New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#151 Re: Human missions » Mars Direct 3 is a Mars mission architecture developed by Miguel Gurre » 2025-09-21 17:33:34

#152 Re: Human missions » Starboat » 2025-09-21 17:24:04

This is in essence "A toehold mission to Mars is a strategic, multi-phase approach designed to establish an initial, minimal but sustained human presence on the Martian surface. The concept is derived from corporate strategy, where a "toehold" is a small, initial investment in a target company to gain a foothold before a larger acquisition. For Mars exploration, this strategy avoids a single, large-scale, "flags and footprints" style mission in favor of a gradual, cost-effective build-up of infrastructure.

Core design principles

The toehold mission design is founded on several core principles to mitigate risk and maximize resource utilization:

Split-mission strategy: Mission hardware, supplies, and habitats are deployed robotically to Mars in advance of the crew, reducing the overall mass that the crewed vehicle must carry and minimizing risk.

Use of in-situ resources (ISRU): A primary objective of the initial robotic phase is to land and operate an ISRU plant to manufacture resources from the Martian atmosphere and soil, such as methane fuel and oxygen. This is crucial for the crew's ascent and return vehicle.

Fast transits with surface abort options: Crew transport is designed for fast transits to limit exposure to deep-space radiation and the physiological effects of long-duration microgravity. A "surface abort" option is also built in, providing a safe haven at the base camp should an in-flight emergency occur.

Short stays followed by extended exploration: The first crewed missions involve relatively short stays (e.g., 30 days) to establish the initial outpost and prove the return-trip technology. Subsequent missions would leverage the existing base to enable longer stays and more extensive exploration.

Mission phases of a toehold strategy

A Mars toehold mission would proceed through several phases, combining robotic and human-tended elements to create a sustainable outpost.

Phase 1: Robotic infrastructure deployment

Launch: A series of heavy-lift launches send robotic landers carrying equipment to Mars during a favorable launch window.

Resource manufacturing: The landers use the Sabatier process to combine hydrogen (brought from Earth) with carbon dioxide from the Martian atmosphere to produce methane fuel and water.

Habitation and systems: The landers also deploy a basic habitat, a surface rover, power systems, and life support equipment for the arriving crew.

Phase 2: Initial crewed mission

Crew transit: An Earth Return Vehicle (ERV) and the crew transit habitat are launched into low-Earth orbit (LEO) and transferred to a Mars trajectory.

Mars arrival: The crew enters Mars orbit and performs a rendezvous with the surface habitat.

Surface stay: The crew spends 30 days on the surface, performing initial reconnaissance, confirming systems, and evaluating the ISRU-produced fuel.

Return journey: The crew ascends from the surface in the Mars Ascent Vehicle (MAV), which was pre-fueled by the ISRU plant, and returns to Earth in the ERV.

Phase 3: Extended exploration and base expansion

Expansion: Subsequent crewed missions expand the base using additional pre-deployed robotic systems.

Infrastructure development: Infrastructure such as additional pressurized rovers, power plants, and laboratory modules are added, enabling longer and more ambitious missions.

Extended stays: With more robust infrastructure, astronauts can conduct longer stays (e.g., 300+ sols) to perform deeper scientific research"

