New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2018-11-30 20:31:08

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,436

Lunar Cots Cargo

Nasa has decided to go in the direction that will lead to an increase of capability not in SLS.

NASA chooses nine companies to bid on flying to Moon

The US space agency on Thursday announced nine private companies, mostly start-ups, that will bid on $2.6 billion in contacts to build spacecraft to carry payloads to the Moon as early as 2019. The decision marks a stark change in NASA's mode of operation when it comes to America's Moon aspirations -- though private companies have been used for years to ferry gear to the International Space Station, and SpaceX and Boeing are working on spacecraft to carry astronauts to the Moon as early as 2019. Instead of running a government-funded space program, like Apollo, the US space agency will buy services, essentially becoming a customer to private businesses that build their own spacecraft.

NASA Announces New Partnerships for Commercial Lunar Payload Delivery Services

Selected companies are:

Astrobotic Technology, Inc.: Pittsburgh

+ Deep Space Systems: Littleton, Colorado

+ Draper: Cambridge, Massachusetts

+ Firefly Aerospace, Inc.: Cedar Park, Texas

+ Intuitive Machines, LLC: Houston

+ Lockheed Martin Space: Littleton, Colorado

+ Masten Space Systems, Inc.: Mojave, California

+ Moon Express: Cape Canaveral, Florida

+ Orbit Beyond: Edison, New JerseyLunar payloads could fly on these contracted missions as early as 2019. In October, NASA issued a call for potential lunar instruments and technologies to study the Moon, with proposals due in January.

These early missions will enable important technology demonstrations that will inform the development of future landers and other exploration systems needed for humans to return to the lunar surface, and help prepare the agency to send astronauts to explore Mars.

NASA will re-examine the private market periodically for new and emerging lunar delivery capabilities, and may offer additional companies an opportunity to join Commercial Lunar Payload Services through a contract process called on-ramping.

Lockheed Martin Selected for NASA's Commercial Lunar Lander Payload Services Contract

Lockheed Martin's lander design builds on four decades of experience engineering deep space missions, including Mars landers. The McCandless Lunar Lander is based on the proven design of the InSight lander

The McCandless Lunar Lander is capable of transporting large payloads weighing hundreds of kilograms - including stationary scientific instruments, deployable rovers, or even sample return vehicles - to the surface of the Moon.

The lander uses a proven propulsive landing approach that relies upon on-board radars and a set of rocket thrusters firing 10 times a second to slow to just five mph before touching down. Once on the lunar surface, the lander can provide power, communications and thermal management for sophisticated payloads

Offline

Like button can go here

#2 2018-12-01 03:51:13

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Lunar Cots Cargo

There must be pressure on Musk to leave the Moon as NASA's playground...if he does that will be a shame as the Moon will be ripe for lunar surface tourism once the BFR Starship is in operation.

I noticed the side story there:

"Moon rocks sell for $855,000 in New York: Sotheby's

New York (AFP) Nov 29, 2018 - Three moon rocks brought to Earth nearly half a century ago and the only known documented lunar samples in private hands, sold for $855,000 in New York on Thursday, Sotheby's said."

So much for those who tell me Mars rocks will soon lose their value!

Here we have people paying nearly a million dollars for what are probably very small lunar samples dating from 50 years ago - despite the fact that they know that within a few years huge amounts of lunar regolith will be landed on Mars.

And that is without any real marketing programme.

Last edited by louis (2018-12-01 03:52:37)

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#3 2018-12-01 09:22:41

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,436

Re: Lunar Cots Cargo

The way I see it they are doing whats required to lower costs for staying on the moon by controlling launch costs of the cargo. This is what Space x and others are doing for the ISS. It also makes the Dr. Robert Zubrin Moon Direct: How to build a moonbase in four years plan much more possible.

Offline

Like button can go here

#4 2018-12-15 19:21:53

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,436

Re: Lunar Cots Cargo

Seems Nasa has lost its ability to get to the moon even if it copies the past line for line....

