New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#26 2025-12-11 16:03:15

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,109

Re: This title is meaningless or unwanted

The issue I see is the simulant does notlook anything like the regolith surface of mars images which the rovers have broadcasted.

How to make metals from Martian dirt

The idea of building settlements on Mars is a popular goal of billionaires, space agencies and interplanetary enthusiasts.

But construction demands materials, and we can't ship it all from Earth: it cost US$243 million just to send NASA's one ton Perseverance Rover to the Red Planet.Unless we're building a settlement for ants, we'll need much, much more stuff. So how do we get it there?

CSIRO Postdoctoral Fellow and Swinburne alum Dr. Deddy Nababan has been pondering this question for years. His answer lies in the Martian dirt, known as regolith.

Building an off-world foundry

As it turns out, Mars has all the ingredients needed to make native metals. This includes iron-rich oxides in regolith and carbon from its thin atmosphere, which act as a reducing agent.Swinburne University of Technology astrometallurgist, Professor Akbar Rhamdhani, is working with Dr. Nababan to test this process with regolith simulant—an artificial recreation of the stuff found on Mars. The work was published in two papers in the journal Acta Astronautica.

https://linkinghub.elsevier.com/retriev … 6525002814

https://www.sciencedirect.com/science/a … via%3Dihub

"We picked a simulant with very similar properties to that found at Gale Crater on Mars and processed them on Earth with simulated Mars conditions to give us a good idea of how the process would perform off-world," he said.

The simulant is placed inside a chamber at Mars surface pressure and heated at increasing temperatures. The experiments showed pure iron metal formation around 1,000°C, with liquid iron-silicon alloys produced around 1400°C.

"At high enough temperatures, all of the metals coalesced into one large droplet. This could then be separated from liquid slag the same way it is on Earth," Professor Rhamdhani said.

Along with Dr. Nababan, Prof Rhamdhani is collaborating with CSIRO's Dr. Mark Pownceby to further advance the process. They're particularly focused on making metals with zero waste, where the byproducts of the process are used to make useful items.

If you can't ship it, make it

ISRU is a growing area of space science because in rocket launches, every kilogram counts. While the cost of launches is going down, the demands of human exploration are immense.But huge developments are already happening, including the first demonstration of ISRU off-world: The MOXIE experiment onboard the Mars Perseverance rover produced breathable oxygen using only the carbon dioxide in the planet's atmosphere.

Metal production is the next giant leap. Professor Rhamdhani hopes Mars-made alloys could be used as shells for housing or research facilities, and in machinery for excavation.

"There are certainly challenges. We need to better understand how these alloys would perform over time, and of course whether this process can be recreated on the real Martian surface," he said.

But in the meantime, Swinburne and its partners are doubling down. Professor Rhamdhani together with Dr. Matt Shaw and Dr. Deddy Nababan from CSIRO recently delivered a four-day joint Swinburne-CSIRO bespoke workshop on astrometallurgy in South Korea, and the feedback was promising.

"We're starting to see increased interest in this field globally as the world gets serious about Mars exploration," he said.

"To make it happen, we're going to need experts from many fields—mining, engineering, geology, and much more."

For Dr. Nababan, the benefits go beyond exploration. He hopes their research will also drive more efficient metallurgy on Earth.

"By doing this, I wish that I can help the development of space exploration, and at the end it will bring good to human life here on Earth."

Offline

Like button can go here

#27 2025-12-11 19:04:24

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,109

Re: This title is meaningless or unwanted

This is JSC Mars-1 Martian Soil Simulant

Chemical composition mineralogical standard analog based on data collected from the Mars Science Laboratory Curiosity rover. MGS-1 is made by sourcing a spectrum of terrestrial minerals, then mixed together in specific proportions to generally replicate the Martian surface. This is in contrast to previous Mars simulants that were typically sourced from a single terrestrial deposit (basalt or palagonite) fraction of less than 1 millimeter

https://en.wikipedia.org/wiki/Martian_regolith_simulant

After milling to reduce its particle size, JSC Mars-1A can geopolymerize in alkaline solutions forming a solid material. Tests show that the maximum compressive and flexural strength of the 'martian' geopolymer is comparable to that of common clay bricks.

other simulant attempts https://www.themartiangarden.com/mars-simulant

https://en.wikipedia.org/wiki/Martian_regolith

here is the sand with rocks.

https://en.wikipedia.org/wiki/Martian_r … agment.jpg

So lots of preperation of the soil is needed to make use of it in milling it to size, seperating the mineral content and making it perchlorate free.

