New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#51 Re: Planetary transportation » Internal combustion engines for Mars » 2025-12-23 17:54:04

The what appears to Th is that they are difficult on earth and make no profits for the other fuels of choice.

#52 Re: Meta New Mars » Housekeeping » 2025-12-23 15:56:50

Actually its the second Christmas without her as she passed on 9-20-24.

She loved this time of the year best.

#53 Re: Exploration to Settlement Creation » Brick on Mars » 2025-12-23 15:42:31

Technical Notes 31 - Brick Masonry Arches

300 plus pages Practical architectural guidelines to design a Martian base

Architectural problems of a Martian base design as a habitat in extreme conditions

#54 Re: Planetary transportation » Internal combustion engines for Mars » 2025-12-23 15:14:33

While there aren't standard engines running directly on a simple CO + O2 mix (CO is an exhaust product, not usually fuel), research explores using CO-rich syngas (CO + H2) or adding CO2/CO to fuels for oxy-fuel combustion in specialized engines (like rocket engines, ship engines for CO2 carriers), and engines can be designed to reform CO2 into fuel, but these are for specific applications or research, not typical vehicles.

Key Concepts & Applications:

Oxy-Combustion/Oxy-Fuel Engines: These use pure oxygen (or enriched air) and a fuel, potentially with CO2 added for control, to increase efficiency and reduce NOx/soot, seen in research for power plants and some ship engines.

Syngas (CO + H2): Carbon monoxide mixed with hydrogen (syngas) can be used as fuel in modified internal combustion engines, common in gasification systems.

CO2 as a 'Fuel' (Reforming): Some systems use engines (like Rapid Compression Machines) to convert CO2 and other gases into valuable syngas (CO + H2) for reuse, creating a circular carbon economy.

Rocketry: NASA studied CO and O2 as propellant combinations for potential rocket engines.

CO2 Carriers: Engines like MAN B&W's ME-GI are used to power ships transporting liquid CO2, though they burn traditional fuels, not the transported CO2.

Why Not Just CO + O2?

CO is a Product: Carbon monoxide (CO) is usually the "ash" from burning carbon-based fuels, not the fuel itself; it needs more oxygen to become stable CO2.

Energy Density: While CO burns, engines are optimized for hydrocarbons or hydrogen. Direct CO + O2 combustion requires specialized systems to manage extreme temperatures and efficiency.

In summary, while not standard, research and niche applications are developing ways to utilize CO, CO2, and oxygen in advanced combustion systems, focusing on efficiency or carbon capture, often using syngas mixtures

#55 Re: Exploration to Settlement Creation » To RTG or not to RTG the size is the question » 2025-12-23 14:35:01

Well the desire to use an RTG of the Perseverance size just does not make to common test of financial responsibility.

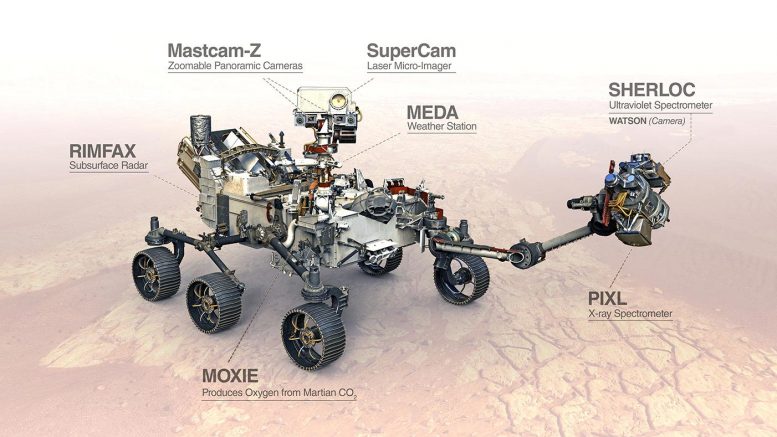

The Perseverance rover's power source is a Multi-Mission Radioisotope Thermoelectric Generator (MMRTG), essentially a nuclear battery using heat from plutonium-238 decay to generate steady electricity (around 110 watts) and heat for its systems on Mars, providing reliable power for its long mission unlike solar panels. Provided by the U.S. Department of Energy, this compact device uses the Seebeck effect with thermocouples, offering dependable power for years in the cold Martian environment, crucial for science and operations.

How it Works:

Heat Source: The MMRTG contains plutonium-238 dioxide, a ceramic material that releases heat as it naturally decays.

Conversion: Thermoelectric couples (semiconductors) convert this heat directly into electrical current through the Seebeck effect, creating a temperature difference.

Electricity & Heat: The system produces both electricity for the rover and heat to keep its instruments and systems warm in extreme cold.

Reliability: With no moving parts, MMRTGs are highly reliable and provide continuous power for extended missions, essential for deep space and Mars exploration.

Key Features:

Power Output: Starts at about 110 watts and gradually decreases over time as the plutonium decays.

Fuel: Uses plutonium-238, a robust and long-lasting radioisotope.

Heat Management: Has "fins" to radiate excess heat and also provides warmth for the rover.

Provider: Supplied to NASA by the U.S. Department of Energy (DOE).

Why it's Used:

Provides consistent, long-term power, independent of sunlight, making it ideal for Mars exploration.

Compact and durable for space travel.

Enables long-duration missions and complex scientific operations far from the Sun

https://en.wikipedia.org/wiki/Perseverance_(rover)

While the total Perseverance rover mission cost around $2.7 billion, the specific Radioisotope Thermoelectric Generator (RTG) powering it isn't itemized in the overall budget, but similar NASA RTGs cost roughly $100 million each, requiring plutonium and years of production, with Perseverance using about 10.6 pounds of plutonium for its.

