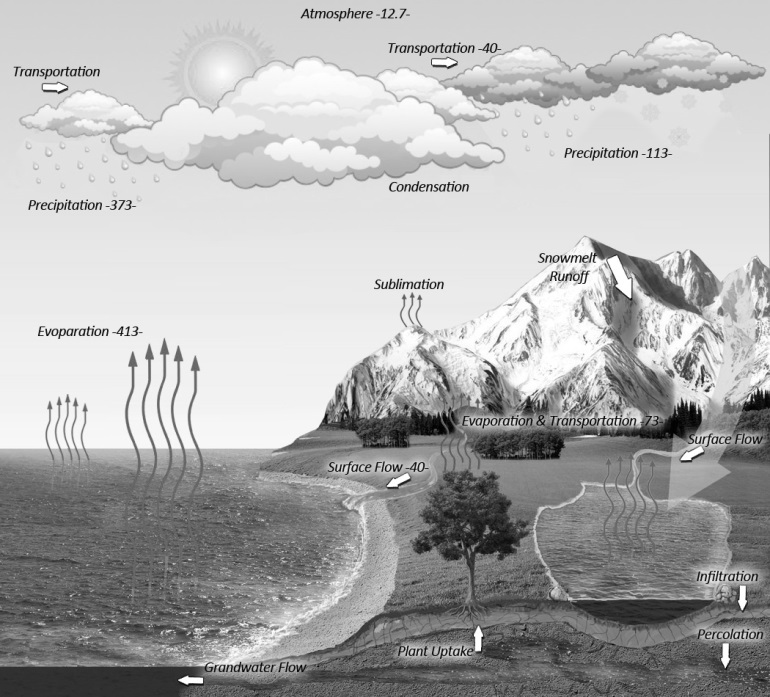

solar concentration Water steam energy creation

I am currently looking at a self contained pressured gas electricity producing system in which the sun plus concntration is used to heat the cyclinder to cause the pressure to rise and vent through a turbine to make power exiting to the low pressure chamber in which the shade and cooling of the gas will take place for the days power creation. The following day the roles are swapped and flow of gas goes in the oposite direction. One can use well water or heat echanging or even an ac cooling unit as part of the design for heat pumping or for cooling of the home as a side part of the energy creation. As for cooling refridgerant mars would need something that gets colder than co2 does to be able to freeze it out and the same for liquifying oxygen in the cryo system of which nitrogen, helium and many others are used..

Offline

Like button can go here

#2 2020-01-19 14:20:57

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,269

Re: solar concentration Water steam energy creation

I am currently looking at a self contained pressured gas electricity producing system in which the sun plus concntration is used to heat the cyclinder to cause the pressure to rise and vent through a turbine to make power exiting to the low pressure chamber in which the shade and cooling of the gas will take place for the days power creation. The following day the roles are swapped and flow of gas goes in the oposite direction. One can use well water or heat echanging or even an ac cooling unit as part of the design for heat pumping or for cooling of the home as a side part of the energy creation. As for cooling refridgerant mars would need something that gets colder than co2 does to be able to freeze it out and the same for liquifying oxygen in the cryo system of which nitrogen, helium and many others are used..

I would propose a sub-atmospheric steam engine. At 0.2atm, water will boil at 60C. At 0.042atm, it will condense at 30C. The waste heat is still warm enough to have some use for space heating. Efficiency will be low, about 5%. But the advantage of a system like this is its extreme simplicity. The single low-pressure turbine is the only moving part. Water flows from the condenser beneath the turbine, back into the boiler by gravity. Because the differential pressures are so low, a feed pump is not required. Gravity provides enough head pressure to push water back into the boiler against the steam pressure. Because the pressures are so low, expensive pressure shell would not be needed and gravity stabilised masonry or rammed soil should provide as much strength as needed for the pressure shells.

S-CO2 could in principle provide an alternative working fluid. The problem is that internal pressures will be greater, which will complicate pressure containment and mean that feed pumps are needed between the condenser and boiler. If efficiency and power density are both low, it is very important to minimise complexity and embodied energy if the system is to be economically viable.

