New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#101 Re: Science, Technology, and Astronomy » Building Solar from scratch » 2025-08-17 13:49:53

Here is the really issue in that for embedded energy to make solar panels but this is nt the total answer.

AI Overview

The embodied energy to make solar panels refers to the upfront energy consumed throughout the manufacturing process, from mining raw materials to producing the panels. This energy includes the high-temperature processes needed to refine silicon, as well as energy for manufacturing glass, aluminum frames, and other components. The total energy varies by panel type and manufacturing location, but a 1 kW solar system might have about 2.5 MWh of embodied energy, with the silicon component alone being highly energy-intensive.

Key Factors Affecting Embodied Energy

Silicon Processing:

The production of highly purified silicon, the primary material for most solar panels, is a very energy-intensive process.

Manufacturing Location:

Panels manufactured on grids rich in renewable energy sources have a lower embodied energy and carbon footprint compared to those made on coal-rich grids.

Panel Type:

Thin-film solar cells, such as those made from cadmium telluride (CdTe), can have a lower embodied energy than silicon-based panels.

Balance of System (BOS):

The total energy required for a project includes the energy to manufacture the panel itself (the module) and the energy for other components like inverters and mounting structures.

Measuring the Energy Footprint

Energy Payback Time (EPBT):

.

This metric shows how long a solar panel must operate to generate the same amount of energy that was used to produce it. Modern solar panels have a relatively short EPBT, meaning they quickly "pay back" their initial energy investment.

Life Cycle Assessment (LCA):

.

This is a comprehensive tool used to assess the total embodied energy and carbon emissions of a product over its entire life cycle.

Trends and Innovations

Grid Decarbonization:

As more renewable energy enters the grid, especially where panels are manufactured, the embodied energy of solar panels decreases.

Alternative Materials:

Research into thin-film technologies and materials like those derived from food waste aims to reduce energy consumption and carbon emissions in solar panel production.

#102 Re: Human missions » Going Solar...the best solution for Mars. » 2025-08-17 13:35:43

Here is the really issue in that for embedded energy to make solar panels but this is nt the total answer.

AI Overview

The embodied energy to make solar panels refers to the upfront energy consumed throughout the manufacturing process, from mining raw materials to producing the panels. This energy includes the high-temperature processes needed to refine silicon, as well as energy for manufacturing glass, aluminum frames, and other components. The total energy varies by panel type and manufacturing location, but a 1 kW solar system might have about 2.5 MWh of embodied energy, with the silicon component alone being highly energy-intensive.

Key Factors Affecting Embodied Energy

Silicon Processing:

The production of highly purified silicon, the primary material for most solar panels, is a very energy-intensive process.

Manufacturing Location:

Panels manufactured on grids rich in renewable energy sources have a lower embodied energy and carbon footprint compared to those made on coal-rich grids.

Panel Type:

Thin-film solar cells, such as those made from cadmium telluride (CdTe), can have a lower embodied energy than silicon-based panels.

Balance of System (BOS):

The total energy required for a project includes the energy to manufacture the panel itself (the module) and the energy for other components like inverters and mounting structures.

Measuring the Energy Footprint

Energy Payback Time (EPBT):

.

This metric shows how long a solar panel must operate to generate the same amount of energy that was used to produce it. Modern solar panels have a relatively short EPBT, meaning they quickly "pay back" their initial energy investment.

Life Cycle Assessment (LCA):

.

This is a comprehensive tool used to assess the total embodied energy and carbon emissions of a product over its entire life cycle.

Trends and Innovations

Grid Decarbonization:

As more renewable energy enters the grid, especially where panels are manufactured, the embodied energy of solar panels decreases.

Alternative Materials:

Research into thin-film technologies and materials like those derived from food waste aims to reduce energy consumption and carbon emissions in solar panel production.

#103 Re: Single Stage To Orbit » A SSTO research project. » 2025-08-13 15:16:07

AI Overview

My 2nd SSTO. How can I give it more delta V when it reaches ...

A Single-Stage-To-Orbit (SSTO) vehicle's payload fraction, the ratio of payload mass to initial mass at liftoff, is a critical factor for its viability. While SSTOs aim for a high payload fraction, achieving a truly competitive one is challenging, often requiring advanced technologies. Typical payload fractions for SSTO vehicles range from 1% to 5%, with some advanced designs potentially reaching 10% or even higher.

Factors Influencing SSTO Payload Fraction:

Propellant Fraction:

.

A large portion of an SSTO's mass is dedicated to propellant. High specific impulse (Isp) engines are crucial for reducing the required propellant mass, but even with high Isp, the propellant fraction can still be significant.

Inert Mass Fraction:

.

This refers to the mass of the vehicle structure, engines, and other non-propellant components. Reducing the inert mass fraction is vital for increasing the payload fraction.

