New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#351 2024-06-15 17:01:05

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,626

Re: Fixing Americas car industry

The system's four Level 2 charging ports are fueled by a 6.2-kilowatt solar array mounted on a dual-axis tracker, as Electrek details. By following the sun's movement throughout the day, the tracker harvests a whopping 40% more solar energy than standard fixed panels. All that extra sunshine means more clean power for EVs.

Offline

Like button can go here

#352 2024-06-16 12:30:53

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Fixing Americas car industry

SpaceNut,

Can you tell us what a dual axis sun tracker does to solve the problem of lengthy charging times, battery fires, and a grid that isn't ready to charge a minor fraction of the vehicles that would need to be charged?

If you charge the battery as fast as you possibly can, you greatly reduce its service life. If you fast charge the battery every day, then you don't have to worry about it lasting for 10 years or even 5 years, because it won't.

How about Copper and Lithium mining shortages?

Major Copper mines in South America are being shut down, and there are no new major mines to take their place. About a third of annual Copper "production" is actually recycling of existing Copper.

Does deploying more photovoltaics ease or increase the pressure on Copper mining?

The all-electric / all-electronic future was never thought through. All the people who could do basic math were telling our green energy "true believers" what the major underlying problems were going to be with their ideological dogma, which was never based upon anything but pure belief. Nobody took a look at the ugly materials data to show why it wasn't feasible.

Every part of the proposed solution should've been subjected to rigorous rationalization and accounting practices. Not even a little bit of critical thinking was applied toward that end. Now mining and resource scarcity reality, which is applicable to all metals (especially Copper and Lithium) and all other energy sources (coal, oil, gas, fissile materials), is reasserting itself with gusto. A sane and rational person would quit blindly pursuing unworkable solutions. A religious person would double-down on their religious dogma.

I made a dead serious good faith effort to work within the framework of your religion- that everything must be powered by the Sun in some way, that electricity was the primary means of transmitting power, and that we would stop burning things for energy wherever feasible. I never saw any refutation of the ideas. All of the proposed solutions were based upon exceptionally abundant materials, electricity was generated and transmitted to point of use only where required, and thermal energy from the Sun was used to power all the major energy consumers, because that was the only practical way to power everything using the Sun.

The compressed air or thermal battery and refrigerant loop car designs I proposed, that used hot water or rock imparted using electrical power that doesn't require a specific voltage or amperage or frequency, within reason of course, was entirely about eliminating scarce materials consumption so that everyone could afford to buy an electric car, which would mean that they actually do it, because it's the cheapest option available, performance is like a normal car, and range is no worse than existing electronically-controlled electro-chemical battery operated vehicles, except that no electronics or scarce battery making materials are required.

There is nothing we're going to do about battery energy density / performance / input materials scarcity problems, short of inventing a battery technology that doesn't have those problems. If that's not possible, then the solution doesn't work because it's not meant to work. A 50% energy efficiency improvement can't overcome a 100X gravimetric energy density deficit, relative to gasoline, for transport applications.

This is exactly why electric vehicles were abandoned 100 years ago. The engineers knew electricity was more efficient than combustion engines, but none of that mattered in the slightest when the batteries were 200X heavier. Now the batteries are merely 100X heavier (160Wh/kg vs 16,850Wh/kg for the latest 50% efficient gasoline or diesel fueled internal combustion engines). The 200X heavier batteries had far fewer problems with fires than the 100X heavier batteries, but that didn't make the concept more practical than the alternative (combustion). 160Wh/kg is what a Tesla achieves at the battery pack level. I've not seen or heard of any other models, whether mass produced or not, that do substantially better than that.

I think that one British electric racing plane stunt achieved 200Wh/kg by using a Tesla battery pack and removing all the thermal runaway cell isolation safety features. That seems like a particularly brilliant idea if you wish to incinerate all the passengers in the vehicle after any one of thousands of cells suffers a casualty from a manufacturing defect or charging anomaly, but not something a prudent automotive manufacturer would ever allow.

At the end of the day, we're "stuck" with Lithium being the lightest and most reactive metal on the Periodic Table. We can use heavier elements in a battery to store electric charge, but then the batteries become heavier and they don't perform as well. We may be able to use solid electrolytes or no electrolytes. That might double the battery pack level energy density. That means we're at a 50X gravimetric energy density disadvantage, relative to combustion engines.

We're literally and figuratively "spinning our wheels" with batteries. The most advanced lab models still use the same scarce materials, they don't last substantially longer than the more well-established varieties, and all of them come up woefully short on gravimetric energy density. To my knowledge, absolutely nobody has a working rechargeable electro-chemical battery prototype with an energy density remotely equivalent to gasoline.

There are two roughly correct solutions to this problem. If you are going to design a short range vehicle that is ultimately treated as a disposable appliance, then design one that only uses very abundant raw materials that are easy to acquire and to recycle. If you're going to design a long range vehicle, then make its combustion engine or fuel cell as efficient and power-dense as possible. 50% thermal efficiency without major alterations to the engine is a really good place to start. If we can do better than that, then we should. Modern fuel cells and composite fuel tanks can almost match combustion engine performance in vehicle applications, but not on cost, at least not yet.

If we perfect solid oxide fuel cells that burn normal fuels, then there won't be any non-imaginary batteries, and very few internal combustion engines, capable of matching their overall performance. After all is said and done, a SOFC with a 100L / 26.4 US gallon 250bar CH4 tank would be capable of about 615 miles of driving range. You get to "keep" / turn into useful work, 11,120Wh of 13,900Wh/kg of the Methane fuel, which means you're consuming about 388.75Wh per mile at high way driving speeds. That's about the cleanest / greenest we're going to get from something that performs like a normal vehicle, can be rapidly "recharged" in mere minutes, and is long-term viable as a replacement for combustion engines. The overall solution will weigh around 150kg, including the fuel itself. That's about the same as an equivalent combustion engine, but the 50% thermally efficient combustion engine solution would only require 14 gallon tank, rather than a 26 gallon tank. Most American trucks and SUVs have 25 to 35 gallon gasoline or diesel fuel tanks, which is why 100L was selected as the tank volume. At 700bar and 30C, pure Methane's density is still only 297kg/m^3. 700 bar tanks are still relatively expensive, although getting cheaper over time.

What's "less obvious" is that our 50% efficient internal combustion engine, generating 20% low grade waste heat sunk into engine coolant and 30% high grade waste heat in the exhaust stream, whereas the 80% overall efficient SOFC solution is only generating 20% waste heat, all of that is high grade waste heat capable of powering the vehicle's HVAC and hydraulic (brakes and power steering, and potentially windshield wipers as well) subsystems without sapping any electrical power from the drive motors. The quality of the waste heat and where it's rejected to actually matters. That's as close as we're going to get to achieving electro-chemical battery-like efficiency from combustion processes. The trade-off is increased fuel tank volume. Overall, our fuel system weight is about the same because gasoline is fairly heavy, our engine / drive motor tech is on-par or modestly under that of the combustion engine, yet overall weight is a wash. If someone figures out how to cost-effectively consume most of the waste heat from the combustion engine and convert it back into motive power, similar to the power recovery turbines connected to 1950s era piston engine airliners, then total efficiency might be similar. sCO2 gas turbines with power recovery turbines might also prove fruitful.

This is the sort of research that automotive companies should be doing, rather than spinning their wheels with batteries hamstrung by absurdly low energy densities that aren't likely to change in the near future. I wish we had better electro-chemical battery solutions on offer, but there don't appear to be any. I think it's remarkable how much progress companies like Tesla have made in streamlining all aspects of energy storage and consumption, and I like the overall efficiency, but 95% of hardly any energy, relative to gasoline, is STILL hardly any energy to work with.