RTG Specifics

Cost: While not a separate line item, similar NASA RTGs cost around $100 million to produce.

Plutonium Content: The system on Perseverance uses about 10.6 pounds of plutonium-238.

Production: RTGs are complex systems built at national labs (Oak Ridge, Los Alamos) and assembled at Idaho National Laboratory (INL) over years, involving robotic assembly and rigorous testing.

Perseverance Rover Total Cost Breakdown

Total Mission: ~$2.7 billion (including inflation, closer to $2.9 billion).

Spacecraft Development: ~$2.2 billion.

Launch Services: ~$243 million.

Operations (2-yr prime): ~$200-300 million.

So, while the RTG is a critical component, its significant cost is bundled into the overall spacecraft development, with estimates placing it around $100 million for the power system alone.

https://en.wikipedia.org/wiki/Multi-mis … _generator

The MMRTG cost an estimated US$109,000,000 to produce and deploy, and US$83,000,000 to research and develop. For comparison the production and deployment of the GPHS-RTG was approximately US$118,000,000.

it only produced the 100 watts that was used for the cycle of 3.5 hours which gave us the stated 300 watts for the device to make oxygen and the co as its is an incomplete design.

Yes an RTG gives continuous power but its at a very low level, at a very high cost and the device to use that power is a mismatch as its cycles.

#56 Re: Exploration to Settlement Creation » To RTG or not to RTG the size is the question » 2025-12-23 14:25:39

For SpaceNut re new posts in MOXIE topic ...

Thanks for the new posts you added, with what sure looks like ** very ** encouraging news of larger scale operations on Earth.

My point was (and remains) that the original small MOXIE unit could be replicated in large numbers and deployed to Mars with an RTG able to provide the 300 watts it needs. It does NOT need to be mounted in a rover. That was convenient for the research mission.

Your posts show that researchers/engineers are working on larger scale versions.

That is all good, but the fact remains, the ONLY such system tested on Mars is the 300 watt version.

So we should be able to figure out how many 300 watt units are needed to supply oxygen for humans or fuel and oxidizer for machinery.

***

In one of your posts you seemed (as I read it) to think that carbon monoxide had never been tested on Earth for internal combustion engines. I am 95% confident that kbd512 researched that long ago and found that such engines had most definitely been tested on Earth.An internal combustion engine that runs on CO and O2 will produce less power than would an engine that has hydrogen in the fuel, but I question why that makes a difference. To make hydrocarbon fuels will consume energy that you might be able to get back if you have an engine designed for it, but why bother? CO and O2 make a perfectly acceptable energy storage system and the whole process is so much simpler, I just don't see why anyone would go to all the trouble of fooling around with hydrogen.

(th)

#57 Re: Unmanned probes » Perseverance New 2020 Mars Rover based on MSL » 2025-12-22 18:49:13

Perseverance may soon set a Mars rover mileage record

One standout moment came when NASA reported that Perseverance used its navigation cameras to complete a single drive of exactly 1,350.7 feet, or 411.7 meters, a stretch that set a new personal best for the rover and highlighted how efficiently it can now move across Jezero’s surface. That feat, documented in a mission update on 1,350.7 and 411.7 meters of progress, was not just a stunt; it demonstrated that the rover’s autonomous systems can safely handle long, continuous traverses that are essential for any bid at a distance record.

Recent mission commentary notes that the rover’s six wheels have already carried it roughly 25 miles, or about 40 kilometers, since touchdown, a figure that puts Perseverance in direct contention with the longest-ranging Mars rovers of the past. That cumulative distance, cited in a discussion of how far the rover has gone at around 40 kilometers, reflects not only the rover’s mechanical durability but also the mission team’s willingness to keep pushing the envelope on daily drive plans.

#58 Re: Civilization and Culture » Civilization collapse, signs of the past and may be happening now » 2025-12-22 16:19:05

How distortions occur by creating labels that are not accurate.

"Rich people" are a diverse group with varied political views, and it is a misconception to characterize them all as holding the same ideology. Historically, the very wealthy have often leaned conservative (right-wing), but recent trends, particularly in the U.S., show a shift where many in the upper-income brackets, especially the college-educated or those in certain industries, are increasingly likely to be liberal or lean Democratic.

General Trends in the U.S.

Overall Political Affiliation: Polling data has indicated that when party leanings of independents are included, the wealthiest 1% of Americans were somewhat more Republican-leaning than the rest of the population, although this gap was not as large as other demographic differences like education level.

Income vs. Education: One of the most significant factors is education. High-income individuals who also have a college or postgraduate degree are more likely to support Democratic candidates, creating a "U-shape" in voting patterns by income level, where both the lowest and highest income groups show increased support for the Democrats compared to middle-income brackets.

Industry and Occupation: Political affiliation among the wealthy often depends on their source of wealth and occupation.

People in traditional industries like oil, manufacturing, real estate, and finance tend to be more right-wing or Republican.

Those in high-tech, human services, arts, and professional/scientific occupations tend to be more liberal or Democratic.

Ideology vs. Party: While wealthy individuals might lean toward one party, their views on specific issues, particularly economic ones, can still be conservative. Many are generally conservative in the classical sense of resisting change to a system that has benefited them financially.

