New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#176 2024-04-11 14:01:47

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,616

Re: Thermal Energy Storage

Offline

Like button can go here

#177 2024-04-15 15:34:09

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Thermal Energy Storage

Calcium nitrate has a melting point of 561°C and a heat of fusion of 24KJ/mol. Based upon a density of 2500kg.m-3, this gives it a volumetric heat of melting of 101.5kWh.m-3.

https://en.m.wikipedia.org/wiki/Calcium_nitrate

Calcium nitrate has a bulk cost of $570/tonne.

https://www.chemanalyst.com/Pricing-dat … trate-1555

Suppose we wanted a grid energy storage system that provide days worth of energy storage. One way of doing this would be to couple a large tank of calcium nitrate with an S-CO2 power generation loop. During times of plenty, resistance heaters in the tank would melt the salt. The S-CO2 power generation loop would generate power continuously, smoothing fluctuations in energy supply. At a melting point of 561°C, it should be possible to recover 50% of the electricity input to the resistance heaters.

How much calcium nitrate would we need to store enough power for the UK grid for a whole day? UK baseload is about 30GWe, so we would need to store 720GWh. Our power generation is 50% efficient, so lets say 1440GWh of heat. To store this much we would need 14,187,000m3 of salt or 35.5m tonnes. That much salt would cost $20bn. But the energy storage plants should last for at least fifty years, whereupon the salt can be reused in new plants. So purchasing the salt is a one time cost of a few hundred dollars per capita.

Thermal storage plants like this would work particularly well if built close to towns and cities equipped with district heat networks. The wasteheat from the energy storage plants would be hot water at a temperature of 30°C. This would fit well into town heating systems that can deliver the heat to houses and buildings via a pipe network.

Last edited by Calliban (2024-04-15 16:03:50)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#178 2024-04-16 06:37:34

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Thermal Energy Storage

If you tried to store that much power in Lithium-ion batteries, at $100/kWh, which doesn't describe the actual grid-connected battery pack installation cost, which is presently around $300/kWh, but just the batteries themselves, you're looking at $144B USD. For the people asserting that $50/kWh Sodium-ion batteries are going to "save the day", that's still $72B for the batteries alone, not an actual battery pack installation. NREL's "rose tinted" 2030s cost estimates of $159/kWh for installed battery cost, means $229B. So $229B worth of Sodium-ion batteries that don't actually exist, merely to store 24 hours of power, or $20B worth of salt. That seems like a pretty straightforward choice to me.

That salt will remain salt from now until the end of time, rather than a toxic chemical mess for someone to clean up in 10 years or less. Salt never has to be recycled into a brand new electrochemical battery, so no energy needs to be consumed to create the salt more than once. That has to be the greatest bargain of all time, for an energy storage medium that lasts from now until the end of time. It's elegantly simple, yet profoundly powerful. The more you use the salt, the more it "pays you back". It's an appreciating rather than depreciating asset. That is the real fundamental difference between solar thermal energy storage vs photovoltaics and electrochemical batteries.

The people pushing this "electronic everything" futurism fantasy either know it's a pointless pipe dream, but are too dishonest to tell non-engineers the truth about its utter impossibility, or else they flatly refuse to believe that there are any cost or materials limits to what we can do using photvoltaics, wind turbines, and batteries. Thermal systems is how we make green energy affordable, available, pervasive, and usable the way we presently use energy, which is on-demand. The embodied energy, net energy gain, input materials requirements, and economics math are all stacked firmly against both known and projected electronics-based energy solutions. Anything is possible if you know how to invent drastically improved photovoltaics and batteries, but when do we suppose that might happen? Much like fusion, the answer is always "in the future". Futurism is why we haven't already fully implemented green energy technology. You build the energy future you want with what you have and what you know, accepting that there are limits to all things, and that those limits must be treated as real. That is how you arrive at workable solutions that are broadly applicable, affordable, maintainable, and sustainable.

Offline

Like button can go here

#179 2024-04-17 04:59:26

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Thermal Energy Storage

A molten salt thermal storage system like this could be used as a hybrid system. On sunny days, it could be charged using direct heat from a concentrating solar system. It could also contain electric heating elements to absorb excess electric power from the grid. This is advantageous for European countries, which receive most insolation in summer months and strong winds during colder months.