We gave photovoltaics and electro-chemical batteries serious R&D money / effort for multiple decades, and devoted some truly gifted minds to that effort, but we don't have enough to show to justify the precious time wasted on non-solutions. It's not all wasted effort, as mobile electronics have benefited immeasurably, but they are not now a viable transportation energy storage medium. They never have been. We need to move past the present fixation on these non-viable technologies, and onwards to potentially viable energy storage solutions.

Offline

Like button can go here

#353 2024-06-16 13:23:47

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,626

Re: Fixing Americas car industry

The first sentence "problem of lengthy charging times, battery fires, and a grid that isn't ready to charge a minor fraction" means that people rushing to charge have not planned the vehicles use which means they are not using an off grid charging during the day to charge when they are working. Planned charging means that time is not something to think of and that in itself reduces chance of fire as the charge circuits are not causing the over current heat. Since tis an off grid there is no power supply issue from the grid as its not attached.

The second "Copper and Lithium mining shortages" means not using copper or lithium as other materials can be used for each.

The following pressure and change are of the same but moving to different materials is just shifting the issues.

As the heat must come from some sort of mining/pumping plus processing if not from the same free sun energy to make the heat.

I know that you did install solar, but the company did not provide the best it could and caused damage to the panels by not controlling how they were placed into the array.

I have a brother that just did this but on a mountain top as its totally off the grid with a large array for all uses as the road does not always allow passage. Plus, there is no electrical or water or any other utilities to this location

Offline

Like button can go here

#354 2024-06-16 14:13:06

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Fixing Americas car industry

SpaceNut,

In the day-to-day lives of real-world people, charging your car is not perfectly planned so that it happens at the exact optimal time for every other person using the electric grid. That is not reality. That has never been reality. For starters, I have no way of knowing what the "right time to charge" happens to be. Even if it's correct at the time I started, what about 1 or 3 hours from then? Something sub-optimal is going to happen, and that is what we should have carefully thought-out prior to pushing EVs.

Back in the real world, real EV batteries use Lithium, real EV motors use Copper windings, and real PV panels use Copper conductors to collect the current off the panels. What else would we use, if not Copper? Aluminum? Your EV motor then weighs 2X as much, according to someone who designs EV motors for a living, because it occupies 2X as much volume to generate the same amount of torque. Aluminum requires more energy input than Copper, about 3X more, pound-for-pound, to be more exact. Where does that energy come from? Oh, right, from burning something.

We installed PV because our home consumed such an absurd amount of electricity to power the pool and 3 AC units, because my wife wanted a giant home with a giant pool. My solution would be to not have a pool at all (because we have plenty of public pools near the house- and for some reason those were always "good enough" when I was a kid), not buy a giant house that comes with giant electricity bills, and oh, I would not drive a giant car the way she does, either. That requires spending no money on PV, no money on a giant house, and no money on giant cars. All in all, that's a solution that works for most people in most places.

The company that installed the panels didn't mess up anything. The environment itself caused the on-panel inverters to short-circuit and die. How do you get around that? It probably involves spending more money and consuming more materials. If your only solution is "more" to each and every energy problem, then it's probably not the correct solution.

For someone who lives on top of a mountain, PV might be the most viable power solution, and maybe the only viable solution. Most people on the planet aren't living in isolated mountain top areas, though. A niche solution which is right for them probably isn't right for everyone else.

When I think about design, I don't look for exceptions to the rule, nor do I attempt to assert how exceptional cases invalidate general rules. Instead, I choose to focus on averages, or "what is typical". If I devised a battery that stores 5,000Wh/kg, but it's made from pure Gold, then you won't see me touting my breakthrough battery design that is wildly unrealistic for general use, on cost alone. Instead, I'll say, "Wow, that seems fantastic, but we're never going to mass manufacture something made from pure Gold, so what else do we have that's able to beat gasoline on energy density?" If the answer is nothing, then I move on to asking more fruitful questions, such as "Can we possibly make gasoline perform more useful work for us, per unit weight burned?" The answer to that question is that we probably can, and we should probably try to do it, because we can probably get real world usable results. Will doing so validate or invalidate someone's religious beliefs about gasoline? Only they can answer that question. All I know for sure is that usable results applicable to the widest possible user base tend to be the most useful.

Offline

Like button can go here

#355 2024-06-16 17:44:23

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,626

Re: Fixing Americas car industry

Much like all refueling of an automobile one must pay attention to the fuel level gauge and yes, I have run out of fuel as I have no current credit cards to draw fuel when needing it. So having cash in the pockets takes care of not paying attention to the gauge.

Electric is not all that different as one must place charge into the battery when one is able to do so. We do have a topic about the charging as a business that is part of making that ability to charge whenever one needs to. Having these charging stations just as available as the gas or other fuels is part of the answer.

Here’s how many public EV charging ports the US has now

Level 1

Automakers often include Level 1 charging equipment with new electric cars. This device plugs into a typical household 120V outlet. Level 1 alone won't be enough to keep up with the charging needs of most EV owners. That said, if you only drive 20 miles or so each day, perhaps you could get by with Level 1 only.Level 2

Level 2 charging operates at 240 volts and typically at three to four times the amperage of a lesser Level 1 unit. As such, the majority of Level 2 units add electricity to your EV's battery pack at a rate that's roughly six to eight times faster than Level 1 setups, equating to 12–32 miles of driving range for each hour of charging.But the charging rate of Level 2 can vary quite dramatically. A typical 240-volt, 24-amp unit can put out about 6.0 kW of continuous power. But the fastest possible Level 2 charging is at 80 amps, or 19.2 kW, which is more than three times faster. The hardware on your car dictates the maximum Level 2 charge rate, and most cars aren't capable of charging at 19.2 kW, so you'll want to match your charging equipment to what your EV can handle to avoid paying for capability you can't use.

Level 3 or DC Fast-Charging

Level 3 chargers are the quickest of the bunch. Alternatively known as DC fast-chargers, Level 3 chargers are especially useful during long trips that necessitate charges between destinations, as this sort of charging can add around 100–250 miles of range in 30–45 minutes. Unlike Level 1 and Level 2 charging, Level 3 setups connect to the vehicle by way of a socket with additional pins for handling the higher voltage (typically 400 or 800 volts).Level 3 charge rates currently range from as little as 50 kW to as high as 350 kW, depending on the charger. But charge rate is a two-way relationship. If your EV can only handle a maximum of 50 kW on a Level 3 charger, then it will not charge any faster than this, even if it's plugged into a charger capable of topping out at 350 kW.

Offline

Like button can go here

#356 2024-06-19 07:47:03

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,626

Re: Fixing Americas car industry

A Radical New Magnet Without Rare-Earth Metals Is About to Change Motors Forever

A U.K. tech company called Materials Nexus recently announced, with the help of its AI platform, they’d developed a magnet that’s completely free of rare earth metals. While this isn’t the first such device—other companies have also created “clean earth” magnets—they did so after a about decade of trial-and-error. According to Materials Nexus’ press release, the company’s AI platform took only three months to design its rare earth metal-free creation, MagNex.

“The current industry standard permanent magnet took decades to discover and even longer to develop into the products we use today; MagNex took just 3 months to design, synthesize and test—x200 faster,” the press statement reads. “MagNex can be produced at 20 percent of the material cost and a 70 percent reduction in material carbon emissions (kg CO2/kg), compared to rare earth element magnets currently on the market.”

Offline

Like button can go here

#357 2024-06-19 12:17:13

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Fixing Americas car industry

SpaceNut,

The article you linked to in Post #356 then links to multiple other fact-free "newsy" articles which make vacuous specificity-free claims about "green energy".

See if you can provide one relevant technical detail about this supposed low-cost / abundant materials AI-created permanent magnet. A claim without evidence provided doesn't count, either. I've spent two hours looking for any further detail and cannot find any at all. I can find all the "newsy articles" repeating the same marketing claims made by this company, but nothing as simple as, "most of the MagNex permanent magnet is comprised of Iron or Aluminum", or "the MGOe and Curie Temperature range is comparable to NdFeB magnets", or "we determined CO2 emissions and materials cost by comparing our MagNex technology to those of prototypical NdFeB permanent magnets". Those are all very specific and testable marketing claims which can be independently evaluated by anyone who knows enough about how NdFeB permanent magnets are made, if in fact NdFeB magnets were used as their basis for comparison.