#153 Re: Human missions » Starboat » 2025-09-21 17:23:21

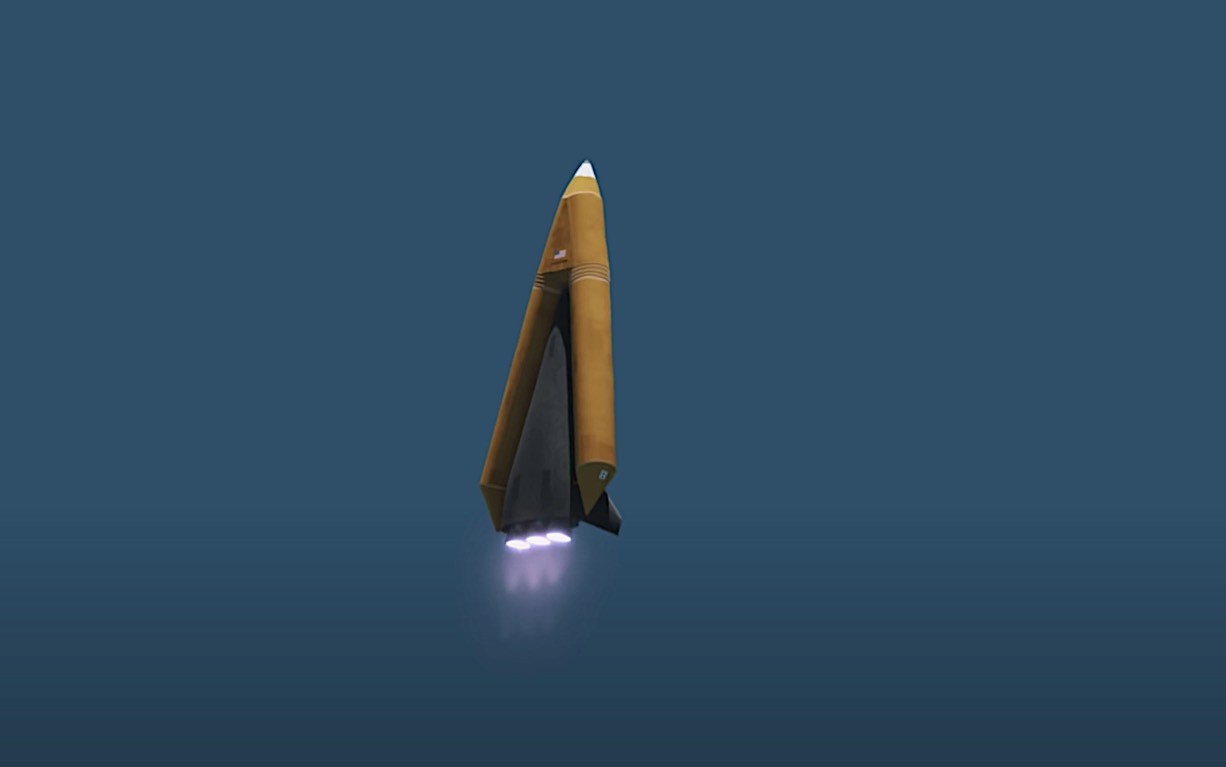

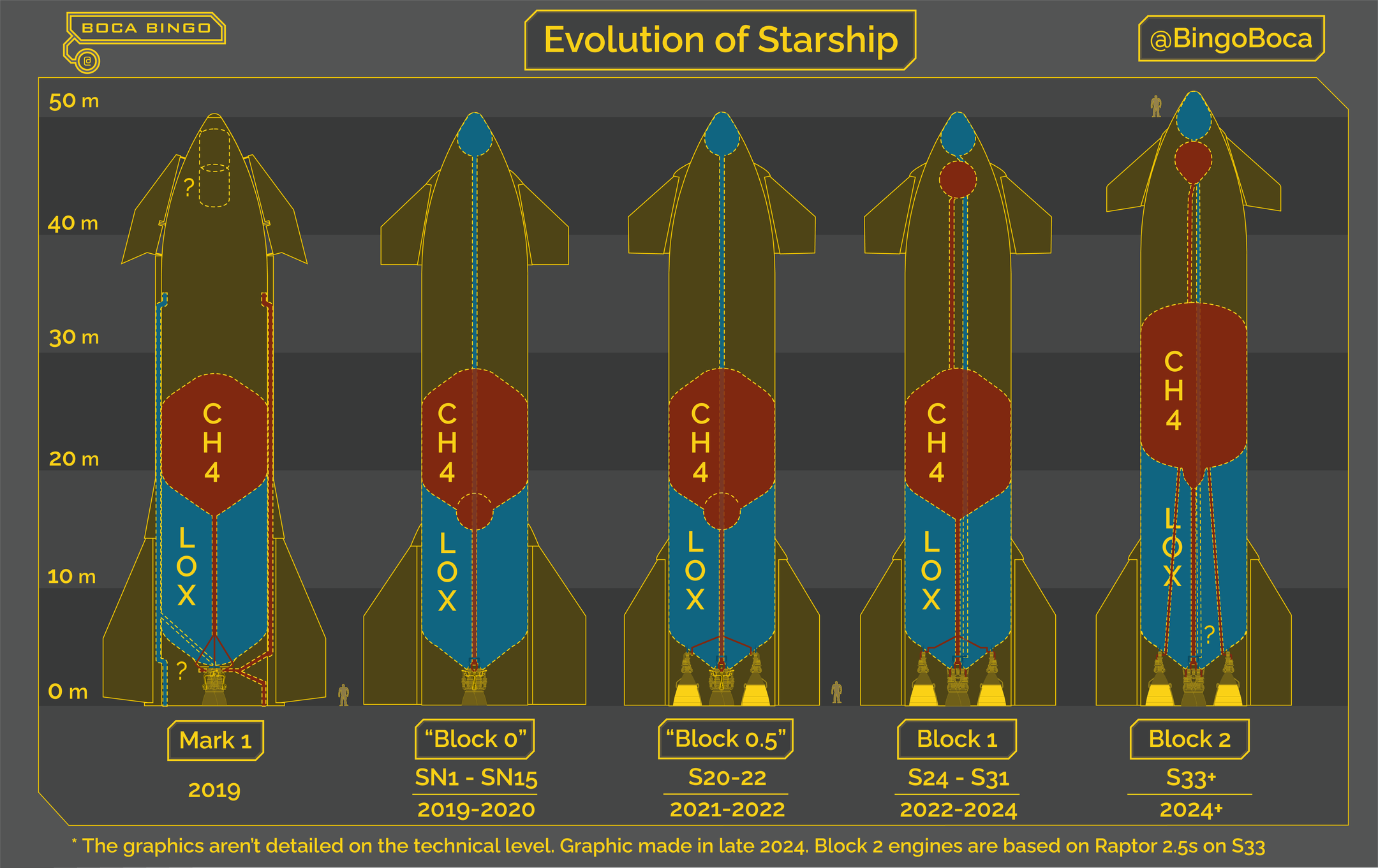

Robert Zubrin's "Starboat Mars Mission" concept proposes a smaller, dedicated ascent/descent vehicle called Starboat for Martian surface operations, reducing reliance on the large Starship for return trips. The plan involves a large Starship delivering the Starboat to Mars, where it would act as a surface-to-orbit ferry, performing direct returns to Earth or rendezvousing with a Starship tanker in Mars orbit for refueling. This approach aims to simplify the mission architecture and improve ascent efficiency from Mars.