NASA seeks US partners to develop reusable systems to land astronauts on Moon

NASA announced plans on Dec. 13 to work with American companies to design and develop new reusable systems for astronauts to land on the lunar surface.

Sure if they will listen...

The agency is planning to test new human-class landers on the Moon beginning in 2024, with the goal of sending crew to the surface in 2028.

The agency's leading approach to sending humans to the Moon is using a system of three separate elements that will provide transfer, landing, and safe return. A key aspect of this proposed approach is to use the Gateway for roundtrip journeys to and from the surface of the Moon.

Using the Gateway to land astronauts on the Moon allows the first building blocks for fully reusable lunar landers. Initially NASA expects two of the lander elements to be reusable and refueled by cargo ships carrying fuel from Earth to the Gateway.

The agency is also working on technologies to make rocket propellants using water ice and regolith from the Moon. Once the ability to harness resources from the Moon for propellant becomes viable, NASA plans to refuel these elements with the Moon's own resources. This process, known as in-situ resource utilization or ISRU, will make the third element also refuelable and reusable.

Ok lots of lunar oxygen but its still a stretch to find the water ice in the creators....

Offline

Like button can go here

#5 2018-12-15 21:10:04

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,436

Re: Lunar Cots Cargo

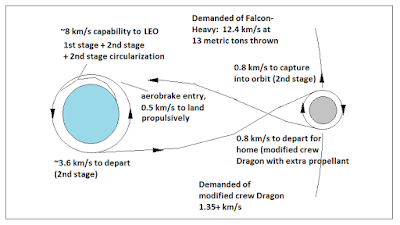

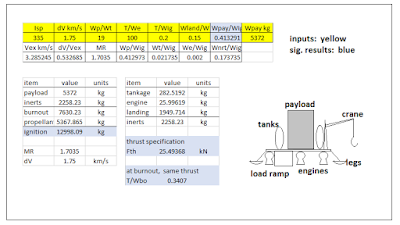

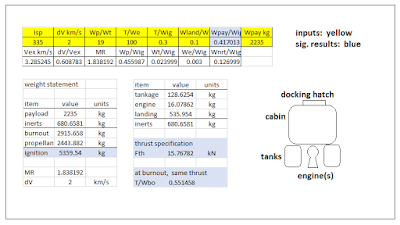

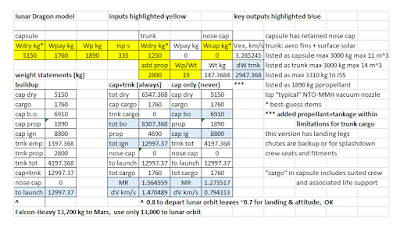

Some thoughts from GW on the subject. "clean sheet" bounding analysis

http://exrocketman.blogspot.com/2017/03 … ander.html

Descent numbers

Ascent to Orbit

Converting a Dragon for the lander

Offline

Like button can go here

#6 2018-12-15 21:16:12

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,436

Re: Lunar Cots Cargo

I guess my first question for those in the know would be can we use composite fuel tanks?

Next would to see if we could use a Beam inflatable to lesson the landers mass?

Offline

Like button can go here

#7 2018-12-16 20:01:34

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,436

Re: Lunar Cots Cargo

Another thought is can we make a composite fuel tank into the landers human hab area as a means to reduce mass.

Offline

Like button can go here

#8 2019-07-21 15:15:45

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,436

Re: Lunar Cots Cargo

A much needed zubrin's concept to make a Falcon heavy mission possible for the moon...

Offline

Like button can go here

#9 2021-05-21 04:46:00

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Lunar Cots Cargo

Firefly Aerospace raises $75 million

https://www.cnbc.com/2021/05/04/firefly … icorn.html

Offline

Like button can go here

#10 2021-05-21 20:32:11

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,436

Re: Lunar Cots Cargo

By not continuing with Bezo's lunar lander and going to take a space x starship its really killing any chance to foster others to build for profit competing rockets to take it to the tasks of moving cargo...