Variations Among Different "Rich" Groups

Billionaires: A small group of high-profile billionaires like George Soros and Bill Gates are known for liberal donations, while others like Charles Koch are strongly conservative. The general perception is that the vast majority of billionaires are very right-wing on economic issues, even if a few prominent ones are liberal.

Celebrities/Entertainers: People in the entertainment world and arts tend to lean strongly liberal, which often leads to the public perception that many rich people are left-leaning.

"Old Money" vs. "New Money": Some analyses suggest that "old money" (inherited wealth) might have different political attitudes than "new money" (self-made), with those who became rich through disruptive entrepreneurship sometimes leaning more liberal than those whose wealth is tied to long-standing, traditional industries.

In conclusion, the political views of the rich are not monolithic. While economic self-interest often drives support for conservative, pro-capitalist, and lower-tax policies, factors like education, occupation, and personal values mean many affluent people align with the left or the Democratic party, especially on social issues

#59 Re: Science, Technology, and Astronomy » Re-purposing Moxie for Co + O2 Fuel » 2025-12-22 16:06:28

If the question are put into the topics then one can make better sense of what is required.

Astronauts can approach an operating Radioisotope Thermoelectric Generator (RTG) very closely, even working in its immediate proximity, but the exact safe distance is determined by mission design, the specific RTG's shielding, and the total duration of exposure, as part of strict radiation safety protocols.

Safety limits are based on the principle of keeping exposure As Low As Reasonably Achievable (ALARA) and not exceeding established dose limits.

Key Safety Principles

Distance is a Primary Shield: Radiation exposure decreases significantly with distance. Doubling the distance from a source can reduce the exposure rate by a factor of four (inverse square law).

Mission-Specific Limits: NASA sets specific limits for radiation exposure from nuclear technologies, which are typically capped at an effective dose of 20 millisieverts (mSv) per mission year (prorated for mission duration). This limit is designed not to add more than 10% to the unavoidable background space radiation dose of a mission.

Shielding: RTGs used in space missions are designed with shielding to minimize external radiation. For planetary surface operations (like on Mars or the Moon), the mission plan factors in habitat shielding, terrain as a potential shield, the distance from the source, and the duration of extravehicular activities (EVAs).

Time: The duration of exposure is strictly managed to stay within short-term and career dose limits.

Practical Application

In practice, astronauts on Apollo missions worked near the deployed RTGs of the Apollo Lunar Surface Experiments Package (ALSEP). They would align the ALSEP so that the RTG's cable exit pointed toward the central station, and while they avoided unnecessary proximity, no specific maximum distance constraint was imposed in the same way as avoiding a rocket launch, due to the contained nature and shielding of the RTG's radioactive material.

For future missions, safety zones and operational procedures are established through rigorous analysis to ensure that cumulative and acute radiation doses remain within safe, regulated limits for all crew members

Mars has quite a bit of radiation already for a crew to deal with so additional shielding would be needed.

The other is mass shipped to mars is not sustainable.

#60 Re: Science, Technology, and Astronomy » Re-purposing Moxie for Co + O2 Fuel » 2025-12-22 16:02:31

For SpaceNut re new posts in MOXIE topic ...

Thanks for the new posts you added, with what sure looks like ** very ** encouraging news of larger scale operations on Earth.

My point was (and remains) that the original small MOXIE unit could be replicated in large numbers and deployed to Mars with an RTG able to provide the 300 watts it needs. It does NOT need to be mounted in a rover. That was convenient for the research mission.

Your posts show that researchers/engineers are working on larger scale versions.

That is all good, but the fact remains, the ONLY such system tested on Mars is the 300 watt version.

So we should be able to figure out how many 300 watt units are needed to supply oxygen for humans or fuel and oxidizer for machinery.

***

In one of your posts you seemed (as I read it) to think that carbon monoxide had never been tested on Earth for internal combustion engines. I am 95% confident that kbd512 researched that long ago and found that such engines had most definitely been tested on Earth.An internal combustion engine that runs on CO and O2 will produce less power than would an engine that has hydrogen in the fuel, but I question why that makes a difference. To make hydrocarbon fuels will consume energy that you might be able to get back if you have an engine designed for it, but why bother? CO and O2 make a perfectly acceptable energy storage system and the whole process is so much simpler, I just don't see why anyone would go to all the trouble of fooling around with hydrogen.

(th)

#61 Re: Science, Technology, and Astronomy » Re-purposing Moxie for Co + O2 Fuel » 2025-12-22 15:29:49

