New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#51 Re: Terraformation » Electrostatic atmospheric confinement » 2025-08-14 13:30:45

It turns out that magnetic fields have little effect on the atmospheric loss rate for terrestrial planets.

https://www.aanda.org/articles/aa/full_ … 34-18.html

Magnetic fields trap charged particles and may reduce the rate of escape close to the equator. But the open field lines close to the poles can have the opposite effect. So magnetic confinement of an atmosphere is unlikely to be successful.

#52 Re: Not So Free Chat » Oil, Peak Oil, etc. » 2025-08-13 04:10:03

Spaniard, I searched the internet and found a copy of Hall and Pietro's EROI analysis free to download here.

https://libgen.li/edition.php?id=136738520

Maybe you can find holes in their analysis?

#53 Re: Not So Free Chat » Oil, Peak Oil, etc. » 2025-08-11 15:15:20

Spaniard, It would take me hours to answer every detail in this ridiculous word salad. I don't have it to spare. It is a mixture of denial, wishful thinking and ignorance of physics and engineering.

Hall and Pietro estimated the EROI of Spain's solar PV industry to be 2.45:1. An EROI of 10:1 is about the minimum that an industrial society can work with. Without that level of surplus energy, there just isn't enough left over for an economy to function. It was only possible to build these plants in the first place because fossil fuels are available to manufacture, transport and install every part of it. And the wealth to pay for it is generated by a fossil fuel powered economy. Since Hall & Pietro published their work, most of the solar supply chain has shifted to the western provinces of China. This will push EROI down further. But the cheapness of coal and forced labour, have allowed modules to be produced and sold at attractive prices. It just isn't a practice that can continue for much longer. A low system EROI tells us that this energy source is not sustainable when cheap fossil fuels are removed from its manufacture.

You talk about using various different types of storage to manage the problem of intermittency. Energy storage has significant embodied energy of its own. There are also losses in storage. And adding storage means adding complexity. All of this degrades the EROI of the energy source, increases cost and adds vulnerability. Without a complete analysis, you really aren't in a position to be able to tell us that these problems can be overcome.

You mention hydrogen as an energy storage technology. In principle, it all sounds very simple. Use electrolysis when power is abundant and store hydrogen in a gasometer tank. A combined cycle gas turbine can then convert the hydrogen back into electric power at 60% efficiency. But electrolysis stacks are very expensive. Using them only intermittently results in a high marginal capital cost for each kWh stored in H2. And of course the cost of the hydrogen depends on the cost of electricity needed to produce it. Hydrogen has low density and a low energy density, unless it is either liquefied or compressed to very high pressures. Even with generous assumptions, less than half of the input electricity into such a system can be recovered. Collectively, these problems have resulted in most hydrogen projects being abandoned. It just isn't a good option for storing electrical energy to turn back into electrical energy.

#54 Re: Not So Free Chat » Oil, Peak Oil, etc. » 2025-08-11 02:25:22

Positions don't change for two reasons. Either one of the positions is wrong, or the people holding them don't listen. Usually, both are true at once.

Spaniard wrote: 'And about "renewables need fossil fuels". That's wrong. The right statement is, renewables needs storage. Fuel has advantages and disadvantages, as well as batteries.'

Intermittent renewables have short term and long term variability. Batteries are expensive and have high embodied energy, meaning a lot of energy is needed to make them. What this means in practical terms, is that batteries can be used for smoothing short term variability. A battery big enough to power your house for weeks, would be as big as your house. And it would cost as much as your house. And most of the batteries would only be used a few times per year. What would that do to the marginal cost of storage? Would the system ever return the energy needed to build it?

This is why in real grids, batteries are used for frequency control. They are there to meet demand for as long as it takes to bring backup fossil power online. That is usually gas turbines burning LNG. LNG isn't cheap by historical standards. But it is a bulk commodity that can sit in an underground tank. The marginal cost of storage is very small. Do you understand what is being said here?

Spaniard wrote: 'Renewable reduce the fossil fuel usage today per $ more than nuclear. Invest on renewable today helps more on reduce our fossil fuel dependency than nuclear.'