Offline

Like button can go here

#11 2021-05-26 21:18:57

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,436

Re: Lunar Cots Cargo

With space x getting a contract for a lunar starship then why would we not ride around in a brand new Telsa….of course not so fast

U.S firms GM, Lockheed aim for the moon with lunar rover venture

Elon Musk's rocket launch company, SpaceX, won a $2.9 billion contract last month to build the spacecraft to carry NASA astronauts to the moon. That award is being challenged by Jeff Bezos' BlueOrigin and defense contractor Dynetics Inc.

Offline

Like button can go here

#12 2021-05-27 17:04:44

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 3,823

Re: Lunar Cots Cargo

A lunar vehicle is an even tougher design project than a Martian vehicle. It's tires must maintain traction in 1/6g. The regolith is an extremely fine and abrasive material. It will wear down tires quickly and any of it getting into bearings will destroy them quickly. Making an EV that will work for a short flags n footprints mission is relatively simple. But a durable long-lived product that will last for years and is easily maintained? That is tough challenge.

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#13 2021-06-06 08:00:44

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,436

Re: Lunar Cots Cargo

Astroport Space Technologies, awarded a NASA Technology Research contract for lunar construction

http://www.spaceref.com/news/viewpr.html?pid=57471Lockheed Martin, General Motors Team-up to Develop Next-Generation Lunar Rover for NASA Artemis Astronauts to Explore the Moon

https://www.prnewswire.com/news-release … 00065.html

Offline

Like button can go here

#14 2021-06-08 11:27:40

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 7,938

Re: Lunar Cots Cargo

Does anyone know if there's been WPC treatment / micro shot-peening experimentation to extend the service life of wire wheels or track links?

Perhaps a combination of Tungsten Carbide bearings and steel with a WPC treatment applied could provide the necessary durability. If that's insufficient, then perhaps a Tungsten Carbide oxy-fuel sprayed coating could be applied to sufficiently harden the bearing surfaces. A track link would only need the track pin bosses sprayed with the coating. The polymer bearings we insert into the pin bosses for use here on Earth would probably be abraded into uselessness rather quickly, but given the low speeds and comparatively light loads, I think a harder material such as the Alumina nanoparticle-infused Aluminum alloys could work. Those are very hard and difficult to machine, but easy to cast. The track pin bearings would be sacrificial in nature, but the alternative is hogging out the track pin bosses by grinding up regolith and abrading the Tungsten Carbide coatings away.

We should do some high pressure injection molding experiments on the moon to see if we can recycle Aluminum bearings and other pieces of scrap Aluminum repurposed from rockets or other equipment that has reached the end of its service life. The ability to fabricate fresh bearings for rotating machinery, seems pretty fundamental to life on the moon or Mars.

Offline

Like button can go here

#15 2021-06-08 16:58:27

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 3,823

Re: Lunar Cots Cargo

Does anyone know if there's been WPC treatment / micro shot-peening experimentation to extend the service life of wire wheels or track links?

Perhaps a combination of Tungsten Carbide bearings and steel with a WPC treatment applied could provide the necessary durability. If that's insufficient, then perhaps a Tungsten Carbide oxy-fuel sprayed coating could be applied to sufficiently harden the bearing surfaces. A track link would only need the track pin bosses sprayed with the coating. The polymer bearings we insert into the pin bosses for use here on Earth would probably be abraded into uselessness rather quickly, but given the low speeds and comparatively light loads, I think a harder material such as the Alumina nanoparticle-infused Aluminum alloys could work. Those are very hard and difficult to machine, but easy to cast. The track pin bearings would be sacrificial in nature, but the alternative is hogging out the track pin bosses by grinding up regolith and abrading the Tungsten Carbide coatings away.

We should do some high pressure injection molding experiments on the moon to see if we can recycle Aluminum bearings and other pieces of scrap Aluminum repurposed from rockets or other equipment that has reached the end of its service life. The ability to fabricate fresh bearings for rotating machinery, seems pretty fundamental to life on the moon or Mars.

