New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2022-05-05 01:31:46

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,274

Direct Electric Power for Vehicles & Equipment

John Deere are developing an electric farm vehicle that is equipped with an automatic cable drum, that winds and unwinds as it moves up and down fields. This allows the vehicle to be powered by mains electricity (without batteries) to perform the bulk of its work. It is equipped with batteries to get it to the field and back, but otherwise all power is delivered by cable on demand. Alice Friedemann is dismissive of the idea in her article below.

https://energyskeptic.com/2022/the-late … gridcon-2/

However, I can see many advantages to this idea, on Earth and especially for a Mars colony. Vehicle propellant production is an inefficient process. For each MWh consumed by the propellant plant, we would be lucky if one third of that energy is captured as useful work by a vehicle. The nuclear powered vehicle solution is also inefficient, because two powerplants are needed - one stationary, producing LCO2 and the other of the vehicle, heating the CO2 to raise mechanical power. With direct electric, equipment is coupled by an electric cable to a single stationary powerplant and electricity is converted to mechanical work with an efficiency of 80-90%.

The idea clearly has limitations. Attachment by cable to a power supply is cumbersome. This is a solution that only works for vehicles that operate in a narrowly defined area. But that would appear to be the case for things like digging and mining equipment. Direct electric could be simplified by eliminating all battery drives. Equipment items could be towed to the right location by a propellant powered or battery electric tractor vehicle and then plugged in. It would then operate within the limits allowed by cable length.

For trucks operating between two discrete points, an overhead cable or third rail could be installed to provide power. We have also discussed in the past the use of cable ways, conveyors and rail tracks for transportation of bulk materials. All of these can be direct electric, with power drawn directly from the busbars of a nuclear powered generator or solar array. This is in fact how most electric transportation has worked on Earth for over 100 years. Trains and trams do not generally attempt to store electricity in batteries. Power is drawn directly from the grid via sliding contacts with wires or conductor rails.

Last edited by Calliban (2022-05-05 01:42:54)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#2 2022-05-05 05:09:37

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,524

Re: Direct Electric Power for Vehicles & Equipment

For Calliban re new topic ...

Best wishes for success! There ** should ** be ample room for development of this topic on Mars, as well as on Earth.

The scenario for Mars seems even better!

Greenhouses are the ONLY practical way that humans can grow crops on Mars (for the foreseeable future).

Electrical conduit can run the entire length of a long, narrow greenhouse, so crop tending machinery can draw power for the entire length of the greenhouse.

I'd like to toss into the early development of this new topic, an observation I made in the past couple of Earth days.

Somewhere in all the Internet traffic, i caught a headline that John Deere may be advancing rapidly in the field of artificial intelligence.

If there is anything to that hint, it might blend well into the vision your new topic has the potential to document.

We (NewMars as part of the Mars Society) have the opportunity to define entire industries for Mars, and perhaps even some that might come into being on Earth.

The vision of long, narrow greenhouses stretching across the Arabian desert, or across the comparable deserts in Africa and the US seems quite practical (to me for sure).

Such greenhouses for Mars might have mirrors on the side, to collect solar illumination, but otherwise they might be quite similar to the ones designed for Earth.

(th)

Offline

Like button can go here

#3 2022-05-05 18:28:21

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,939

Re: Direct Electric Power for Vehicles & Equipment

Key content

The John Deere Sesam 2 (also known as GridCON 2) is an 8.5 metric ton automated electric tractor with 1,000 kWh of energy storage and 500 kW (680 hp) of power. It comes with a 1-kilometer-long cable (max 2.5 kV/300 kW) which rolls on and off automatically. The electric power unit delivers 100 kW (136 HP) to the wheels, and 200 kW (272 HP) to power additional machinery.

The next version, the 8R, will have a power line of 3,000 meters, 8 kV, 1000 kW and be able to operate in swarms.

It is driven to the field with a wireless remote control and then the farmer can use a computer to tell the tractor what to do and which paths to take.

So to make it practical we need to create a poled power grid for hook up that spiders out in all directions.

Offline

Like button can go here

#4 2022-05-06 12:29:43

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,352

Re: Direct Electric Power for Vehicles & Equipment

Calliban,

Alice Friedemann is dismissive of the idea because it's so impractical, much like all the rest of these "let's electrify everything" ideas. John Deere's electric tractor is about the same price as their most expensive diesel powered models, but it can only do about 1/6 as much work per day without that grid connection. John Deere won't allow anybody but their technicians to service these things, either, so good luck if your new high-tech toy breaks down. You'll either need 6X as many machines and drivers, without many megawatts of grid power and suitable connections, meaning brand new infrastructure additions that will ultimately cost billions of dollars to deliver that power to the middle of nowhere, else this doesn't work.

The intractable technical issues are not snagging or otherwise severing the giant power cables on anything that will tear the plug out of the vehicle, recharging the onboard battery fast enough for it to matter, if used that way since the tractor in question still has a monstrous onboard battery. It has the 100kWh Tesla Model S battery times 10, but it still can't do more than 2 hours of field plowing work using its onboard 1MWh battery. The Tesla Model S battery weighs 625kg, and their battery technology is more advanced than anything else, so this battery electronic tractor facsimile carries a bare minimum of 6,250kg of battery weight.

That's like carrying the 1,500kg diesel engine plus 1,475 gallons of diesel fuel. A diesel powered machine of equal weight would then contain enough onboard fuel to run for almost 48 hours straight without refueling. The John Deere 600hp 13.5L diesel weighs 1,493kg, plus 1,288kg (400 gallons) of diesel fuel, and we're still less than one half of the battery weight with enough fuel to run a tractor for 13 hours vs 2 hours. Their engines are running near maximum rated output the entire time the plow is in the ground tilling soil.

That means you need a 450kWe grid hookup to run the vehicle off the grid, which is also mostly powered by fossil fuels. Each tractor needs half a megawatt of power output and you'd normally run 2 to 4 of these machines at a large farm nearly 24/7 during planting time, and similarly power-hungry machines during harvest time. That means you're gonna run power cables capable of delivering 1MWe to 2MWe to every farm located in the middle of BFE, because by definition every farm is in the middle of BFE relative to the cities of people they feed. If you're going to try to recharge batteries in 15 minutes, then each large farm requires a bare minimum of 4MWe to 8MWe if you stagger start times so as to ensure that no two vehicles are being recharged from the grid at the same time. This quickly becomes wildly impractical to do.

A high temperature fuel cell would drastically reduce the installed powertrain weight, and if these things are going to be sold for $600,000 each, then I'm pretty sure we can afford the fuel cell since no high cost catalysts are used in solid oxide electrolysis fuel cells. A 400 gallon diesel tank then provides 26 hours of run time, which means refueling once vs twice per day. Daily operating costs are effectively halved, or they remain unchanged even if diesel fuel is twice as expensive. The fuel cell itself weighs around 150kg, if another 150kg is devoted to insulation and control electronics, then the powerplant and fuel source weighs about as much as the 600hp diesel engine itself.

If you're going to manufacture these battery powered machines that weigh north of 8.5t, then you may as well put a SOXE fuel cell onboard with a 1,475 gallon fuel tank, and that way the tractor can run for nealry 4 days without refueling. That idea still seems pretty silly to me, but 96 hours of total runtime (plowing / tilling and seeding) is still better than 2 hours before recharging, or building entirely new grid additions that don't presently exist. The number of "ifs", "ands", and "buts" for a battery or grid powered tractor to function at all, are nearly a mile long.