Engine Technology:

.

Advanced engine technologies, like air-breathing engines, offer potential for higher Isp and reduced propellant needs, but they also come with their own set of engineering challenges.

Launch Altitude:

.

Launching from a high altitude can significantly improve performance, reducing atmospheric drag and allowing for higher engine performance, which can translate to a higher payload fraction.

Vehicle Design:

.

The overall design of the SSTO vehicle, including its aerodynamics and structure, plays a crucial role in maximizing payload fraction.

Examples and Considerations:

Reusable SSTOs:

.

Reusable SSTOs face the challenge of balancing reusability with low inert mass. The need for robust structures to withstand multiple flights can make it difficult to achieve high payload fractions.

Expendable SSTOs:

.

Expendable SSTOs, where the vehicle is not recovered, can achieve higher payload fractions due to lower structural requirements, but at the cost of reusability.

Air-Breathing Engines:

.

Air-breathing engines, which utilize atmospheric oxygen, offer the potential for significant performance gains, but they are complex and require significant technological development.

Nuclear Propulsion:

.

Nuclear thermal or nuclear electric propulsion systems offer the potential for very high Isp, which could drastically improve SSTO payload fractions, but they present their own set of challenges and safety concerns.

In essence, while achieving a high payload fraction for an SSTO vehicle is difficult, it is a key factor in determining its economic viability. Advanced technologies and careful design are necessary to push the payload fraction to levels that make SSTOs truly competitive with traditional multi-stage rockets

#104 Re: Single Stage To Orbit » The Space Plane Corporation » 2025-08-13 15:11:53

Take off from a runway search

AI Overview

Determining the precise runway launch length for a hypothetical "space plane" or future runway-launched spacecraft is complex, as it depends heavily on the specific design, weight, and desired flight profile of the vehicle.

However, we can look at existing and proposed spaceplane systems and their runway requirements for landing, which can provide insights into potential launch needs:

Space Shuttle: The Space Shuttle orbiters landed on a 15,000-foot (4,572-meter) concrete runway at the Kennedy Space Center (SLF), according to NASA.gov. While the Shuttle launched vertically, this demonstrates the significant runway length required for landing a vehicle returning from space at high speeds.

Stratolaunch: This aircraft, designed to air-launch rockets carrying spacecraft, requires a 12,000-foot (3,700-meter) runway for takeoff.

Radian One: This proposed spaceplane aims to take off horizontally from a runway and fly directly into orbit. While the exact runway length needed is still under development, a Futurism article suggests it will utilize a rocket-powered sled for initial acceleration.

Virgin Galactic's SpaceShipTwo: This suborbital spaceplane takes off on a 2-mile (approximately 10,500 feet or 3,200 meters) runway, attached to a carrier aircraft, before being released at altitude to proceed under its own power.

In conclusion, while there isn't a universally standardized runway launch length for spaceplanes, based on existing and proposed systems, it's evident that runways in the range of 10,000 to 15,000 feet (approximately 3 to 4.6 kilometers) or longer would be necessary to accommodate future spaceplanes designed for horizontal takeoff, and even longer runways or additional launch assistance might be needed for orbital launches. This is considerably longer than the runways required for typical commercial aircraft, which generally fall within the 1,500 to 3,000 meter range.

#105 Re: Planetary transportation » Shutterbugs Shoot 'Scarecrow' » 2025-08-13 15:06:48

Reading the topic did remind me.

AI Overview

Mock Mars Rover Takes Desert Test Drive | Space

The "Scarecrow" rover is a testbed for NASA's Curiosity Mars rover. It's a full-scale replica of Curiosity, but stripped down and without an onboard computer, allowing engineers to test its mobility and suspension performance in a Mars-like environment without the risk to the actual rover. It's designed to weigh the same on Earth as Curiosity weighs on Mars, accounting for the difference in gravity.

Here's a more detailed explanation:

Purpose:

Scarecrow is used to evaluate the rover's mobility and suspension system. This includes testing its ability to climb slopes, traverse different types of terrain, and handle various driving conditions.

Design:

It's a full-scale replica of the Curiosity rover, but without the complex computer brain. This makes it lighter and allows engineers to focus solely on the mechanical aspects of mobility.

Weight:

Scarecrow is designed to weigh the same on Earth as Curiosity weighs on Mars. This is crucial for accurately simulating how Curiosity will behave in the Martian environment.

Testing Location:

Scarecrow is tested in the Mars Yard at NASA's Jet Propulsion Laboratory (JPL), a simulated Martian landscape that includes rocks, slopes, and other obstacles.

Benefits:

By testing with Scarecrow, engineers can identify potential problems and refine the rover's driving capabilities before sending it to Mars, minimizing risks to the actual Curiosity rover.