1. What's this new permanent magnet made from (which elements is this new permanent magnet made from, even if the specific composition or processing methods are not disclosed, because they're trade secrets, which I would find perfectly understandable for companies wishing to sell their inventions)?

2. How much do both the materials used and production processes differ in monetary cost, in relation to existing permanent magnets which don't use Rare Earths?

3. What's the MGOe of this permanent magnet (so that we could evaluate and compare the newly created magnetic material to all existing permanent magnets, whether made from Rare Earths or not)?

4. Tell me how anyone could possibly evaluate whether or not it can be produced at "20% of the material cost", as compared to what types of other magnets (Neodymium Iron Boron, Samarium Cobalt, Aluminum Nickel Cobalt, ceramic ferrites)?

5. Tell me how anyone could possibly evaluate whether or not it can be produced with a "70% reduction in per-kg of magnet material CO2 emissions", when compared to which types of magnets (Rare Earth permanent magnets, non-Rare Earth permanent magnets, superconducting magnets, electromagnets, or some other AI-created miracle magnets which likewise don't exist)?

As near as I can tell, this is yet another load of "green fantasy" bovine excrement. As with all other evidence-free claims, it's created for the express purpose of enticing gullible people into handing over their money. Wealth transfer from your pocket to their pocket is the only real world objective. It's the type of predatory capitalism that our leftists used to be dead-set against, but now cheer on endlessly. When you "re-tweet" something which you should know is a marketing claim without any evidence, then you are perpetuating this insidious form of predatory capitalism which subverts valid science and the faith most ordinary people have that hard science is mostly immune to any specific ideologically-held beliefs. The end goal of MSN's newsy articles is promotion of the green religion to conduct legal but morally reprehensible wealth transfers. It's like promising starving people a miraculous new machine that will feed them for the rest of their lives, if only they hand over the very last of their food to someone who is already morbidly obese. I can't speak for anyone else, but I find such behavior grotesque and impossible to defend, so I would never try to defend it, nor would I purposefully engage in it.

Look at us, we're so green and trendy and virtuous. We're "making a difference". We made claims that agree with your religious beliefs, now give us your money. The undeniable fact that this supposed invention, assuming it actually exists since we're left with zero tangible evidence, is utterly irrelevant to the fact that precisely zero electric motors or generators have been made using any of these miraculous AI-invented materials. I can't find one lousy patent connected to any of the work done by this "Green Tech Startup Company to Watch", according to the chorus of green energy religious zealots touting their "work" (separating gullible people from their money, until proven otherwise). There are no related patents posted on the Materials Nexus website, nor indication that a patent was ever filed. If I came up with a new technology set to make permanent magnets from abundant and low cost materials, and my magnets would be performance-competitive with NdFeB permanent magnets, you can take it to the bank that I would have patents filed to protect my invention as if it was worth more than all the Gold in the world, because it truly would be.

Remember that article I posted about Niron Magnetics Iron-Nitride permanent magnets, which contained the exact chemical formula of the material (Fe16N2), details about the manufacturing process, energy inputs required, comparative input energy and materials costs with NdFeB permanent magnets, and the MGOe of Fe16N2?

They have filed and been granted more than 100 patents, the last time I checked.

That's how I can tell that I didn't "re-tweet" someone's wild marketing claims. I can look at their claims, I can see independent labs and government labs testing their inventions and either confirming or refuting what the company says about their invention's production methods and costs, etc. Incidentally General Motors is paying Niron Magnetics to create Rare Earth free permanent magnets for their line of EVs.

When it comes to marketing claims made about something we already have, in wide variety of kinds with known performance qualities and costs, Stanford Science absolutely should apply. While Stanford Science is not actual science, it is science reducible to repeatable engineering practices. If you have a new magnet, energy production or storage device, or structural materials, Stanford Science should be called Standard Science. In the realm of new understanding of physical laws that govern energy and matter interactions within the universe, then only actual science should apply, wherein data is king, even when we don't understand the data. No religion I can think of is worth sacrificing objectivity and rigor.

How can we tell when we're posting something beyond specious or speculative marketing claims?:

Freedom from rare earth magnets?

A good alternative to magnets made from rare earth elements such as neodymium, dysprosium and samarium – which are expensive, volatile in price and supply and polluting in their extraction – is something of a holy grail for the electrical industry in general and EVs in particular.

Enter Niron Magnetics with its Clean Earth iron nitride magnets. These have attracted interest from organisations including General Motors and Marquette University, in the US, with whom Niron has partnered for the development of EV drivetrains, starting with a demonstrator for the Chevrolet Bolt. Niron CEO Andy Blackburn talks exclusively to Peter Donaldson about the technology.

The neodymium used in the most popular rare earth magnets (NdFeB, for example) costs about $120 per kilo, while the iron and nitrogen used in Niron magnets are tens of cents per kilo.

Saturation refers to the point at which a material can hold no more magnetisation, regardless of the strength of the magnetising field to which it is exposed. When the field is removed, the remaining flux density, known as the remanence, is a better indicator of the magnet’s inherent strength. Blackburn explains that the remanence of the pure materials falls as other substances are added, for example to stabilise the magnet’s performance with temperature.

“The top-performing neodymium magnets are around 1.3 T,” he says. “When you put dysprosium in to make the higher temperature grades the remanence falls to about 1 T, while samarium cobalt magnets are in a similar range but with better temperature performance.”

A practical iron nitride magnet would be in the 1-1.5 T range, but would retain that strength at higher temperatures, such as those in an EV motor, at which only the most expensive rare earth magnets can compete, he adds.

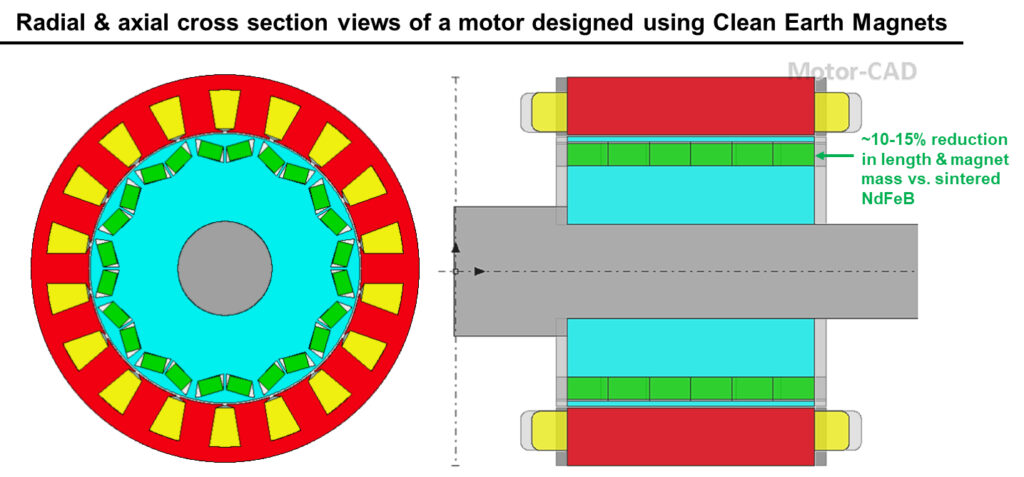

Motor Design came up with designs for a 30 kW, 125 Nm drive motor that would fit a Toyota Prius, achieving a 10-15% reduction in length and magnet mass compared with sintered NdFeB but keeping the original motor’s diameterOne apparent disadvantage of iron nitride magnets is that their coercivity is less than that of neodymium. Coercivity is a measure of the magnet’s ability to resist having the polarity of its field flipped when exposed to a strong opposing field. Without coercivity, the magnetic fields in a motor would rotate without turning the shaft.