That is unlikely. A renewable system feeding a grid needs a fossil fuel power station as backup. It will be very difficult and expensive to build enough storage to obviate the need for backup. And remember that 'storage' is really just another powerplant that sucks in electricity at one end and spits out less electricity as output. Backup means building two power plants and paying for the capital and operating costs of both. You also have to invest in additional transmission infrastructure and frequency control, because intermittent renewables have no inertia. Levelised cost of energy does not account for these things. At the end of that process, you achieve a modest reduction in fossil fuel consumption. But the added cost is huge. And all of that extra infrastructure has a lot of embodied energy, most of which comes from coal, natural gas and diesel.

The cost of new nuclear power depends primarily on build times. These have stretched from just a few years back in the 70s, to about two decades today. Part of this is due to regulatory burden and part is due to the loss of all scale economies and supporting industries over the past forty years. The French built nuclear powerplants cheaply, because they were able to build quickly and in large volume. They established a national industry that met all parts of the nuclear supply chain. No one has this now. But it was a policy choice to shut that down. It isn't an inherent problem. And we could, with political will, rebuild it.

Spaniard wrote: 'Insist in making linear projections of copper. But as offtherock commented (and I did in the past), copper usage per unit power is not fixed.'

Yes it is. The cross sectional area of a copper conductor is directly proportional to the power transmitted. That is basic physics. So the more power produced, the more copper needed. It is possible to use other conductors in particular situations. Aluminium alloys have always been used in high voltage transmission lines. We could use aluminium in more applications. But there will be penalties in terms of power density, corrosion protection and fatigue. Iron can be used to transmit DC power (though not AC). Here again, there are penalties in terms of power density, weight and the need for corrosion protection. As Void noted, carbon nanotube conductors may become practical at some point. But all alternatives come with cost or performance burdens at present technology sets. We would already be using them otherwise.

The other alternative for intermittent renewables, is to accept the fact that power will fluctuate and plan your activities around that. If that is possible, then the energy could indeed be quite cheap, because backup and storage are no longer needed. But how much of society could work that way? Could grids function with continuous rolling blackouts? I don't know. I would guess that an intermittent energy supply would burden society with a lot of other costs. But it is the only way I can see this working.

The old fashioned windmills did not try to store wind energy to cover periods when wind was not blowing. They just varied work rate to match supply. And they harnessed mechanical energy from the wind to drive mechanical processes with only basic, short range mechanical power transmission. Those were cheap and simple systems. But the people involved had to work with intermittent power. Can we adjust our society to do the same? Again, I think this is the only way this can work.

#55 Re: Not So Free Chat » Oil, Peak Oil, etc. » 2025-08-10 15:26:41

Additional: A mechanical windmill could be used to produce heat, cold and mechanical power. It can do this by compressing air. As air compresses, it gets hot as internal energy is added to it. A single stage compressor could be used to generate compressed, hot air at say 200°C. The air could then pass through tubes in an oven, heating it. The still hot air could then pass through a counterflow heat exchanger, producing hot water. This would cool the air to roughly 20°C, but it would still be at pressure. The air would then expand through a turbine, generating mechanical power. The exhausted air from the turbine would be cold enough to freeze water. This cold air could be used to keep a large freezer cold. By combining outputs in this way, we can get far more out of a mechanical wind turbine.

#56 Re: Not So Free Chat » Oil, Peak Oil, etc. » 2025-08-10 14:57:55

Another option that has received surprisingly little attention, is that we escape our pointless addiction to electricity. I have said this many times before, I know. We don't anywhere near as much electricity as we use.

Both wind and solar thermal power systems can be used to provide direct mechanical power for many applications. That power doesn't have to be transmitted using electricity. Hydraulics, compressed air and mechanical power transmission would all work. Before the invention of the electric motor, line shafts were used to transfer power from a central waterwheel or steam engine, to multiple machines on a machine shop floor. There are still factories in the US that use this solution today. Hydraulics could do this even more efficiently. Wind turbines or solar thermal plants equipped with hydraulic pumps, can generate and transmit power without need for copper, cobalt or rare earths. Just steel, concrete and synthetic rubber.

Stationary mechanical power sources can also transport goods. This can be done by pumping water down a pipeline, carrying floating capsules. An old fashioned windmill could do that. In fact, the inland freight transport of entire nations could be done in this way. No need for electricity. Just mechanical wind pumps raising water through a head of a few metres.