We can do a single test on a farm that already has a substantial amount of grid power or its own power plant from Ethanol production, but I'm guessing that this is wildly impractical. All of these ideas have been thought of before. There's nothing new about the concept of using grid power for large and heavy machines. It's been done many times in major cities. It works acceptably well for vehicles like trains or trolley cars because they have fixed / static routes with catenary wires providing the power. This still cost an absolute fortune, which is why only very large major cities have them. If you've ever attempted to mow a good-sized lawn using a plug-in electric mower, you'll quickly "discover" the nature of the problem. You spend a lot more time fiddling with the cord than you do cutting the lawn. The mower itself works great and is highly reliable and will easily last for 20+ years, because simple electric motors with no electronics or batteries are highly reliable and have far lower maintenance requirements than combustion engines. The grid is great when it's reliable, corded-electric tools are incredibly powerful and relatively light, but that's clearly not what this is. It's a giant rolling battery-powered computer pretending to be an industrial farming tractor, even though it has grid-connect capability. It's still getting most of its power from coal or gas, but you have a 35% to 40% total efficiency improvement at most. You'd get the same improvement by switching to fuel cells, and then you don't need a multi-MW electric power outlet delivered to your doorstep, dozens to perhaps 100 miles away from a major step-down transformer station. Maybe this would work better on smaller farms or using smaller tractors, but "building it bigger" when the power supply is the fundamental problem doesn't make the solution more affordable or less consumptive of the resources to deliver the power.

If we'd already built the electric grid improvements to deliver megawatts of power to the farms and eliminated the onboard batteries, simply tow the corded "work machines" back to the storage barn using a tracked battery or diesel powered work truck, then I could see this working much better. If the electric grid improvements won't cost hundreds of billions of dollars, then I'm fine with it. Say it costs $50B for the infrastructure upgrades. No big deal. $500B? No bueno. That's another government boondoggle / massive theft of money since they pay no attention to where the money goes or if stuff actually gets built. I don't know exactly how many miles of wiring is required, but I'd wager it's in the low hundreds of thousands of miles. This won't be practical without the grid improvements and eliminating the onboard batteries so that the machine is an empty steel can for dumping seeds into. At that point, it should cost less than, rather than more than, a diesel powered machine. Selling the concept at that point is also much easier to do. The overall grid had better be boringly reliable, though.

Offline

Like button can go here

#5 2022-05-06 12:46:58

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,524

Re: Direct Electric Power for Vehicles & Equipment

For all contributing to this point ... the discussion is certainly entertaining.

The objection of kbd512 (just one of many, of course) about the power source can be met by sourcing renewable energy.

The problem of cables snagging can be solved/avoided by using the overhead wire method pioneered by electric cable cars a century ago. Many of the objections (quite rightly) listed in this first set of responses can be addressed (and solved) with systems level engineering.

The stock holders of John Deere are paying for this research, by foregoing immediate profits.

I haven't talked to any John Deere stock holders, so can't report on their attitude.

SpaceNut ... if you run across anything, please post it in this topic.

My guess is that behind all this work is the solemn understanding that beloved diesel is going away, and all the companies that hang onto it to the bitter end will be the buggy-whip makers of yesteryear.

***

Hydrogen fuel cell ??? how large would the LH2 tanks be to give this vehicle the 48 hour range suggested by kbd512?

(th)

Offline

Like button can go here

#6 2022-05-06 13:38:09

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,352

Re: Direct Electric Power for Vehicles & Equipment

tahanson43206,

Repeating falsehoods often enough doesn't make them true. You can proclaim gravity isn't real as often as it pleases you, but after jumping off a bridge there's only one direction you're headed and it's not "up". Industrial farming tractors don't till the soil only when it's convenient to do so. They run 24/7 until the job is done, rain or shine, wind blowing or not blowing, daylight or dead of night. Relying on unreliable energy is suicidal lunacy. I know they teach that idiocy in the universities now, but that still hasn't changed reality one iota.

John Deere most likely isn't paying for much of anything. They receive our tax dollars to throw at making their company profitable, same as Solyndra. Stop worrying about shareholder attitudes and start focusing on where their money is coming from. My guess is that all this work is the solemn understanding that the average voter isn't very bright and can be convinced of absolutely anything using enough propaganda and falsehoods. So long as they make a profit, they don't care how poor you become, nor whether or not you die of starvation.

Go take a look at an energy consumption chart that goes back to the 1800s. We're still burning cow poop to this day, and more of it than we were back in the 1800s. Ditto for coal, gas, oil (which includes gasoline and diesel), wind, solar, and nuclear. The only real trend over time that we can point to, is the use of more energy from all sources, never less. Whenever we had less energy usage, that's when we also had famine, plagues, and wars that killed tens of millions to hundreds of millions of people. All that recorded data should be an object lesson, but it never is for people who are entranced with their ideology.

This isn't a "feelings" issue. Your feelings and my feelings about how well something works has nothing to do with whether or not the math and engineering checks out. As of right now, your "buggywhip makers" are keeping you fed, clothed, and housed. No part of what you own or what you do is possible without coal, oil, and gas. When that stuff goes away, best of luck posting your thoughts on the internet. Reality sucks, but that's life. We don't have Star Trek replicators yet, and "green fantasy" remains further afield from reality than warp drives or teleportation.