Last edited by Calliban (2020-01-19 14:25:27)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#3 2020-01-19 16:25:15

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: solar concentration Water steam energy creation

So the tank for collecting the steam is at the top slightly angled to feed the drain opening at the bottom with a check valve at the end of the feed line that goes into the boiler. A pump if one is needed is to keep a given level of water in the bolier to be able to keep making steam. The float would be a low to high limit of water to have in the tank to control the pump for boiler water levels.

The outlet side of the boiler could have an steam injector control to allow for so called control of the pressure going out to the generating turbine unit. With the outlet side of the turbine going to the expansion capture tank where it will cool and be used once more.

Any refilling of water takes place in that tank to satisfy the system water level which could have a fault low and high limit indicator for manual refilling needed.

To make the low pressure levels work one needs to evacuate the pressure side and the return side to those levels by pumping out the air that remains in the system. To do this means holding the pump turbine and the check vakve with a bypass to allow for the first water levels to be established in the system before trying to heat the boiler to creat power for the first time. Pressure indicators could be located as needed for each boiler and expansion tank.

This all sounds so simple as you can get the tanks and some stuff at the local hardware construction places such as The Home Depot or Lowels but there are still plenty of things which will need to be fabricated.

Offline

Like button can go here

#4 2020-01-19 17:46:33

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,269

Re: solar concentration Water steam energy creation

Spacenut,

I think it could be even more simple than you think. If the boiler is heated by a coiled hot water pipe, pressure cannot rise above the saturation pressure of steam at that temperature. So long as inlet temperature to the heater coil does not exceed 70C, say, it will be impossible for pressure to rise much higher than 0.2bar, because higher pressure would collapse the steam bubble and there is always some temperature differential across a heat exchanger. The system is self regulating.

You also don't need level sensors or check valves. The condenser will drain into the boiler by gravity through a simple tube between the two. Remember, the system is closed. If pressure rises in the boiler, it will push water back up into the condenser until head pressure balances boiler pressure. If too much water is pushed out of the boiler, the heat exchanger tubes are uncovered and pressure begins to drop again. But we have already established that pressure cannot rise much higher because feed water temperature is too low to allow it.

The boiler will produce wet steam (basically froth) that would need to be dried before entering the turbine. Steam dryers work by either passing steam through baffles that cause water droplets to stick to the surfaces or through swirl vanes, which introduce vorticity. The easiest option would be to fill the boiler with coarse gravel. Above the gravel, you would have a steam drum, which is little more than a void that sits above the entrance to the turbine. You don't need check valves at this point, just a pipe. If the turbine loses load and starts to over speed, the temperature and pressure will begin to rise in the condenser. So long as the turbine has enough inertia, the transient will correct itself.

The turbine is the only part of the system that strictly needs to be a moving part. The heat exchanger could make use of solar, geothermal or any other source of low quality heat and could work on natural convection. The system is self-regulating at many levels. An increase in load would result in pressure drop ahead of the turbine, which would increase boiling rate in the boiler. This would in turn lead to a drop in boiler temperature, which would be compensated by increased rate of heat transfer from the heat exchanger into the boiler and so on.

Because pressure is so low and temperature is less than 100C, material selection is easy. The whole system is under vacuum, so concrete or rammed earth could be used to resist external pressure here on Earth. On Mars, a few metres of soil would provide enough resisting pressure. Heat exchanger pipes could be plastic or maybe even ceramic. Design for the greatest simplicity and minimal embodied energy.

Last edited by Calliban (2020-01-19 18:05:59)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#5 2020-01-19 19:09:37

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: solar concentration Water steam energy creation

Baffle plates act as a restrictor of flow if the holes are to small and of course each plate is out of alignment for the holes as to make the steam change course through the number of plates needed to make all the water go out of the steam. That would make the baffle chamber the means for water to re-enter the boiler chamber and no tank after the turbine as there is no water to collect only a tube back into the boiler for what little makes it through the turbine.

The tank after the turbine is the expansion tank so as to drop the pressure. Where the outer wrap echnager coil can as you noted even plastic as its about coiling the larger volume chamber to cause liquid water to form. The cooling liquid would have a pump from the water source and sensor to see how cold the exchanger is as to increase or decrease the flow of water through the exchanger.

Braking the turning shaft for rpm over run is just a sensor and braking system to control. One could also do a magnetic coupling to connect the shaft to the load.