“We think the maximum possible coercivity is between 4000 and 5000 oersteds, compared with around 12,000 oersteds or more for neodymium. However, their coercivity drops off as temperature rises, so at typical operating temperatures we are pretty competitive.”

Niron is working to perfect its magnet production using a powder metallurgy process in which nitrogen gas is diffused into the metal in a precisely controlled process designed to yield Fe16N2 powder. This is then consolidated into the required shapes using a polymer binder for the first-generation magnets, which is intended to be replaced by what Blackburn calls cold sintering in the “fully dense” second generation.

Iron nitride magnets should not be thought of as simple drop-in replacements for rare earth magnets though, he cautions. The differences in flux density, coercivity and temperature stability of performance affect how electrical machines using them should be designed, he emphasises. Based on simulations, UK company Motor Design has designed two Prius-class 30 kW, 125 Nm motors, one using each generation of iron nitride magnets, with a motor using N42UH neodymium magnets for comparison.

“You end up with a motor certified at 10% smaller and lighter, with less steel and copper and 15-30% less magnet material because of the higher flux,” Blackburn says. “You get somewhere between two-and-a-half and three times as much power per dollar of magnet cost.”

Funded in part by the US Department of Energy, the Chevrolet Bolt drivetrain demonstrator will use Niron’s second-generation magnet material, and should be ready by the end of 2023. However, the company should be ready to provide samples of this material to other interested parties by late 2022.

Do you notice how oddly specific all the data were surrounding Iron-Nitride permanent magnets, such as costs per kilo of magnetic materials, residual magnetic field strength after magnetization, coercivity measurements, a CAD drawing of an actual EV motor design used in independent testing to evaluate how much power was available from how many kilos of which metals (namely, Iron and Copper)?

Did you also notice how its not all rainbows and sunshine? The fact remains that at room temperature, if you can maintain that in your electric motor or generator, the people working on the new magnetic materials tech flat-out state that NdFeB remains the superior permanent magnet material. Knowing details like that allows a would-be investor to know which markets the tech is applicable to, where it is likely to be used and where it remains an inferior choice to existing tech, such as NdFeB, hence why it is unlikely to be used there unless some outside forcing function pressures the companies involved into selecting inferior material choices. That could be cost, it could be geopolitical, or it could be a technical / engineering problem that is not solvable.

It's almost as if that was how I knew what I posted wasn't another internet marketing claim about a computer program's output. It's as if there was real testing conducted by real materials scientists across the world, and that real companies (with globally recognizable names like General Motors and Toyota) were paying Niron Magnetics for the products being produced, in order to end American and Japanese reliance on China (a hostile communist nation with both written-down and publicly expressed plans for global economic and military domination) for Rare Earth elements, because that would mean anyone with a little bit of electrolytically-separated powdered Iron and Nitrogen from the atmosphere could make their own very powerful permanent magnets with broadly comparable performance to NdFeB.

That is also why we never should've allowed our bulk Iron industry to be exported to China or other countries. People with short and ignorant views of history and human behavior were allowed to make monetary decisions which came with highly adverse long-term strategic and globally applicable consequences that they neither stopped to think about, nor cared about, because it was benefiting them monetarily, "in the moment". Now that moment is gone, it no longer benefits the wealthy over here, and we're spending more public money to bring back all the industries that never should've been exported. In their selfishness and unwillingness to adapt to ensure their businesses remained competitive, they screwed over the common working man or woman, not just in America, but over most of the western world.

Offline

Like button can go here

#358 2024-06-22 15:54:55

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,626

Re: Fixing Americas car industry

Trusting AI is a problem when it leaves out details that are key to the article for sure.

EV Charging vs. Gas: We Do the Math to See Which is Cheaper

EV charging costs vs. fuel costs

EV charging per month Gasoline car (ICE) per month

Average miles driven per month 1,250 miles 1,250 miles

Average fuel cost per gallon — $3.65 per gallon

Average miles per gallon —25 mpg Average no. of gallons of fuel required — 50 gallons

Average power needed for an EV 3 miles per kWh

—

Average kWh used per month 416 kWH

—

Average cost of electricity is (per US household) 16 cents per kWh

—

Average energy cost per mile 5.3 cents 14.6 cents

Monthly comparison $66.56 recharging costs $182.50 fuel expense

Offline

Like button can go here

#359 2024-06-23 00:42:11

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Fixing Americas car industry

SpaceNut,

Every single one of these MSN "green energy" articles is entirely devoid of pertinent information. I merely "fill-in" all the information they left out while propagandizing to their target audience (people who can't do math). I can do math, which is why I don't waste my time reading what they write until one of our green energy "true believers" posts something absurd.

The Tesla Model 3 (ships from Austin, TX) and Toyota Corolla (ships from San Antonio, TX) are both subcompact cars, both take you from Point A to Point B, and both are made in America (two different cities about 1.5hrs apart, driving at 65mph by highway, in Texas, if we want to be very precise).

2024 Telsa Model 3: $39,000; $650/month payment w/o interest over 5 years

2024 Toyota Corolla (32mpg city, 41mpg highway): $22,000; $367/month payment w/o interest over 5 years

Gasoline costs about $3.10 per gallon here in Houston. Average residential electricity rates are $0.13/kWh (lower than the national average). If you live in California, land of green energy, then your average electricity rate is $0.31/kWh.

1,250 miles of driving per month equates to 15,000 miles per year, or 75,000 miles over 5 years, which is something akin to a national average across all miles driven by American drivers. Let's presume you drive all city miles using either vehicle, and never drive on a highway. This is not reality for most people here in Texas, but let's presume the worst case scenario for the gasoline powered car.

75,000 miles / 32mpg = 2,343.75 gallons of gasoline

2,343.75 gallons of gasoline * $3.10 = $7,265.63

Tesla Model 3 tires cost about $1,500, according to the Tesla Service Manager who literally lives next door to my family, and need to be replaced every year most of the time. Sometimes they last a little longer, sometimes a little less, according to her. The vehicle is very heavy, which is why it eats tires faster than a normal car. This is what I've observed from my own experience driving a Cadillac Escalade over 5 years, which is also a very heavy car, and a set of 4 tires also costs about $1,500 for the Escalade. Escalade tires are supposed to last for 45,000 miles, but they never do. Over 5 years, you should expect to pay about $7,500 for new tires, according to a real life / non-AI Tesla Service Manager (my nextdoor neighbor who runs a Tesla Service Department at a Tesla dealership here in Houston, TX). That means Tesla Model 3 tires alone end up costing as much as the gasoline. Maybe someone out there makes their Tesla tires last longer, but on balance of probabilities they're probably either lying or don't do routine maintenance on their vehicle.

Toyota recommends oil changes every 3,000 to 5,000 miles. The oil manufacturers claim their oils will last 7,500 to 10,000 miles, and perhaps they do in some application which is not reality-based, but I know of nobody who wasn't born yesterday, who believes their marketing claims. I will presume 5,000 miles for full synthetic, but only 3,000 miles between oil changes for blends or standard. We're going to presume the owner likes his or her engine, so we're going with full synthetic motor oil, which is made from natural gas. 5 quarts of Pennzoil full synthetic motor oil costs $25.00 at Wally World. The entire service will cost about $75.00, though, with labor (most people don't change their own oil) and consumables (oil and air filters) and fees (to recycle the used motor oil). That equates to what I know about the oil change fees for my wife's Toyota Rav4. That means we're looking at 15 oil changes over 75,000 miles, which comes to $1,125.00 over 5 years.