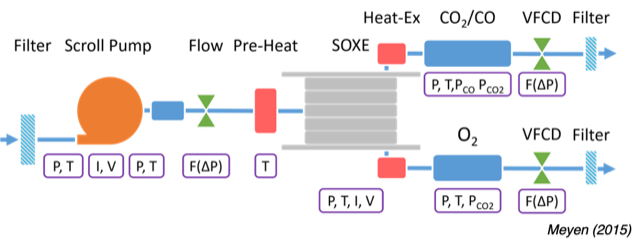

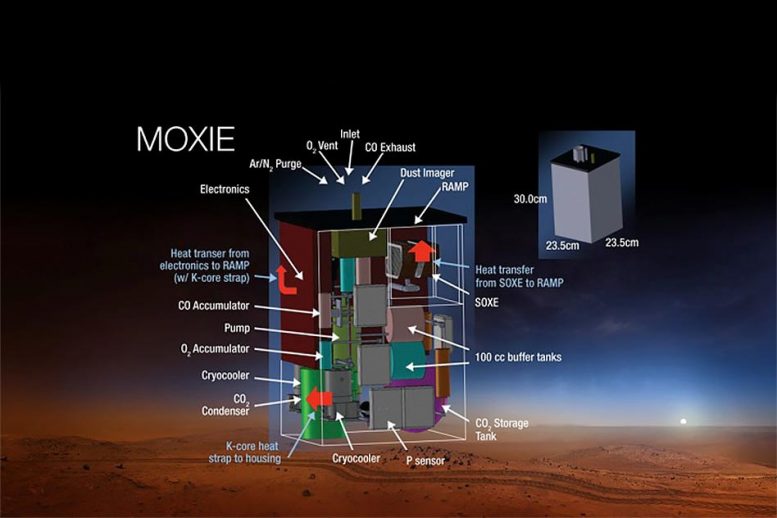

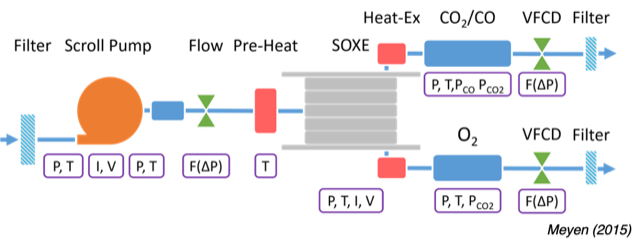

The largest solid oxide electrolyzer (SOE) developed for Mars is the mission-scale SOXE stack by OxEon Energy, a 33x scaled-up version of the toaster-sized MOXIE device on NASA's Perseverance rover, designed to produce propellant for human return missions, though the MOXIE unit itself was the first SOE to operate on Mars, generating oxygen from CO2. On Earth, Bloom Energy's 4 MW Bloom Electrolyzer is the world's largest SOE system, stemming from that original NASA Mars technology.

For Mars Missions (Technology for Future Human Exploration):

MOXIE (Mars Oxygen ISRU Experiment): This small, toaster-sized SOE device on the Perseverance rover successfully demonstrated solid oxide electrolysis on Mars, producing oxygen from the thin CO2 atmosphere.

OxEon Mission-Scale SOXE: OxEon scaled up its MOXIE technology significantly (33x) for potential Mars crewed missions, aiming to produce large quantities of oxygen for propellant (Mars Ascent Vehicle) and life support, according to this TTU DSpace Repository document and OxEon Energy's website.

For Earth (Current Largest SOE):

4 MW Bloom Electrolyzer: Bloom Energy built the world's largest solid oxide system, operating at NASA's Ames Research Center, with roots in the original Mars technology to produce clean hydrogen for terrestrial decarbonization.

In summary, MOXIE was the first SOE on Mars, OxEon scaled it up for future large-scale Mars needs, and Bloom Energy created the largest SOE on Earth based on that heritage

The cell can also be used to make power from the input at about 60% efficiency.

#62 Re: Science, Technology, and Astronomy » Re-purposing Moxie for Co + O2 Fuel » 2025-12-22 15:23:42

I think that I miss read you post as it appears that the life support for humans is not what you are asking about.

Gold box being positioned over the rover.

The unit rides currently on Perseverance which supplies power from its RTG as electrical for the unit to work at 300 watts. As the unit does not have its own power system or supply.

The main parts are a compressor to draw pair in, the co2 electrolysis unit ( Solid OXide Electrolyzer (SOXE),). and lots of sensors and filters.

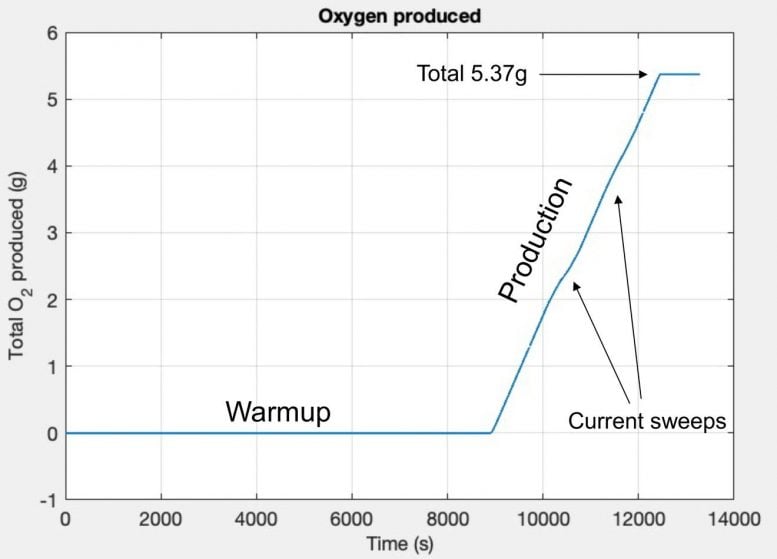

NASA's MOXIE on Mars produces about 6-10 grams of oxygen per hour (like a small tree) after a warmup, with runs lasting around 3.5 hours (2.5 hrs warm-up, 1 hr production). The initial target was 6g/hr, but it exceeded goals, reaching up to 12g/hr at peak performance, proving scalable technology for future human missions by converting Martian CO2 into oxygen.

MOXIE's Performance & Process:

Standard Output: Around 6-10 grams of oxygen per hour (g/hr).

Peak Output: Achieved up to 12 g/hr, doubling initial targets.

Typical Run: About 3.5 hours total (2.5 hrs warm-up, 1 hr oxygen production).

Total Produced (by late 2021): Over 100 minutes of breathable oxygen for an astronaut, or 50 grams.