Starboat's Role

Surface-to-Orbit Ferry:

Starboat serves as the primary vehicle for the crew to return from the Martian surface.

Flexible Rendezvous:

It can either return directly to Earth or rendezvous with a Starship in Mars orbit for refueling.

Mission Architecture

Initial Starship Launch: A large Starship is launched to Mars with the Starboat as cargo, or the Starship acts as a fuel tanker.

Martian ISRU: The Starship, after delivering the Starboat, serves as a base for Martian resource utilization (ISRU) to produce methane and oxygen.

Mars Operations: The Starboat uses the produced propellant for a 3.8 km/s delta-V burn to reach Mars orbit.

Return Trip: The Starboat either:

Direct Return: Uses its full fuel load to return directly to Earth.

Orbit Rendezvous: Transfers some of its fuel to a Starship tanker in low-Mars orbit to allow for a shorter, more fuel-efficient return to Earth.

Advantages

Reduced Complexity:

Eliminates the need for a large Starship to be the primary ascent vehicle from Mars.

Optimized Ascent:

Starboat is a smaller, more efficient vehicle for returning from the Martian surface.

Increased Flexibility:

Offers options for both direct and orbital rendezvous return trajectories.

Challenges

Power Requirements:

Producing sufficient propellant on Mars requires a significant power source, such as a large solar farm or a nuclear reactor.

Infrastructure:

Transporting and deploying the necessary infrastructure for propellant production poses a challenge for initial mission

#154 Re: Human missions » Starboat » 2025-09-21 17:15:22

in the inital title and post.

Much like other plans put forth ffrom Zubrin which could work as many other before have fallen on deaaf ear..

AI Overview

Robert Zubrin proposes integrating his "Mars Direct" philosophy with SpaceX's Starship through the "Starboat," a smaller, reusable vehicle that serves as a surface-to-orbit shuttle for early Mars missions, reducing the need for the large Starship to land on the planet. The Starboat would use less propellant, operate as a mini-Starship with a smaller crew, and act as a shuttle for a Starship parked in Mars orbit, making Mars exploration more flexible and efficient. This approach provides a pathway for early human missions to Mars by leveraging the reusable infrastructure of a larger Starship in orbit and the efficiency of a smaller vehicle for surface operations.

Zubrin's Mars Direct and the Starboat

Mars Direct Philosophy:

Zubrin's original Mars Direct plan emphasized a "live-off-the-land" approach, utilizing a nuclear-powered rover to produce fuel on Mars for the Earth Return Vehicle (ERV).

Starboat Concept:

The Starboat is Zubrin's adaptation of this idea to the SpaceX Starship architecture, envisioning a smaller version of the Starship as a dedicated surface-to-orbit shuttle.

Key Aspects of the Starboat for Mars Missions

Reduced Propellant Needs:

The Starboat requires significantly less propellant to land on Mars and return to orbit compared to the full-size Starship.

Efficient Surface Operations:

Instead of a large Starship landing on Mars, a Starship could remain in orbit, and the Starboat would shuttle crews and cargo between the surface and the orbiting Starship.

Flexibility and Crew Size:

The smaller size of the Starboat makes it more suitable for early, smaller-crew missions focused on establishing infrastructure on Mars.

Refueling and Reusability:

The Starboat's high reusability and lower fuel requirements would make missions more efficient.

How it Works with Starship

Orbital Starship: A full-sized Starship is sent to Mars orbit and remains there as a "parked" asset.

Starboat as a Shuttle: The smaller Starboat would launch from Earth (potentially fully fueled by a single Starship), travel to Mars, and then perform the surface-to-orbit shuttle role.

Surface-to-Orbit Transport: The Starboat's primary role would be ascending from the Martian surface to the orbiting Starship, requiring less propellant than a full Starship would for the same task.

This concept offers a more scalable and efficient approach to early human Mars exploration, aligning with Zubrin's core principles of resourcefulness and efficiency

Zubrin’s New Mars Plan with a Mini Starship Called Starboat

Specification for a Mini Starship Using Two Raptor Engines

Robert Zubrin talks about reducing the mass of SpaceX Starship by a factor of 5 for a Starboat mini-Starship. The linear dimensions would scale by the cube root of 1/5 ≈ 0.58. This gives a diameter of 9 × 0.58 ≈ 5.2 meters. The mass would then be 1320 / 5 = 264 tons (assuming proportional scaling of dry mass and propellant). For a thrust-to-weight ratio of 0.91, the required thrust is 0.91 × 264 ≈ 240 tons. One Raptor (200 tons thrust) is slightly insufficient, while two Raptors (400 tons) provide excess thrust, yielding a ratio of 400 / 264 ≈ 1.52, which is reasonable for an upper stage. There are more advanced Raptors where one engine could get the thrust.