Electricity, at $0.13/kWh and 250Wh/mile, amounts to $2,437.50. If you have as much green energy as California, then it costs $5,812.50. We're assuming Texas prices because only Californians like paying 3 times as much for the same electricity, while pretending their "green", albeit getting most of their energy to recharge their vehicles from the coal burning power plants in other states like Arizona or Idaho.

2024 Toyota Corolla Total Cost of Ownership for 75,000 miles / 5 years:

$22,000 (car) + $7,265.63 (gasoline) + $1,125.00 (oil changes): $30,390.63

Toyota Corollas have a 21% depreciation value over 5 years, which means $17,380.

2024 Tesla Model 3 Total Cost of Ownership for 75,000 miles / 5 years:

$39,000 (car) + $2,437.50 (electricity) + $7,500 (tires): $48,937.50

Tesla Model 3's theoretically have a 21% depreciation value over 5 years, which means the car will be worth $30,810. A Tesla Model 3 owner reported last year on Clean ARS Technica, with documentation from the dealership, that his vehicle depreciated 58% after just 4 years of ownership, which means $16,380 is all a Tesla Model 3 owner can expect to resell the vehicle for, assuming someone wants it. In short, he's upside down on resale value.

You will never ever see a monetary "payback" from the supposed energy efficiency improvement associated with driving a Tesla Model 3 instead of a Toyota Corolla. Since all the energy consumed at night comes from burning coal or natural gas, your electricity is not cleaner or greener, especially if you live in California. The only thing that's green about "green energy", is the color of the money being lit on fire in blind pursuit of the math-free and therefore science-free "green ideology". Global warming is real, but the solutions being offered to "solve it" are more fraudulent than three dollar bills.

What is money (fiat currency)?

It's debt, obviously, but it's actually a claim on energy and labor ("the debt") yet to be converted into goods and services.

The reason the Tesla Model 3 costs more than a Toyota Corolla, regardless of how long you own it, is right down to the fact that it takes more energy to create and power one. Most of that energy is produced by burning something. Tesla's labor and energy consumption is as efficient as anyone knows how to make it. I've seen no other automaker do things as efficiently as they do. Every other car maker loses money on every EV they sell. Tesla had to raise their prices because they started losing money. In the realm of efficiency / innovation / quality control in mass manufacturing, General Motors, Ford, Toyota, Chrysler, and Volkswagen are jokes compared to Tesla.

Be that as it may, Tesla can't make their cars any cheaper. If we're talking about a general purpose passenger car that represents an acceptable substitute for a gasoline powered car, under most use cases, then the Model 3 is the baseline against which other makes and models must be judged. The energy consumed is the entire reason a Tesla costs more than a gasoline powered car. Tesla is not profiteering. They're a legit automotive business, with a 5% to 10% profit margin (less or negative in some years), like all other legit businesses. They happen to make general purpose EVs. They have some AI and other tech-related business divisions, but selling cars is how they make money. They do that better than anyone else I've seen. BYD is not going to "eat Tesla's lunch" until they stop burning their showroom floors to the ground with Lithium battery fires. If you make enough money to pay for 2 brand new Corollas, then you can afford to own the cheapest / most efficient EV that Tesla presently makes. You should expect to pay the same or more for a materially inferior EV from other manufacturers. A BYD might be wonderfully cheap, at least until it burns your home or apartment complex to the ground, and then it won't seem very cheap after the other liars, I mean lawyers, get involved. Lawyers are "very green", too, but only when dollars are involved. I've never seen the entire rear axle fall off a Tesla driving down the road, either. Just sayin.

I'm still waiting for these cheap / green / more reliable EVs.

We need to pursue more realistic alternatives, such as compressed air or thermal power stored in rock, salt, sand, or water. We know how to make them, but people need to be realistic about their range expectations, and we need to store energy using something cheaper than electro-chemical batteries, or this green energy transition, which hasn't happened, will remain a pipe dream forever.

Offline

Like button can go here

#360 2024-06-23 14:37:20

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,626

Re: Fixing Americas car industry

Automotive gasoline price National Average $3.456 NATIONAL AVERAGE GAS PRICES

Automotive national gasoline vehicle mileage average 25.4 miles per gallon Average US Vehicle Fuel Economy Was 25.4 MPG In 2021

Automotive national gasoline vehicle yearly driven average is 14,489 in 2022 Average Miles Driven Per Year: Why It Is Important

Automotive national electric vehicle yearly driven average & Automotive national electric vehicle mileage average Average EV Owner Drives Half as Many Miles as Other Drivers—Study

The number, 2.9 kWh, was then run through a formula with a number of other factors to come to an estimate that EV drivers go around 5300 miles a year. That's about half of what gas-powered cars do each year.

They found that the national average EV charging cost ranges from eight cents per kilowatt-hour (kWh) to 27 cents per kWh, with an average of 15 cents per kWh.

Since apples to oranges are being set up we will equalize them.

15 + 27 = 42/2 = 0.21 cents.

14,489 / 5300 = 2.73377 x 2.9 kWh = 7.9279 kwhr equivalent. x .21 = 1.664868 or $1664.868

14,489 / 25.4 = 570.433 x $3.456 = $1,971.41669

Sure we can have cars that use less in either case and those that cost twice that for having mileage capability that are real low.

Offline

Like button can go here

#361 2024-06-24 04:26:15

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Fixing Americas car industry

SpaceNut,

Using averages or national averages doesn't help, unless they're population weighted averages. People guy gasoline or electricity, and the number of people buying it at a given rate is what matters. If Hawaii charges $10.00 for gasoline, then it wildly skews the national average, despite the fact that the population of Hawaii is tiny compared to the most populous states. Nobody purchases gasoline or electricity at "national average" prices. If you want to evaluate the total economic effect of "A vs B", then population-weighted averages or volume-weighted averages are the most accurate ways of doing that. If gasoline and electricity prices varied very little from state-to-state or region-to-region, then using national averages would be an acceptable substitute or proxy for evaluating "what does it cost the average American".

In relative terms, a lot more people pay higher prices or lower prices for gasoline or electricity than the national average, because California, New York, and Texas are the most populous states.

Driving a Tesla Model 3 is all about money. If you can afford to purchase a pair of brand new Toyota Corollas, then you can afford to purchase a single Tesla Model 3.

If you expect your Tesla's battery to last 10 years, then you will routinely discharge from 80% to 50% of its capacity, and then recharge it from 50% capacity to 80% capacity. If there are no manufacturing defects, then it's a pretty safe bet that a battery cared for in that manner will actually last 10 years, based upon what I know about battery wear and real life experience making laptop and cell phone Lithium-ion batteries last for 10 years. That means you realistically have 98.4 miles of nominal range while driving your Tesla, while simultaneously making its 82kWh Lithium-ion battery last 10 years in most cases. That's for the long range model that costs more than $39,000, though. For the standard model that costs $39,000, you realistically have 69 miles of nominal driving range before you must recharge, assuming you wish to preserve the battery's useful service life for a full 10 years of operation.

Anyone who wishes to argue that point with me is welcome to do so, but should be aware that they're arguing against the recommendations of major Lithium-ion battery manufacturers such as Panasonic. Tesla is in the business of selling cars, so they're probably not going to mention the physics of battery charge-discharge when they're touting driving range as a selling point for buying their car. Yes, you absolutely can charge to 100% battery capacity every single day, and discharge to 0% capacity, but you should not do that while also expecting the battery to last for 10 years, because that is highly unlikely to actually happen if that's how you treat your vehicle's battery.

I cannot tell you or anyone if the current generation of control electronics will actually last for 10 years, and I seriously doubt that anyone can, because we have no examples to work with ("prima facie evidence"), because the tech is too new to actually "know" how many mass manufactured units (battery charge controllers, motor controllers, sensor chips, etc) will last that long. Given all the premature failures across the entire electronics industry, I would say that any claim that the power electronics will routinely last for 10 years is dubious at best without a lot of test data, which nobody has.