Heat exchangers for a wrap around or in the tank still need sensors to monitor the heating function so as to keep it constant for the steam pressure to work within the limits of the turbine shaft rotation speed rpm for the desired frequency if not converting the wide ac into dc before using and invertor to make the line voltage and frequency desired.

Offline

Like button can go here

#6 2020-01-19 21:11:48

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: solar concentration Water steam energy creation

Here is a batch of stuff for design:

http://www.mechanicalengineeringsite.co … sic-parts/

https://www.technologyreview.com/s/4061 … generator/

https://www.turbinegenerator.org/steam/

https://www.homesteadingtoday.com/threa … or.431513/

Steam engines can run 24 hours a day regardless of location, weather or daylight.

There are no construction costs, towers, roof panels or permits required.

There is no noise or environmental impact associated with steam power.

The Green Steam Engine® may be powered by the widest range of alternative fuels, including solar and geothermal.

No back-up power required as it is for wind and solar systems.

When operated on solar, excess energy may be stored in compressed air which can be returned to the steam engine later for electrical generation. Compressed air is much cheaper than batteries.

http://www.johnforester.com/Maritime/St … Basics.pdf

https://otherpower.com/steamengine.html

2kW Steam Engine and Alternator

Real homebrewed build

This one was made due to solar and wind not being able to supply all of energy needs all the time which meantion running generator.

Offline

Like button can go here

#7 2020-01-19 21:55:15

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,269

Re: solar concentration Water steam energy creation

Spacenut, impressive list. I will try and make time to read through them. If your source of heat is at a temperature less than 100C, then a lot of energy could be stored in hot water at ambient pressure. Maybe insulation could be provided by low energy materials, like sand, soil or straw?

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#8 2021-12-31 20:36:16

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: solar concentration Water steam energy creation