The sun can also provide direct heat. This is useful for a huge range of things, from cooking, to iron reduction to brick making. Crude iron powder can be produced by heating a retort containing iron oxide to 800°C and passing hydrogen or methane through it. The reduced iron powder can then be seperated from silicate slag by crushing, followed by magnetic seperation. It can then be converted into steel using an electric arc furnace. A town could have a centralised oven that cooks food using solar heat. A laundrette could wash all of the clothing for a town using a mixture of mechanical wind energy to run machines and solar hot water.

To summarise, we don't need high tech solutions to build a society that works with far less consumption of fossil fuels. It is our slavish addiction to electricity that stands in the way of doing these things. Also, the fact that we don't seem to be able to conceive solutions that might require a different way of life. For example, using the town laundrette instead of a home washing machine. Using a public bathing faciluty instead of a home bathroom. Eating out at a town restaurant fitted with a large solar cooker with hot rock thermal storage. Changing energy sources means changing our way of life. There is surprisingly little thinking about this.

#57 Re: Not So Free Chat » Oil, Peak Oil, etc. » 2025-08-10 12:13:06

World electricity consumption in 2022 was 24,398TWh.

https://en.m.wikipedia.org/wiki/Electri … onsumption

According to the DOE, a PWR needs roughly 3 tons of copper for each TWh of electricity it produces over its life cycle.

https://www.energy.gov/quadrennial-tech … eview-2015

Replacing present electricity production with nuclear power, would require 73,194 tons of copper per year, assuming that we don't recycle. That is 0.37% of the present day copper production of 20 million tonnes per year.

In the 1970s, light water reactors were being constructed for $1000/kWe in modern money. How do we get back to that? Why is it that we cannot do now what we could do 50 years ago?

#58 Re: Not So Free Chat » Oil, Peak Oil, etc. » 2025-08-10 11:17:29

Solar thermal power has some very significant advantages. It doesn't really offer better power density than PV. But the materials needed to build it out are steel and concrete. It is thermal concentrators, boilers and steam generating sets. Things that we have been building since the end of the Victorian age. The materials involved are abundant and recyclable. Energy storage can be added to it with a tank of molten salt. And we don't need to depend on a Chinese economic system that will soon be gone.

#59 Re: Not So Free Chat » Oil, Peak Oil, etc. » 2025-08-10 10:25:56

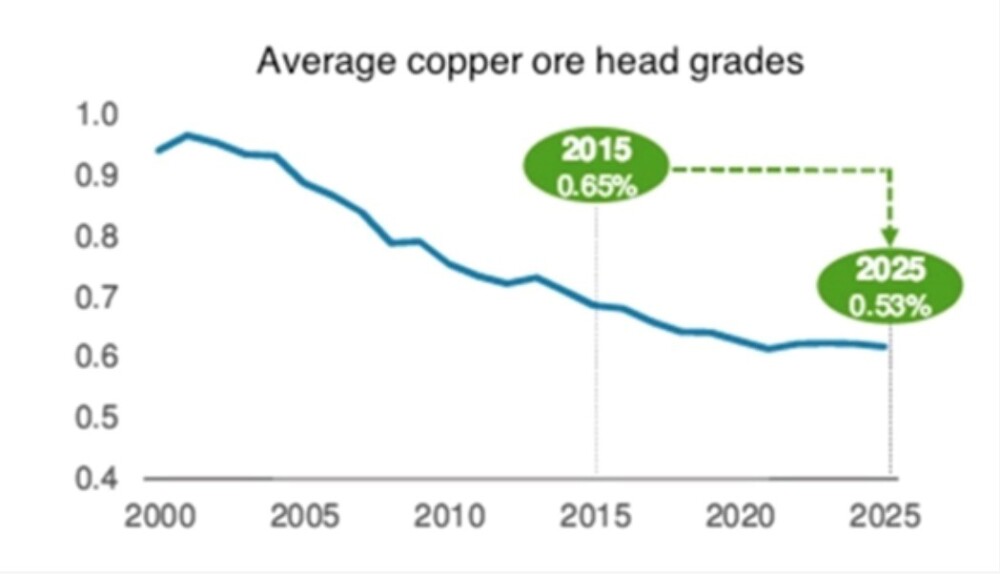

The average grade of mined copper ore has been declining steadily for many decades.