I can assert with a high degree of confidence that a 700 bar CFRP compressed air tank will last for at least 25,000 fully-reversing (0psi to 10,290psi) cycles, because there's an ever-growing mountain of evidence that H2 tanks for fuel cell vehicles last about that long in actual service.

If you can get 75 miles of range from a compressed air car, then 25,000 cycles before an unacceptable probability of failure of the storage tank means you can drive 1,875,000 miles. If you can only get 50 miles of driving range, then 1,250,000 miles. If you can only get 25 miles of driving range, then 625,000 miles. Most passenger vehicles based upon internal combustion engines or electro-chemical batteries will not reach a half million miles before major parts replacement (such as the engine or battery or transmission) is required. Compressed air providing 25 to 100 miles of driving range has been thoroughly proven, but the automotive manufacturers thought there would be no market for the vehicles due to "range anxiety". Even at only 25 miles, that's 62,500 miles per year over 10 years. Almost nobody except for a taxi cab driver or long haul truck driver runs their vehicle that hard.

About 15 years ago, CFRP 700 bar H2 tanks with HDPE liners were achieving 21,000 cycles. Modern ones achieve 25,000 cycles with improve resins. A compressed air tank, which doesn't have H2's inherent degradation mechanisms might achieve more cycles, but we know it will at least achieve 25,000. When they do fail, they turn into "Carbon spaghetti", rather than throwing shrapnel like Aluminum or steel. The newest ultra-thin CNT-reinforced tanks have very little spaghetti to throw, so they're even safer. In all cases, the storage compartment or the tank itself is protected with Kevlar fiber to prevent sharp shards of CFRP from hurting anything. It's still spectacular and a little scary when one lets go, but the damage done is very minor. The prices of these tanks have been steadily dropping from mass production as well.

Since an electro-chemical battery that will last for 10 years is only going to net somewhere between 25 and 100 miles of range dependent upon the size of a realistic battery, why can't we substitute a very costly, resource-intensive, energy-intensive, and environmentally destructive electro-chemical battery for a compressed air storage tank?

Your practical driving range is the same using both technologies, but using the compressed air tanks give you many more guaranteed miles of driving range, since the capacity of the storage tank does not diminish with time. Unless the tank or its fittings leaks, if you charge your tank to 100% of its nominal capacity, then you can be assured that you have a given number of miles of range to work with. There's no "guess work" regarding how far you can drive. You also have a built-in air conditioner system provided by your vehicle's exhaust, so that doesn't need to be a separate engineered system onboard the vehicle. There won't be any Lithium or Sodium metal fires which achieve arc-welding temperatures, nor fuel-air explosions. If a CFRP tank ruptures, then the tank releases cold air back into the air.

Hot water, salt, or rock could potentially damage the road surface or vehicles or burn people involved in the accident, but compressed air becomes cold air during an accidental release. 700bar H2 tanks struck by bullets will release their stored H2, but they don't burn or explode, so compressed air stored in the same manner would result in a lot of nothing happening.

The CFRP Type IV (HDPE liner or liner-less) H2 tank that US DoE is evaluating at has a 253L water storage capacity, operates at 700bar, and weighs 182kg. That would provide 177.1m^3 of compressed air (0.253 * 700 = 177.1m^3 or 6254.2275ft^3).

A 1hp air motor regulated at 90psi is equal to a volumetric flow rate of 12scfm to 15scfm. Actual flow rate depends upon the type of air motor involved. Turbines tend to be more efficient than pistons and gerotors, because pistons have more friction and starting torque to overcome. They provide more torque, but not more power per volume of air flowed through them.

6,254ft^3 / 12ft^3 per minute = 521 minutes of operation at 1hp, or 8.68hp-hrs

6,254ft^3 / 15ft^3 per minute = 417 minutes of operation at 1hp, or 6.95hp-hrs

That's not very much, but the horsepower required to move a vehicle at a given speed is a function of aerodynamic drag and rolling resistance. As speed increases, aerodynamic drag force becomes the limiting factor.

Force(drag) = 0.5 * Density(air) * velocity^2 * Area * Cd (drag force coefficient)

F = 0.5 * rho * V^2 * A * Cd

rho = 0.07647lbs/ft^3 (sea level "standard atmospheric density")

V = 55mph

A = 8ft^2 (standard full size passenger car frontal area)

Cd = 0.31 (Toyota Corolla drag coefficient used, most passenger cars fall between 0.25 and 0.3, 0.35 to 0.45 for most trucks and SUVs)

F = 0.5 * 0.07647 * 3,025 * 8 * 0.31

F = 286.84ft-lbs

That means aerodynamic drag requires 0.522hp to overcome at 55mph.

Coefficient of rolling resistance (Crr) is mass, gravity, and surface-dependent. On a concrete roadway, which is what we have here in Houston and in many other major cities, the following is what your rolling resistance looks like for a 1,000kg total vehicle weight and "grippy" tires rather than absolute minimum coefficient of friction tires:

F = mass * gravitational acceleration * Crr

F = 1,000kg × 9.81m/s^2 × 0.015 = 147.15N

F = 108.54ft-lbs

In total, 395.38ft-lbs of force needs to be produced by the drive system to maintain 55mph, or 641.92ft-lbs to maintain 75mph.

There's nothing magical about 700bar storage tanks, but the relative storage volume required at 450bar vs 700bar makes the lower pressure tanks too physically large to store the required volume of air aboard a vehicle of the same shape and size as any other modern vehicle. If the range requirement is decreased, then lower pressures or much smaller high pressure tanks become feasible. Since so much effort and money has already been expended on 700bar tanks, there's little cost advantage to using lower pressures. The most recent development efforts have focused on 850bar tanks and drastic weight reduction by including CNT in the resin matrices to bind layers of fibers together. If you have T1100G fiber, the right kinds of resins, and CNT additives to dramatically increase inter-laminar shear strength, then you can achieve even lower tank masses than the 182kg tank mass taken from DoE research and evaluation efforts. With the compressed air and tank masses taken together, there's about 400kg of weight locked up in the energy storage subsystem. If the chassis, wheels, and suspension are also made from high-strength CFRP tapes, then 1,000kg is a very reasonable weight target to meet while still achieving acceptable highway crash protection standards. A Tesla Model 3 contains a 481kg battery pack. This storage system is about equal to a Tesla battery pack in terms of range provided, even if it does so in a very different way.

If you used T700 fiber tape to wind / wrap the chassis, then you're looking at about 300kg and $3,450 for the fiber, at $11.50/kg. Assume that the resin costs about twice as much per kg as the fiber, in bulk, so 200kg and $4,600. The chassis and "fuel tank" become very expensive relative to other types of cars which use more machining of heavier steels or Aluminum alloys, but there's not as much total cost for all the other components, simply because there aren't very many of them. We're looking at a drastically simplified vehicle design. It has a monocoque chassis, air turbine motor, flywheel, pneumatically-shifted transmission, brakes, wheels, and tires, like any other normal passenger car, but all major components have greatly reduced weight.

That is the aerospace solution to achieving greater energy efficiency while using abundant natural energy resources. When you sufficiently reduce the total weight being propelled, the total power required becomes quite small. The same applies to boats and aircraft, although I doubt we'll ever see practical compressed air flying machines much larger than model aircraft.

If you want to walk away from a high-speed crash, then you use 6-point harnesses, not electronically-deployed air bags. The number of race car drivers who have walked away from 200mph crashes is now in the low hundreds. The number of passenger car drivers who have walked away from 200mph crashes due to air bags, is zero. If there were no electronically-deployed air bags in a car, then they cannot fail. All the weight, cost, and complexity associated with air bags goes right out the window with them. Having a solid connection to your seat and vehicle chassis, by wearing a suitable restraint harness and using chassis materials that can absorb the force of impact better than steel, is what saves lives.