Offline

Like button can go here

#7 2022-05-06 16:48:02

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,352

Re: Direct Electric Power for Vehicles & Equipment

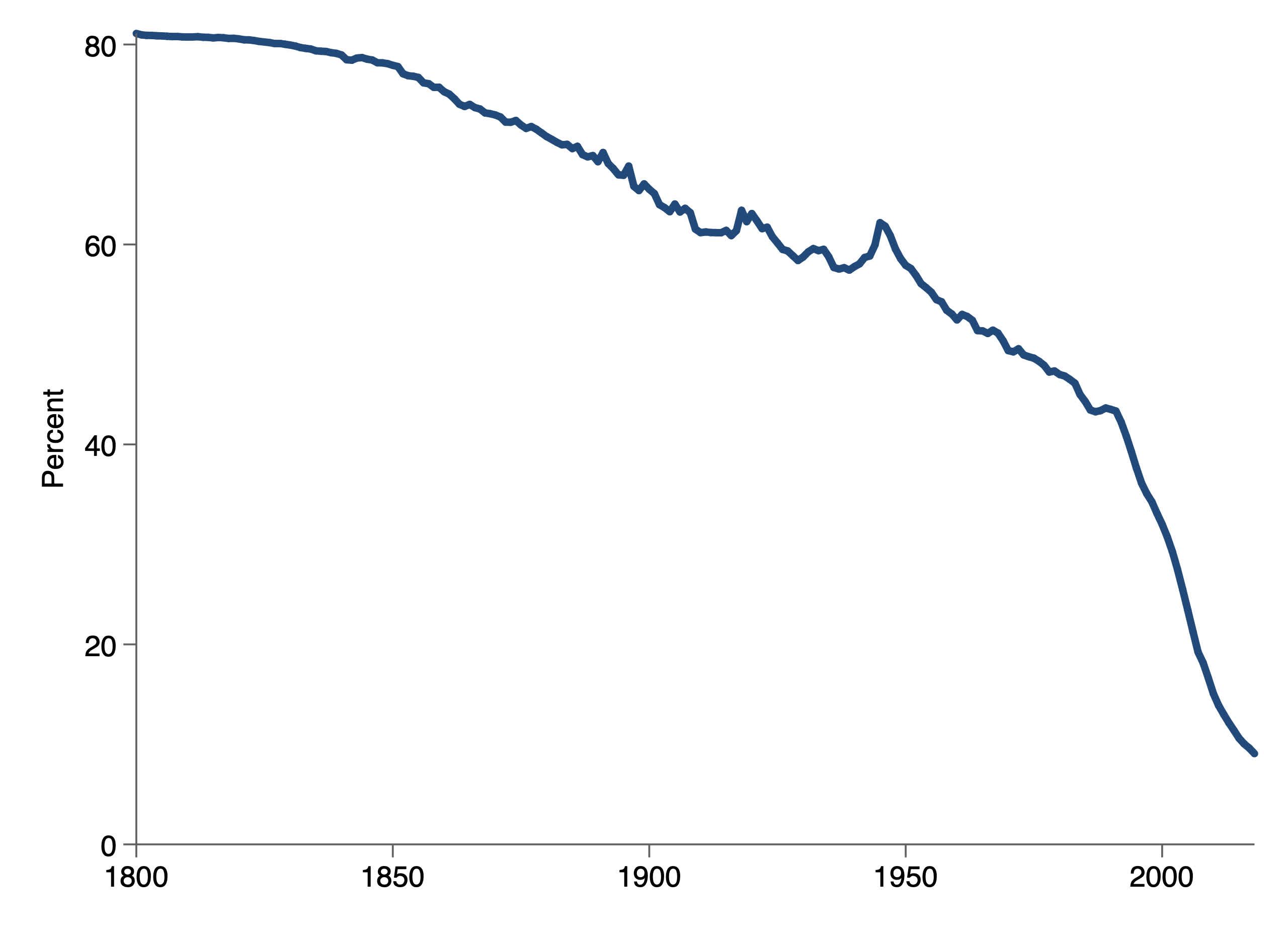

Anyone who believes in this "green fantasy" needs to look at this chart and tell me what they think it means:

I'll go first and I'll tell you what I think it means. Over time, humanity uses more energy from all available sources. That means anything they can use to obtain energy they need, for whatever purposes, regardless of the source. Anyone who thinks otherwise needs to provide a very detailed and thorough explanation of their logic.

We stopped burning so much poop and wood here in America and in other industrialized countries when coal, oil, and gas became easier to transform into usable energy using all available technology. We did the same thing with atoms, photons from the Sun, and wind or wave currents driven by the Sun or by gravity. Humanity as a whole sure as hell did not STOP burning poop, just because coal and gas became more readily available.

That chart, which is merely an illustration of a simple fact of life, does not bode well for those of us who are enamored with futurism and "green ideology". If a picture is worth a thousands words, then that particular picture tells us all we really need to know about what life will be like if diesel fuel is no longer available.

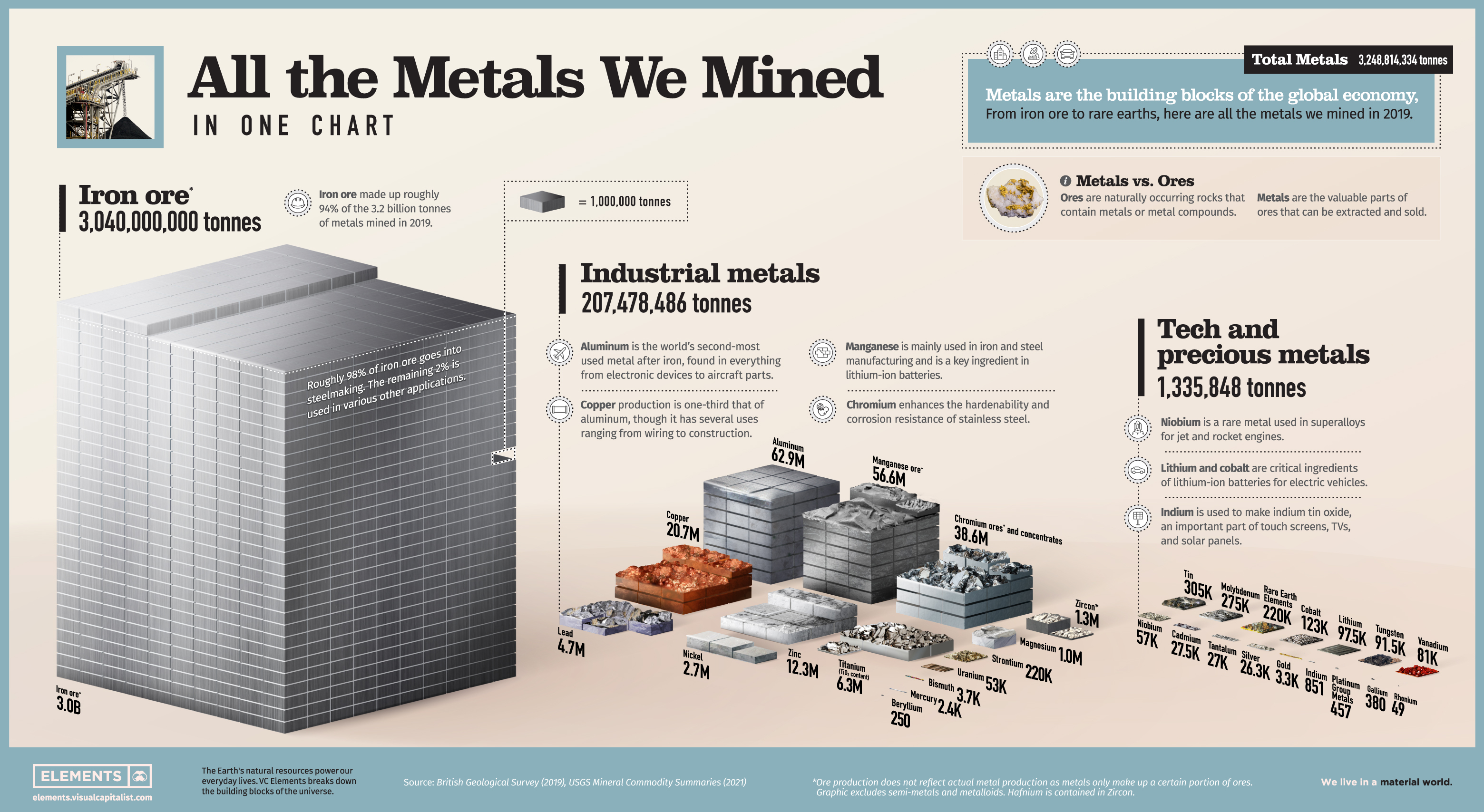

This is the abject poverty rate graphed over the same time period:

Much has been written about the huge gains in global poverty reduction in recent decades. There is broad agreement that this has been one of the great success stories in the history of international economic development, and scholars have rightly sought to determine how and why this success story occurred. However, an examination of surprisingly few factors greatly narrows our search for explanations.

Consider that in 1800, by a $1.90 per day standard, 81 percent of people worldwide were in poverty. One-hundred-ninety years later, only 44 percent were in poverty — a reduction of less than one-fifth of a percentage point per year. By contrast, in the 28 years since 1990, the rate of $1.90 per day poverty fell by more than 1.2 percentage points per year to less than 10 percent.

Putting aside any question as to the validity or general usefulness of this particular definition of poverty, in recent decades the world has by this measure progressed considerably. Bloomberg columnist Noah Smith described this decline as “incredible — nothing short of a miracle.” But scratch beneath the surface and we find the far more mundane fact that China and India had grown to the point they they happened to have accumulated large numbers of poor people just below the poverty line. Consequently, modest growth in these two countries alone would have sufficed to lift a great number of the world’s poor out of poverty.

...