The key is to find a phase change material that melts at a sufficiently high temperature to allow efficient power generation with an S-CO2 power generation loop. Calcium nitrate appears to be ideal, as it melts at 561°C, does not have materials compatability issues with steel and is quite cheap. At a temperature of 561°C, low alloy steels still retain about half of their room temperature strength. So a welded steel containment vessel can be used, with a concrete surround. Rammed earth or sand can be used as insulation. The use of S-CO2 may allow the use of non-stainless steels for heat exchangers which would save a great deal of capital cost.

We begin to see a potential solution that could allow intermittent renewable energy to provide baseload power in suitable locations.

Last edited by Calliban (2024-04-17 05:12:09)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#180 2024-04-17 06:24:26

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,126

Re: Thermal Energy Storage

For Calliban re #179

It seems to me that the contributors to this topic are a short distance from having a concept in hand suitable for development.

While you and kbd512 are the primary contributors, Terraformer and SpaceNut are supporters.

I'd like to see this topic expand from this auspicious point to include solid plans that can be implemented.

Location for the first plant may be an important decision point. You and Terraformer would be carrying the ball for the UK.

kbd512 and SpaceNut would have a similar opportunity in the US.

In both cases, the prevalent capitalist systems present in those nations implies that plans must be designed so that investors see a return in some reasonable number of years.

Related to selection of a site for a new plant, is the search for existing plants or ones that may be under serious consideration.

As a reminder, this forum is set up to admit new members who will be able and willing to make contributions. If you know of someone suitable, please invite them to join you in development of a serious plan on the UK side.

(th)

Offline

Like button can go here

#181 2024-04-17 07:32:27

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Thermal Energy Storage

For the UK, a hybrid concept would be most appropriate. Solar resources are weak and highly seasonal. Wind resources are some of the best in the world, although the high population density of the UK has tended to favour offshore development, which is a much more difficult and expensive environment.

Countries like Germany, have poor solar and wind resources. Germany in particular is too densely populated for biomass to meet more than a small fraction of energy needs. Hydropower is available, but resources fall far short of what is needed. Geothermal has some potential. The country has no ocean front, so wave power potential is effectively nil. But Germany does have a Baltic sea coast. With this in mind, it would be interesting to explore the potential for using molten salt to ship heat to a country like Germany.

Imagine that we build concentrated solar power facilities on the coasts of Morocco, Libya or Western Saharra. These facilities would collect heat and melt calcium nitrate salt within a large, insulated and floating tank. When the salt is fully melted, we tow the tank to the German northern coast and plug it in to a coastal S-CO2 power generation facility. When the heat carried by the salt is exhausted, we unplug the tank and tow it back to the solar plant, where it is recharged.

Let us consider for example a tank that is 30m in diameter and 100m long. It would contain 70,686m3 of calcium nitrate salt, capable of storing some 7.175million kWh of heat in its latent heat of melting. If an S-CO2 power generation unit were used with 50% efficiency, it could generate 150MWe for 24 hours. Germany would need about 300 of these units to be delivered each day. Could this be made to work?

Last edited by Calliban (2024-04-17 07:41:08)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#182 2024-04-17 07:32:39

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 4,000

- Website

Re: Thermal Energy Storage

Of all the people on here, I think GW Johnson is best placed to do any real world testing, since he has a ranch in Texas. Britain's pretty overcast many days, and land here is limited (and I have none at all of my own).

Still wondering about the Compact Linear Fresnel Reflector, since flat/slightly curved lengths of mirror laid flat should be a lot easier to mass manufacture and transport than parabolic troughs. What's driving the costs of solar thermal systems?

Use what is abundant and build to last

Offline

Like button can go here

#183 2024-04-17 07:44:29

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Thermal Energy Storage

Terraformer, I refer you to this post.

https://newmars.com/forums/viewtopic.ph … 85#p221885

Calcium nitrate could be used as a grid electricity storage system with or without the sun, if molten salt heat storage can drive an efficient S-CO2 power generation loop. Storage efficiency ~50%. The other 50% is low grade waste heat which we could find other uses for.

Because of heat losses from hot containers and irreversibilities in power generation, this works best at large scale - i.e. hundreds of MW for hours or days.

Last edited by Calliban (2024-04-17 07:46:59)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#184 2024-04-17 08:43:52

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,126

Re: Thermal Energy Storage

For Terraformer ... The number of active UK members of this forum is 2.

We (the forum) have been supported by UK members from the beginning.

Of the two of you still active, I see two significant roles....

It seems to me that Calliban is capable of handling everything involved in the engineering of an energy storage site.