To build with Mars regolith, milling equipment (like vibratory/planetary ball mills) reduces particle size, while separation methods use techniques like laser sintering, cold sintering (CSP), polymer binders, or microwave systems to bind or melt regolith into structures, often requiring 3D printers for shaping, aiming for materials like bricks, shielding, or metal parts from extracted elements like iron/titanium. Key processes involve size reduction (milling) and consolidation (sintering/binding) to create usable materials like "Mars concrete" or fused components, with focus on robotic, energy-efficient systems.

Milling Equipment & Processes

Ball Milling (Planetary/Vibratory): Used to reduce particle size (PSD) of raw regolith simulant, with planetary mills being faster but roller banks better for large slurries.

Sieving: Separates milled particles into specific size ranges (e.g., 60-mesh).

Separation & Consolidation Technologies

Laser Sintering: Uses high-power lasers to melt and fuse regolith into solid layers, creating paving or structural elements.

Cold Sintering (CSP): Binds regolith with water/alkaline solutions at low temperatures (under 250°C) and pressure, forming strong bricks or blocks.

Polymer Binders: Mixes regolith with polymers (made from Martian CO2/water) for 3D printing concrete-like materials.

Microwave/Solar Sintering: Alternative methods to use focused energy for hardening regolith.

Metal Extraction: Processes like carbonyl metallurgy or vapor deposition extract iron and other metals for 3D printing steel parts.

Additive Manufacturing & End Products

3D Printing (Extrusion/Powder Bed): Deposits processed regolith/binders layer-by-layer, building structures like domes, habitats, tools, or rebar.

Products: Sintered bricks, concrete-like blocks, radiation shielding, metal components (rebar, gears, tools), and coatings.

Key Considerations

In-Situ Resource Utilization (ISRU): The core principle, maximizing use of Martian soil.

Energy Efficiency: Focus on low-energy methods like cold sintering.

Robotics: Automation is crucial for mining, milling, and construction

Offline

Like button can go here

#28 2025-12-12 15:05:27

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,109

Re: This title is meaningless or unwanted

Another reference topic for construction materials for floors within the structure.

Offline

Like button can go here

#29 2025-12-12 18:38:49

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,109

Re: This title is meaningless or unwanted

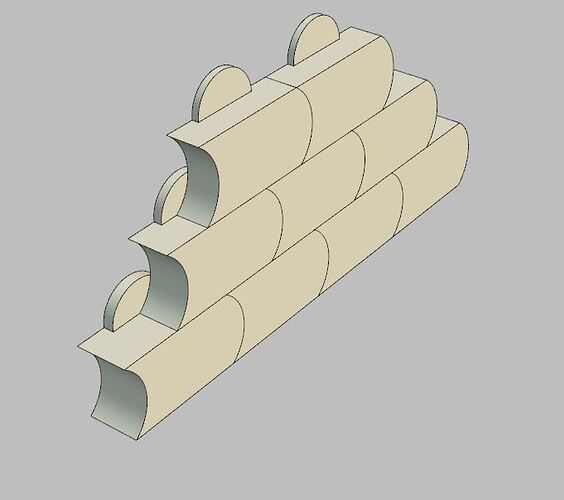

This might work for cieling construction for each floor or tier

If the top of the arch is near 4 m with floor joined to each then we can have some where near 26 floors within the dome.

Space requirement to each crew must leave open space for the gardens that will create food and oxygen.

Offline

Like button can go here

#30 2025-12-14 16:08:34

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,109

Re: This title is meaningless or unwanted

post for the dome

The dome shown here has a diameter of 200m (650'). This gives an internal land area of 3.14 hectares.

I am reminded of Biosphere 2 size and scale.

https://en.wikipedia.org/wiki/Biosphere_2

It is a 3.14-acre (1.27-hectare)[2] structure originally built to be an artificial, materially closed ecological system, or vivarium.

The main Biosphere 2 crew size for its primary two-year mission (1991-1993) was eight people (four men, four women) in a sealed, self-sustaining ecosystem, with a smaller, seven-person crew for a shorter, second mission in 1994. These crews studied closed-system living, a precursor to space colonization, managing complex biomes and food production within the massive glass structure.

seven biome areas were a 1,900-square-meter (20,000 sq ft) rainforest, an 850-square-meter (9,100 sq ft) ocean with a coral reef, a 450-square-meter (4,800 sq ft) mangrove wetlands, a 1,300-square-metre (14,000 sq ft) savannah grassland, a 1,400-square-meter (15,000 sq ft) fog desert, and two anthropogenic biomes: a 2,500-square-meter (27,000 sq ft) agricultural system and a human habitat with living spaces, laboratories and workshops.