Below, we take a closer look at the history of poverty worldwide and establish that the acceleration of poverty reduction coincided with the establishment of a critical condition for such rapid improvement: the existence of a large number of poor people that happened to be just below the poverty line. The sudden drop in global poverty was due at least as much to happenstance of timing as it was to rapid income growth.Thus, the policy question that emerges is the same question that has dominated for decades: what has China — and later India — done to develop so successfully?

Well, gee whiz Dave, what the hell else accelerated so greatly in recent decades?

There's not one word about energy availability in Dave's entire article, but anybody who can see what else happened couldn't possibly miss it. It doesn't matter one little bit if they were only slightly poorer before, THE POINT IS, DAVE, YOU FULL-ON ROCKET SCIENTIST, THEY'RE WEALTHIER NOW! If you don't want to "see it", then it's because you don't like what it means. All the blather on Dave's page about poverty doesn't make a single mention of energy availability, not even "green energy" availability. The word "energy" is not present, period.

Does anybody else here see the direct correlation between energy availability over time and global poverty rates, or are these pictures too difficult to understand?

David Rosnick has a PhD in computer science from NC State. This is precisely what I mean when I say "educated into stupidity".

They used a hell of a lot more energy, genius! We all did!

You can be every bit as obtuse about the correlation as you want to be, but it will not change measurable results, now or ever.

People who are not ideologically disabled will easily see and understand that increases in our standard of living rise sharply as energy becomes available, but the corollary is also true. When energy is not available, then our standard of living will decrease just as sharply.

Economy is not a metaphysical entity. It is driven by the most efficient use of all available energy, capital, and labor resources. Unfortunately for us, all of those resources are finite. Breaking all the windows in a city does not provide a net increase to the economy of that city. The glass makers and installers get richer, but everybody else gets poorer, and if everyone in the city is still eating, then not everyone can make or install new glass. There are lots of people who should know better, regarding this point.

Economics In One Lesson, by Henry Hazlitt

For the love of all that is holy and unholy, someone besides myself please read that damn book. If you didn't understand it the first time, then read it again. Sometimes, and especially when you've been indoctrinated to believe in false ideologies, it takes a little while for ugly objective reality to finally sink in.

Edit: Edited to move Dave Rosnick's commentary into a single quote, despite the fact that I thought certain paragraphs from the article were worth repeating to show how silly this "no-seeum" ideology and "metaphysical" woo woo BS economics "research" has become. Once again, we're now living in "Derpistan".

Last edited by kbd512 (2022-05-06 16:56:21)

Offline

Like button can go here

#8 2022-05-06 17:41:08

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,274

Re: Direct Electric Power for Vehicles & Equipment

Alice Friedemann is a bit of a doomer. I always listen to what she has to say, but I am acutely aware that she romanticises a return to wood based civilisation. She is inclined to presuppose that any other outcome will be an automatic failure. Although her work is always intelligent, I am aware that her belief system tends to slant her towards conclusions that may not always be justified.

I think the point I would make is that high power electrical machines are the workhorses of every industrial economy and that has been the case for almost a century now. Very few factories are powered by steam engines or direct drive DGs these days. You still see a few workshops with line shafts driven by water wheels and things like that. But they are curiosities rather than being the norm. Some individual industrial machines pull megawatts of electric power. Large cranes are most often electric, usually 415V. But no high power machines run on batteries. All those electrical machines in all of the factories of the world, draw power directly from the grid. Heavy industry draws power at 11KV. In industry, it is quite common to find machine tools powered at 415V of even 11KV. That is normal. In the UK, residential mains supply is 240V 50Hz. With a 30 amp fuse, that will deliver about 5kW of power. That is enough for a hobby workshop doing woodwork and metal work on a small scale. My bandsaw struggles with thick hardwood planks. But I can compensate by cutting thick pieces more slowly. My neighbour wanted to get 415V 3-phase installed to our close about 10 years back. But the cost was more than we were collectively prepared to pay at the time, given that 240V single phase was adequate for anything we really needed. The 415V would have allowed higher power machines that would have saved time. But neither of us do enough milling or lathe work to really justify the cost.

But batteries? Don't make me laugh. I have battery electric drills that I use most days. The plug in tools are less heavy and more powerful, but the lead makes them more cumbersome. But my bandsaw, lathe and milling machine, all require kilowatts of power. You cannot use batteries for high power tasks like that. They become impractically heavy, expensive and don't allow the endurance that is needed to do a days work. I don't have to use diesel engines to power these devices. But batteries aren't up to the task either. High power loads are grid powered.

Electric transportation has been the workhorse of most European public transport systems for about a century now. But a train requires megawatts of power. All are grid electric powered. No serious heavy vehicle is battery electric. In the south of England, there is an extensive third rail network which powers trains at 750V DC. This can provide up to 3MW of power to a train. That is sufficient for passenger trains, but heavy freight needs something a bit more manly. Which is why freight lines are diesel or 30KV catenaries, with the second gradually replacing the first.

Electricity can indeed provide the energy needed for things like farming and soil moving. But for that to be practical, these machines must draw power from fixed generators (grid). Attempt to use batteries and they become impossibly heavy. The way this would work best is to eliminate batteries altogether. Use small IC tractors to tow large machines to tye edge of the field where they plug in to a cable connector mounted on a pole. From then on, all work is provided by grid electricity, or electricity generated on site.

On Mars, we are proposing to use electricity from a generator to power a fuel synthesis plant producing chemical fuels, which we then burn to produce mechanical power. In situations where a vehicle is doing work in a limited area, such as a building site or mine, it makes much more sense to power it directly from the original energy source by cable, rather than attempting to store energy in synthetic fuels or batteries. Which is why I believe that grid connected electric vehicles probably have more of a part to play in future, on Earth and Mars, than battery electric vehicles. But the solution has limitations. Powering vehicles using catenaries, third rails or long cables is too inflexible for many applications. But if I wanted to do a lot of digging to create an underground colony of Mars, a cable connected vehicle provides the sort of power and efficiency needed to get the job done. But it only works within the realistic reach of the cable.

Last edited by Calliban (2022-05-06 17:58:42)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#9 2022-05-06 20:30:29

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,939

Re: Direct Electric Power for Vehicles & Equipment

In a word why because its "easier" that is why we are where we are due to our own choices to make more of life rather than hard work.

Not to get us into politics but I found it sort of funny that the John Deere Remotely Disables Tractors Stolen in Ukraine by Russian Troops

Offline

Like button can go here

#10 2022-05-07 00:11:10

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,352

Re: Direct Electric Power for Vehicles & Equipment

Calliban,

Pumping 450kWe of power through a 1 mile long 10kV electric power cable requires a 2 AWG, 3-core, 1.92"OD shielded power cable that weighs around 5,594kg / 12,330 pounds, excluding its mandatory Kevlar chafe guard. You also need a hefty step-down transformer inside the vehicle. I think we can get away with 800kVA using 3-phase AC at 10,000V and 45A. Typical AC induction motors have a power factor near 0.2 at no-load or very light load and 0.8 to 0.9 at full load, so 800kVA seems about right after losses are taken into consideration. SpaceNut can tell me how far off my calculations are. Using even higher voltages only means more insulation that those "buggywhip" makers are providing.

The 800kVA 3-phase transformer with Aluminum from Page 19 windings weighs 1,950kg / 4,298lbs (600hp diesel engine plus fluids / fuel / fuel tank). That's about a third of what the Lithium-ion batteries would weigh. A cast resin transformer is much less expensive, though, and should last longer in operation without significant loss of performance:

Bahra Electric TBS Transformers Catalog

The power cable that this vehicle is dragging around the field will be a good percentage of its own weight, and care will have to be taken to never run over it because we have a bunch of metal blades churning up the ground behind the machine.