Taken from this report.

https://www.streetwisereports.com/artic … rt-of.html

Whether it is possible to reduce copper intensity for solar PV, electric cars and the myriad other electronic products of modernity, I do not know. Aluminium alloys could be substituted for some applications. If it were easy and advantageous to do that, it would have happened already.

Regarding the present relatively low cost of PV modules. This is largely a product of the Chinese industrial system. Back in the early 2000s, the Chinese communist party made the decision that PV was one of the industries that they wished to dominate globally. They built polysilicon factories in Xinjiang and Inner Mongolia. Polysilicon is one of the most energy intensive materials known to man. These places contain a lot of otherwise stranded coal, too far from the Chinese heartlands to be useful. They built coal burning powerplants close to the mineheads. These produced some of the cheapest electricity on Earth. They used forced islamic labour to mine the coal and man the factories making the polysilicon and modules. They set all of this up with zero interest loans. The result was extremely cheap PV modules. These were used in China and shipped all over the world.

Why would the Chinese do this? There is one overriding reason. Coal production in core Chinese provinces has stagnated, but electricity demand has kept growing. By building PV into grid, coal powerplant capacity factor can fall, allowing more electricity to be generated using less coal. It makes sense for the Chinese to do this, as Xinjiang coal cannot be transported to demand centres in eastern China, but PV modules can. If they can export them to the rest of the world as well, that is a bonus. At the same time, China is building nuclear powerplants morerapidly than the entire rest of the world combined. But this will take time. They need to stretch out their coal reserves until they have enough nuclear reactors to replace coal outright.

For the rest of the world, PV modules produced using stranded coal and slave labour, are a short term thing. If tge Chinese industrial system breaks down, they disappear overnight. If by some miracle that doesn't happen, PV will disappear when the Chinese build enough nukes not to need it anymore. Either way, this is ashort term phenomena, propped up by factors that are unsustainable.

#60 Re: Home improvements » Misc. Home Projects » 2025-08-10 08:45:29

I have installed the cradle for the wind turbine.

The next step is to hoist the nacelle and blades into the cradle. That is going to take some creative thinking. The nacelle is as finished as I can get it.

#61 Re: Home improvements » Misc. Home Projects » 2025-08-09 15:38:32

I have put up a scaffold tower around the windmill tower. Tomorrow is the day of final assembly. It has been a long road getting to this point. I will post pictures on here.

#62 Re: Not So Free Chat » Oil, Peak Oil, etc. » 2025-08-09 15:29:00

A good place to start if you wish to understand the resource intensity of different energy sources, in the US DOE Quadrennial technology review. Specifically, chapter 10.

https://www.energy.gov/quadrennial-tech … eview-2015

The DOE have already done the work in estimating the amount of materials of different types needed per TWh of electricity generated. Solar power especially, is a horrendous resource hog. Wind power is better, but the material needs are still an order of magnitude greater than nuclear or natural gas. It was this realisation that awakened my interest in direct mechanical power from the wind.

The economics of intermittent renewables are a strong function of where they are being built. Location matters for RE in a way that it doesn't for other energy sources. If the world economy ran on wind and solar energy, there would be huge geographic disparities in wealth, given that the resource is very geographically dependant. In an RE world, your wealth would depend very much on the location of your birth.

But there is a simple reason why RE will never provide cheaper grid based electricity than nuclear power or fossil fuels. The reason is that wind and solar cannot replace fossil powerplants. Those power plants have to be there in standby, waiting for windspeed to drop or the sun to be obscured by cloud or night. The only thing the RE plant can do is reduce the fuel consumption of the fossil plant. The fossil plant still has to be built, it has operating cost and maintenance cost. This is in addition to whatever the RE capacity costs. All of these costs end up on your power bill. RE and fossil economics cannot be looked at seperately because they are both needed to ensure a reliable power supply.