Lunar regolith is highly abrasive, so any tire material will be subject to heavy wear. If we do intend to established a permanent presence of the moon, then vehicles can be equipped with replacable parts. Why not make replacable tires or wheels from cast metallic iron and accept the fact that service life will be limited? Iron for wheels will be the most commonly available metal if lunar surface materials are reduced to produce oxygen. Worn out wheels can be remelted and recast.

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#16 2021-06-08 17:19:57

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 19,746

Re: Lunar Cots Cargo

For Calliban re #15

Your suggestion of making wheels/tires for the Moon from iron caught my eye ... Thanks for writing that in the context of kbd512's discussion of superhard materials for wheels and for parts of the suspension system.

Aluminum is an interesting material (in the context of the suggestion I am about to offer) because it is capable of generating counter-EMF when subject to a moving magnetic field.

Iron, in contrast, is (as far as I know) a purely attractive material in the presence of a magnetic field.

The idea that came to mind, when considering your two posts simultaneously was to inquire about magnetic suspension for a lunar vehicle, totally eliminating physical contact.

Magnetic trains are successful on Earth. Some use overhead suspension (I think Germany is the leading player in that realm) and some use under-vehicle support systems, for which I think Japan and possibly China may be the leading practitioners.

A wheel system for the Moon need not look like the traditional wheel system we've become used to on Earth.

If we eliminate physical bearings, the axle can be much larger in diameter, so that less magnetic force (pulling OR pushing) is needed per unit of surface area.

A system like this would require high levels of computational capability for a dynamic force management system.

From the standpoint of the operator, a simple set of familiar controls would provide the interface between the human being and the navigation/suspension system.

(th)

Offline

Like button can go here

#17 2021-06-08 20:27:15

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,436

Re: Lunar Cots Cargo

Here is what Nasa wanted to do:

Chariot - lunar truck prototype

In preparation for the US led effort to build a lunar outpost, NASA has completed the first lunar truck prototype, named Chariot. Realizing the importance of crew and payload mobility on the lunar surface, the Exploration Technology Development Program's Human-Robotics Systems Project set out, in Apollo-like style, to build a lunar truck and the team that could shepherd future lunar truck efforts. With only one year to design, manufacture, and assemble Chariot, NASA, teamed with companies from all across America, conquered the challenge.

Key Design Specifications:

Chariot Spec .... Earth Prototype (1g) ... Lunar System (1/6g)

Payload .............. 1000 kg ..................... 3000-6000 kg

Vehicle Mass ....... 2000 kg ..................... 1000 kg

Top Speed .......... 20 KPH ...................... 20 KPH

Slope Climbing .... 15 Deg ...................... 25 deg

Range ................. 25 Km ....................... 100 KmAnimation showing Chariot excavating a site for a nuclear power unit (video 5MB)

Offline

Like button can go here

#18 2021-06-08 20:29:57

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,436

Re: Lunar Cots Cargo

Goodyear’s lunar tireJoint Lunar, Mars project capability could yield "Earthly" rewards

AKRON, Ohio, Dec. 13, 2007 – Goodyear, the innovator of run-flat tire technology on Earth, is working with NASA Glenn Research Center (GRC) to significantly evolve the technology and take its capabilities to the rest of the universe. Part of a funded program by NASA’s Innovative Partnership Program (IPP) to develop non-pneumatic tires for use first on the moon, and eventually on Mars, the IPP Seed Fund was established to advance key technologies to meet critical needs for NASA’s missions.

Because of the unique atmospheric characteristics of the operational environment, "The basic rubber-pneumatic design used on Earth does not have the same utility on the moon," said NASA Principal Investigator Vivake Asnani. "The challenges associated with creating a lunar tire are further complicated by the fact that there are no lunar roads. Lunar tires need to be designed to develop traction on sandy undulated terrain, in regions that humans have never even seen up close. Plus, the prospect of an immobilizing ‘flat tire’ would be devastating to the mission."

Vivake is a founding member of the Surface Mobility Technology team at GRC that was created in late 2005 in response to the announcement by President Bush in 2004 that the United States would embark on an initiative to further explore the moon and Mars. Vivake said Goodyear was selected to work with GRC because of its experience in previous lunar programs, understanding of vehicle dynamics and state-of-the-art computer modeling capabilities.

