New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

Pages: 1

#1 2005-06-19 22:23:04

- PurduesUSAFguy

- Banned

- From: Purdue University

- Registered: 2004-04-04

- Posts: 237

Re: The viability of the DC-Y

Hello all,

In a number of posts I have heard many people cite the DC-Y as the program that should have been the launch vehicle of the 90s'. Given the imense sucess of the DC-X I think it's fair to say that McDonnel Douglas should have gotten the X-33 contract based on that alone, but there's a topic for another post.

My point is I was just reading up on the DC-Y on astronautix and I am not horribly well informed on that project, but I'm inclined to wonder if it would have been able to make it as an SSTO given that it would have to carry fuel for landing, a significant mass penalty. The issue of tankage would be the same as on the failed LockMart X-33, but I am of the opinion that we gave up on that too quickly (the tanks not the X-33). The problem with laminating carbon fiber is just engineering, there are no fundamental systemic problems with the technology.

I guess specifically I was hoping that the newmars hivemind could point out.

A.) What effects that higher density liquid hydrogen, or hydrogen slush would have and

B.) Wether Aluminum-Lithum alloy tanks have weight advantages over carbon fiber and which of the two has a strength advantage.

Offline

Like button can go here

#2 2005-06-20 00:08:05

- United Space Alliance

- Banned

- Registered: 2005-06-17

- Posts: 17

Re: The viability of the DC-Y

Don't give up on X-33/VentureStar just yet. Lockmart's got two, one at Edwards and USAF is sniffing around this still.

Linear Aerospikes = good

Tanks - possible solution over the past year.

She's not totally dead.

Offline

Like button can go here

#3 2005-06-20 07:01:49

- GCNRevenger

- Member

- From: Earth

- Registered: 2003-10-14

- Posts: 6,056

Re: The viability of the DC-Y

The DC-I (-Y would have been the orbital proof of concept) would ultimatly have been pretty difficult to pull off simply because it would have been a real challenge to make it blow up an acceptably small number of times and to do this with a useful payload without the thing getting too big. The original DC-I concept would already have been nearly the size of Shuttle's main tank, but only carry 10-12MT of payload in a pretty cramped cargo bay with some pretty optimistic mass estimates. I say that you would have to hit about 20MT for it to be really useful for carrying stuff besides fuel and satelites, so slushed Hydrogen would probobly be nessesarry to keep it from getting too big.

DC-X already used a composite skin, Hydrogen tank, and probobly some of its structure, so making the thing much lighter empty will be difficult. If making a satelite launcher and fuel tanker is okay and you don't need to carry anything big or heavy, then that would make life alot easier to get a "basic" version off the ground.

I'm still banking on expendable rockets... DC-I would be difficult to make reliable enough.

Edit: Oh, and DC-I could probobly really really bennefit from radial aerospike engines, or ones with adjustable bell nozzles... or maybe to keep things simple, just mix short and long bell nozzle engines, and shut the short ones down after liftoff.

[i]"The power of accurate observation is often called cynicism by those that do not have it." - George Bernard Shaw[/i]

[i]The glass is at 50% of capacity[/i]

Offline

Like button can go here

#4 2005-06-20 11:51:11

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,371

- Website

Re: The viability of the DC-Y

The problem with X-33 was not laminated carbon fibre tanks; it was that Lockheed Martin was counting on a lot of business from satellites for Iridium or other satellite phone system. When that business proved to die, Lockheed Martin wasn't interested in a reusable launch vehicle any more. Also, NASA wrote into the contract that the contractor had to share the cost of any cost overrun. Lockheed Martin refused to abide by the clause.