Example:

In one instance, Scarecrow was used to test a new traction control algorithm designed to reduce wheel wear on the Mars Curiosity rove

#106 Re: Meta New Mars » Scarecrow Postings » 2025-08-13 15:04:22

Hopefully Scarecrow will make an impact with this memebership.

#107 Re: Meta New Mars » Housekeeping » 2025-08-13 15:03:06

Good that decision to create as fresh an acount as possible. I did look at my email to see if I remembered the user but did not. Hopefully this new memeber will join in.

#108 Re: Meta New Mars » Housekeeping » 2025-08-11 17:20:33

What was the username?

As for the fuel tank they are of different configuration. Also anything smaller than an ISS module is not practical.

#109 Re: Terraformation » Exponential Growth of Solar Powered Industry » 2025-08-09 16:00:23

Depends on the type of panel and materials in metals that are needed.

AI Overview

Do we have enough silver, copper, and other materials to ...

Solar panels require several types of metals for construction, including aluminum, steel, copper, and silver. Aluminum and steel are often used for the frames and support structures, while copper and silver are crucial for wiring and electrical contacts within the solar cells. Additionally, minor metals like indium, gallium, and tellurium are used in specific types of solar cells.

Here's a more detailed breakdown:

Aluminum:

Used for the frame that holds the solar panel together, providing a lightweight yet durable structure. It is also sometimes used for wiring.

Steel:

Often used in conjunction with aluminum for the support structure or racking system of the solar panel.

Copper:

Essential for wiring and electrical connections within the solar panel and the overall solar array.

Silver:

A key component in the conductive layer of solar cells, facilitating the flow of electricity.

Zinc:

May be used in the solar panel's construction, although its specific role varies.

Minor Metals:

Indium, Gallium, Selenium, Tellurium: These are used in certain types of thin-film solar cells like CIGS (Copper Indium Gallium Selenide) and Cadmium Telluride (CdTe) solar panels.

Cadmium: Used in CdTe solar panels.

Silicon: The most common material for solar cells, formed into wafers and used as a semiconductor to convert sunlight into electricity.

Other Materials:

Glass: Typically used to protect the solar cells from the elements and provide a transparent surface for sunlight to pass through.

Ethylene tetrafluoroethylene (ETFE): A polymer material used in some solar panel designs as a transparent encapsulant.

Nickel: While not directly involved in energy conversion, nickel may be used in plating for corrosion resistance or in the support structures.

Tin: Used to protect contact layers and prevent corrosion

#110 Re: Human missions » Starship is Go... » 2025-08-07 14:41:48

Saw a youtube video that indicate that they are for the block 2 of starship that is going to be 10M taller.

AI Overview

Evolution of the Raptor engine, by @cstanley : r/SpaceXLounge

SpaceX's Raptor 3 is an upgraded version of the Raptor rocket engine, boasting increased thrust, higher efficiency, and a simplified design compared to its predecessors. It eliminates the need for an external heat shield by utilizing a secondary cooling loop and is lighter and more powerful, enabling Starship to carry heavier payloads.

Here's a more detailed breakdown:

Key Improvements:

Increased Thrust:

Raptor 3 delivers significantly more thrust than previous versions. For example, it produces 280 tons of thrust at sea level, a 21% increase over Raptor 2.

Higher Efficiency:

The engine features a higher combustion chamber pressure and improved fuel efficiency, enhancing its overall performance.

Simplified Design:

Raptor 3 incorporates a more streamlined design with fewer components, including the elimination of the external heat shield and the integration of secondary piping and electronics into the engine structure.

Weight Reduction:

The simplified design and removal of the heat shield contribute to a significant weight reduction, with Raptor 3 being lighter than both Raptor 1 and 2.

Enhanced Durability:

The engine is designed for 1,000 flights with minimal maintenance and utilizes welded joints for increased strength and reduced potential for leaks.

More Payload Capacity:

The lighter weight and increased thrust of Raptor 3 allow Starship to carry a greater payload mass to orbit.

Key Features:

Full Flow Staged Combustion Cycle:

This advanced cycle maximizes efficiency and performance.

Liquid Oxygen and Methane Propellants:

These propellants enable cleaner burning and potential in-situ resource utilization on Mars.

Regenerative Cooling:

The engine uses a secondary cooling loop to manage extreme temperatures and pressures, eliminating the need for a heat shield.

Welded Joints:

Welded joints replace screws, bolts, and flanges in many areas, improving structural integrity and streamlining production.

Impact:

Enabling Deeper Space Exploration:

.

The improvements in Raptor 3 are crucial for SpaceX's ambitious goals of establishing a self-sustaining civilization on Mars.

Advancing Rocket Engine Technology:

.