To accelerate at any reasonable speed, we'll need that turbine to spin-up a flywheel to rapidly impart the force required to accelerate the vehicle, which will waste more energy, but overall, the amount of force required to accelerate a light vehicle falls within the realm of compressed air and flywheels.

Knowing what we know about these dramatically simpler methods of achieving the same end goal, where upon the spectrum of relative importance does electrification fall to achieving energy independence? I would say it's not very important, and likely to be a rather expensive disabling technology, rather than an enabler for energy self-sufficiency. However superficially efficient electricity may appear, storing electrical potential energy in significant quantities remains wildly impractical.

If our green energy advocates want a return to late 1800s energy consumption rates, then combining advanced materials technology with abundant energy sources is the only practical way to do that with the number of people presently on Earth. Otherwise, nothing of the sort will ever happen by using ever-increasing numbers and varieties of disposable electronic devices, because it can't. If you demand multiple orders of magnitude of entropy decrease, which is what electrification and electronic devices actually represent, then your total energy consumption to do that must increase accordingly. Where the energy is expended or "sunk" merely shifts into mining or production or storage with electrification. At no point in time is any energy actually saved. You may not "see" your energy demand increasing, because much of that happens across regions of the world far away from where you drive your Tesla, but it's still there.

I'm left puzzled as to what our "Jetsons lifestyle" advocates thought would happen with electrification of transport. A vertical takeoff flying car requires stupendously more energy in operation than a road-bound machine of any description. In rough general terms, a rotary wing aircraft or "helicopter" requires double the energy expenditure to move a given payload to a given distance, as compared to a fixed wing aircraft, and a fixed-wing aircraft powered by a piston engine has double to quadruple the energy expenditure of a road-bound piston engine car. The number of miles traveled for a given fuel burn can be roughly equal to some of the most fuel-efficient cars by traveling at higher speeds through thinner air, but the power demanded virtually ensures that it's using twice as much fuel per unit of time.

How does this apply to EVs?

Even if the daily energy usage efficiency jumps up from 35% (combustion engine) to 75% efficient (batteries and electric motors), that doesn't result in an overall or net energy consumption rate decrease, because every EV made has double to triple the energy input, relative to a combustion engine car, because the specific metals content of the EV requires dramatically more energy input. We're playing a pointless shell game with when and where the energy is demanded. EVs demand 2X as much up-front energy, and then consume about half as much energy in operation. Norway has already run this experiment. Eliminating nearly all the combustion engine powered cars only resulted in a 10% oil energy decrease, but they have loads of hydro power and wind to exploit. That's great, but there's very little heavy industry in Norway. They don't make Teslas. America does. China does. We mostly burn the dirtiest grades of coal to do that, BTW. If every Tesla in Norway lasts for 10 years, then we might come out ahead on total energy consumption, oil and coal in particular. If most of those cars become scrap inside of 6 years, as virtually all "modern" vehicles do, then we're probably increasing our CO2 emissions because we're consuming more energy to make a car and a battery that weighs as much as a car.

Let's contrast that with compressed air cars. If we built 400 million compressed air cars vs EVs, then collectively they weigh about 400Gt vs 800Gt, which means both creating and powering them requires no more energy than a regular steel car, they still don't burn any oil in operation, and likely require half as much energy input as a battery powered car with a battery that weighs as much as the air powered car. There's no shortage of "air", nor Carbon for Carbon Fiber. The vehicle is mostly Carbon by weight. It likely has the same or fewer moving parts as the EV, especially if we delete the motorized door handles and every other form of pointless cost and complexity. It's range doesn't decrease at all over time, so there's no real need to make a new storage tank unless the existing vehicle's air storage tank has been damaged beyond economical repair, which would typically involve a crash that sees all types of vehicles scrapped. If someone needs to repair the vehicle, that requires hand tools. All of the vehicle parts are light enough to move by hand or with a hand crane. When the time does come to recycle the car, it's mostly Carbon and plastic, which are materials we know how to recycle in bulk, just like steel. The energy required to recycle CFRP is much lower than the energy required to make it. The fiber will end up as chopped fiber filler for making low-cost CFRP parts with about 80% of the strength of a fabric or tow / roving.

I only see up-sides to doing this, because it means we're not "short" on any critical materials, and the infrastructure to compress air is already widely available. This is merely one possible solution. There are others. None of them involve making and consuming more metals or electricity, because we simply cannot do that at the scale required to electrify everything. Earth lacks the metal resources to electrify everything, and if we substituted Aluminum for Copper, then we need 3X more energy input per pound of metal, our emissions absolutely will increase from doing that, and thus there is no CO2 emissions benefit, which was the entire stated reason for electrifying everything.

Offline

Like button can go here

#362 2024-06-24 17:25:39

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,626

Re: Fixing Americas car industry

Operational replacement of parts that wear out is a different problem for owning either vehicle type as they age.

Changing the source of the energy that makes the car move does not really change the cars mileage as the energy still comes from the same sources that will fill the vehicles tank to make it move.

Offline

Like button can go here

#363 2024-06-24 18:03:58

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,130

Re: Fixing Americas car industry

For kbd512 re *361

You and Calliban have made arguments in favor of compressed air energy storage, but so far as I can see, the rest of the human population is not interested in the idea.

I was ** very ** interested in the idea, and was prepared to make investment in a modest demonstration system. I bought a generator capable of producing 12 volts with sufficient amps of power to light a small set of bulbs. I was interested in turning the generator using an air motor, but the bugaboo was that there does not seem to be an energy storage module available on the open market suitable for this application.

I am no longer in a position to pursue this, but I was most definitely interested for a considerable period of time.

It seems to me you and Calliban need a gullible person with deep pockets to follow the direction you both seem to believe will lead to a good result.

Neither of you are (apparently) in a position to make anything happen on your own.

Let's hope that such a gullible person shows up,

I would very much like to see a practical demonstration of the vision you and Calliban appear to share.

(th)

Offline

Like button can go here

#364 2024-06-25 01:54:48

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Fixing Americas car industry

tahanson43206,

1. Immediately going out and buying an electric motor, with the idea of turning it into an air compressor, runs directly counter to the use of basic engineering principles to first work out what to build and then how to build it. Do you recall how we were still debating whether the compressed air or hot fluid power source would work best? I admire your enthusiasm for the idea, but I never asked anyone to do such a thing.

2. The equipment to make an air powered car does exist, but much like the tech to make an internal combustion engine or a battery for a road car, it's not something you're likely to fabricate in your garage, absent a substantive investment in time and money.

Hydrogen Type 4 Cylinder 700 bar 103L

You have to buy at least 3 of these, or they're not interested in selling to you. They're not cheap.

3. I wouldn't waste my time and money or anyone else's on ideas that I wasn't already quite certain would actually work. I would hope that anyone investing their own money has the attention span and level of understanding required to fully comprehend what we're proposing and why, before they ever spend one cent of their money. I would insist that they show some baseline level of comprehension before taking their money. I'm not a salesman for climate change or any other religion, so I don't offer up "solutions" that are not actually solving real problems for most people in practical ways.

I'm not the least bit interested in selling more disposable appliances to rich people. There's an endless variety of novelties for rich people to spend their money. I'm not enamored with novelties. If I never see my customers again, unless they wreck their car or their kids need cars, too, then I will consider that an actual worthwhile achievement. There are plenty of other ways to make money. After I solve one problem, I move on to the next. That's why Elon Musk went from payment software, to rockets, to cars, to tunnel boring, to AI machines. If a prospective investor has a problem with conducting business that way, then I don't want their money. If that means none of these ideas ever see the light of day, I really don't care.

I guess the kind of investor I'd be after is someone who genuinely cares about both people and the environment, and does not look down their nose at their fellow man merely because he has more money than they do. There aren't many Henry Fords left in this world, but there have to be some, and all it takes is one.