To make this work, the batteries need to become a lot more energy dense, or they must recharge much faster, or we're stuck with a vehicle that's using a lot of energy to drag its own very heavy power cable around. We need a series of cable-minder robots that can "roll over" without damage, so giant wheels that keep the cable close to but not entirely dragging on the ground. There are about 2 milllion farms and 4 million tractors in the US, so 2 million miles of Copper cabling, so 12,000,000,000kg of Copper cabling. Total global production of Copper is around 18 million metric tons per year, which means 2/3rds of total global annual Copper production from one year just to supply each farm in the US with 1 mile of Copper cable. The US devotes about 1.4 million square miles to farmland, so I suspect 1 mile of power cable per farm is wildly optimistic. The average family farm is pretty small, maybe 450 acres or so, but the largest farms are gigantic. Large farms are where hordes of diesel-powered machines are used, thus where electrification would have the greatest impact. They also typically already have significant infrastructure in place, so making this work at all would or should be easier (no guarantees on that).

The scaling implications of this "pie-in-the-sky" ideation about what we could do, versus what's practical to do, are pretty dramatic. Where will all the Copper and Aluminum for the solar panels and wind turbines come from during this same time period? Over 30 years, this might be doable, but this looks a lot like pure fantasy to me.

Liquid hydrocarbon fuels exist for a reason. They're very energy-dense, which is why they're so useful. We'd be much better off recycling the CO2 and making more gasoline and diesel fuels from the recycled CO2 and seawater.

Offline

Like button can go here

#11 2022-05-07 07:26:25

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,524

Re: Direct Electric Power for Vehicles & Equipment

The discussion in this topic may inspire readers to see the original source material...

The UK research establishment is where the first trial system was developed, in 2019.

The research team has continued work, and there is an up date dated 2021.

A limitation of the presentation I found (so far) is that the connection at the base of the cable is not shown.

A "new" feature (from my perspective) is to employ the concept of "swarm" computer coordination, so that there are up to five satellite tractors taking power from the base unit that is tending the cable.

The folks doing this work are in possession of ** Real Universe ** experience, which may be compared to theoretical hand waving.

Calliban, since you started this topic, and since you are close to the research facilities, please see if you can find out more about how the technical challenges are being dealt with.

(th)

Offline

Like button can go here

#12 2022-05-07 07:30:07

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,524

Re: Direct Electric Power for Vehicles & Equipment

It might turn out that the source of the electric power for the tractors shown in the John Deere videos is a diesel powered generator.

An alternative is a hydrogen fuel cell base station.

Either way, the question for the farm operator is whether the convenience of having electric agents on the field, compared to ones with self-contained fossil fuel power supply, makes a difference?

Update: Another question I have, from the perspective of a farm operator, is maintenance on the cable shown in the video from 2019. That cable might last 10 years, but eventually wear and tear is going to make it dangerous.

Calliban, if you do decide to contact the UK researchers, please see if they are willing to predict service life for the cable they selected for their demo.

Related question: The ideal service for this equipment configuration is initial field preparation.

That is an important part of farm management, but only a part. Can this configuration handle weed discovery/removal?

Can this equipment configuration handle harvest operations? I can imagine it might, for crops such as tomatoes, that can be kept in rows and are low to the ground.

(th)

Offline

Like button can go here

#13 2022-05-07 07:55:55

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,524

Re: Direct Electric Power for Vehicles & Equipment

The 2021 John Deere video showing evolution of their electric tractor research shows short cables between the head tractor and the satellite equipment.

That head could be a diesel generator able to service all the subsidiary vehicles.

The advantage that would accrue to the farm operator is reliability of all components.

The advantage of having a wide pass coverage is weather related.

A single tractor could service a large field, but the time required is maximum.

Wheat harvest is often performed with multiple harvesters running at full tilt 24x7 when conditions are optimum.

(th)

Offline

Like button can go here

#14 2022-05-07 22:23:50

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,939

Re: Direct Electric Power for Vehicles & Equipment

The issue with the feed cable for the tractor to connect to at distance is one where the cable needs to actually be larger but with small conductors that are twisted so that the conductors have less surface loss in the total length of the cable.

I agree that the line to the feed should be higher in voltage with step down transformer at the destination so as to reduce the losses in the length of cable.

Also if we need to do that we should simply use RF charging to remove the large step down transformer.

Mars application the extra mass to turn the equipment into construction types would be an aid to not needing to add mass. The cold of mars would also help in the conductor loss as well. Of course onboard battery would be better protected from the cold.

Offline

Like button can go here

#15 2022-05-07 23:09:35

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,352

Re: Direct Electric Power for Vehicles & Equipment

tahanson43206,

Don't confuse activity with accomplishment. Apart from increasing energy consumption, no part of this "green energy" fetish has actually reduced energy consumption of any kind, at all or ever. If the goal was to reduce energy consumption through improved energy efficiency, then we can clearly see that no such outcome has ever happened in all of human history. The objectively false belief that "one day" we'll consume less energy will only occur through energy poverty, never through increased energy efficiency associated with electrification or any other power generation scheme. Using more energy implies more pollution and more energy on top of that for recycling to make new things. If the end goal was to decrease CO2 emissions, then there's zero evidence for that as well.

A farmer would ponder over this proposition and say to himself, "Well, I would need to buy at least 6 tractors to do what my previous tractor did, because the passage of time doesn't care about anyone's ideological beliefs about saving the planet. If I don't plant my crops fast enough, then I don't get to harvest them before they freeze." That's how a real farmer views this, even the ones who are willing to try and pay for the new technology. Ideology doesn't make industrial food production any less energy-intensive. Nobody is against cleaner ways to do what we already do, least of all farmers. They're against expending vastly more money and energy, which they don't have, to do what we've done using traditional methods on the never-proven premise that it'll be cleaner or more efficient to consume more energy from the same ultimate sources to produce the same end result. If the power ultimately comes from a diesel engine or gas turbine generator at all times, then what did we actually accomplish, apart from making the entire solution far more expensive than it already is?

If the source of power can't realistically be provided by a centralized grid generation facility that produces reliable power, then this concept doesn't work for any number of reasons. In 2000, there were 13.7 million tractors on farms across the Top 7 nations. The average age of a tractor in the US is now around 25 years, because our farmers can't afford to purchase new ones. For all its shiny "newness" that excites consumers who don't understand that they will ultimately pay for this, this proposition looks like a great way to make farming a lot more expensive, less productive, and less sustainable as a result. Those are all "features" that you can't afford when you have to do more farming with fewer farmers, fewer pieces of equipment, and more expensive fuel.

An all-electric corded tractor has been technologically feasible for many decades now, but all industrial farming uses diesel powered tractors. I have to believe that if there were practical but cheaper and more efficient ways of tilling soil and planting seeds, then at least the largest farms would've started using the technology to either increase profits or at least reduce their operating costs. All these purported "solutions" that I see being offered up either provide drastically less performance for the same amount of money, or drastically more cost for the same performance. Since all of the existing solutions have the required level of performance, all of these "new solutions" end up being dramatically more expensive in practice.

John Deere is offering a far less capable battery electronic tractor for the same amount of money as a diesel powered machine of equivalent capability, to till soil and plant seeds. There's no way they'd ever offer up a dramatically less expensive tractor that was purely corded-electric, because that would mean less profit for them if those farmers ever figured out a way to use a purely corded electric machines.