The Raptor 3 engine represents a significant step forward in rocket engine design and manufacturing.

Increasing Launch Efficiency:

.

The engine's increased thrust, reduced weight, and higher efficiency translate to greater payload capacity and lower launch costs

#111 Re: Science, Technology, and Astronomy » Invelox Wind Turbine » 2025-08-07 14:39:06

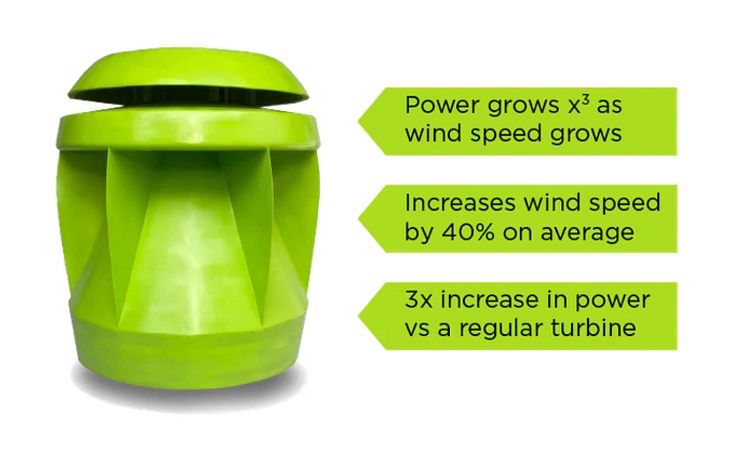

I have seen another that is simular.  Is this the ‘safest, most powerful wind turbine in the world’?

Is this the ‘safest, most powerful wind turbine in the world’?

#112 Re: Meta New Mars » Housekeeping » 2025-08-07 14:35:09

You can also find the post in GW Johnson Postings and @Exrocketman1 YouTube videos

#113 Re: Single Stage To Orbit » The Space Plane Corporation » 2025-08-06 14:38:35

For PhotonBytes...

GW is working on a spreadsheet to calculate a complete SSTO design.

The prototype has run through scenarios with LH2, methane and RP1.

He is looking for ** real ** data on two specifics and perhaps your company can help:

a) mounts for engines which do NOT gimbal

b) mounts for engines with gimbal

3) plumbing to carry fluids from tanks to enginesThe spreadsheet depends upon real data to produce reasonable results.

(th)

These question have been looked up for the Delta rocket and Atlas family of rockets

#114 Re: Meta New Mars » GW Johnson Postings and @Exrocketman1 YouTube videos » 2025-08-06 14:36:41

AI Overview

Determining the precise gimbal mass for each engine in the Atlas family of rockets is challenging as manufacturers generally don't publicize such specific breakdowns.

Overall engine dry masses can be examined to understand the gimbal systems' contribution to these values:

Atlas V Engines

The RD-180 engine, used on the Atlas V first stage, has a dry mass of approximately 12,000 lbs (about 5,443 kg). It has two thrust chambers that can gimbal independently for pitch, yaw, and roll control, according to Space Exploration Stack Exchange.

The RL10 engine family, used on the Atlas V's Centaur upper stage, has dry masses ranging from 289 to 699 lbs (131 to 317 kg), depending on the specific version. The RL10 also utilizes gimbaling for thrust vector control, with the engines typically able to gimbal up to ±4 degrees.

RL10 Gimbaling System

Early versions of the RL10 engine, such as the RL10A-3-3A, employed a gimbaling system for flight control, allowing for pitch and yaw steering.

Later versions, like the RL10B-2, featured electro-mechanical gimbaling for improved performance and reliability.

In summary, although the specific gimbal masses are not readily available, the engines (RD-180 and RL10) used in the Atlas family are equipped with sophisticated gimbaling systems vital for controlling the rocket's trajectory

AI Overview

Detailed specifications regarding the exact mass of the engine mount structure for the Atlas family of rockets are not readily available in publicly accessible documents.

Some information about related masses is available:

The Atlas I first stage had a booster section with a dry mass of 3,646 kg.

The Atlas II first stage's booster section had a dry mass of 4,187 kg.

The Atlas V Common Core Booster has a dry mass of 20,743 kg (or 21,173 kg for the 55X configuration), which includes the engine and the surrounding structure.

These figures likely include more than just the engine mount itself, encompassing other components of the booster stage structure.

The purpose of the engine mount in the Atlas rockets is crucial for:

Securing the engine during launch and flight.

Aligning the thrust for stable flight.

Providing structural support by connecting the engine to the rocket's airframe and pylon.

Detailed engineering schematics and specific design documents may be needed to find the exact mass of the engine mount structure

AI Overview

Estimating the precise mass of the fuel plumbing specifically within the Atlas family of rocket engines is challenging because this information is not typically broken out as a separate metric in the available documentation.