I had worked out the insitu refueling for a total large starship and it need to many landing off equipment to make a single return ship happen.

Mars surface to Earth using 120 tons of propellant or perform a low-Mars-orbit rendezvous using just 50 tons of propellant, with a single tanker in low Mars orbit being able to support five such return flights. It could also be lifted to Earth orbit fully fueled by a single Starship and sent directly to Mars with five tons of cargo without any Earth-orbit refueling, or 25 tons of cargo with a single tanker refueling.

Mars Landing and Operations

Efficient Design: The Starboat needs five times less propellant than the Starship for landing on Mars and returning to orbit. For comparison, refueling the Starship on Mars requires approximately 600 tons of propellant, while Zubrin’s Mars Direct plan uses vehicles needing only about 120 tons.By a rough estimate, to make the 600 metric tons of propellant required to refuel the Starship once on Mars within a year and a half would require a power source with an average round-the-clock output of 600 kilowatts. A solar array that could do that would cover 60,000 square meters — that’s over 13 football fields in size — and weigh about 240 metric tons. It would require three Starship flights just to deliver such a solar array to Mars, and it would then be a major burden to deploy and maintain. A more practical alternative would be to use nuclear power. We could imagine a plausible reactor design at this power level with a mass of about ten tons.

#155 Re: Science, Technology, and Astronomy » Google Meet Collaboration - Meetings Plus Followup Discussion » 2025-09-21 17:13:45

I have been ill with a virus thaat is finally lossing its grip. I might not make it to the fun.

#156 Re: Human missions » Why Artemis is “better” than Apollo. » 2025-09-21 15:38:16

NASA’s mega moon rocket gets key upgrades for upcoming crewed mission

NASA is gearing up to send its first astronauts toward the moon in five decades.

The Artemis II mission is currently set for early next year and will use NASA’s next-generation SLS rocket and Orion spacecraft.

Although none of the four crew members will be stepping foot on the lunar surface, they will come The much-anticipated mission will take about 10 days from launch to splashdown, making it 15 days shorter than the uncrewed Artemis I mission in 2022 that operated as a test run for Artemis II.

NASA has just shared an update on its preparations for Artemis II, focusing on some of the improvements made to the SLS rocket and the Orion since the Artemis I mission.

As with the SLS rocket’s first flight three years ago, the 322-feet-tall (98-meter) still comprises a central core stage, four RS-25 main engines, two five-segment solid rocket boosters, the ICPS (interim cryogenic propulsion stage), a launch vehicle stage adapter to hold the ICPS, and an Orion stage adapter connecting SLS to the Orion spacecraft.

NASA said that as the SLS rocket heads skyward next year, it will jettison the spent boosters four seconds earlier than it did in the Artemis I ascent. Dropping the boosters a little earlier will reduce the weight that the core stage needs to carry after booster separation. The saved weight should allow the rocket to carry more cargo or heavier payloads to space, and the Artemis II flight will allow engineers to compare data to confirm their calculations.as close as 4,000 miles (around 6,440 km) of it before flying around the moon and returning home.

The SLS rocket’s maiden flight in the Artemis I mission experienced unsteady airflow that caused higher-than-expected vibrations near the solid rocket booster attachment points, and so NASA has added a pair of six-foot-long aerodynamic surfaces for a smoother ascent.

Upgrades to the flight system include optical targets fitted to the ICPS that will function as visual cues for the four Orion astronauts when they come to manually pilot the spacecraft around the rocket’s upper stage, at the same time practicing maneuvers to gather data for docking operations for the future Artemis III mission. During that mission, which is currently set for 2027, the Orion will link up with SpaceX’s Starship spacecraft for a crewed lunar landing — the first since 1972.

The rocket’s navigation system has also been enhanced — alongside improvements to its communications capabilities — by repositioning antennas on the rocket to ensure continuous communication with NASA personnel on Earth.

Notably, the emergency abort system has been refined to add a time delay to the self-destruct sequence. This will give the Orion and its crew more time to move clear of the rocket in the event of an abort, better protecting the astronauts from any destructive actions that occur soon after.

Other improvements include work on the core stage power distribution control unit, which controls power to the rocket’s other electronics and protects it from electrical hazards.

“While we’re proud of our Artemis I performance, which validated our overall design, we’ve looked at how SLS can give our crews a better ride,” said John Honeycutt, NASA’s SLS program manager.

Honeycutt added that some of the changes have been made in response to specific Artemis II mission requirements, while others are the result of ongoing analysis and testing, as well as insights gained from the Artemis I voyage.

he Artemis II crew includes NASA’s Reid Wiseman, Victor Glover, and Christina Koch, together with Jeremy Hansen of the Canadian Space Agency. The four astronauts have been in training since they were announced as the Artemis II crew in 2023.

#157 Re: Exploration to Settlement Creation » Foot hold for manned missions » 2025-09-21 14:43:32

Minimal mission size is partly due to lift and duration of mission. It takes planning and multiple landing with a limited capacity capability.

#158 Re: Meta New Mars » Housekeeping » 2025-09-21 14:30:43

I sent to both a test message

signing it

#159 Re: Meta New Mars » offtherock postings » 2025-09-21 14:24:59

Its not the first time others have made this label to a oneway plan but it requires a desire to stay and remain for the propose of digging in from mission 1 permanently rather than going back.