#63 Re: Science, Technology, and Astronomy » Invelox Wind Turbine » 2025-08-08 13:16:42

In the UK, the wind predominantly blows from the west. The majority of wind energy comes from this direction as well. If the funnel is angled towards to the west, it would gather almost as much energy as the multidirectional funnel over a year.

#64 Re: Not So Free Chat » Politics » 2025-08-07 02:27:17

Turns out that the Russia collusion scandal was a hoax invented by Obama on behalf of Clinton. Most people suspected this at the time, there is now solid evidence.

https://youtu.be/tJbsz3sbVz4

Presumably, Obama will face criminal charges now. I doubt that Trump will see him executed. But one thing is for sure. Both Obama and Clinton are finished as political players now. There is clear evidence that they misled the public with false information.

#65 Re: Science, Technology, and Astronomy » Nano Nanotechnology Nanometer Nanofiber Nanoscale » 2025-08-06 15:51:20

Sonny White designs chips with nanoscale cavities to harness quantum vacuum energy.

https://www.nextbigfuture.com/2025/08/s … hones.html

The proposed power levels are small. But if it works, it has uses in many small power applications. This is in effect an inexhaustible battery.

#66 Re: Science, Technology, and Astronomy » Invelox Wind Turbine » 2025-08-06 15:22:28

A ducted wind power concept. I like it. The cross sectional area of the duct is lower than the swept area of a conventional horizontal axis wind turbine of the same tower height. So power density is lower. But the tower and duct are static structures and won't wear out quickly. The moving parts are relatively compact and close to ground, making it easy to swap them out as modular components. So this design benefits from greater longevity and is easier to repair. If I wanted building integrated wind power, this sort of ducted design is where I would start.

#67 Re: Home improvements » Misc. Home Projects » 2025-08-06 12:57:28

I have been casting epoxy resin today, trying to strengthen the bond between the blades and bracing ring. It is cussed stuff to work with. It is almost impossible to build a mould that will contain it. Despite being viscous, it leaks through gaps smaller than the point of a pin. It dissolves its way through other adhesives. I have had failures in the past, where I have poured resin into a mould that I was sure was perfectly sealed. I came back the next morning to find the mould empty with epoxy all over the floor. It is the houdini of substances. I have learned that the only way of succesfully casting resin is to cast in small batches. I am therefore building up the cast in thin layers, about 1mm each. This minimises leakage, as there is little static pressure at the bottom of each layer being cast. It does make the process more time consuming, but it seems to be the only way to cast epoxy.

#68 Re: Science, Technology, and Astronomy » Pure Fission Reactor Announcements/News » 2025-08-05 14:14:54

The Trump administration is to fast track development of a lunar nuclear reactor.

https://www.zerohedge.com/geopolitical/ … actor-moon

This is expected to be a 100kWe system. This would also be useful in supporting Mars mission and allowing ISRU propellant production.

#69 Life support systems » Supercritical Water Oxidation » 2025-08-04 14:33:43

- Calliban

- Replies: 1

This technology may be useful for disposing of organic wastes on Mars and elsewhere.

https://en.m.wikipedia.org/wiki/Supercr … _oxidation

Oxidation and salt deposition are noted as being significant problems. One option for resisting corrosion would be a pre-stressed cast iron pressure vessel, with an internal cast basalt liner. The liner would be compressed in excess of operating pressure to prevent cracks from opening. The system would operate in batches. The vessel would be opened and solid wastes would be loaded in. Once sealed and filled with water, the retort would be heated slowly up to supercritical temperatures, with care taken to avoid thermal shock. Oxygen would be injected into the vessel and a counterflow heat exchanger would extract heat from exhausted gases.

#70 Re: Interplanetary transportation » Solar Sails » 2025-08-04 10:03:49

Solar wind sails with dynamic soaring could propel a spacecraft to 6900km/s - 2.3% of the speed of light.

https://www.nextbigfuture.com/2025/08/b … aring.html

That would get us to Proxima Centauri in less that two centuries. To Barnards Star in about three. This is a tool that really could be used for starflight.