The overall dry mass of the engines and components can offer insight into the scale involved:

Atlas I Stage 1 (MA-5 propulsion system): Dry mass is 7,882 kg, including a 3,646 kg booster section.

Atlas II Stage 1 (MA-5A): Dry mass is 10,282 kg, with a 4,187 kg booster section.

Centaur Upper Stage: Dry masses range from 1,700 kg to 2,053 kg depending on the variant (e.g., Centaur (Atlas Version), Atlas II Stage 2, Atlas IIA Stage 2).

RD-180 (Atlas III and Atlas V first stage): Dry mass is 5,480 kg.

Atlas V Common Core Booster (CCB): Dry mass is 20,743 kg (or 21,173 kg for the 55X configuration).

Important Considerations:

Engine Plumbing is Integrated: Fuel plumbing is an integral part of the engine and booster assembly, including the turbopumps, fuel lines, valves, and other related components.

Material and Design: Materials like aluminum-lithium skin/stringer and frame for the Atlas III first stage can impact overall weight.

Staged Combustion Cycle: Engines like the RD-180 employ complex plumbing for their high-pressure, staged combustion cycle, which requires an oxidizer-rich preburner and intricate pathways for fuel and oxidizer.

Multiple-Burn Capability: Upper stages like the Centaur with restartable engines have additional plumbing for multiple ignitions and propellant management.

Mass Optimization: Engine designers focus on minimizing the overall mass of the engine systems to maximize the rocket's payload capacity.

Although a definitive number for fuel plumbing mass is not readily available, the figures above provide a general idea of the overall dry mass of the Atlas family's engine components, which includes the plumbing systems.

#115 Re: Meta New Mars » GW Johnson Postings and @Exrocketman1 YouTube videos » 2025-08-06 14:30:53

AI Overview

The Delta rocket family utilizes gimbaled engines to steer the vehicle during launch. The mass of the gimbal mechanism varies depending on the specific engine and rocket configuration, but it generally contributes a small percentage to the overall vehicle mass, typically around 0.1% to 0.5%. The RS-68A engine on the Delta IV Heavy, for example, has a gimbal system that allows for thrust vectoring, enabling the rocket to steer during ascent. While the exact mass contribution of the gimbal mechanism to the RS-68A engine isn't explicitly stated, it's a relatively small fraction of the engine's overall mass.

Here's a more detailed breakdown:

Delta IV Heavy:

The Delta IV Heavy uses three RS-68A engines, each capable of producing 2.1 million pounds of thrust. The RS-68A is a gimbaled engine, allowing for thrust vectoring for steering.

Engine Mass:

The RS-68A is a large engine, and the gimbal mechanism is a relatively small part of its overall mass. The RL10B, used on the Delta IV upper stage, has a mass of 664 lbs and includes a large carbon-carbon nozzle extension.

Gimbal Contribution:

Studies and examples suggest that gimbals typically contribute between 0.1% and 0.5% to the total launch mass. For example, in the case of the Antares 100 rocket, gimbals on the NK-33 engines contributed about 0.16% of the liftoff mass.

Delta II:

The Delta II used the RS-27 engine, and later the upgraded RS-27A, which also employed a gimbaled system for steering. The RS-27A produced 1,054 kN (237,000 lbf) of thrust.

Other Factors:

The mass of the gimbal mechanism can also be influenced by factors such as the size and complexity of the actuators, hydraulic systems, and other associated components

AI Overview

Delta family of rockets: engine mount mass

Determining the exact mass of engine mounts within the Delta family of rockets can be difficult because the manufacturer often considers this information proprietary, and rarely discloses it as a separate component. However, related data can be analyzed to infer some insights into their mass:

1. Engine dry mass

Delta IV RS-68 Engine: The RS-68 engine used in the Delta IV Common Booster Core has a dry mass of 6,604 kg.

Delta RS-27A Engine: The RS-27A engine used in the 7000 and 8000 series Delta rockets has a dry mass of 1,091 kg.

Delta II RS-27A Engine: The RS-27A engine featured in the Delta II rocket has a dry mass of 1,146 kg.

Delta IV RL10B-2 Engine: The RL10B-2 engine utilized in the Delta IV's second stage has a dry mass of 301 kg.

2. Structural considerations

Engine mounts, along with other structural components like the motor cases, are designed to withstand the extreme forces and vibrations generated during launch and flight.

Material selection for these components is crucial and includes high-strength options such as steel, aluminum, and alloys like Inconel and Titanium.

3. Comparison with overall vehicle mass

The engine dry mass represents a relatively small fraction of the overall mass of a Delta rocket. For example, the Delta IV Heavy has a total launch mass of 733,400 kg.