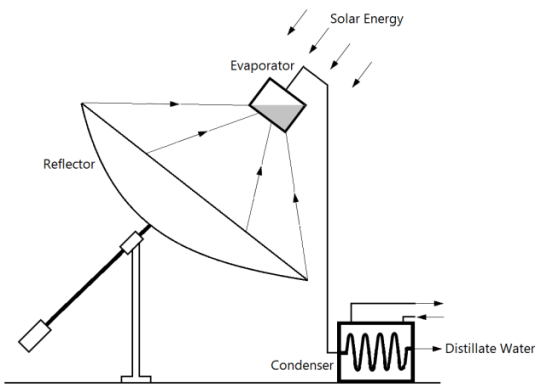

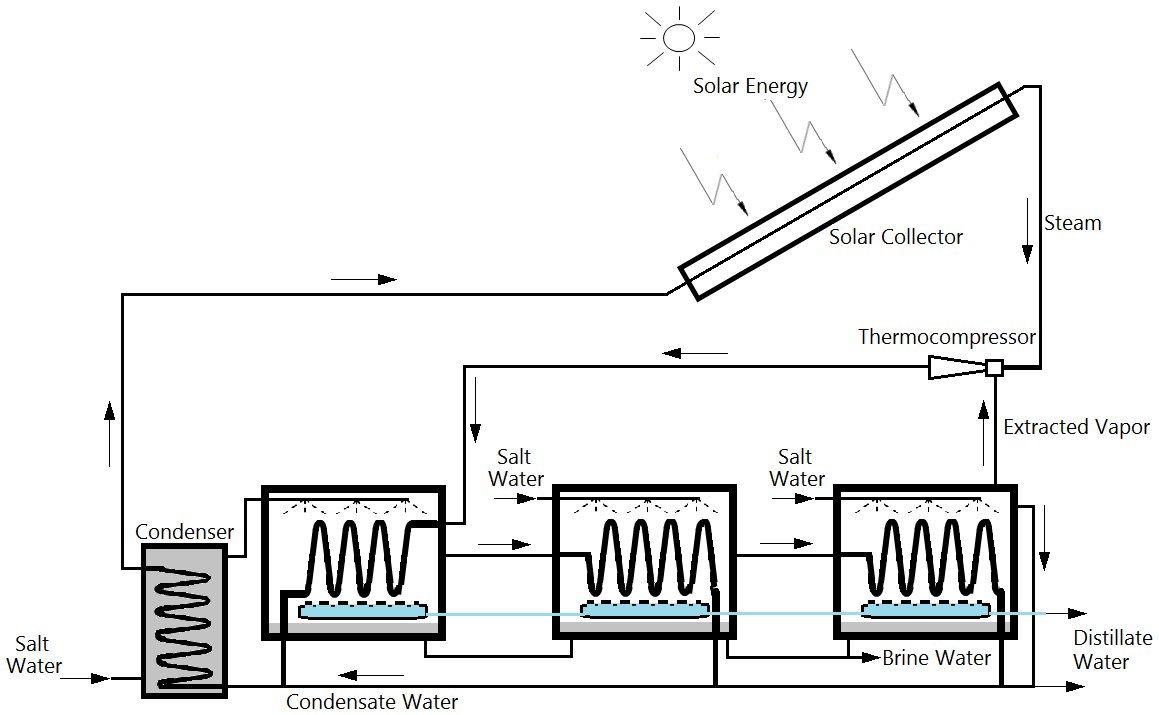

Two topics in one with regards to distillation and solar concentrating all in one.

2400 watts =

3.218 british horsepowers

Convert 2400 Watt to Horsepower (W to hp) - Power Conversion

www.theunitconverter.com › watt-to-horsepower-metric-conversion › 240...

Result : 2400 Watt = 3.26309 Horsepower (metric). How to convert Watt to Horsepower ? 1 watt (W) is equal to 0.00136 horsepower (hp). 1W = 0.00136hp.

Convert 2,400 Watts to Horsepower - CalculateMe.com

www.calculateme.com › power › watts › to-horsepower › 2400Next, I asked Google if there is a steam engine that can produce 3 horsepower,,,

Here is a web site for a company that (apparently) offers steam engines of 1, 3 or 20 horsepower

https://mikebrownsolutions.com/steam-engines/

Mike Brown Steam Engines

Mike Brown Solutions offers 1, 3 & 20 horsepower steam engines.

Our 1-horsepower Steam Engine:

(1-cylinder)Our 3-horsepower Steam Engine:

(2-cylinder)Efficiency of a steam engine is low ... I'm guessing the best that can be hoped for is 30% ...

Here is a snippet that indicates 40% is possible for a turbine system:

What is the average efficiency of a steam engine?

Steam engines and turbines operate on the Rankine cycle which has a maximum Carnot efficiency of 63% for practical engines, with steam turbine power plants able to achieve efficiency in the mid 40% range. In earliest steam engines the boiler was considered part of the engine.

Engine efficiency - Wikipedia

en.wikipedia.org › wiki › Engine_efficiency(th)

Offline

Like button can go here

#9 2021-12-31 20:37:50

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: solar concentration Water steam energy creation

reposting the solar concentrating.

This post should fit well into this topic:

https://www.inceptivemind.com/engineers … 8XXvgPQ_W8

The experimental new solar distiller incorporates a rectangular basin, inside of which is a horizontally oriented black steel cylinder. The basin is filled with undrinkable water, and the cylinder is slowly rotated by a solar-powered DC motor.

The rotating hollow cylinder inside the solar distiller accelerates water evaporation in the vessel by forming a thin film of water on the outer and inner surface of the cylinder, which is constantly renewed with each turn. As the film is so thin, the water film quickly evaporates due to the rapid transfer of heat from the surface of the cylinder to the adjacent water film. To increase the temperature of water under the cylinder, the engineers used a solar collector.

“The performance improvement factor of the created solar distiller, compared to traditional devices, was at least 280% in the relatively hot months (June, July, and August) and at least 300% and 400% in the cooler months (September and October), at the same time, the cumulative water distillation capacity reached 12.5 l/m2 per day in summer and 3.5 l/m2 per day in winter,” commented Alharbawi Naseer Tawfik Alwan, a research engineer at the Department of Nuclear Power Plants and Renewable Energy (UrFU).

The rotating drum method has been tested and results are encouraging.

It might even work at Mars, with a bit of mirror magnification of the solar flux.