Technology: Uses Solid Oxide Electrolyzer (SOXE) at 800°C, splitting CO2 into oxygen and carbon monoxide.

Significance:

Demonstrates In-Situ Resource Utilization (ISRU) for Mars colonization.

Knowledge gained will inform future, scaled-up MOXIE systems needed for crewed missions, potentially producing kilograms of oxygen

Mars Oxygen ISRU Experiment (MOXIE)—Preparing for human Mars exploration

It cycled 16 times during night and day with the pressure measure with temperature with timed duration for oxygen creation.

It does not run continuous but must cycle to make it not become damaged.

It has no storage tanks for the exiting gasses which will check values, pumps to pressure rise the amounts stored.

KBD512 pg 14 post gave a scaled up post in the Internal combustion engines for Mars which is theoretical as no vehicle has had it done to the engine. Tank size is dependent on how long you wish to use the fuel but also how much it can carry on its frame.

We also do not have a production rocket engines that I could find. Plus the rockets that we are using to get to its surface is a CH4+O2 engine.

Carbon Monoxide and Oxygen Combustion Experiments: A Demonstration of Mars In Situ Propellants

#63 Re: Human missions » Moxie and only Moxie » 2025-12-21 18:18:06

Rather than using the electrical power we could use the Krusty reactor heat to do the job.

The KRUSTY (Kilopower Reactor Using Stirling TechnologY) reactor operated at a target core temperature of around 800°C (1472°F), reaching up to 880°C during testing, to generate about 4-5.5 kW of thermal power for space applications, demonstrating efficient fission power at relatively high temperatures for long-duration missions.

Key Temperatures & Operations:

Design Goal: Achieve steady-state operation at ~800°C (4 kW thermal).

Peak Test Temperature: Reached up to 880°C (1616°F) during the full-power run.

Warm Criticals: Pre-test experiments heated the core to 200°C, 300°C, and 450°C to study reactivity.

Control: Temperatures were adjusted by moving control rods, allowing for standby heat or shutdown.

Significance:

Demonstrated the Kilopower system's ability to operate reliably at high temperatures, crucial for space power.

Validated nuclear codes and material performance for potential long-term use in space

I did this equation back in the 1 m water topic.

MOXIE converts Martian CO2 into oxygen (O2) and carbon monoxide (CO) using solid oxide electrolysis, where roughly 2 moles of CO2 yield

1 mole of O2, meaning for every ~44 grams of CO2 consumed, MOXIE produces ~32 grams of O2, though its actual output is ~6-10 grams O2/hour from ~55 grams CO2/hour, with CO as a byproduct, not just pure O2 output.

MOXIE's Process & Ratios: Input: MOXIE takes in Martian atmosphere (95% CO2).Reaction: It uses electrolysis to split CO2 into Carbon Monoxide (CO) and Oxygen (O).

Output: Oxygen gas (O2) is collected, and Carbon Monoxide (CO) is released as a byproduct.

Stoichiometry: The balanced equation is roughly \(2CO_{2}\rightarrow 2CO+O_{2}\) (simplified for mass flow).

Mass Conversion (Theoretical): Molar Mass of \(CO_{2}\approx 44\) g/molMolar Mass of \(O_{2}\approx 32\) g/molFor every 44g of CO2, you get 32g of O2 (and 28g of CO).

This means for every 1 gram of O2 produced, about 1.375 grams of CO2 are needed (44/32).

MOXIE's Actual Performance: MOXIE aims for 6 grams of O2 per hour using about 55 grams of CO2 per hour.

This 55g CO2/hour input yields ~6g O2/hour output, which is roughly a 9:1 mass ratio of CO2 in to O2 out, reflecting the byproduct CO and operational inefficiencies.

In summary, it's not a direct 1:1 mass conversion; a larger mass of CO2 is consumed to produce a smaller mass of pure oxygen, with the rest becoming carbon monoxide

One cubic meter of Mars \(\text{CO}_{2}\) (assuming the general Martian atmosphere which is predominantly \(\text{CO}_{2}\) gas) is approximately 19 grams (0.019 kg), though the exact value varies with location and season on Mars.

#64 Re: Science, Technology, and Astronomy » Re-purposing Moxie for Co + O2 Fuel » 2025-12-21 18:03:18

Moxie used just 300 Watts to do this experiment from the radioactive generator.. The system while it may scale does not mean that its going to process even when fully tested here on Earth.

The Co is only part of a fuel as it needs an oxidizer to make it useful.