Even when considering the mass of the engine mount alongside the engine's dry mass, it would still be a minor portion of the rocket's overall weight.

4. Other types of engine mounts

Smaller-scale model rockets utilize simpler engine mount designs. These use materials like cardboard, phenolic resin, or fiberglass, with associated mass implications.

Important Note: The engine mounts are integral to the rocket's structure, designed to safely contain forces and maintain trajectory during flight. While the precise mass might not be publicly available, the information above helps to understand the scope and scale of this critical component

AI Overview

Detailed public information on the specific mass of the fuel plumbing within the Delta IV rocket family is limited in the provided search results. However, the available information provides insights into the fuel systems and related components, allowing for some inferences.

The Delta IV family of rockets utilized liquid hydrogen and liquid oxygen (LH2/LOX) as propellants for both its first stage (Common Booster Core - CBC) and second stage (Delta Cryogenic Second Stage - DCSS). The fuel plumbing would be a critical part of delivering these propellants from the tanks to the engines.

The search results offer information about the Delta IV's fuel systems and their components:

CBC Construction: The CBC includes isogrid aluminum barrels, spun-formed aluminum domes, machined aluminum tank skirts, and a composite centerbody. A cable tunnel carries electrical and signal lines, along with a feedline for liquid oxygen to the RS-68 engine. This indicates fuel plumbing within the structure.

DCSS Construction: The DCSS also uses isogrid aluminum ring forgings, spun-formed aluminum domes, machined aluminum tank skirts, and a composite intertank truss.

Engine Connections: The RS-68 engine on the CBC connects to the thrust structure via a quadrapod thrust frame and is enclosed in a composite conical thermal shield.

RL10B-2 Engine: The RL10B-2 engine, used in the DCSS, weighs 664 lbs. This weight likely includes internal plumbing but doesn't specify the plumbing mass.

Simplified Design: The RS-68 engine was designed for simplified construction, with a lower chamber pressure, efficiency, and a simpler nozzle than the Space Shuttle Main Engine (SSME). It has fewer parts than the SSME and a simpler nozzle. This might suggest a less complex (and potentially lighter) plumbing system for the engine, but it does not specify the mass of the entire fuel delivery system.

Although the exact mass of the fuel plumbing is unavailable, it is a key component constructed with materials like aluminum alloys and composites. The focus on reduced weight in components like the isogrid tanks suggests an effort to optimize the rocket's overall mass.

Additional points:

The Delta IV Heavy, with three Common Booster Cores, has a larger fuel plumbing system than other Delta IV variants.

In conclusion, although the exact mass of the fuel plumbing is not disclosed, it is an integral part of the Delta IV rocket family's structure and performance, designed with weight and reliability in mind.

As you can see most are not forth coming with all dtails but if you know enough of the dry mass of select parts you can ball park the others.

#116 Re: Human missions » Whither the ISS? » 2025-08-05 16:37:59

The plan is flawed as its basing life of modules not with reality. Not to mention US modules are more robust and have been looked into for partners from the commercial industy.

AI Overview

NASA selects Axiom Space to build commercial space station ...

Yes, there is increasing commercial use of the International Space Station (ISS), including the attachment of commercial modules built by companies like Axiom Space. NASA is actively encouraging this, aiming to foster a low-Earth orbit economy and eventually transition to commercial space stations.

Here's a more detailed look:

Axiom Space's Module:

Axiom Space is developing a commercial module that will be attached to the ISS, with the goal of eventually becoming an independent commercial space station.

NASA's Support:

NASA is actively supporting the development of commercial space stations, including providing access to the ISS for these ventures.

Commercial Activities:

NASA is allowing commercial activities, including manufacturing, production, and marketing, in the USG (United States Government) modules of the ISS.

Commercial LEO Destinations (CLD) Program:

NASA has a program, CLD, to support the development of commercial space stations, with Axiom Space being a key player.

Future of LEO:

The goal is to transition from the ISS to a more commercially driven space environment in low-Earth orbit (LEO), with the ISS eventually being retired

#117 Re: Not So Free Chat » slavery - why does it still exist? » 2025-08-05 16:34:12

Wages do not go down ith robotics and actually climb due to requirement as they are not dumb button pushers. You need techinical skills, programing and industrial engineers for what was just hands.

#118 Re: Science, Technology, and Astronomy » Google Meet Collaboration - Meetings Plus Followup Discussion » 2025-08-05 16:26:53

As you can see most are not forth coming with all dtails but if you know enough of the dry mass of select parts you can ball park the others.

#119 Re: Science, Technology, and Astronomy » Google Meet Collaboration - Meetings Plus Followup Discussion » 2025-08-05 16:25:28

AI Overview

Detailed public information on the specific mass of the fuel plumbing within the Delta IV rocket family is limited in the provided search results. However, the available information provides insights into the fuel systems and related components, allowing for some inferences.