(th)

Offline

Like button can go here

#10 2021-12-31 20:38:49

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: solar concentration Water steam energy creation

Novel device harvests drinking water from humidity around the clock

The small pilot system with a pane diameter of 10 centimeters delivered 4.6 milliliters of water per day under real-world conditions. Researchers were able to show that, under ideal conditions, they could harvest up to 0.53 decilitres of water per square meter of pane surface per hour.

https://advances.sciencemag.org/content/7/26/eabf3978

Exploiting radiative cooling for uninterrupted 24-hour water harvesting from the atmosphere

Offline

Like button can go here

#11 2021-12-31 20:39:33

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: solar concentration Water steam energy creation

I will actually need something more inclusive to storage and more to make this plausible for the well that has high iron and other mineral conditions but have gotten some more ideas going for the least cost to do so.

https://solarcooking.fandom.com/wiki/Water_distillation

https://www.sunoven.com/home-grown-food … er-health/

What this is is solar concentrating to cause the water to evaporate but in the same token if I can get power from steam I also get the drinking water at the same time.

The standard parabolic reflector for cooking that could be modified 1.5m Diameter Parabolic Focal Spot Temperature:700-1000°C 1800 w priced at $160 can be had from several vendors. Would definitely want to give a clock to shade the reflector when working around the focus point.

Something like this requires sensing of the temperature to cause flow of the or a float like device to cause the water to flow into replace the amounts that are turned to vapor or steam depending on how hot one wants it to get.

The well can act to cool the water after it evaporates

I can only spend the money once so I need a full end to end design to build.

Here is another design

Offline

Like button can go here

#12 2021-12-31 22:11:41

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: solar concentration Water steam energy creation

https://cms.qut.edu.au/__data/assets/pd … -Final.pdf

How Do We Make Electricity from Steam?

https://www.instructables.com/Solar-OSE … eneration/

Solar-OSE: Solar Concentrator for Steam Generation

http://ng.cba.mit.edu/neil/06.08.fab/pr … e.jpg.html

https://www.technologyreview.com/2006/0 … generator/

Affordable solar power using auto parts could make this electricity source far more available.

https://www.motherearthnews.com/renewab … az79mjzraw

Plumbing Up Mother’s Solar Steam Generator

Offline

Like button can go here

#13 2022-01-01 09:59:13

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: solar concentration Water steam energy creation

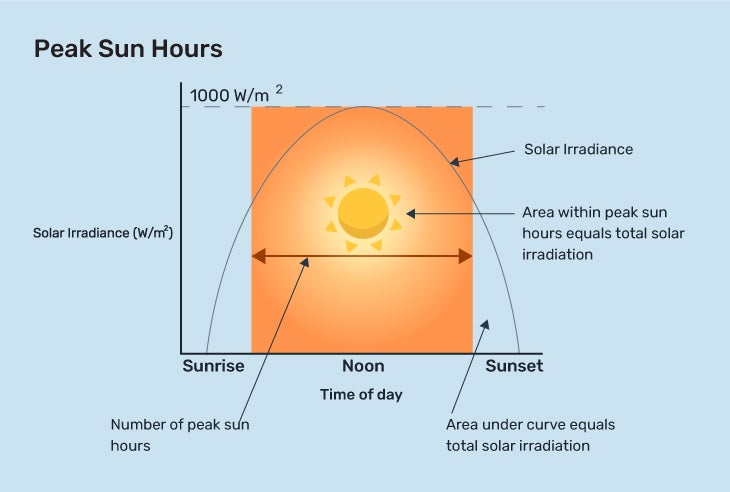

The quantity of water processed is based on whr of the absorbed energy which is applied to the quantity of water in the unit. The amount processed is also depended on what quantity is available for the process in the first place.

Southern areas of the US are in the isolation zones where solar is best get close to 6hrs and in the north we are closer to 2.5hrs so the reflecting or concentrating of solar will be a factor of 3 time greater to get the same input energy over the shorter time span.

This factor of 3 can be in size of a single unit or by making 3 of them to combine for through put.