All the technology in X-33 was proven. NASA developed lifting bodies in the '60s and early '70s: X-24A, X-24B, HL-10, Hyper III, M2-F1/F2/F3. Aerospike engines were one option for the original Shuttle developed in the 1970s. Conformant fuel tanks are used in aircraft all the time, as is composite tanks. The DC-XA used a solid wall graphite/epoxy liquid hydrogen tank, and a lithium-aluminum oxygen tank. I'm told graphite/epoxy is lighter than lithium-aluminum alloy, I can give you numbers for lithium-aluminum but I don't have numbers for graphite/epoxy. DC-XA also used lithium-aluminum alloy 1460 instead of 2195. Remember 2195 is 0.4% silver while 1460 doesn't have any, that 2195 has a density of 2.60 g/cm^3 while 1460 is 2.59 g/cm^3. The 'S' factor is strength calculated from the smaller of ultimate tensile strength multiplied by a safety factor and yield tensile strength multiplied by a safety factor; at liquid hydrogen temperature alloy 1460 has a slightly higher 'S' factor, not much but higher. I don't have strength figures for liquid oxygen temperature. To me the issue is to not build an expendable component out of precious metal. That's $30,000 (commodity price) of precious metal in a $60M tank, but each company along the way will add its mark-up: alloy company, the manufacturing plant at Michoud operated by Lockheed Martin, and there will be waste in the manufacturing process. I still think the price per tank is too high. The original design for X-33 used solid wall graphite/epoxy tanks, like the hydrogen tank of DC-XA. It would have worked, but Lockheed Martin made a last minute change to paper-thin laminated honeycomb structure. That used graphite fibre for the inner and outer walls, but kevlar paper set on edge and arranged in a honeycomb pattern between the walls. The dramatic failure was caused by a worker using a piece of adhesive tape to hold a sheet in place while it was epoxied on; at cryogenic temperature and at pressure that tape was a foreign object that formed a point of weakness. However, study showed that although the point of failure was the tape, it would have failed anyway. At cryogenic temperature it formed micro-fractures that let cryogenic nitrogen (used for the test) to seep into the honeycomb cells. When the tank was drained the cryogenic liquid in the hollow wall remained. When it warmed the micro-fractures sealed shut, but nitrogen boiled to gas creating pressure. That blew out the honeycomb cells from the inside. Lesson learned: solid wall graphite/epoxy is compatible with cryogenic propellant, paper-thin hollow wall is not.

One issue with graphite/epoxy is that graphite and liquid oxygen burn. That's why they used aluminum-lithium alloy for the LOX tank of DC-XA. However you can add a liner to separate LOX from graphite. There are a couple fluoropolymers that can do the job. As I mentioned on this board before, I talked to a representative from XCOR at a NASA conference last November, they didn't want to confirm which fluoropolymer they used but I weaselled out of him that it was FEP. I advised him to use PCTFE instead; it's stronger, lighter, and more impermeable to oxygen. Of all the polymers that can handle LOX temperature, it's the most impermeable to oxygen or nitrogen. I suppose you could add a PCTFE liner to a graphite/epoxy hollow-wall honeycomb structure tank. As long as you use an elastic binder to hold the liner to the tank so thermal expansion doesn't tear the liner, it should work. The liner was for LOX, but it could solve the micro-fracture problem in LH2 hollow-wall tanks.

Offline

Like button can go here

#5 2005-06-20 14:05:28

- GCNRevenger

- Member

- From: Earth

- Registered: 2003-10-14

- Posts: 6,056

Re: The viability of the DC-Y

NASA and Lockheed wouldn't have put so much effort into the X-33 project if it had a decent chance of working, and I think it was pretty low down of Lockheed to jump ship when it was clear NASA wouldn't put up much of a legal fight... I wonder if this will have any bearing on selecting contractors for VSE?

There are possible problems with using an elastic binder for that polychloroflurocarbon Hydrogen tank liner, that will it remain flexible at those single-digit-Kelvin temperatures and if there is any chemical incompatibility if it does rupture.

[i]"The power of accurate observation is often called cynicism by those that do not have it." - George Bernard Shaw[/i]

[i]The glass is at 50% of capacity[/i]

Offline

Like button can go here

#6 2005-06-20 14:49:06

- C M Edwards

- Member

- From: Lake Charles LA USA

- Registered: 2002-04-29

- Posts: 1,012

Re: The viability of the DC-Y

NASA and Lockheed wouldn't have put so much effort into the X-33 project if it had a decent chance of working...