I offer you the option of becoming the social leader for folks in your Nation to persuade them to make the prodigious investments necessary.

The normal impulse for anyone faced with a challenge like this is to go small. The impulse might be to propose a teeny tiny demonstration system about the size of a bathtub, that would light an LED bulb for 20 minutes.

However, you are capable of bold leadership.

My proposal is to build a thermal energy storage system for London, capable of providing all the power the City needs for a full week.

If you decide to take this on, at that level, I think you will be supported by other UK residents.

Your success will depend, in large measure, upon how successful you might be in persuading Calliban to move beyond the current notes-on-a-napkin stage, to a fully populated detailed plan for a London Power Storage facility.

(th)

Offline

Like button can go here

#185 2024-04-17 09:17:46

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 4,000

- Website

Re: Thermal Energy Storage

I care far more about my hometown than I do about Londoners. Afaic, I might as well work on one for Dublin lol. Or Berlin.

Also my town has obvious places to start and a somewhat functional town council. I suppose my university does also.

A London system would not be one system anyway. It's far too big for that.

Use what is abundant and build to last

Offline

Like button can go here

#186 2024-04-17 09:45:50

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,126

Re: Thermal Energy Storage

For Terraformer re #185

Please take this opportunity to be goaded into action!

You can start by using this teeny tiny group to build up a head of steam!

You've already reported making contact with an elected official (if memory serves).

Please see if the idea of building a storage system (to be designed by Calliban or it doesn't count) is of interest.

Do you like the idea of sizing the system to support the community for a week?

That is an arbitrary time ... do you want to go with that or try something else?

If you want a bathtub demo system I'm sure Calliban can design one.

I'm hoping you will decide to invest the psychic energy to create the town system. It is likely to be almost exactly the same investment as the bathtub.

How can you possibly lose? If the initiative fails, that would be the status quo. If it succeeds, you'll be legendary.

If the result is somewhere in between, then there'll be abundant material for a book, or a stream of articles.

(th)

Offline

Like button can go here

#187 2024-04-17 16:39:02

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Thermal Energy Storage

Perhaps we could start with Lancaster? This is a relatively small city of about 50,000 people in the North of England.

https://en.m.wikipedia.org/wiki/Lancaster,_Lancashire

It is about an hour away from where I live by train. Much of the housing stock is terrace housing, which should make heat distribution easier to achieve. Some scoping calculations are needed. What is the optimum scale of heat storage? Could the city be served by a single centralised molten salt heat storage system, or would a larger number of smaller units be more economical? The system I have in mind would absorb electricity from the grid, store energy as heat and then generate a mixture of electric power and low temperature waste heat at about 30°C. For every unit of electrical energy that is stored within the plant, we get about 0.5 units back as electricity and 0.5 units of waste heat. The electric power goes back onto the grid and the waste heat is used locally.

Lancaster sits on the edge of Morcambe bay. The bay itself has some tidal power potential and the Irish sea beyond offers offshore wind potential. Solar resources are poor, but supplying a thermal storage system with concentrated solar heat is an option that woukd work during summer months. A hybrid thermal storage system is possible, with molten salt heated using direct solar heat, wind electricity and potentially natural gas or biogas (during dunkelflaute).

Last edited by Calliban (2024-04-17 16:47:05)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#188 2024-04-18 01:40:48

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 4,000

- Website

Re: Thermal Energy Storage

Unfortunately, run by the Green Party. Sure they are looking into district heating, but they're also known for being incompetent. The most obvious source of heat of course is Heysham, but I do not think they'll be enthusiastic.

Perhaps we could start about six miles north, in my hometown? At the triangle between the A6, Lower North Road, and Kellet Road, where there's accessible open land for any boreholes and a hotel that could be interested in cheap hot water? And a school that perhaps would be interested in revenue...

Use what is abundant and build to last

Offline

Like button can go here

#189 2024-04-18 04:20:21

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Thermal Energy Storage

Assuming we are talking about a pure heating scheme, rather than grid electric storage...

The River Keer runs directly past that area. It has a mean flowrate of 0.61m3/s, so really it is little more than a stream.

https://nrfa.ceh.ac.uk/data/station/meanflow/73015

However, it could serve as a heat source for a heat pump. If the river temperature were reduced by 1°C, the total heat that coukd be harvested would be:

Q = Cp x m x dT = 4200 x 610 x 1 = 2.56MW.

That is enough heat for most of the town I would expect.