By the way this is the issue for mars to start with since we are dropping from the 1100 w/m to just 430 w/m average and that is why solar is so hard to design.

https://www.sciencedirect.com/topics/ea … insolation

https://en.wikipedia.org/wiki/Solar_irradiance

Offline

Like button can go here

#14 2022-01-02 18:13:41

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: solar concentration Water steam energy creation

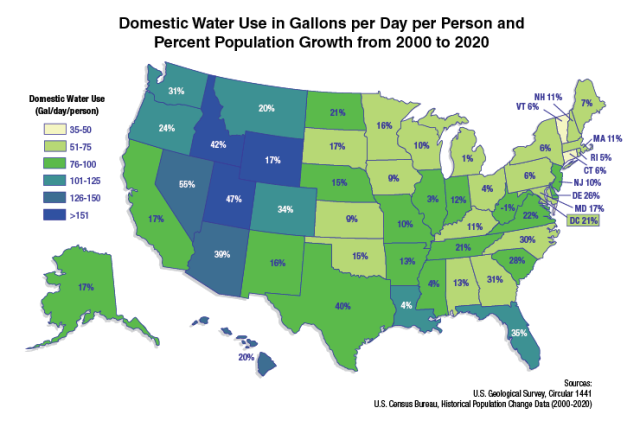

Something that we need is the "single person daily water use" to make a base design from.

https://www.usgs.gov/special-topics/wat … e-each-day

Estimates vary, but, on average, each person uses about 80-100 gallons of water per day, for indoor home uses. Are you surprised that the largest use of household water is to flush the toilet, and after that, to take showers and baths?

https://www.epa.gov/watersense/how-we-use-water

The average family uses more than 300 gallons of water per day

The report found the following breakdown of average daily household water usage.

Toilet - 24%

Shower - 20%

Faucet - 19%

Washing Machine - 17%

Water Leakage - 12%

Other - 8%With 12% of our daily water usage coming from leaks, that might actually be a spill worth crying over.

Average water usage per person per day

According to the EPA, here are how many gallons the average American uses in each room, per day:

Toilet – 18.5 gallons per person, per day

Washing Machine – 15 gallons per person, per day

Shower – 11.6 gallons per person, per day

Faucet – 10.9 gallons per person, per day

Dishwasher – 1 gallon per person, per day

Offline

Like button can go here

#15 2022-01-02 19:28:08

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: solar concentration Water steam energy creation

solar also rely on good weather days in your area as well.

https://www.currentresults.com/Weather/ … y-city.php

Average Annual Sunshine in American Cities

https://www.currentresults.com/Weather/ … -month.php

https://www.currentresults.com/Weather/ … eather.php

https://www.currentresults.com/Weather/ … eather.php

https://www.solarreviews.com/blog/peak- … -explained

Peak Sun Hours (PSH)

Arizona 7 – 8

New Hampshire 3 – 3.5

https://www.solardirect.com/archives/pv … hours.html

GIVE SUMMER AND WINTER AVERAGES

Its these combinations that give you the power for the investment payback

Of course a nuclear power source would not see this issue in the desalination topic which shares some of this content

Offline

Like button can go here

#16 2022-02-12 21:13:14

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: solar concentration Water steam energy creation

Of course once you have the heat source we need an engine to put with it that generates power.

https://www1.eere.energy.gov/ba/pba/pdfs/solar_dish.pdf

https://www1.eere.energy.gov/solar/revi … nfinia.pdf

https://commons.erau.edu/cgi/viewconten … ontext=edt

https://www2.eecs.berkeley.edu/Pubs/Tec … 07-172.pdf

https://www.ohio.edu/mechanical/thermo/ … Cogen.html

https://www.stirlingengineforum.com/vie … php?t=2303

https://www.fieldlines.com/index.php?topic=143774.0

https://en.wikipedia.org/wiki/Stirling_engine

This just gave me an idea for mars also for capturing co2.

Offline

Like button can go here

#17 2023-01-02 13:03:59

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: solar concentration Water steam energy creation

Found this topic while searching and it shows just how fast we are forgetting what we are exploring for mars to get what we know we need to survive.

After all of this time I still have only a vague idea of the amount of heat that one can collect from reflective concentration.

If you have a meter sq and you shape to focus on a target of just a 1" area at the focal point you get the 1 kw but what is the temperature you end up with.

https://www.analyzemath.com/parabola/fo … lator.html

https://www.e-education.psu.edu/eme812/node/557

https://pages.mtu.edu/~jstallen/courses … hp_VII.pdf

cost to have an installed system

https://homeguide.com/costs/solar-water-heater-cost

Offline

Like button can go here

#18 2023-01-02 16:29:53

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Re: solar concentration Water steam energy creation

105 gallons of water per person per week to wash clothes?