The equation for converting CO₂ to O₂ and CO involves the decomposition of carbon dioxide, often requiring energy, and the balanced form for producing both is complex, but for simple decomposition into solid carbon and oxygen, it's \(2CO_{2}(g)\rightarrow 2C(s)+2O_{2}(g)\) (or simplified \(CO_{2}\rightarrow C+O_{2}\)), while the reverse, forming CO₂, is \(2CO+O_{2}\rightarrow 2CO_{2}\). For a reaction that yields both CO and O₂, it's a partial combustion of carbon, like \(2C+O_{2}\rightarrow 2CO\), or a mix, but you can have \(C+O_{2}\rightarrow CO+CO_{2}\) (which balances to \(2C+2O_{2}\rightarrow 2CO+CO_{2}\) or \(C+O_{2}\rightarrow CO+\frac{1}{2}O_{2}\) if you want CO + O₂). Key Reactions Complete Combustion (CO₂ Formation): \(2CO+O_{2}\rightarrow 2CO_{2}\) (Carbon monoxide + Oxygen \(\rightarrow \) Carbon dioxide).Partial Combustion (CO Formation): \(2C+O_{2}\rightarrow 2CO\) (Carbon + Oxygen \(\rightarrow \) Carbon Monoxide).Decomposition (CO₂ to C + O₂): \(2CO_{2}\rightarrow 2C+2O_{2}\) or \(CO_{2}\rightarrow C+O_{2}\) (Carbon dioxide \(\rightarrow \) Carbon + Oxygen).Mixed Products (From Carbon): \(2C+2O_{2}\rightarrow 2CO+CO_{2}\) (Carbon + Oxygen \(\rightarrow \) Carbon Monoxide + Carbon Dioxide). Balancing Example (CO₂ \(\rightarrow \) C + O₂) Unbalanced: \(CO_{2}\rightarrow C+O_{2}\) (1 C, 2 O on left; 1 C, 2 O on right - Wait, the O is split!).Balance Oxygen: You need 2 O on the right (from \(O_{2}\)) and 2 O on the left (from \(CO_{2}\)).Final Balanced (Simplest): \(CO_{2}\rightarrow C+O_{2}\) (This looks balanced but often needs coefficients for real-world application, like \(2CO_{2}\rightarrow 2C+2O_{2}\) to ensure whole numbers if you are breaking down multiple molecules). The specific equation depends on what you're starting with (CO or C) and what you want as products.

The balanced chemical equation for the decomposition of carbon dioxide (\(\text{CO}_{2}\)) into carbon monoxide (\(\text{CO}\)) and oxygen (\(\text{O}_{2}\)) is:

2CO[sub]2[/sub] → 2CO + O[sub]2[/sub]This equation can also be represented in BBCode format using HTML-like tags for subscript:

2CO[sub]2[/sub] -> 2CO + O[sub]2[/sub]

#65 Re: Human missions » Moxie and only Moxie » 2025-12-21 15:52:49

Still waiting for updates but here is the test that was done on mars. MOXIE accomplishes this by sucking in Martian atmosphere, scrubbing out dust, and then compressing and heating it to almost 1,470°F (800°C). Inside the module, a solid oxide electrolyzer breaks down carbon dioxide molecules (CO₂) in to oxygen ions and carbon monoxide. The oxygen ions are recombined into O₂, quantified for purity, and discharged. The waste, carbon monoxide, is discharged back into the Martian atmosphere. Overall, MOXIE produced 122 grams of oxygen, enough for a small dog to breathe for 10 hours or a human for 4 hours. But it only produced 6 grams with a limitation of an hour, With hopes of getting to 14 grams.

Currently, a crew of four astronauts would require approximately 55,000 pounds (25 metric tons) of oxygen for rocket propellant, while only about one metric ton is needed for breathing over a full year on Mars.

update to get better runtime to output.

NASA's MOXIE experiment on the Perseverance rover produces oxygen by electrolyzing Martian CO2, with a typical run taking about 3.5 hours (2.5 hours warmup, 1 hour production) to generate roughly 6-10 grams per hour, enough for a small dog to breathe, exceeding initial goals by generating higher purity oxygen and scaling up production, proving technology for future human missions.

MOXIE Run Cycle Breakdown

Warmup: About 2.5 hours for the Solid Oxide Electrolyzer (SOXE) to reach ~800°C.

Production: Around 1 hour of active oxygen generation.

Total Cycle: Roughly 3.5 hours.Production Output & Goals

Rate: 6-10 grams of oxygen per hour (g/h) in its standard runs, later reaching up to 12 g/h.

Purity: Achieved high purity (98% or better).

Total: Generated over 122 grams by its mission's end.

Analogy: 6 g/h is like a modest Earth tree; 100 minutes of oxygen is enough for one astronaut for a short time.Key Achievements

Demonstrated oxygen production in various conditions (day/night, seasons).

Proved the viability of In-Situ Resource Utilization (ISRU) for human exploration.

Exceeded initial goals for production rate and purity, paving the way for scaled-up versions for future missions

Goal is continuous run not a cycled loop. So the above is not representing this information.

#66 Re: Human missions » Starship repurposed to make first habitat spaces » 2025-12-21 15:29:41

Starship's payload shroud, or bay, offers a massive volume of around 800-1000 cubic meters (m³), with a large 8-meter diameter and up to 22 meters in height for extended payloads, designed to deliver over 100 tons of cargo to Mars, enabling truly large-scale surface operations and habitats, far exceeding previous missions' capabilities.

Key Dimensions & Capacity:

Diameter: 8 meters (26 feet).

Usable Volume: Up to 1000 m³.

Height Options: Standard volume plus an extended option up to 22 meters (72 feet) for tall cargo.Cargo Mass to Mars: Over 100 metric tons (100,000 kg) in its reusable configuration, potentially up to 150 tons for LEO, making it a game-changer for Mars colonization.

What This Means for Mars Missions:

Large Hardware: The enormous volume allows for sending substantial components for habitats, pressurized rovers, and even entire small settlements, not just small scientific instruments.Autonomous Deployment: The bay is designed for autonomous cargo deployment, meaning Starship can deliver supplies and infrastructure without needing a human crew on board for the initial missions.

Game-Changing Scale: This capacity is orders of magnitude greater than previous Mars landers, allowing for the transport of materials for sustainable human presence, from building supplies to massive power systems

#67 Re: Human missions » Why Artemis is “better” than Apollo. » 2025-12-21 12:19:43

Artemis III pressure and the threat to SpaceX

all about meeting the lunar manned mission date.