Here it is, enjoy reading

One man one way suicide mission

Mission One: a one way ticket to Mars?

of course we are also talking about

The "newmars toehold mission" is a concept frequently discussed in the New Mars Forums, an online community dedicated to the human exploration and settlement of Mars. It is not a formal mission by a space agency like NASA, but rather a theoretical approach to the initial crewed landing on Mars, intended to establish a basic, self-sufficient human presence.

Key features of a newmars toehold mission, based on the forums, include:

Minimalist crew and hardware. The idea prioritizes minimizing the crew size and the amount of payload mass sent from Earth to reduce launch costs and complexity.

In-situ resource utilization (ISRU). A central component is "living off the land" by using Martian resources to produce consumables and rocket fuel. The mission would rely on pre-landed robotic rovers to scout and process local resources, such as water ice.

Contingency philosophy. Unlike missions that plan for a full return-mission contingency, the "toehold" approach suggests that astronauts should train rigorously and be prepared to rely on the pre-landed habitat. The cost of a full, Earth-based solution for all possible contingency scenarios is considered economically unfeasible.

Pre-positioned cargo. Before the crew arrives, robotic missions would launch and land habitats, power systems, and supplies at the designated landing site. This would ensure the basic infrastructure is in place and functioning before humans are committed to the long journey.

Incremental settlement. The "toehold" is viewed as the first step toward a more permanent settlement. The mission is a stepping stone that demonstrates the feasibility of self-sufficiency, which is necessary for long-term growth on Mars without constant resupply from Earth.

Origin and context

The concept is similar in philosophy to "Mars Direct," a plan developed by Robert Zubrin in the 1990s and discussed on the New Mars forums. Both concepts focus on self-sufficiency and resource utilization as a way to make crewed Mars missions economically viable. The "newmars toehold mission" specifically emphasizes taking the bare minimum for the initial human arrival to get the "first foot in the door".

#160 Re: Human missions » Mars Direct; Mars Semidirect; Design Reference Mission. Need Updating? » 2025-09-21 14:20:44

Kicking the can down the road to get to the next big thing will not solve how to build from nothing to something over a few cycles.

Nasa is currently challeneged to get a heatshiled to hold coming back from the moon and starship still is trying to prove one that only shows promise.

#161 Re: Science, Technology, and Astronomy » Wind Energy Capture - All methods in one topic » 2025-09-20 14:57:01

if the images are important upload them to the php3 site

#162 Re: Human missions » Mars Direct; Mars Semidirect; Design Reference Mission. Need Updating? » 2025-09-20 14:55:41

Much like other plans put forth ffrom Zubrin which could work as many other before have fallen on deaaf ear..

AI Overview

Robert Zubrin proposes integrating his "Mars Direct" philosophy with SpaceX's Starship through the "Starboat," a smaller, reusable vehicle that serves as a surface-to-orbit shuttle for early Mars missions, reducing the need for the large Starship to land on the planet. The Starboat would use less propellant, operate as a mini-Starship with a smaller crew, and act as a shuttle for a Starship parked in Mars orbit, making Mars exploration more flexible and efficient. This approach provides a pathway for early human missions to Mars by leveraging the reusable infrastructure of a larger Starship in orbit and the efficiency of a smaller vehicle for surface operations.

Zubrin's Mars Direct and the Starboat

Mars Direct Philosophy:

Zubrin's original Mars Direct plan emphasized a "live-off-the-land" approach, utilizing a nuclear-powered rover to produce fuel on Mars for the Earth Return Vehicle (ERV).

Starboat Concept:

The Starboat is Zubrin's adaptation of this idea to the SpaceX Starship architecture, envisioning a smaller version of the Starship as a dedicated surface-to-orbit shuttle.

Key Aspects of the Starboat for Mars Missions

Reduced Propellant Needs:

The Starboat requires significantly less propellant to land on Mars and return to orbit compared to the full-size Starship.

Efficient Surface Operations:

Instead of a large Starship landing on Mars, a Starship could remain in orbit, and the Starboat would shuttle crews and cargo between the surface and the orbiting Starship.

Flexibility and Crew Size:

The smaller size of the Starboat makes it more suitable for early, smaller-crew missions focused on establishing infrastructure on Mars.

Refueling and Reusability:

The Starboat's high reusability and lower fuel requirements would make missions more efficient.

How it Works with Starship

Orbital Starship: A full-sized Starship is sent to Mars orbit and remains there as a "parked" asset.

Starboat as a Shuttle: The smaller Starboat would launch from Earth (potentially fully fueled by a single Starship), travel to Mars, and then perform the surface-to-orbit shuttle role.

Surface-to-Orbit Transport: The Starboat's primary role would be ascending from the Martian surface to the orbiting Starship, requiring less propellant than a full Starship would for the same task.