That seems more than a little high.

How about 10 gallons of water per load, two loads per person per week (1 whites, 1 colors)?

Offline

Like button can go here

#19 2023-01-02 17:33:57

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,269

Re: solar concentration Water steam energy creation

I can remember reading that supercritical CO2 could be used for clothes washing. That would be interesting on Mars. Not so practical on Earth.

I am going to set up Imgur tomorrow using the instructions provided by Steve Stewart. I will post a picture of my concept for a sub-atmospheric steam engine.

Last edited by Calliban (2023-01-02 17:36:48)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#20 2023-01-02 18:27:30

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: solar concentration Water steam energy creation

Here is the flat plate collector equations for solar heat rise

https://www.builditsolar.com/References/ColFlowRate.htm

https://ases.org/resources/renewable-en … r-heating/

The collector holds 30 to 50 gallons of water in a serpentine pipe with a heat-capturing coating.

https://www.energy.gov/energysaver/solar-water-heaters

Another site with tons of information

https://crestonesolarschool.com/

The minimum requirement for hot water is 120 degrees. If a business is unable to provide adequate hot water at this temperature, then may be shut down by the health department. The average residential water heater delivers water anywhere from 120-145 degrees. Most households are set around 125.

I was sort of surprised how cold the water in my area could be coming out of my well.

https://www.energy.gov/energysaver/sizi … ter-heater

https://www.wbdg.org/resources/solar-water-heating

https://www.wbdg.org/FFC/DOE/DOECRIT/re … _guide.pdf

The following renewable energy technology resource pages, which are noted below in the

parentheses) on the Whole Building Design Guide site were developed in conjunction with this

guide:

• Biomass

• Biogas (www.wbdg.org/resources/biogas.php)

• Biomass Heat (www.wbdg.org/resources/biomassheat.php)

• Biomass Power (www.wbdg.org/resources/biomasselectric.php)

• Geothermal

• Geothermal Direct Heat (www.wbdg.org/resources/geothermalenergy.php)

• Geothermal Electric (www.wbdg.org/resources/geothermalelectrictech.php)

• Ground Source Heat Pump (www.wbdg.org/resources/geothermalheatpumps.php)

• Hydroelectric (www.wbdg.org/resources/hydropower.php)

• Hydrogen and Fuel Cells (www.wbdg.org/resources/fuelcell.php)

• Ocean (www.wbdg.org/resources/oceanenergy.php)

• Solar

• Daylighting (www.wbdg.org/resources/daylighting.php)

• Passive Solar (www.wbdg.org/resources/psheating.php)

• Photovoltaics (www.wbdg.org/resources/photovoltaics.php)

• Solar Ventilation Preheat (www.wbdg.org/resources/svap.php)

• Solar Water Heating (www.wbdg.org/resources/swheating.php)

• Wind (www.wbdg.org/resources/wind.php)

Offline

Like button can go here

#21 2023-01-02 18:57:18

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,269

Re: solar concentration Water steam energy creation

I always had this mental picture of Nevada being a roasting hot desert, full of tumble weed and fossilised lizards. Spacenut's diagram above shows that it is no hotter on average than Pennsylvania. I need to see more of the world.

Last edited by Calliban (2023-01-02 18:59:01)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#22 2023-01-02 19:13:12

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: solar concentration Water steam energy creation

That is underground where the sand acts as an insulator to the heat being absorbed from the sun's rays. To which I just learned that in the past few days after coming across a UK sand heating unit that made use of wood to heat the sand.

One issue is that a home water heating water temperatures of 125°F to 140°F call for solar collectors constructed with metals like copper that conduct heat well, and insulation and glass cover plates to keep the heat from being dissipated into the air.

Swimming pool solar collectors typically operate at temperatures of just 76°F to 95°F, so they can be constructed of polypropylene plastic and do not require insulation or cover plates. Which also goes for the PVC types as well.

https://civil-engineering-calculators.c … Calculator

The thumb rule in deciding the capacity is that a person requires 30-50 litres of water per day for bathing. And considering average size of the family 3 – 4 person 250 Liter capacity solar water heater is ideal.

Found this site searching for data on the sand battery...

Offline

Like button can go here