#68 Re: Human missions » Blue Origin » 2025-12-21 12:14:48

Blue Origin's historic flight on December 20, 2025, marked the first time a person using a wheelchair was successfully launched into space and returned safely. Michaela "Michi" Benthaus, an aerospace engineer at the European Space Agency, became the first wheelchair user to reach the Kármán line, the internationally recognized boundary of space. The mission lasted about 10 minutes, during which Benthaus experienced several minutes of weightlessness. The launch was conducted from Blue Origin's West Texas site, and the capsule was designed with accessibility in mind, requiring only minor modifications to accommodate Benthaus. The successful flight by Blue Origin demonstrates the company's commitment to promoting disability inclusion in human space exploration.

#69 Re: Human missions » A City Rises on the Plain... » 2025-12-21 11:39:58

I do not know if this will work but here is the facebook page.

First Congregational Church of Farmington NH

The page does have the internal roof support beams going into the brick column supports.

#70 Re: Science, Technology, and Astronomy » Architectural Engineering on Mars » 2025-12-21 07:49:59

Parts of What we need to go to Mars - short term projects some of which applies to exploration as well as for building.

#71 Re: Exploration to Settlement Creation » Dome LED lighting and for crops » 2025-12-21 07:43:54

Not all crops will be done in hydroponic growth systems as some will desire being grown in soil.

Mars Soil Factory

#72 Re: Meta New Mars » Housekeeping » 2025-12-20 20:01:06

I saw that the images gave the smooth thoughts for using epoxy to make them adhere to each other. I would use these for the inside of the dome once its sealed and heated so that we could control the curing process. The interlaced blocks would allow for building the dome and then berm before allowing more construction within it.

#73 Re: Life support systems » Mars Colony Cement & Concrete » 2025-12-20 18:58:24

For in situ (on-site) brick mortar on Mars, scientists developed StarCrete, a strong, starch-based biocomposite using Martian dust (regolith) and potato starch as a binder, mixed with a little salt for enhanced strength, creating materials stronger than Earth concrete, ideal for building habitats with minimal imported materials. This method uses local resources (dust, starch from food) for cost-effective, sustainable construction, producing bricks that can be made in a microwave at home-baking temperatures.

How StarCrete Works

Ingredients: Martian regolith (simulated dust), potato starch, and salt (like magnesium chloride found on Mars).

Process: Mix the starch and salt with the regolith to form a gelatinous binder, then compress into molds and heat (like in a microwave) to create strong bricks.

Strength: Martian StarCrete boasts compressive strengths of about 72 MPa, more than double ordinary concrete (around 32 MPa).

Key Advantages

In-Situ Resource Utilization (ISRU): Uses readily available Martian dust and starch from food, drastically cutting down on expensive Earth launches.

Simplicity: Can be produced with relatively low energy (home baking temperatures), unlike traditional concrete.

Resourcefulness: Starch is a food source, making it a practical, dual-purpose material.

Alternative Binders: While starch works well, researchers also explored human waste (urea from urine/sweat) as a binder, showing high strength but with potential practicality issues compared to starch.

Application for Mars

This "cosmic concrete" provides a pathway to build essential infrastructure—habitats, roads, shelters—using what's already on Mars, making long-term colonization more feasible and sustainable

'cosmic concrete' made from potato chips, salt, and dust can be used to build homes on mars

StarCrete: Materials Scientists Create Starch-Based Concrete for Extraterrestrial Construction

When tested, StarCrete had a compressive strength of 72 Megapascals (MPa), which is over twice as strong as the 32 MPa seen in ordinary concrete.

StarCrete made from the lunar dust was even stronger at over 91 MPa.

The researchers calculated that a sack (25 Kg) of dehydrated potatoes (crisps) contain enough starch to produce almost half a ton of StarCrete, which is equivalent to over 213 brick’s worth of material. For comparison, a 3-bedroom house takes roughly 7,500 bricks to build.

Additionally, they discovered that a common salt, magnesium chloride, obtainable from the Martian surface or from the tears of astronauts, significantly improved the strength of StarCrete.

The next stages of this project are to translate StarCrete from the lab to application.

StarCrete: A starch-based biocomposite for off-world construction

#74 Re: Life support systems » Iron and Steel on Mars » 2025-12-20 17:14:02

Yes, smelting iron ore (regolith) on Mars to make girders for dome supports is a viable concept, with recent research showing scientists can extract pure iron and iron alloys from simulated Martian soil using Mars-like conditions (low pressure, high heat), making in-situ resource utilization (ISRU) possible for building habitats, though domes themselves face tension challenges requiring strong materials like steel.

The Process:

Extracting Iron: Researchers heat Martian regolith simulant (like that from Gale Crater) in a furnace simulating Mars's low atmospheric pressure.

Smelting: At around 1000°C, pure iron forms; at 1400°C, liquid iron-silicon alloys are produced, similar to Earth's processes but optimized for Mars.

Refining: This metal can then be separated from slag and potentially used to create steel or other structural components.

Why It Matters for Domes & Girders:

Reduces Earth Reliance: Instead of shipping massive amounts of steel, future colonists can "live off the land" (ISRU).

Structural Strength: Martian domes, pressurized by internal air, are under tension (trying to tear themselves apart) and need strong materials like steel for reinforcement, making locally produced girders crucial.