Yeah, I thought it was a conspiracy, too. :;):

"We go big, or we don't go." - GCNRevenger

Offline

Like button can go here

#7 2005-06-21 00:50:23

- Euler

- Member

- From: Corvallis, OR

- Registered: 2003-02-06

- Posts: 922

Re: The viability of the DC-Y

DC-X/DC-Y/DC-I probably would have had a better chance of succeeding than the X-33/VentureStar concept; with our current level of technology, wings are simply too heavy for any practical SSTO to carry. However, I doubt that even the DC-I could have become a successful launch vehicle. The vehicle would have to stretch the limits of technology so much that it would have the same sort of cost and safety issues that have plagued the shuttle, only more so.

Offline

Like button can go here

#8 2005-06-21 06:21:16

- GCNRevenger

- Member

- From: Earth

- Registered: 2003-10-14

- Posts: 6,056

Re: The viability of the DC-Y

In order for a truely reuseable (and not refurbishable) RLV to ever really be practical, it must have a degree of reliability that no space vehicle has ever had before so that you loss to attrition doesn't bankrupt you.

Making DC-I this reliable, especially given its kind of scarry flight profile, would have been extremely difficult and expensive. I think its a safe bet that the quoted $6Bn figure was a deep "under bid."

[i]"The power of accurate observation is often called cynicism by those that do not have it." - George Bernard Shaw[/i]

[i]The glass is at 50% of capacity[/i]

Offline

Like button can go here

#9 2005-06-21 16:40:46

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,371

- Website

Re: The viability of the DC-Y

Personally I think a lifting body orbiter that lands without propellant is more practical for Earth than a DC-X land-on-your-tail rocket. The DC-X and DC-XA (Delta Clipper - eXperimental Advanced) proved you can land that way; but propellant is heavy, use of propellant for landing will seriously reduce payload capacity. Similarly for heat shield, an active heat shield will take more weight than an ablative heat shield. Active cooling requires a tank for liquid coolant, insulation to keep the tank cool, plumbing and valves, and some sort of refractory outer layer to the heat shield with pores to deliver that coolant. It's complex with many small parts that can fail, an ablative heat shield is one big piece of solid material that will melt at atmospheric entry temperature, molten material will blow away in the high speed air stream and the solid will not heat more than its melting temperature. Simple and effective. But its not reusable, a wholly refractory material is required for a reusable system. The first generation was shingles of titanium on a titanium skin, but that was heavy so never went beyond concept study. The second generation was silica fibre foam tiles, that was built as the first system for the Space Shuttle. Further improvements have developed improved glazing for black tiles (HRSI), replaced white tiles (LRSI) with thermal blankets, developed new better thermal blankets (AFRSI and DurAFRSI), and FRCI to replace HRSI. I'm ranting about the cooling system of Lockheed Martin's offering for CEV, but the point is consumables for landing systems are too heavy.

The atmosphere of Mars is too thin for a flying orbiter. The HL-20 has a lift-to-drag ratio of 5.5 on landing, the same as the current Shuttle orbiter. But on Mars don't expect any significant lift. The thin atmosphere means the heat shield doesn't have to deal with as much heat or stress either. The lower gravity of Mars makes a SSTO much more viable. All these things make the DC-X or its derivatives ideal for a Mars SSTO RLV.

Offline

Like button can go here

#10 2005-06-22 02:17:30

- Fledi

- Member

- From: in my own little world (no,

- Registered: 2003-09-14

- Posts: 325

Re: The viability of the DC-Y

The Rotary Rocket concept of a propeller landing is also an interesting option. Most of the landing approach can be done with autorotation that way.

Offline

Like button can go here

#11 2005-06-22 06:11:18

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,397

Re: The viability of the DC-Y

While a "DC-X land-on-your-tail rocket" is a great idea for a moon lander.

Offline

Like button can go here

#12 2005-06-22 06:50:04

- GCNRevenger

- Member

- From: Earth

- Registered: 2003-10-14

- Posts: 6,056

Re: The viability of the DC-Y

Roton? The Roton rocket was an insane idea... I mean come on, intentionally spinning your spacecraft? Dozens of tiny engines?