I forgot to include this before, but here is the electric cable I used, since it should carry 10,000V / 45A 3-phase AC power over the required distance:

Nassau National Cable - 10kV 2 AWG 3-Cores Flame Retardant Copper Wire Braid Shielded Cable

That power cabling is primarily a Marine applications type of product, but should also work for our purposes. It requires a chafe guard to prevent the cord from being cut by being dragged across the ground.

A very large portable diesel-electric generator could be co-located in the field with the soil tilling tractors so that far fewer diesel engines are required, the generators that the farm has would be very large as a result, and hopefully they'd also have improved thermal efficiency as a result (lower speed, less heat loss, less wear at lower rpm), and reduced PM and NOx but not CO2 emissions if the emissions equipment were up to snuff and they were using natural gas. We're about to see that such is not the case.

Our example engine will be the Caterpillar 3612 diesel generator set.

Engine Model: Caterpillar C3612 (diesel) / G3612 (natural gas)

Power Output: 4,962hp at 1,000rpm (C3612); 4,000hp at 1,000rpm (G3612)

Displacement: 222L / 13,527CID 4-stroke V12 diesel

Weight: 25,091kg / 55,300lbs

Engine Only Dimensions: 180"L x 67"W x 127"H

Emissions Control Equipment: None

A 3612 would have to be mounted to a tracked crane-chassis type unit, which means an extra vehicle has to be in the field. A high-efficiency electric generator of the axial flux variety could considerably reduce the total weight of this mobile gen set. One thing to note about C3612 is that it burns 252 gallons per hour at full load, which works out to 31.5gph per tilling machine. Smaller displacement 600hp class diesel engines burn less fuel, between 25gph to 28gph across the Cummins / Caterpillar / John Deere models I've checked. The reason is quite simple. The mass of the rotating assembly of a C3612 is near to the total weight of these 13L to 15L heavy duty truck engines. It takes a lot of power to keep that much mass spinning. Each piston in the C36XX series of engines is nearly identical in size to a 5 gallon bucket. Caterpillar's C15 ACERT engine, which is a gen set version of their heavy duty semi-truck engine, only burns 28.1gph at full load. Cummins, Detroit Diesel, John Deere, Caterpillar, NaviStar, Scania, and others all have very similar engines with very similar power output and fuel consumption, because these are competitor products used in heavy duty trucks, generator sets, pumps, and marine applications. C15 ACERT has a 15.2L displacement and Inline-6 configuration / layout (same as all the others). Maybe we could knock-down C3612's diesel consumption by applying ACERT technology to it (electronic injector control, very high injection pressure, etc).

Caterpillar C3612 Diesel Generator Set

Caterpillar G3612 Natural Gas Engine

Caterpillar C15 ACERT Diesel Generator Set

If you run the G3612 (natural gas-fueled), assuming that the natural gas fuel provides 55MJ/kg, and accept that only 6 machines can be powered by the gen set, then you burn 500kg / 1,102lbs of CH4 at 4,000hp output, which works out to 0.2755lb/hp/hr. You give up 962hp of engine output switching from diesel to natural gas. However, natural gas ranges between 42MJ/kg and 55MJ/kg. If the gas only provides 42MJ/kg, then you're burning 1,443lbs at 4,000hp output. The diesel-fueled C3612 burns 200g/kWh, so 596.6kg of diesel per hour at 4,000hp, or 1,315lbs of diesel per hour, or 185.2gph (at 7.1lbs per gallon of diesel fuel). The 252gph figure previously mentioned corresponds with the C3612's maximum output of 4,962hp at 1,000rpm, but we want apples-to-apples CO2 emissions comparison between natural gas and diesel.

US EPA defines diesel fuel CO2 emissions as 10.18kg per gallon, so 1,885kg of CO2 to produce 4,000hp for 1 hour. Natural gas combustion is 2.252kg per kg of CH4 at 42MJ/kg or 2.666kg per kg of CH4 at 55MJ/kg. That means natural gas reduces CO2 emissions to 1,333kg of CO2 at 55MJ/kg or 1,474kg at 42MJ/kg, so 21.8% to 29.3% lower CO2 emissions. If you instead had 6 individually powered tractors, all using 600hp engines, each burning 28.1gph at full output, then your total CO2 emissions are 1,716kg/hr, so at most CO2 emissions could be reduced by 22.3%. LPG produces 1.665kg of CO2 per liter or 6.3kg of CO2 per US gallon for comparison purposes.

Here are your sources:

US EPA - Greenhouse Gases Equivalencies Calculator - Calculations and References

EcoScore - How to calculate the CO2 emission from the fuel consumption?

This is possibly doable, does not require hundreds of thousands to millions of additional miles of wiring to connect farms to the grid in a way that allows for transfer of megawatts of power, no step-down transformer substations on farms, and we can choose from CNG, LPG, or diesel fuel, dependent upon what's available.

Tomorrow I'll try to start compiling a list of pragmatic recommendations for reducing CO2, NOx, and PM emissions. Some range from simple and cost-effective solutions like fuel-polishing, to more expensive but longer-term solutions such as using atmospheric and/or sea water CO2 to produce liquid hydrocarbon fuels using solar thermal power out in the deserts. Using LPG immediately knocks-down CO2 by 38%, per unit weight of fuel burned. LPG is storable at room temperature without resorting to crazy-high pressures, whereas LNG is not and never will be. LPG burns quite well in spark ignition, compression ignition, gas turbines, external combustion type engines such as boilers or cooktops, rocket engines, and high temperature fuel cells, with minimal modifications.

Offline

Like button can go here

#16 2022-05-08 06:19:44

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,524

Re: Direct Electric Power for Vehicles & Equipment

For kbd512 re #15

Thanks for taking up the suggestion of a base power unit.

What you may not have realized is that farmers are among the most practical people ** and ** the most productive people alive on the planet at any given time.

John Deere has been in business serving these very practical people for many decades.

We are not (of course) able to know what the thought process is at the highest levels of John Deere management, but wasting money, time or effort is NOT high on the list.

This is purely a guess on my part, but I'm betting that elimination of the human operator (and all the associated expense) is a major driver in technology development for farm operations.

Another driver would be customer demand.

I doubt the older generation of farmers have a great concern for elimination of fossil fuels, but they may. I just don't know. What i expect would show up if anyone ever actually ** asked ** younger farmers, is that they understand climate change and the end point for agriculture if practices don't change.

The deep - profound - impressive devotion of some to the proven technology of the past is definitely a factor to be reckoned with.

How this will turn out is unpredictable, as the vigor of your presentation makes clear.

John Deere was founded in 1837.

My guess would be they have never hired (or kept in employment) a single impractical person.

Back to Post #16

This is an impressive analysis and presentation.

The forum is lucky to have it.

SearchTerm:JohnDeere analysis of prospects for large scale farm equipment

(th)

Offline

Like button can go here

#17 2022-05-08 10:01:12

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,352

Re: Direct Electric Power for Vehicles & Equipment

tahanson43206,

The deep, profound devotion of some to technology that costs absurdly more than existing technology is equally impressive, especially given the utter lack of desired end results, by their own definition.

To wit:

1. You can't point to any actual energy efficiency improvement. Shell games and cheap numbers tricks with the energy source doesn't make anything more efficient or supplant existing energy supplies. That's what our local Greentologists, first cousin to our Scientologists, have done here in Houston. Houston is 100% powered by "green energy" according to the propaganda, but all of the fossil fuel powered gas turbines never stop spinning.