As I see it, the EV market is presently floundering due to intractable material scarcity issues that no amount of climate religion or happy talk will ever resolve, technical issues related to the fact that current battery technology is now well past any step-change performance improvements, and because the world's supply of snobbish wealthy leftists wishing to tell everyone else how green and clean they are, merely because they went out and bought a fancier disposable appliance than most other people could afford, has mostly dried up. Very few people who actually require a reliable car are buying EVs. They're status symbols for city-dwelling hipsters and middle-aged tech and finance guys with no wives or children- the kind of people who have plenty of disposable income, but would never get their hands dirty working on a car, because that's something they pay someone else to do for them. For the rest of the driving public, which is most people, buying a car with an internal combustion engine remains their only realistic option. The people who mow lawns, turn wrenches, or weld pipes are my target customers, regardless of how much disdain our snobs have for them. The major automotive manufacturers, at least those not presently firing all of their employees, are collectively returning to making more combustion engine vehicles, because they don't have any other workable solutions.

Yes, GM could've sold EVs to our Hollyweirdos back in the 1990s. They'd be the only people buying that product, and there simply weren't enough of them to justify the many billions spent trying to make EVs work at the scale required.

In the 1960s, Ford sold a million Mustangs in about 18 months. Tesla sold their millionth vehicle after 92 months of operations- almost 8 years of losing billions of dollars, every single year. Investors and governments wanted to force the technology into existence, so they kept dumping money into it, continued the PR campaign, and then they mostly sold them to people overseas who wanted to be "green and trendy". Your pizza delivery driver doesn't care about being trendy. He's not trying to keep up with the cool kids. He's busting his rear end to try and make ends meet. China now has acre after acre of EVs rusting in scrap yards, never to be sold to anyone. They keep their local firefighters gainfully employed, but that's about it. Nobody is buying the product because they can't afford to and they're not getting any cheaper than they already are. Most people need a reliable car that doesn't require factory disassembly because one battery cell out of thousands quit working. Putting a minor dent in the battery pack casing is grounds for the insurance company to total the entire car. I'm not sure how ridiculous the results have to become in order to convince people to try a different plan.

EVs remain an utterly impractical solution to personal mobility for most people, unless we're talking about a bicycle or moped. The people who buy those don't care at all about the clean green electrification religion. Transportation is purely a practical proposition for them. They either get a reliable vehicle, of whatever variety, or they don't get to work to make their money and pay their bills. EVs were sold to the general public as being a lot of things they're clearly not. 10 years from now our illustrious "scientists" will suddenly "discover", much the same way they did with corn-based Ethanol production, that in point of fact, the EV is no cleaner or greener, it merely shifts when and where the CO2 emissions occur to some place that nobody is presently fixated on measuring. EVs are not more reliable. I had an oil exec coworker who told me how reliable his Tesla had been, while it was sitting in the shop for 3 months, after asking him where his car was. EVs are not cheaper than gasoline powered cars, unless you get one that performs very differently than a normal gasoline powered car. They're not any less polluting until you drive the thing longer than most people keep a car and you power it using an energy mix that doesn't presently exist in most countries on planet Earth, and won't exist for lack of all that Copper and Lithium that we don't have and flatly refuse to invest more money into. They're nearly impossible to service, and the dealership won't even sell the parts to you to make your own repairs, if they even had parts to sell, because most of them don't.

4. It doesn't matter to an engineer if you know you're wrong, or not. All those people who swore up and down that the Earth was flat were still wrong. Valid math and therefore science is not consensus-based. If 97% of "scientists" agree that the Earth is flat, that only means 97% of them have no business attempting to apply the principles of valid science, never mind engineering, because they prioritize their ideological / philosophical / religious beliefs over observational evidence, or whatever makes money, which means what they're doing is no longer science. It's like a doctor selling pills he knows is killing his patients. Wearing that white lab coat is the most meaningless part of what makes you a medical doctor.

I can use simple historical observational evidence to "know" that at no point in time in all of human history has production of a metal that we already mine expanded by 50% in 10 years time. The probability that Copper and Lithium become the only exceptions to that rule is statistically zero or near-zero. That is precisely what any real engineer would tell you, because he doesn't care about his ideology, your ideology, or that of anyone else's while he's making math-based decisions about what will or won't work at the scale required, in the time frame required, and at the cost required to implement the new tech. Someone who is simply collecting a paycheck while not telling the truth to his employer about the practicality of what they're attempting to do is likewise, an engineer in name only.

5. I would like to see a practical application of these ideas as well, if only to finally realize the otherwise "impossible dream" of this cleaner and greener energy that we're thus far not getting, but maybe that won't happen until we run out of oil and specialty metals. I already see the engineers coming to the realization that in the future centralized power plants using dramatically simpler and cheaper energy production and storage methods than those involving power electronics will be required, else there will not be any energy transition.

Everyone seems to want to live the Jetsons lifestyle, which demands more and more energy, while they also demand that energy consumption to somehow be less impactful to Earth's environment. Those are opposing engineering requirements. Pick one or the other. If you want cleaner and greener, that requires using more abundant materials, simpler and longer lasting machines that are easier to recycle, thus fewer of them, and people who broadly accept that you can't randomly throw money every which way with the expectation of a desirable outcome. In short, learn how to prioritize in a way most people can live with.

Offline

Like button can go here

#365 2024-06-25 06:22:02

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,130

Re: Fixing Americas car industry

For kbd512 re Post #364

Thanks for a thoughtful review of the comparison between technology options.

Your observation about not buying equipment before a complete system is designed is certainly valid, as experience has shown. I was trying to create a psychological framework for members of this group to solve the problems of creating a small scale compressed air energy storage system. No one asked me to do anything! Calliban specifically asked that no one spend any money on anything.

Had my gambit been successfully we would now have a working compressed air energy storage system able to light a set of 12 volt bulbs.

Now we will remain as we were, just a forum with ideas and plenty of interesting information, but there will be no demonstration of capability in our archives.

The resources available to throw at a problem are certainly a factor in success vs failure.

If you look at Calliban's member text, you'll see a mantra that argues against thinking about how to do something, vs acting to make it happen.

My guess is that you'd find that most entrepreneurs do NOT know how to do something that is new, and many fail, but a few succeed, and our vibrant civilization thrives because of their willingness to take the risk.

Elon Musk is a reasonably good example of an entrepreneur who has the risk tolerance to address an opportunity, whether it is business or a technology or a combination. Losses go with that boldness, and by observation, I deduce that he has the ability to accept the early failures as the price for eventual success.

In any case, the inspiration you and Calliban have provided to forum readers remains available, and it may yet inspire someone to attempt to create a viable compress air energy storage system beyond known capabilities.

(th)

Offline

Like button can go here

#366 2024-06-25 18:47:33

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,626

Re: Fixing Americas car industry

I have seen 5,000 psi scuba style takes used for self-contained breathing equipment that are composite that do not explode when ruptured.

https://wilcoxind.com/backend/wp-conten … ochure.pdf

Offline

Like button can go here

#367 2024-06-27 14:26:11

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Fixing Americas car industry

SpaceNut,

450bar to 850bar Type IV CFRP high-pressure H2 tanks are quite real, even if most people don't normally see them in their daily lives. A Type IV pressure vessel is a very specific US Department of Transportation H2 / CNG storage container rating that comes with safety and testing requirements attached to it, because rated pressure vessels are used for transportation of compressed gases. Type IV works equally well for air and most other high pressure gases. There are highly acidic or basic chemicals for which CFRP is not a good storage container, but they are typically compatible with air, Oxygen, Hydrogen, Methane, Helium, Nitrogen, Argon, and other common gases. For gases such as Chlorine and Fluorine, you're better off using stainless steel, potentially with a fluoropolymer liner, and accepting reduced storage pressures. Composite tanks with fluoropolymer liners can store Chlorine and Fluorine gases, but that's not how it's typically done. I assume there are good engineering and economic reasons for continuing to use stainless steels and reduced pressures for such aggressively oxidizing chemicals.