The DC-I wouldn't make a good Lunar lander because its way too big, you wouldn't want to push its entire mass from LEO to the Moon.

A spaceplane is probobly a better option for Earth, given that it wouldn't have to carry tonnes of landing fuel.

[i]"The power of accurate observation is often called cynicism by those that do not have it." - George Bernard Shaw[/i]

[i]The glass is at 50% of capacity[/i]

Offline

Like button can go here

#13 2005-06-22 07:08:29

- Fledi

- Member

- From: in my own little world (no,

- Registered: 2003-09-14

- Posts: 325

Re: The viability of the DC-Y

No, I was only talking about the propeller part, that spinning engines part is another thing.

Although it is an interesting concept to replace turbopumps by centrifugal force.

Offline

Like button can go here

#14 2005-06-23 06:12:39

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,397

Re: The viability of the DC-Y

Ironically, the U.S. government had the most advanced soft lander program in the world in the mid-1990s. The Delta Clipper, or DC-X, was an experimental vehicle ordered by the Department of Defense but later handed over to NASA. In one test, it climbed to 8,200 feet and traveled downrange before turning back and landing near the launch site.

But an explosion after a landing in 1996 destroyed the vehicle and NASA did not have the budget to rebuild the spacecraft, so the program was canceled.

There are a few in the alternative space that have continued to work on this technique of VTVL vehicles.

Offline

Like button can go here

#15 2016-01-03 22:09:15

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,397

Re: The viability of the DC-Y

Bump topic all fixed and wow does it bring back memories.....

Offline

Like button can go here

#16 2016-01-16 20:31:46

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,397

Re: The viability of the DC-Y

Reusable Launch Vehicles and Lunar Return

The real value of the SpaceX and Blue Origin achievements is to make living on the Moon more feasible.