The oxygen inside the facility, which began at 20.9%, fell at a steady pace and after 16 months was down to 14.5%. This is equivalent to the oxygen availability at an elevation of 4,080 meters (13,390 ft

Lets not repeat failure by assuming earth as the base.

Offline

Like button can go here

#31 2025-12-20 16:53:45

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,109

Re: This title is meaningless or unwanted

The concept of 3-axis interlocking bricks for building structures like parabolic domes on Mars is an active area of research within extraterrestrial construction, focusing on using local resources (regolith) and robotic assembly.

Key Research & Design Concepts

Interlocking Design: The primary goal of interlocking bricks is to create strong, form-fitting, and compression-dominated structures without relying heavily on traditional Earth-based mortars or adhesives, which are problematic in Mars's thin atmosphere. The wedging action of correctly shaped blocks provides stability.

3-Way Interlocking Units: Architectural and engineering research has explored using "3-way interlocking units" or "universal joints" to map non-planar, complex geometries like hemispherical or parabolic domes. These designs maximize surface contact and prevent horizontal movement, often involving complex computational design (CAD) and robotic fabrication processes (like multi-axis CNC or 3D printing with robotic arms) to achieve the precise, varied angles required for a curved surface.

Material Sourcing (ISRU): To minimize materials shipped from Earth, researchers use Martian regolith simulants to create "space bricks". Methods include:

Compression: Applying high pressure to iron-oxide-rich Martian simulant causes the nanoparticles to bind, forming solid bricks without any additional binders.

Biopolymers: Using synthetic living materials (like cyanobacteria and fungi) to "glue" regolith particles together into building blocks.

3D Printing/Sintering: Using high-powered lasers or a binding agent (such as sulfur cement) to fuse regolith layers, often employing 3-axis or 4-axis Cartesian robots to print specific material paths.

Specific Project Examples

TESSERAE Tiles: Research at MIT has focused on self-assembling tiles called TESSERAE, which use embedded magnets and specifically beveled faces to automatically assemble into complex shapes, such as a "buckyball" or dome structure, in microgravity or a controlled environment.

NASA 3D Printed Habitats: NASA has sponsored competitions and research into large-scale additive manufacturing (3D printing) of entire habitats using Martian regolith materials, often resulting in dome or vault designs (e.g., the Mars Dune Alpha habitat).

The creation of actual physical 3-axis interlocking "pieces" is generally part of specialized academic research and robotic fabrication workflows, not commercially available products in the traditional sense, as the geometry is highly specific to the intended dome's exact curvature and size

3-way Interlocking Units on Hemispherical Dome Surface

Sort of like a tongue and grove but not only the top an bottom but also the ends of the block sized brick.

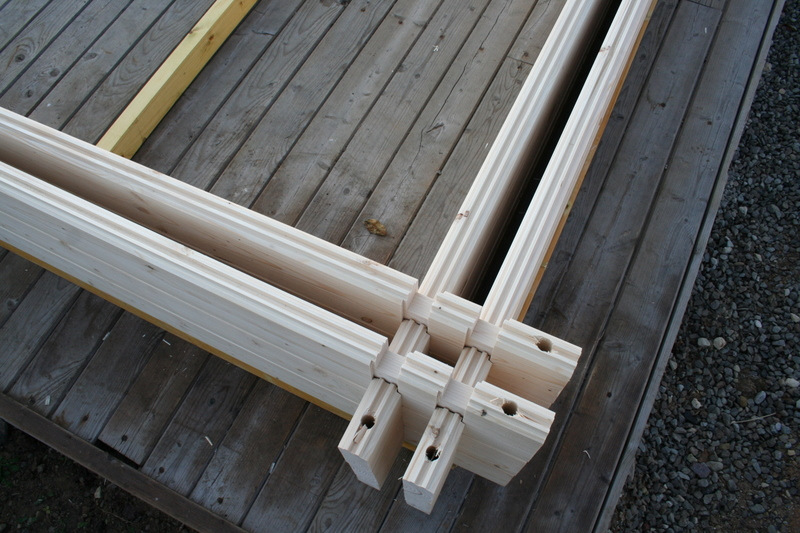

prefabbed log cabin wall

Dome would be double walled and have insulation for the inner space between the block or brick that we use.

Offline

Like button can go here

#32 2025-12-23 15:42:31

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,109

Re: This title is meaningless or unwanted

Technical Notes 31 - Brick Masonry Arches

300 plus pages Practical architectural guidelines to design a Martian base

Architectural problems of a Martian base design as a habitat in extreme conditions

Offline

Like button can go here