This concept offers a more scalable and efficient approach to early human Mars exploration, aligning with Zubrin's core principles of resourcefulness and efficiency

Zubrin’s New Mars Plan with a Mini Starship Called Starboat

Specification for a Mini Starship Using Two Raptor Engines

Robert Zubrin talks about reducing the mass of SpaceX Starship by a factor of 5 for a Starboat mini-Starship. The linear dimensions would scale by the cube root of 1/5 ≈ 0.58. This gives a diameter of 9 × 0.58 ≈ 5.2 meters. The mass would then be 1320 / 5 = 264 tons (assuming proportional scaling of dry mass and propellant). For a thrust-to-weight ratio of 0.91, the required thrust is 0.91 × 264 ≈ 240 tons. One Raptor (200 tons thrust) is slightly insufficient, while two Raptors (400 tons) provide excess thrust, yielding a ratio of 400 / 264 ≈ 1.52, which is reasonable for an upper stage. There are more advanced Raptors where one engine could get the thrust.

I had worked out the insitu refueling for a total large starship and it need to many landing off equipment to make a single return ship happen.

Mars surface to Earth using 120 tons of propellant or perform a low-Mars-orbit rendezvous using just 50 tons of propellant, with a single tanker in low Mars orbit being able to support five such return flights. It could also be lifted to Earth orbit fully fueled by a single Starship and sent directly to Mars with five tons of cargo without any Earth-orbit refueling, or 25 tons of cargo with a single tanker refueling.

Mars Landing and Operations

Efficient Design: The Starboat needs five times less propellant than the Starship for landing on Mars and returning to orbit. For comparison, refueling the Starship on Mars requires approximately 600 tons of propellant, while Zubrin’s Mars Direct plan uses vehicles needing only about 120 tons.By a rough estimate, to make the 600 metric tons of propellant required to refuel the Starship once on Mars within a year and a half would require a power source with an average round-the-clock output of 600 kilowatts. A solar array that could do that would cover 60,000 square meters — that’s over 13 football fields in size — and weigh about 240 metric tons. It would require three Starship flights just to deliver such a solar array to Mars, and it would then be a major burden to deploy and maintain. A more practical alternative would be to use nuclear power. We could imagine a plausible reactor design at this power level with a mass of about ten tons.

#163 Re: Meta New Mars » Housekeeping » 2025-09-15 14:45:56

In the Admin, options the ser ver is blank but I do not remember if there was one.

SMTP server address

The address of an external SMTP server to send emails with. You can specify a custom port number if the SMTP server doesn't run on the default port 25 (example: mail.myhost.com:3580). Leave blank to use the local mail program.

still researching

sent other information to you.

AI Overview

PHPMailer is a popular, open-source library for sending emails in PHP applications. It provides a robust and feature-rich way to send emails compared to the native mail() function in PHP, offering support for SMTP, attachments, HTML emails, and more secure handling of email sending.

Key features and uses of PHPMailer:

SMTP Support:

PHPMailer allows sending emails through an SMTP server, which is generally more reliable and secure than using the local mail() function. This is crucial for ensuring email deliverability and avoiding spam filters.

HTML Emails:

It facilitates sending emails with rich HTML content, including images and styling, for a more engaging user experience.

Attachments:

PHPMailer makes it easy to attach files to emails, such as documents, images, or other media.

Authentication and Encryption:

It supports various authentication methods and encryption protocols (SSL/TLS) for secure communication with SMTP servers.

Error Handling:

PHPMailer provides comprehensive error reporting, making it easier to diagnose and troubleshoot issues during email sending.

Flexible Recipient Management:

It allows setting multiple recipients, including CC and BCC, as well as reply-to addresses.

Using PHPMailer in a project typically involves:

Downloading and Including:

.

Obtaining the PHPMailer library (e.g., from GitHub or via Composer) and including the necessary files in your PHP script.

Instantiating PHPMailer:

.

Creating an instance of the PHPMailer class.

Configuring SMTP Settings:

.

Providing details for your SMTP server, including host, port, authentication credentials (username and password), and security settings (SSL/TLS).

Setting Sender and Recipient Information:

.

Specifying the sender's email address and name, as well as the recipient(s).

Composing the Email:

.

Setting the email subject, body (plain text or HTML), and adding any attachments.

Sending the Email:

.

Using the send() method to dispatch the email and handling potential errors.

Troubleshooting PHPMailer issues often involves:

Verifying SMTP server settings: Ensuring the host, port, and authentication details are correct.

Checking network connectivity: Confirming that your server can connect to the SMTP host.

Reviewing error logs: Examining PHPMailer's error messages for clues about the problem.

Consulting documentation and community resources: Referring to the official PHPMailer documentation, GitHub page, and online forums (like Stack Overflow or specific hosting/framework forums) for solutions to common issues.

#164 Re: Meta New Mars » Housekeeping » 2025-09-14 14:48:53

The username and the banned are 2 seperate tables of information.

The usernames are also linked to the user profile table which contains the email and other information.

There are some usernames that should not be removed as these would not follow simple rules.

The list of banned have 490 ish usernames that can be converted if we would desire to remove them from the banned.

The user profiles will need the username changed as well as the email content as well as putting it into the inactive list.

Changing the username to the group to inactive first does not change it from the banned as it remains banned as its the table of control for that user.

I see that poster seemed to be spamming a link of the same for every discusion as to why it got banned.