2. You can't point to any actual CO2 emissions reductions. CO2 emissions keep going up every year. That's a feature of using more energy from all sources. No new energy sources have ever replaced existing energy sources. The graph shows that quite clearly and you have no answer or response to refute what was so clearly shown with a single picture, because you know it's a simple truth. I didn't "make it up" for sake of argument. I posted it to illustrate what actual human energy consumption actually looks like over time. All wind and solar energy are additive, meaning in addition to all the fossil fuel energy. They have not replaced any gas turbines. The gas turbine is still there in the background, still "turned on" 24/7, because it has to be, in order to smooth out the wild power fluctuations from unreliable energy.

3. You can't point to any example where wind or solar or battery technology has decreased the price of electricity. The price of electricity has only gone up as more "green energy" has been installed. That trend will continue and never reverse. I'm talking about what consumers pay, not marketing BS about what the company producing the energy supposedly pays. Does the simple fact that what you pay continues to increase indicate that it's not getting any cheaper, or does 2 plus 2 not equal 4 when the religion is involved?

That looks like religion to me. It's the religion of someone who has been taught to be fearful of the very technology keeping them alive. In my world, only evil people do this to other people. I don't teach anyone to be fearful or resentful of any technology.

We started operating cars instead of horses because the cars turned out to be cheaper than operating the number of horses capable of producing equivalent work output. You run an internal combustion engine vehicle out of gasoline, which is what the car "eats", and it just sits there until you put more gasoline in it. You run a horse out of hay, which is what the horse "eats", and it dies. You get the horse too hot or too cold and it is either seriously injured or it dies- same thing that happens to all batteries. Since we would need an exponentially greater number of resources for horses or batteries to do equivalent work as internal combustion engines, we started using internal combustion engines. It's a simple math problem, but the religion of climate change has taught the religious faithful to believe in something that is objectively false. To wit, that you can accomplish the same task with dramatically less energy. Unless John Deere can overcome basic physics, and there is no evidence for that, then this scheme doesn't work in a general use case. Trying to find the rare exceptions is "the religion in action", nothing more.

Offline

Like button can go here

#18 2022-05-08 21:10:15

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,352

Re: Direct Electric Power for Vehicles & Equipment

Here is what a Caterpillar 3600 series piston looks like, next to a 5 gallon bucket:

This dude is not a "small guy", either:

It should be obvious how large a Caterpillar 3612 engine is.

IIRC, Caterpillar makes Inline-6, Inline-8, V-12, V-16, and V-20 versions of the engine that uses this piston. If there are other versions, then I'm not aware of them.

Edit: The two holes in the top of the piston's crown are threaded for lifting bolts so that an overhead crane can drop the assembly into the engine block. I don't know what manner of ring compressor is used to compress the piston rings, but that has to be impressive in its own right. I'm imagining a guy using the butt of a 20 pound sledge hammer to drive the piston home.

Last edited by kbd512 (2022-05-08 21:13:49)

Offline

Like button can go here

#19 2022-05-08 21:56:31

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,939

Re: Direct Electric Power for Vehicles & Equipment

So far I would say that they should have focused on a hybrid instead to reduce fuel use.

Offline

Like button can go here

#20 2022-05-09 06:24:51

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,524

Re: Direct Electric Power for Vehicles & Equipment

For SpaceNut re #19

Interesting observation! "Instead" is a word that restricts a designer unnecessarily.

Here is a set of Google snippets that seem to match up with your vision ... It appears to be a case of "And" at work here.

“A hybrid driveline. John Deere is already using a hybrid driveline in the popular 944K wheel loader. In this machine a diesel engine drives a hydraulic pump, but also 2 electric generators. We will probably introduce this technique in agricultural machines as well in the future.”

Jan 8, 2019

John Deere: 'Future tractor drivelines are hybrid'

www.futurefarming.com › tech-in-focus › john-deere-future-tractor-driveli...

About Featured Snippets

Coming out of last night's Zoom, I have the impression that kbd512 is not yet convinced that an all-electric field equipment configuration is practical, let alone cost-effective. He ** did ** offer a diesel powered base station from which electric field equipment could receive power.

The original test vehicle announced in 2019 had a cable run of just 1 kilometer. The 2021 update showed a much longer run.

Equipment can be operating to right and left of a lane where the heavy power provider would sit.

I can envision a field operation that extends a kilometer (or more) on either side (both sides) of a lane, with all equipment electric except for the base unit, and just one human on duty to supervise the operation.

kbd512 pointed out that in the early stages of farm operation stones are found in fields, but I observe that stones and other obstructions are removed when they are found, and shortly (a few years at most) the fields are pristine.

The challenge for John Deere is to anticipate the needs of the most innovative/productive farm managers, and to have the equipment available when it is requested. If you look at their offerings, you will see they are trying to stay ahead of the possible demand, while at the same time meeting all the needs of their existing customer base, including maintaining older models.

This topic sorely lacks input from actual farmers who operate on a scale large enough to justify considering the all-electric concept.

If anyone who has actual experience operating a large farm should happen upon this topic, and care to contribute, please see the Recruiting topic for procedure.

(th)

Offline

Like button can go here

#21 2022-05-09 08:19:22

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,274

Re: Direct Electric Power for Vehicles & Equipment

It's been a few days since I looked at this, so it will take me a while to read through what has been written. But a few thoughts in the mean time.

Firstly: The 450kWe figure that Kbd512 proposed for power consumption looks about right, based on what I have read of power requirements for tractors and combines. In theory, these pieces of equipment can be made in a range of sizes and power consumption, but work done per hour scales with power. Capital cost also scales with power. But labour costs decline in proportion to power, because what a single operator can achieve in 1 hour is proportional to the power driving the vehicle. Practically, there will be a tradeoff between capital cost and labour cost. For small farms with small fields, it won't neccesarily make sense buying the largest machines. But for the purpose of analysis, I will assume a standard 450kW engine power.

Secondly: Diesel burned in compression ignition engines is the standard means of powering farming equipment and most mining and digging equipment. There are very good reasons for this. Diesel fuel has energy density of 45.6MJ/kg. When burned in a 40% efficient compression ignition engine, it provides 18.24MJ of work energy per kg. The amount of diesel fuel required to raise 450kW of power for 8 hours (a standard work shift) is about 710kg and wouod cost around $700.

Third: Lithium ion batteries have an energy density of 0.3-0.8MJ/kg, according to wiki. Taking the higher end energy density, batteries capable of doing the same job as 710kg of diesel, would weigh 16.2 tonnes. Electric vehicle batteries presently cost around $132/kWh. So a battery capable of doing the same thing as 710kg of diesel, would cost half a million dollars. It would be so heavy that it would sink into the mud in a wet field. If electricity is charged at a cost of $0.2/kWh, the energy cost of electric power would be $720. Almost exactly the same as diesel would cost, but with an additional whopping $500,000 cost for the battery.

From the above comparison, it is clear that whilst battery electric could work in principle for powering heavy equipment, it is vastly inferior to diesel in terms of practicality, cost and labour efficiency. And that shouldn't be surprising. If there were a superior option to diesel, we would be using it already. The cost of diesel is not the cost of producing it. It is the cost of withdrawing it from the ground and refining it. Why consider using inferior solutions?

On Earth: Because global oil production has passed it's historic peak. From this point forward, the world will have less and less diesel with every passing year. This is a problem that has its roots in depletion of conventional oil resources. There are technological options that could produce diesel from tar sands, kerogen and biomass, which are either renewable or present in relatively huge quantities. But these are expensive and energy intensive compared to conventional oil.