Offline

Like button can go here

#17 2024-02-16 17:30:03

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,397

Re: The viability of the DC-Y

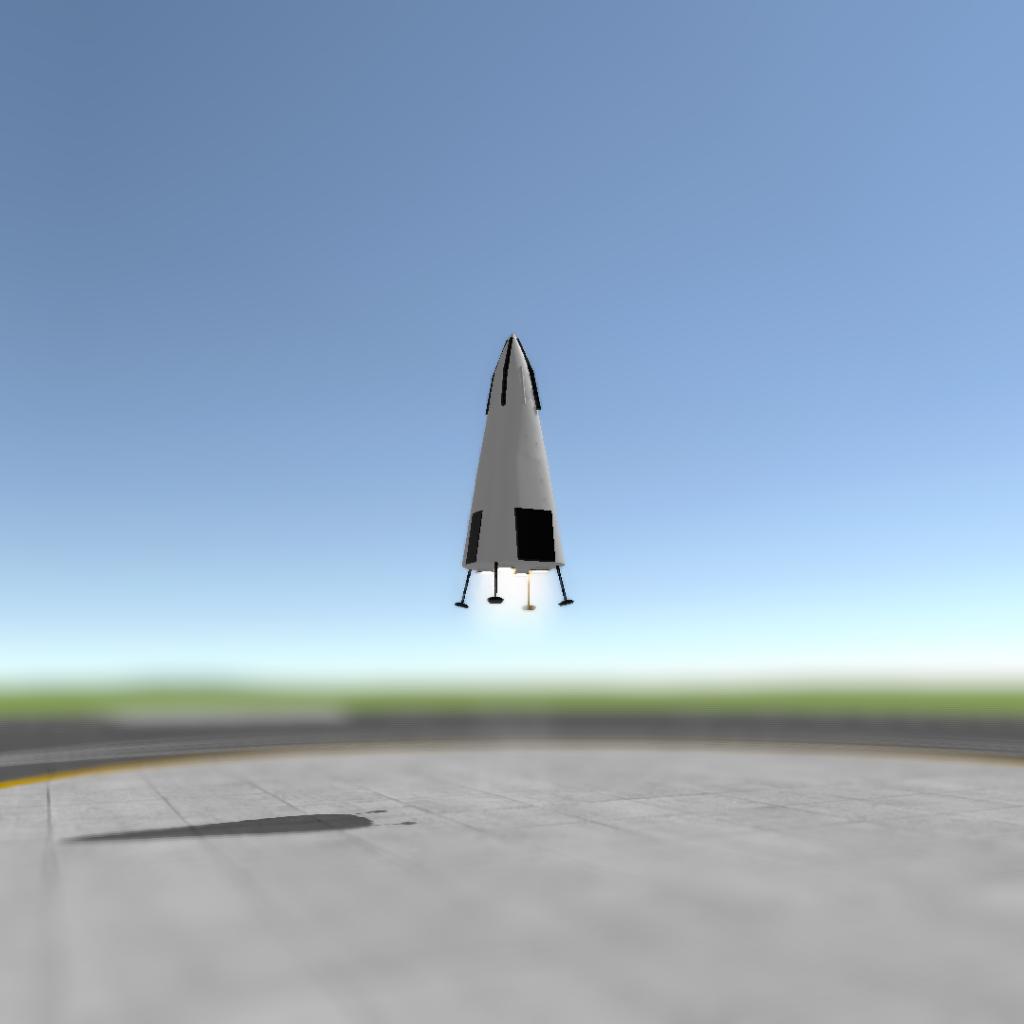

See Full Video at https://youtu.be/HMxcrTFO4Lc DC-X

Delta Clipper Experimental, was an uncrewed prototype of a reusable single-stage-to-orbit(SSTO) launch vehicle built by McDonnell Douglas in conjunction with the United States Department of Defense's Strategic Defense Initiative Organization (SDIO) from 1991 to 1993. Starting 1994 until 1995, testing continued through funding of the US civil space agency NASA. Built as a one-third-size scale prototype, the DC-X was never designed to achieve orbital altitudes or velocity, but instead to demonstrate the concept of vertical take off and landing.

Offline

Like button can go here

#18 2024-03-23 04:05:58

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: The viability of the DC-Y

DC-X the rocketship NASA purchased long ago that Inspired SpaceX and Blue Origin and other spaceflight nations and companies around the world.

https://www.youtube.com/watch?v=z46RiuZvh6c

The Spaceship that Came in From the Cold War: The Untold Story of the DC-X

https://nss.org/the-spaceship-that-came … -the-dc-x/

What made the Clipper Graham unique was that it combined the development of rocket-powered single-stageto-orbit transport with aircraft-like operations and a program approach that featured a modest budget, an accelerated timetable, a small managerial team, and minimal paperwork. No other single-stage-to-orbit project had been run before in this “faster, cheaper, smaller” fashion. Also, the Graham Clipper was the first rocket-powered vehicle, experimental or not, to demonstrate aircraft- like operations. It showed the world that you didn’t need kid gloves to handle a reusable rocket, nor did you need a standing army to operate and maintain it, like NASA’s Space Shuttle. The Flight Operations Control Center at the White Sands Missile Range consisted of a compact, low-cost, 40-foot (12-meter) mobile trailer that contained all necessary ground support equipment. Former astronaut Pete Conrad and two others operated the ground support equipment and launched the Clipper, while only 35 people formed the launch preparation and turnaround crew.

https://webcache.googleusercontent.com/ … 6b083be8d4

Though the program ultimately didn’t achieve its ambitious goals, its legacy is undeniable. It laid the groundwork for the reusable rockets we marvel at today.

DC-X - The NASA Rocket that Beat SpaceX by 20 Years

https://www.youtube.com/watch?v=AC1wgWi9WWU

Vertical Landing Rockets Before SpaceX

https://www.youtube.com/watch?v=39cjZTCay24

Skunk Works' X-33 and VentureStar

https://www.spaceflighthistories.com/po … enturestar

'What are these weird things on the McDonnell Douglas X-33?'

https://space.stackexchange.com/questio … uglas-x-33

Offline

Like button can go here

Pages: 1