Goodyear engineers are used to thinking out-of-the-box in terms of developing entirely new technologies, so thinking "out-of-this-world" was not a stretch, according to Joe Gingo, Goodyear’s executive vice president and chief technical officer. "The mission performance goals for these tires will push known tire technology well beyond its comfort zone," Gingo said, "and I am confident we have the capabilities to do that."

Goodyear Principal Investigator Dave Glemming said the decision to partner with NASA for this initiative was easy. "Not only will the outcome of this project deliver a product that can handle the performance capabilities required for lunar mobility and beyond, we expect the outcome will yield answers to how future non-pneumatic tires may be designed for Earth applications."

The Goodyear team will consist of a cross section of research and tire technology associates at the Akron Technical Center. In the past year Goodyear has been evaluating the Apollo lunar rover wheel, prototype pneumatic tires and non-pneumatic concepts to build a baseline understanding of the mechanics of these wheels and the challenges of the lunar environment.

While a one-year timeline to develop and demonstrate something as novel as a lunar tire seems extremely aggressive, the group is building on technology from the first moon landing, Glemming said. In the 1960s, NASA funded over 10 years of intensive research at Goodyear and General Motors to develop the wire mesh moon tire for the Apollo Lunar Roving Vehicle (LRV).

The LRV tire was woven out of piano wire, in order to provide a soft, springy surface to contour to the ground and provide good ride quality. It looks a bit like the skeleton of an Earth tire. This approach worked very well, because each LRV tire was only required to support about 60 pounds of weight (all things weigh 6x less on the moon than on Earth) and be used for a maximum of 75 miles. The new fleet of lunar vehicles will require tires to support about 10 times the weight and last for up to 100 times the distance. A tire that would meet such requirements would also be useful for commercial applications on Earth, Glemming said.

Offline

Like button can go here

#19 2021-06-08 20:37:12

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,436

Re: Lunar Cots Cargo

Offline

Like button can go here

#20 2021-06-09 11:22:30

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 7,938

Re: Lunar Cots Cargo

Calliban,

What I had in mind was the tracked APC concept I intended to use on Mars. This vehicle chassis would be fabricated from welded stainless plate and contain an interior liner of UHMWPE liner to provide adequate shielding to stop SPE / CME radiation. The combination of SS plate and PE should provide adequate protection from small bits of space debris as well. It's essentially a tank without a turret, or a tracked armored personnel carrier. These types of vehicles have the durability required to survive extended use in off-road environments, whereas wheeled vehicles do not. The weight is necessary to provide both ultimate durability and protection from the environment, the use of tracks provides good traction in sand or volcanic ash, and a simple torsion bar suspension system is adequate for low speed operation in a low gravity environment.

I considered the M113 design and the Russian T-54 / T-55 design for construction equipment, but the M113 requires much thicker Aluminum plate that still doesn't provide much in the way of radiation protection and the T-54 is too heavy and has excessive power requirements for a personnel carrier. For a purpose-built personnel carrier, the US M59 APC is the vehicle that my conceptual moon / Mars APC is modeled after. The US M59 and M75 APCs were constructed of welded steel of various thicknesses. As APCs go, M59s have a good bit of room inside by mounting the engines over the vehicle's sponsons. There would be plenty of room for batteries and electric motors, with an Aluminum radiator panel glacis plate to cool the engine, so no plumbing for thermal transfer fluids is required. The M59's cargo compartment is big enough to carry a jeep, but that's not a design goal for this machine.