The Delta IV family of rockets utilized liquid hydrogen and liquid oxygen (LH2/LOX) as propellants for both its first stage (Common Booster Core - CBC) and second stage (Delta Cryogenic Second Stage - DCSS). The fuel plumbing would be a critical part of delivering these propellants from the tanks to the engines.

The search results offer information about the Delta IV's fuel systems and their components:

CBC Construction: The CBC includes isogrid aluminum barrels, spun-formed aluminum domes, machined aluminum tank skirts, and a composite centerbody. A cable tunnel carries electrical and signal lines, along with a feedline for liquid oxygen to the RS-68 engine. This indicates fuel plumbing within the structure.

DCSS Construction: The DCSS also uses isogrid aluminum ring forgings, spun-formed aluminum domes, machined aluminum tank skirts, and a composite intertank truss.

Engine Connections: The RS-68 engine on the CBC connects to the thrust structure via a quadrapod thrust frame and is enclosed in a composite conical thermal shield.

RL10B-2 Engine: The RL10B-2 engine, used in the DCSS, weighs 664 lbs. This weight likely includes internal plumbing but doesn't specify the plumbing mass.

Simplified Design: The RS-68 engine was designed for simplified construction, with a lower chamber pressure, efficiency, and a simpler nozzle than the Space Shuttle Main Engine (SSME). It has fewer parts than the SSME and a simpler nozzle. This might suggest a less complex (and potentially lighter) plumbing system for the engine, but it does not specify the mass of the entire fuel delivery system.

Although the exact mass of the fuel plumbing is unavailable, it is a key component constructed with materials like aluminum alloys and composites. The focus on reduced weight in components like the isogrid tanks suggests an effort to optimize the rocket's overall mass.

Additional points:

The Delta IV Heavy, with three Common Booster Cores, has a larger fuel plumbing system than other Delta IV variants.

In conclusion, although the exact mass of the fuel plumbing is not disclosed, it is an integral part of the Delta IV rocket family's structure and performance, designed with weight and reliability in mind.

#120 Re: Science, Technology, and Astronomy » Google Meet Collaboration - Meetings Plus Followup Discussion » 2025-08-05 16:24:14

AI Overview

Delta family of rockets: engine mount mass

Determining the exact mass of engine mounts within the Delta family of rockets can be difficult because the manufacturer often considers this information proprietary, and rarely discloses it as a separate component. However, related data can be analyzed to infer some insights into their mass:

1. Engine dry mass

Delta IV RS-68 Engine: The RS-68 engine used in the Delta IV Common Booster Core has a dry mass of 6,604 kg.

Delta RS-27A Engine: The RS-27A engine used in the 7000 and 8000 series Delta rockets has a dry mass of 1,091 kg.

Delta II RS-27A Engine: The RS-27A engine featured in the Delta II rocket has a dry mass of 1,146 kg.

Delta IV RL10B-2 Engine: The RL10B-2 engine utilized in the Delta IV's second stage has a dry mass of 301 kg.

2. Structural considerations

Engine mounts, along with other structural components like the motor cases, are designed to withstand the extreme forces and vibrations generated during launch and flight.

Material selection for these components is crucial and includes high-strength options such as steel, aluminum, and alloys like Inconel and Titanium.

3. Comparison with overall vehicle mass

The engine dry mass represents a relatively small fraction of the overall mass of a Delta rocket. For example, the Delta IV Heavy has a total launch mass of 733,400 kg.

Even when considering the mass of the engine mount alongside the engine's dry mass, it would still be a minor portion of the rocket's overall weight.

4. Other types of engine mounts

Smaller-scale model rockets utilize simpler engine mount designs. These use materials like cardboard, phenolic resin, or fiberglass, with associated mass implications.

Important Note: The engine mounts are integral to the rocket's structure, designed to safely contain forces and maintain trajectory during flight. While the precise mass might not be publicly available, the information above helps to understand the scope and scale of this critical component

#121 Re: Science, Technology, and Astronomy » Google Meet Collaboration - Meetings Plus Followup Discussion » 2025-08-05 16:20:38

AI Overview

The Delta rocket family utilizes gimbaled engines to steer the vehicle during launch. The mass of the gimbal mechanism varies depending on the specific engine and rocket configuration, but it generally contributes a small percentage to the overall vehicle mass, typically around 0.1% to 0.5%. The RS-68A engine on the Delta IV Heavy, for example, has a gimbal system that allows for thrust vectoring, enabling the rocket to steer during ascent. While the exact mass contribution of the gimbal mechanism to the RS-68A engine isn't explicitly stated, it's a relatively small fraction of the engine's overall mass.