Key Takeaway: This technology moves beyond just oxygen production (like NASA's MOXIE) to creating essential building materials, making self-sufficient Martian colonies more feasible

Making iron girders on Mars for dome support involves In-Situ Resource Utilization (ISRU), requiring specialized equipment like furnaces (maybe electric or solar-powered), systems to extract iron from regolith (dirt), a carbon source (from CO2), and technologies for refining and shaping into beams, likely using methods like additive manufacturing (3D printing) or casting, all while managing extreme Martian conditions. Key steps include ore processing, reduction (removing oxygen), alloying for strength, and fabrication into structural components.

Required Processes & Equipment

Regolith Processing & Mining:

Equipment: Rovers with drills, excavators, and material handlers to collect iron-rich regolith (Martian dirt).

Process: Separation of iron-bearing minerals from silica and other materials.

Iron Extraction (Smelting/Reduction):

Carbothermic Reduction: Heating the ore with a carbon source (from Martian CO2) in a furnace to produce molten iron.

Hydrogen Reduction: Using hydrogen (produced on Mars) as a reducing agent.

Molten Regolith Electrolysis: An alternative method.

Equipment: High-temperature furnaces (possibly solar-powered or electric), systems to generate reducing agents (C, H).

Technology: The MMOST (Moon to Mars Oxygen and Steel) system is a NASA-backed concept for this.

Steelmaking & Alloying:

Process: Adding specific elements (like silicon, manganese, chromium) to the iron to create strong steel suitable for construction.

Equipment: Alloying furnaces, refining vessels.

Fabrication (Making Girders):

Additive Manufacturing (3D Printing): Printing complex shapes like girders directly from metal powder or molten metal.

Casting: Pouring molten steel into molds.

Machining: Shaping hardened steel components.

Equipment: Industrial 3D printers, casting molds, robotic arms.

Energy & Infrastructure:

Solar Arrays/Nuclear Power: To provide the immense energy needed for heating and processing.

Habitats & Workshops: Pressurized environments for equipment and personnel.

Key Martian Advantages/Challenges

Abundant Iron: Iron oxides are common in Martian regolith.

Atmosphere: The CO2 atmosphere provides carbon for steelmaking.

Low Oxygen/Water: Less rust/corrosion on finished steel.

Challenges: Low atmospheric pressure, extreme temperatures, and the need to transport initial complex equipment from Earth.

#75 Re: Exploration to Settlement Creation » Brick on Mars » 2025-12-20 16:53:45

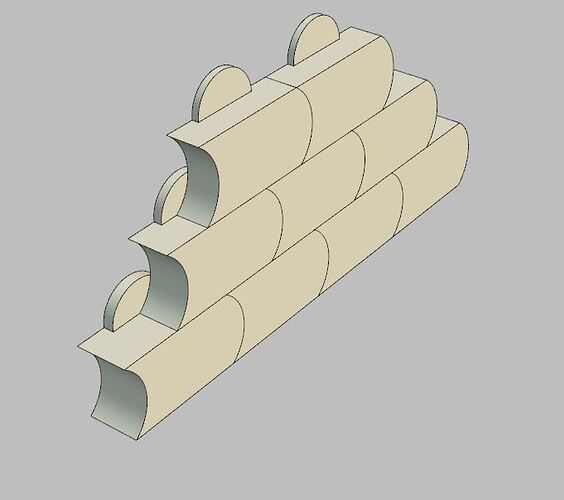

The concept of 3-axis interlocking bricks for building structures like parabolic domes on Mars is an active area of research within extraterrestrial construction, focusing on using local resources (regolith) and robotic assembly.

Key Research & Design Concepts

Interlocking Design: The primary goal of interlocking bricks is to create strong, form-fitting, and compression-dominated structures without relying heavily on traditional Earth-based mortars or adhesives, which are problematic in Mars's thin atmosphere. The wedging action of correctly shaped blocks provides stability.

3-Way Interlocking Units: Architectural and engineering research has explored using "3-way interlocking units" or "universal joints" to map non-planar, complex geometries like hemispherical or parabolic domes. These designs maximize surface contact and prevent horizontal movement, often involving complex computational design (CAD) and robotic fabrication processes (like multi-axis CNC or 3D printing with robotic arms) to achieve the precise, varied angles required for a curved surface.

Material Sourcing (ISRU): To minimize materials shipped from Earth, researchers use Martian regolith simulants to create "space bricks". Methods include:

Compression: Applying high pressure to iron-oxide-rich Martian simulant causes the nanoparticles to bind, forming solid bricks without any additional binders.

Biopolymers: Using synthetic living materials (like cyanobacteria and fungi) to "glue" regolith particles together into building blocks.

3D Printing/Sintering: Using high-powered lasers or a binding agent (such as sulfur cement) to fuse regolith layers, often employing 3-axis or 4-axis Cartesian robots to print specific material paths.

Specific Project Examples

TESSERAE Tiles: Research at MIT has focused on self-assembling tiles called TESSERAE, which use embedded magnets and specifically beveled faces to automatically assemble into complex shapes, such as a "buckyball" or dome structure, in microgravity or a controlled environment.

NASA 3D Printed Habitats: NASA has sponsored competitions and research into large-scale additive manufacturing (3D printing) of entire habitats using Martian regolith materials, often resulting in dome or vault designs (e.g., the Mars Dune Alpha habitat).

The creation of actual physical 3-axis interlocking "pieces" is generally part of specialized academic research and robotic fabrication workflows, not commercially available products in the traditional sense, as the geometry is highly specific to the intended dome's exact curvature and size

3-way Interlocking Units on Hemispherical Dome Surface

Sort of like a tongue and grove but not only the top an bottom but also the ends of the block sized brick.

prefabbed log cabin wall

Dome would be double walled and have insulation for the inner space between the block or brick that we use.