#165 Re: Science, Technology, and Astronomy » Firefly Launch » 2025-09-13 14:55:34

NASA Confirms Private Spacecraft Successfully Lands on the Moon

NASA’s recent confirmation of Firefly Aerospace’s Blue Ghost Mission 1landing on the Moon signifies a transformative moment in the realm of space exploration. The private American spacecraft successfully touched down near Mons Latreille in Mare Crisium, marking a milestone for NASA and its commercial partners.

Firefly Aerospace’s Blue Ghost 1mission represents not just a significant technological achievement but also an important step toward NASA’s long-term lunar exploration plans. The Blue Ghost spacecraft, launched from Florida in January 2025, touched down on the Moon’s surface after a carefully orchestrated sequence of maneuvers involving a cruise, approach, and powered descent phase. Landing in the Mare Crisium region near Mons Latreille, an area with ancient volcanic significance, this location was chosen for its scientific value, offering insights into lunar crustal chemistry and thermal history.

“This incredible achievement demonstrates how NASA and American companies are leading the way in space exploration for the benefit of all,” said NASA’s acting Administrator Janet Petro. This success is also critical for the development of NASA’s Artemis program, which envisions sustainable exploration of the Moon and beyond. The mission’s instruments, designed to support Artemis objectives, include payloads focused on navigation, lunar dust analysis, heat flow measurement, and other crucial data-gathering technologies.

A key component of Blue Ghost 1’ssuccess lies in NASA’s Commercial Lunar Payload Services (CLPS) model. This initiative enables private companies to carry out lunar deliveries rather than having NASA build and operate every spacecraft themselves. By using competitive task orders and indefinite delivery contracts, NASA is able to reduce costs and expedite technological development. This approach helps spread the risk of failure across multiple flights and encourages rapid innovation in the space sector.

The Blue Ghost mission, being only the second commercial soft landing on the Moon, demonstrates the potential of the CLPS model. This framework allows private companies like Firefly Aerospace to contribute significantly to the broader goals of space exploration while simultaneously improving cost efficiency and speeding up the testing of new technologies. By leveraging private sector expertise and resources, NASA is fostering an ecosystem that can deliver critical hardware and data to the Moon sooner than traditional government-funded missions would allow.

The payloads aboard the Blue Ghost 1 spacecraft carry critical instruments designed to provide data that will advance our understanding of the Moon’s surface and subsurface properties. One of the standout instruments is a subsurface drill capable of penetrating about 10 feet (3 meters) into the lunar surface. This drill is designed to gather important data about the Moon’s thermal gradient and heat flow, which will help refine models of lunar crust thickness and its volcanic history.

Additionally, the spacecraft carried a range of other scientific instruments, including a lunar soil sampler and a magnetotelluric sounder. The sampler is designed to collect lunar regolith (soil) using gas-based methods, which is an energy-efficient alternative to traditional robotic arms with moving parts. This technique could potentially simplify future lunar missions, reducing the need for complex machinery.

One of the most notable payloads is theLunar GNSS Receiver Experiment (LuGRE), which successfully demonstrated that weak GPS and Galileo signals can be acquired and tracked on the Moon’s surface. This could revolutionize navigation during future lunar missions by allowing landers to operate more independently, with less reliance on Earth-based tracking systems. This would be particularly beneficial for smaller lunar missions that don’t have the resources for full-scale tracking systems.

Lunar dust presents one of the most persistent challenges for future lunar missions, as it can cling to equipment, damage moving parts, and even pose risks to astronauts’ health. The Blue Ghost mission’s research into dust behavior focuses on how it interacts with electric fields, particularly near the Moon’s terminator (the line between day and night). During the lunar dawn and dusk, the sunlight at low angles creates electric fields that can lift fine grains of dust, creating a phenomenon that could affect equipment and operations.

In addition to dust research, the thermal properties of the Moon are also a key focus.The Blue Ghost spacecraft’s drill will probe the thermal gradient at depths of several feet, helping scientists better understand heat flow from the Moon’s interior. This data could reveal more about the Moon’s volcanic activity, crustal composition, and overall thermal history.

Furthermore, by analyzing the behavior of the spacecraft’s instruments during the lunar twilight, scientists will gather valuable data that could help refine future designs for lunar rovers, spacesuits, and seals, all of which need to withstand the Moon’s harsh conditions.

The success of Blue Ghost 1is a testament to the growing role that private companies are playing in lunar exploration. NASA’s partnerships with companies like Firefly Aerospace show how public-private collaborations are accelerating the pace of innovation and reducing the costs associated with space missions. As companies gain more experience and repeat flights, they will continue to refine their technology, which in turn will reduce mission costs and shorten timelines.

The Blue Ghost mission not only marks a pivotal achievement for Firefly Aerospace but also contributes to the larger effort to build a sustainable human presence on the Moon. As more private companies enter the space race, they will help create a thriving ecosystem for lunar exploration, making it possible to scale operations more rapidly and efficiently.

#166 Re: Life support systems » Excess Oxygen » 2025-09-13 14:49:26

New liquid air storage system bottles electricity on demand, producing 10 tons daily

Korean researchers have unlocked a new way to bank clean energy and turn it back into power on demand.