Here's a more detailed breakdown:

Delta IV Heavy:

The Delta IV Heavy uses three RS-68A engines, each capable of producing 2.1 million pounds of thrust. The RS-68A is a gimbaled engine, allowing for thrust vectoring for steering.

Engine Mass:

The RS-68A is a large engine, and the gimbal mechanism is a relatively small part of its overall mass. The RL10B, used on the Delta IV upper stage, has a mass of 664 lbs and includes a large carbon-carbon nozzle extension.

Gimbal Contribution:

Studies and examples suggest that gimbals typically contribute between 0.1% and 0.5% to the total launch mass. For example, in the case of the Antares 100 rocket, gimbals on the NK-33 engines contributed about 0.16% of the liftoff mass.

Delta II:

The Delta II used the RS-27 engine, and later the upgraded RS-27A, which also employed a gimbaled system for steering. The RS-27A produced 1,054 kN (237,000 lbf) of thrust.

Other Factors:

The mass of the gimbal mechanism can also be influenced by factors such as the size and complexity of the actuators, hydraulic systems, and other associated components

#123 Re: Not So Free Chat » Oil, Peak Oil, etc. » 2025-08-03 18:03:02

Also how hot they get also drops the power output of the panels, other such things as dust settling on them as well.

#124 Re: Not So Free Chat » slavery - why does it still exist? » 2025-08-03 17:58:20

Labor rates for each state means that we have already lost control. That buying power in each have become unequal more so over the range of earnings.

AI Overview

Minimum Wage Rate by State in the U.S. [2025]

In Massachusetts, the standard minimum wage is $15.00 per hour. For tipped employees, the minimum wage is $6.75 per hour, but if their total earnings (including tips) do not reach $15.00 per hour, the employer must make up the difference, according to Mass.gov.

Key points about Massachusetts minimum wage:

Standard Minimum Wage: $15.00 per hour.

Tipped Employees: $6.75 per hour (with tips bringing the total to at least $15.00).

Overtime: Requires payment of 1.5 times the regular wage for hours exceeding 40 per workweek.

Meal Breaks: Employees working at least six consecutive hours must receive a 30-minute uninterrupted meal break.

Wage Deductions: Employers can only make deductions required by law or authorized in writing

Breakdown of minimum wage by state

State Current Minimum Wage Wage Increase Timeline

Alabama none

Alaska $10.34

American Samoa varies

Arizona $12.15

Arkansas $11.00

California $13.00 Increase by $1 per year for two years until $15

Colorado $12.32

Connecticut $12.00 Increase by $1 per year for three years until $15

Delaware $9.25

D.C. $15.00

Florida $8.65

Georgia $7.25

Guam $8.75

Hawaii $10.10

Idaho $7.25

Illinois $11.00 Increase by $1 per year until for five years $15

Indiana $7.25

Iowa $7.25

Kansas $7.25

Kentucky $7.25

Louisiana none

Maine $12.15

Maryland $11.75 $15 effective January 2025

Massachusetts $13.50 $15 effective January 2023

Michigan $9.65 Increase by $0.23 per year until it reaches $12.05 in 2030

Minnesota $10.00/$8.15

Mississippi none

Missouri $10.30 $12 effective January 2023

Montana $8.75

Nebraska $9

Nevada $9.00/$8.00 $12.00/$11.00 effective July 2024

New Hampshire $7.25

New Jersey $12.00 $15 effective January 2024

New Mexico $10.50 $12.00 effective January 2023

New York $12.50 Rate adjusted annually for inflation until $15.00

North Carolina $7.25

North Dakota $7.25

Northern Mariana Islands $7.25

Ohio $8.80/$7.25

Oklahoma $7.25/$2

Oregon $12.00 $13.50 effective July 2022

Pennsylvania $7.25

Puerto Rico $7.25/$5.08

Rhode Island $11.50

South Carolina none

South Dakota $9.45

Tennessee none

Texas $7.25

Utah $7.25

Vermont $11.75

Virgin Islands $10.50

Virginia $7.25

Washington $13.69

West Virginia $8.75

Wisconsin $7.25

Wyoming $7.25

#125 Re: Meta New Mars » Housekeeping » 2025-08-03 17:40:45

Ok as I had forgotten since its been so long.

The Dr in the ER both women did quite a work up to set the stage of treatment for a stroke with ctscan, followed hours later with the MRI to rule it out. The 2 Men Dr's both waited to see results of MRI saying that I did not have a stroke. How wrong they were as the face slid aka Bells palsy which is a form of stroke but the real issue is the hearing on that side was a total lose. Which is a Ear stroke to which medications given where spot on for strokes of both types. I still have some balance issues and no gains on hearing in the left ear still which could gradually come back overnthe next year maybe.