Weight can be economized by only enclosing the crew and cargo compartment in thicker steel plate and mounting the batteries to the exterior of the hull, since there's no advantage to mounting something that could conceivably catch fire and explode inside a pressure hull. Please note that I'm not trying to replicate the exact shape of the M59, either. I'm only interested in using a combat-proven chassis design. I expect the driver's compartment to be a transverse mounted cylindrical stainless steel pressure vessel connected by a double hatch to the larger (large enough to stand up inside) cargo pressure vessel mounted perpendicular (along the length of the chassis) to the driver's compartment. Basically, two beefy stainless steel cylinders with a thick UHMWPE internal liner, with both being affixed to the tracked chassis using shock mounts, in order to limit the transfer of shock from the chassis to the pressure vessels. The cargo pressure vessel would be removable so that the vehicle could act as a flatbed truck for carrying scientific equipment, small nuclear reactors, additional batteries for extended range, construction materials, a dump for hauling / depositing lunar regolith, or act as one half of a double-ended vehicle for carrying a much larger pressure vessel for extended expeditions or a bottom dump with a greater capacity. The electric motors would be of the BLDC variety to eliminate the need for an AC power inverter and integrated circuit electronics (these can be run at low speeds using a series of discrete power transistors and resistors. The reduction / final drive would use magnetic gearing to eliminate the complexity of a geared transmission and to reduce the need for lubricants. The batteries would consist of very large format individual cylindrical Lithium-ion cells in finned Aluminum casings to eliminate the need for a separate radiator assembly and coolant. Each battery is individually hand-removable from atop the sponsons without the need for tools. A set of power transformers would step-up the voltage, as required. The battery "pack" and life support functions would be controlled by a pair of appropriately shielded SRAM-based computers mounted to the exterior of the vehicle. Each component of the electric drive system would be hand-removable without tools, so that only tools to adjust the track tension and change roadwheels are required.

The road wheels, idler pulleys, and drive sprockets would be machined from the same stainless alloy as the chassis and likewise coated in Tungsten Carbide and WPC treated for durability's sake. We can think of the drive components as M&M candies, with a hard and smooth exterior coating and a softer stainless alloy center capable of deflecting a little under load without cracking. At +/-250F, an Aluminum alloy would be a poor choice for the load bearing components (tracks, track pins, drive sprockets, road wheels, idler pulleys, etc). There won't be any rubber or plastic, meaning metal-on-metal at low speed, thus the requirement for hard and smooth aerospace coatings. Overall, this will be an under-stressed design, using extra weight for increased durability and emphasizing ease of serviceability with minimal tooling over compactness.

This is what I had in mind for coating wear-critical parts:

HVOF Tungsten Carbide Coatings

This is what I had in mind for a "softer" bearing material:

Gamma Alloys - Nanoparticle-Reinforced Aluminum Alloys

After the base metal has been appropriately forged and machined, then I wanted to coat the drive sprockets / road wheels / idler pulleys / track pins / pin bosses in each track link with Tungsten Carbide, followed by WPC treatment of bearing surfaces. The use of very hard and wear resistant, yet still softer than Tungsten Carbide, nano-reinforced Aluminum alloy bearing sleeves between the pins and pin bosses is a substitute for the HDPE plastic track pin bearings used in Earth-bound tracked vehicles. The sprayed and treated bearing surfaces are as naturally "wear resistant" and "lubricating" as we can reasonably make them. The nano-reinforced Aluminum alloy bearings must be precision machined and (somewhat loosely) press fit into the pin bosses in each track link to provide a softer surface for the track pins to eventually hog out in use. The coatings would wear off with use and the bearings would need to be periodically replaced, but we're talking about very hard and slick surfaces that should last for quite some time, even when rolling through volcanic ash.

Here's a parts breakdown of the T157I track link assembly to illustrate what I'm talking about:

The track has been designed to reduce rolling resistance using HDPE bearing sleeves (the "black donuts" wrapped around short steel shafts in the photo) inserted into the pin bosses, rather than direct metal-on-metal with the track shoes / links rotating around a press-fit sleeve in the pin boss (metal against metal). In our design the environment forces us to go back to metal-on-metal (albeit with aerospace coating upgrades, and we can still get some of the other benefits of the T157I design that allows for a little bit of lateral motion of track links during turns without placing so much bending stress on the pins and pin bosses, so the shoes and pins can be smaller and lighter), the track shoe / link, pin, and fasteners are forged from stainless to prevent them from becoming too brittle at -250F, the bearings are nano-reinforced Aluminum alloy instead of HDPE which will be abraded away to uselessness by the volcanic ash far too quickly.