#71 Re: Not So Free Chat » Oil, Peak Oil, etc. » 2025-08-03 16:01:17

Void, energy payback time depends upon where the panels are and also depends on assumptions like how well they are positioned and angled towards the sun and whether they are kept clean. Also realise that a 1-4 year EPB is just for the panels themselves. It doesn't include the support frame, inverters, transformers, energy storage for frequency control, transmission. Also, it doesn't include any consideration of backup, which is inescapable if this is part of a grid system. The most detailed EROI analysis that I have seen for solar power was the carried out for the Spanish solar industry. I will see if I can find it again. Lifetime EROI was in the low single digits. In more northern locations it will be lower still. This has real economic implications.

These problems are unavoidable in a demand driven distributed grid system. Supply has to balance demand at all times. There are inherently large energy costs and losses if intermittent renewables are used to supply a system like that. It just doesn't work well.

One way to minimise the embodied energy burden is to use renewable energy as directly as possible with minimal storage. In the case of solar, this would mean using the DC power produced by the panels very close to where it is produced, avoiding the need for inverters and transformers. Avoid unnecessary energy transitions by directly coupling the panels to DC loads consuming the power as low voltage direct current. Also, adjust demand according to supply. Do not attempt to store energy. This eliminates a large part of the embodied energy of the system. But it means that whatever you use the power for has to be very close to the panels themselves and the work rate must directly follow the amount of power produced by the panels at that time. At night, power use will be zero and the processes will stop. At noon, it will reach maximum. It will follow a sine wave between dawn and dusk.

This is a crappy arrangement in a lot of ways, because it makes production planning difficult. It also means that peoplemust work with the weather. On a hot sunny day, a factory must be running flat out, producing at full capacity with a fully engaged workforce. On a winter day, very limited power is available and the workforce must switch to labour intensive but energy frugal tasks, like assembly. At night, the sun provides no power. So the factory is shut down. Storage of inventory and part finished products will be an essential part of this system. It is the opposite of JIT.

My wind powered tumbling mill, when I finally finish it, will be an example of direct mechanical power supplied by the wind. There is only one energy transition - kinetic energy of the wind into rotational kinetic energy of the nacelle. There is no energy storage. The work rate varies with wind speed. On a windy day, the machine could complete a polishing run in just one day. In a becalmed period, a single run could take weeks. Work rate matches power production. This is how intermittent renewables have to work. Humans need to adjust their lives accordingly, if indeed this is an economic model that we can live with at all. I suspect that most people will find it tough working with the weather.

#72 Re: Home improvements » Misc. Home Projects » 2025-08-03 14:25:23

This is how the tumbling machine will work.

The tumbling pot is inside the central nacelle. The wind blows through the blades spinning the nacelle with the tumbling pot in it. The nacelle with the blades mounted on it is the only moving part. The weakness in the design is that I will needs to climb 15' up a ladder to change the tumbling pot.

#73 Re: Home improvements » Misc. Home Projects » 2025-08-03 13:55:00

SpaceNut, that has definitely been the case with this project. It has taken much longer than I had initially planned for. If I had to do it again, I would definitely do things differently. Hopefully, I can keep this working for thirty years. That will see me past retirement.

This diagram is how I intend to build the hoist to lift the cradle and nacelle. Both are far too heavy to carry up a ladder. This is a simple hangman gallow hoist.

I can build the hoist in about 1 day. But I will have to wait until next weekend now.

#74 Re: Home improvements » Misc. Home Projects » 2025-08-03 10:31:44

The tower is now in place.

It is mounted on top of a post. I coated it in creosote and used a post auger to put it about 6' into the ground.

I will need to build a hoist to get the cradle, nacelle and blades onto the tower. The cradle is finished.

I tied the blades together with a hardwood ring.

This has greatly increased the strength of the assembled nacelle. Unfortunately, it has also added a lot of weight.

Tomorrow evening I start work on the hoist.

#75 Re: Interplanetary transportation » Spin Launch SpinLaunch Vacuum Launches Centrifuge Launched Mass » 2025-08-01 17:34:15

Another article here on TARS. This is essentially a solar radiation driven spin launch technology.

https://www.centauri-dreams.org/2025/08 … potential/

We could use TARS to fling probes into the outer solar system. A neat thing about TARS is that it does (effectively) provide propellantless propulsion. The magnetic non-contact version has the advantage of not wearing out. The slow pummeling of micrometeors would eventually undermine the device. But that could take many centuries.