On Mars: Because there is no diesel and no air to burn it in. Heavy work of Mars requires that we either make a synthetic fuel and oxidiser (which is very energy intensive), put nuclear reactors on vehicles or employ an electric solution. Battery electric would be just as massive and costly on Mars as it is on Earth. Hence the proposal for direct electric through power cables. This is only really a solution under specific circumstances. A 1 mile cable weighing 5.5 tonnes sounds excessive for what I had in mind. But it is less than the 16.2 tonnes needed for an equivalent battery electric solution.

On a Mars construction site, we could charge a BEV digger using a solar array on site. Unfortunately, this requires that we charge the vehicle during peak daylight hours. This is exactly the time when we would like to be using the vehicle. So using solar power, we would need two of those 16.2 tonne batteries. One charging whilst the other was in use. Unless the plan is to use the equipment overnight and charge it during the day. But that means working the equipment at temperatures of -90°C, at which point ordinary most steels are brittle. With a nuclear reactor powering a vehicle directly, we could work 24/7. The reactor could be mounted on the vehicle or stationary and attached to it by cable. If mounted on the vehicle, then the vehicle must carry shielding and waste heat disposal panels. But it can use waste heat to prevent any brittle fracture concerns at night. If stationary, then the cable mass must be considered and there may be additional power consumption in heaters. But the powerplant, waste heat radiator and shielding are stationary.

Last edited by Calliban (2022-05-09 09:55:07)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#22 2022-05-09 10:02:56

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,524

Re: Direct Electric Power for Vehicles & Equipment

For Calliban re #21 and entire topic ...

It is good to see you've stopped in to tend the growth of this topic! I think it is important for Mars, and it ** may ** be important for Earth.

Since it is likely you do not have time to read every topic (I sure don't) and since there is a chance I'll catch you here, kbd512 was musing about a solar powered diesel manufacturing plant in Texas.

Hopefully kbd512 will extend and refine the vision, but in ** this ** post, I am hoping to draw your attention back to Mars.

I ** think ** there are signs you are open to considering electric agricultural equipment on Mars.

In hopes I am reading the tea leaves correctly, here is a suggestion to thicken the gruel ... (really stretching metaphors, I admit)...

Electric power can be delivered via hot/cold fixed wires mounted inside kilometers long greenhouse tunnels on Mars.

The strength of a fabric stretched inside a wire frame should be more than sufficient to hold 1/2 Bar for a standard Mars Habitat (per RobertDyck in this forum).

If the fabric is transparent then plants can be set in prepared beds inside those long tunnels, and the weak sunlight from Sol will be sufficient for some of them.

However, the kinds of mirrors discussed multiple times in this forum can gather light and direct it into the tunnels, to achieve near (or the same) solar flux levels as we enjoy at Earth.

Thus, the problem of delivering power to equipment inside the tunnel(s) would appear to be addressable.

The exact same concept would work nicely on Earth, in latitudes near the pole where sunlight is less than in the equatorial regions.

(th)

Offline

Like button can go here

#23 2022-05-09 12:39:43

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,352

Re: Direct Electric Power for Vehicles & Equipment

To understand the rate of growth, in the US in 2021, a total of 317,897 tractors and 6,272 combine harvesters were sold to farmers.

1 Tesla Model S 100kWh battery weighs 1,377.5lbs / 625kg (we know for a fact that these batteries actually make their rated capacity numbers and are mostly reliable, even under less than ideal conditions)

450kWh at rated engine / motor output * 8 hours of runtime = 3,600kWh or 3.6MWh

3,600kWh / 100kWh = 36 of those 100kWh Tesla Model S batteries per tractor (that runs for 8 hours)

36 (100kWh Tesla Model S batteries) * 625kg (per battery) = 22,500kg of battery weight per tractor (bare minimum)

13,000,000 tractors * 22.5t = 292,500,000 metric tons of batteries need to be created to power those tractors

36 100kWh batteries per tractor * 13,000,000 tractors = 468,000,000 of those 100kWh battery packs (1.6 TIMES the number of motor vehicles registered in the US of A)

22 years ago, there were 13 million large industrial farming tractors used across the Top 7 countries that own the most tractors, and many tens of millions more tractors across all the other countries. If there are fewer tractors 22 years later, I'd be shocked. There are fewer farms as the family farms are slowly consolidated into larger and larger industrial farming conglomerates (still farmed by families, oddly enough, who are essentially multi-generational company employees). That was necessary to stay cost-competitive with the largest farms.

Nexus PMG - The Coming EV Battery Revolution - Raw Ore Requirements per 1,000 pound EV battery

Each Tesla Model S 100kWh battery purportedly requires the processing of some 500,000 / 226,860kg / 226.86t pounds of raw ores (not just Lithium, but all the metals that go into making the batteries- Lithium / Cobalt / Manganese / Iron / Copper / Nickel / Aluminum).

226.86t * 468,000,000 (number of 100kWh batteries per tractor, or 36 of the 100kWh batteries) = 106,170,480,000t

Visual Capitalist's Total Global Metals Mining Output in One Visualization:

In 2021, 2.6 billion tons of iron ore were processed, globally.

All metal ores produced across the entire planet do not add up to the amount of material you'd have to process to power 13 million industrial farming tractors using batteries.

The combines used to harvest the crops use even more power, although there are far fewer of those.

Iron ore represents 94% of all the metals we mined in the entire world.

106 billion tons of materials need to be processed just to make the batteries.

Converting all or even most tractors to use batteries is a pipe dream.

Battery powered everything is grossly infeasible without an unimaginable explosion in the use of fossil fuels to make all those batteries, and it sure as hell won't be done in 10 to 20 years.

10 years after you make all those batteries, you'll have to recycle them. You need every bit as much energy to recycle them as the energy that went into making them, and then some, which is why they're not used to make new batteries in most cases.

Offline

Like button can go here

#24 2022-05-09 12:55:58

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,524

Re: Direct Electric Power for Vehicles & Equipment

For kbd512 ....

The title of this topic is: Direct Electric Power for Vehicles & Equipment

I ** think ** that Batteries (of any kind) are NOT what Calliban intended for this topic.

Calliban, please clarify your intention for this topic.

I could be mistaken (of course) .... you may have intended to include discussion of battery powered tractors.

(th)

Offline

Like button can go here

#25 2022-05-09 13:08:17

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,352

Re: Direct Electric Power for Vehicles & Equipment

I think now we know why the number of batteries or electrical cables to wire the tractors to the grid won't be done within our lifetimes. The quantity of materials required is staggering. It may be necessary to power construction vehicles this way on Mars, but it won't be done on Earth any time soon.

Using solar thermal power to produce liquid hydrocarbon fuels from sea water and its dissolved CO2 is the most practical and affordable way to fix the problem. Since we bothered to extract the sea water, we'll extract the Lithium, Magnesium, and Uranium while we're at it, as a side business. I didn't just pull that solution out of my butt after thinking about it for a minute. I looked at what we're presently doing, what we could scale up in a practical way, and how much material and energy would be required to do it. I also admitted to myself that nuclear power couldn't scale up to the degree required, in the time frame required. Here in America, the Nuclear Regulatory Commission's #1 job priority is stopping the building of all new commercial nuclear electric power plants by bankrupting the companies that show good faith efforts to build and certify new commercial power reactors. In lieu of nuclear thermal, solar thermal scales to human civilization levels and lasts as long in operation as nuclear thermal, whereas none of the other purported solutions ever will, at least not within our lifetimes. We don't have endless energy, endless materials, or endless labor to devote to the problem of cleaning up after ourselves. We have finite resources to work with. In energy production and storage, orders of magnitude have meaning. It's time we acted like it.

Offline

Like button can go here