Scientists at the Korea Institute of Machinery and Materials (KIMM) have developed Korea’s first homegrown Liquid Air Energy Storage system, which uses surplus electricity to chill air into liquid, store it, and later release it to generate power.

The team recently achieved the production of up to 10 tons of liquid air per day, representing a significant milestone in advancing the technology toward large-scale commercial viability.

Power on demand

When the grid has more electricity than it needs, the surplus is used to cool air to extremely low temperatures until it becomes liquid. This liquid air is stored in insulated tanks like a giant energy reserve.When demand spikes, the air is warmed again. As it rapidly expands about 700 times its liquid volume, the pressure drives turbines to generate electricity.

When demand spikes, the air is warmed again. As it rapidly expands about 700 times its liquid volume, the pressure drives turbines to generate electricity.

Led by Principal Researcher Dr. Jun Young Park, the KIMM team designed two key components entirely in-house.

A turbo expander that spins faster than 100,000 revolutions per minute and a cold box equipped with multi-layer insulation and a powerful vacuum to keep air at cryogenic temperatures.

These innovations enabled Korea’s first successful air liquefaction test for energy storage. It shows that liquid air storage can work using domestic technology.

“This is an essential step for Korea’s renewable future,” said Dr. Park. “Large-scale energy storage is the missing piece and our work shows LAES can deliver it without geographical limits.”

Most large-scale storage today relies on pumped hydro or compressed air. Both can be effective but they require mountains, valleys, or underground caverns. They also come with environmental trade-offs.

Liquid air avoids those problems. It can be built almost anywhere which makes it a flexible option for cities and industrial hubs. It also comes with added benefits. The extreme cold can be tapped for industrial cooling, and waste heat from factories can be reused to make the process more efficient.

A global race

Korea is not the only country chasing this technology. Companies in the UK, China, and the United States are already exploring liquid air as a storage medium. What makes KIMM’s achievement stand out is that it is fully homegrown.That is a critical step for Korea’s plan to build an energy superhighway to carry renewables across the nation.

The current system is modest compared to the country’s power needs. But its successful operation is proof of concept. If scaled up, bottling air could become one of the cleanest and most versatile ways to store renewable energy.

For now, it is still early days. But in a world desperate for long-duration storage, Korea’s breakthrough shows that the future of power might be hiding in plain sight.

#167 Re: Business Proposals » Mechanical Windmills » 2025-09-13 14:41:32

The life of man changed as energy store allowed for constant supply of what we needed. Its that storage that allowed for a change in our behaviour, no longer at the mercy of inconsistancy that solar, wind, even stream or river sourced energy input.

#168 Re: Interplanetary transportation » Concurrent (nested) Habitat rings » 2025-09-13 14:29:37

Nice html and the brackets from the copy paste of the AI outputted page.

#169 Re: Science, Technology, and Astronomy » Coil gun vs Rail gun military and civilian applications » 2025-09-11 17:12:59

#170 Re: Single Stage To Orbit » SSTO History Atlas and other single stage launchers » 2025-09-10 14:52:00

#171 Re: Human missions » Space Initive Launch Vehicle » 2025-09-10 14:45:18

The Space Shuttle That Never Flew: Lockheed’s LS-200

n 1966, the United States Air Force and Lockheed introduced the Star Clipper concept. At the time, it was “an Earth-to-orbit spaceplane based on a large lifting body spacecraft and a wrap-around drop tank.”

After 1966, NASA began a space program that included a permanently manned space station, a small base on the moon, and the hopes of a soon-to-be crewed mission to Mars. This is where the concept of a “logistics vehicle” emerged in order to lower the cost of space station operations. The vehicle’s role would be focused on changing crews on the space station on a weekly basis.

In 1967, a whole-day meeting was arranged to evaluate the logistics vehicle concept. The Air Force and NASA had already joined forces on a study of existing technologies in the “Integrated Launch and Re-entry Vehicle” project, or ILRV. The meeting resurfaced the ILRV research calling on the same industry partners to present different logistics vehicle concepts.

That’s when Lockheed submitted Star Clipper while General Dynamics introduced their Triamese and Chrysler SERV. Soon, NASA’s own teams joined in on the fun supporting mostly the “classic” flyback design.

Then in 1971 something happened that changed everything and brought the Star Clipper to the forefront. The maximum development budget was reduced by 50% by the Office of Management and Budget, going from a whopping $10 billion to a mere $5 billion.

This is when the Star Clipper became the most viable option as the costs for a stage-and-a-half design were much lesser because it involved the engineering of only one spacecraft. Despite this, in the end, it was not Lockheed’s version that would eventually be chosen to be built, but North American Aviation’s take on the concept.

#172 Re: Meta New Mars » GW Johnson Postings and @Exrocketman1 YouTube videos » 2025-09-10 14:19:57

almost sounds like they are just butting the tiles edges to each other rather than using a gap filler material.

#173 Re: Business Proposals » Mechanical Windmills » 2025-09-10 14:14:45

it could also be made to drive pistons for air compressing as well.

#174 Re: Meta New Mars » Housekeeping » 2025-09-10 14:13:46

todays post show in images how its not a single layer of materials in use.