Offline

Like button can go here

#21 2021-08-24 15:29:27

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Lunar Cots Cargo

Firefly Aerospace’s Alpha rocket ready for first launch

https://spacenews.com/firefly-aerospace … st-launch/

Offline

Like button can go here

#22 2021-08-24 20:19:27

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,462

Re: Lunar Cots Cargo

kbd512-

I didn't see the discussion of using fully tracked vehicles until tonight. I too like the enhanced mobility of an all-tracked vehicle, but there is a significant downside to them: Maintenance.

I was stationed in Germany during the early 1960's and the US Army was still operating M59 APCs, and then the then-new M113 models were introduced as I was getting ready to come back to the ZI. For an armored fighting vehicle, the standard was 9 hours of maintenance for every hour of operation. Maybe not as much for the APCs as for an M60 MBT. But tracks have lotsa parts, unless they are giant rubber bands like on the M2 half tracks. I've looked carefully at the Bobcat ads here on the Internet, and I believe they are still pushing wheeled vehicles over tracks. I think that it's not an either-or situation, but having some of both designs in order to fully evaluate under field conditions. Toyota has released photos of their Moon Rover, and it's a 6 WD vehicle with big wheels and hefty tires. Anything that will work on the Moon should work equally well on Mars.

Offline

Like button can go here

#23 2022-07-30 07:32:28

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Lunar Cots Cargo

NASA taps Draper for first U.S. landing on far side of the moon

Offline

Like button can go here

#24 2022-07-30 19:16:03

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,436

Re: Lunar Cots Cargo

Not a cots just a scientific mission one time ship into the dark side.

Contract for space x sort of killed any other commercial vendor.

Offline

Like button can go here

#25 2022-09-24 05:21:26

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Lunar Cots Cargo

ULA’s Delta 4 prepares for final West Coast launch as Vandenberg seeks new tenants

https://spacenews.com/ulas-delta-4-prep … w-tenants/

A United Launch Alliance Delta 4 Heavy rocket is scheduled to launch a National Reconnaissance Office mission Sept. 24 from Space Launch Complex-6 at Vandenberg Space Force Base, California.

This will be Delta 4’s final launch from the West Coast. ULA is under contract to launch two more missions on the Delta 4 Heavy in 2023 and 2024, but will fly those from Cape Canaveral, Florida, after which the vehicle will be retired.

The launch of NROL-91 marks the end of an era, Col. Chad Davis, the NRO’s director of the Office of Space Launch, told reporters Sept. 22. “I think bittersweet is absolutely the right word to use with that.”

After completing the NROL-91 mission, ULA plans to start vacating the pad, known as Space Launch Complex-6. The company’s future vehicle, Vulcan Centaur, will launch from Vandenberg’s Space Launch Complex-3, from which ULA currently flies its Atlas 5 rocket.

Blue Origin and Northrop Grumman reportedly considered working out an arrangement with ULA to use SLC-6 to launch national security missions had they been selected for the National Security Space Launch Phase 2 contract. But both were edged out by ULA and SpaceX in August 2020.

The pad “has had many lives,” said Titus. “I think everyone at Vandenberg has a warm spot in their hearts for that place, and we’re going to make sure it’s continued to be utilized, but we don’t know exactly how,” he added. “There are many other launch service providers out there that could find utility in that location. There’s a lot of infrastructure there.”

Gary Wentz, ULA’s vice president of government and commercial programs, said the company is preparing for Atlas 5’s final West Coast launch from SLC-3 scheduled for November 1. That will be the Joint Polar Satellite System 2 polar-orbiting weather satellite, developed by NASA and the National Oceanic and Atmospheric Administration.

After that mission is completed, SLC-3 will be outfitted with new equipment in preparation for Vulcan, which is projected to start flying in 2023.

He said ULA did not see a need to keep two launch pads on the West Coast. “From a business perspective, it was appropriate for us to use SLC-3 because there was a lot of commonality between Atlas and Vulcan systems.”

Offline

Like button can go here