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#190 2024-04-18 06:14:08

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 4,000

- Website

Re: Thermal Energy Storage

About 1kW per household. The trouble is, that's just about enough for *average* demand, not winter demand.

Loops in Morecambe Bay might cut it.

But for space heating, I think ceiling radiators + air source heat pumps are the place to start. Having ceiling radiators makes switching to a heat grid later easier.

The centre of town is dense terraces, but with back alleys, and there are car parks we could sink boreholes into (car parks which absorb heat during the summer hmm...). Back alleys are already used for water mains; we could install the heating grid without too much road disturbance I think. Especially in the central triangle.

Use what is abundant and build to last

Offline

Like button can go here

#191 2024-04-18 06:21:51

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,126

Re: Thermal Energy Storage

For Terraformer re project...

It is good to see Calliban's interest in your proposal ...

I note your mention of bore holes and wondered where your community is with respect to the map of hot water from the core that someone published here in the forum a while back. In some regions of the UK, hot water is closer to the surface than others. That would determine the depth to which bore holes would have to go to reach an endless source of thermal energy.

Or your thinking might have been about energy storage? I (vaguely) recall your writing about using bore holes for that purpose, a while back.

If you can combine a deep well to harvest core heat, plus the river Calliban described, plus a few solar panels where local policy will permit them, you might be able to put together a package that would keep a heat sink well supplied throughout the year.

Are there any other patches of open land in the area? The kids at that school might miss the playing field during construction, unless the entire project could be accomplished during the winter, and seed re-established early enough in the following spring.

A parking lot (if England even has such things?) would be ideal, because it can be recovered when the drilling is done.

(th)

Offline

Like button can go here

#192 2024-04-18 07:07:24

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Thermal Energy Storage

Much depends on what exactly we are trying to achieve. My original interest was for a grid battery, that stores energy in high temperature molten salt and then generates electric power for the grid. For every 1MWh of intermittent electricity that it absorbs from the grid, it will return 0.5MWh of baseload electricity and 0.5MWh of heat. The electricity goes back on the grid. The heat can be used for heating a town. So we would ideally build these thermal batteries on the outskirts of towns and cities.

Looking at the specific case of Carnforth, which has a population of about 5000 and about 2000 dwellings. Year round heating requirements would be about 20GWh, with an average of 2.3MW. Peak heating rate would be about 6MW at the height of winter. Fortunately, windpower produces more energy in colder months that in warmer ones.

https://gridwatch.co.uk/Wind

Average capacity factor from October - April is about double what it is between April - October. So wind power produces two thirds of its annyal output during the UK heating season.

Suppise we build a small 24MWe wind farm, connected to a molten salt S-CO2 grid battery. This generates 8MWe on average across the year. About half of the energy generated by the wind farm goes directly onto the grid without storage being involved. The other half gets stored in the molten salt. This would provide Carnforth with most of its required heat with an average power of 2MWe going back onto the grid from the battery. So our 24MWe wind farm, would produce an average electrical power of 6MWe and a thermal power of 2MWth.

I think Carnforth could provide a good demonstration project. For the purposes of this town, we want a heat battery that can absorb up to 24MWe of electric power and generate at 6MWe, producing up to 6MWth of waste heat at maximum output. Let us size the heat battery to store some 3 days of peak output, which is 18MWe-days, or 432MWh. We would need to store some 864MWh of heat, requiring some 8512m3 of salt. Assuming the salt storage tank is a right circular cylinder, it will be 22m in diameter and 22m tall. The heat battery won't need cooling towers, as all waste heat will be going into the town heat network. So most additional space will be taken up by the insulation around the tank and S-CO2 power generating machinery. I think the entire battery could be sited on a 0.5 acre (40 x 50m) plot.

Where to build it? My initial preference would be close to the A6, so the heat main can run beneath the road. There is a field just south of Carnforth rangers football club that looks ideal. Smaller heat pipes would branch from the main and follow the road network. The temperature of the water emerging from the thermal battery heat exchanger will be about 30°C. Houses that have been well insulated and equipped with large surface area radiator panels could use this as it is. The alternative is to fit a house with a heat pump that uses the warm water as a heat source and discharges hot water between 40 - 60°C.

Last edited by Calliban (2024-04-18 08:04:10)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#193 2024-04-18 12:49:52

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Thermal Energy Storage

Project Design Goal

I would like to achieve complete replacement of the burning of hydrocarbon fuels to generate electricity and heat. That is my goal, because it represents the lion's share of all hydrocarbon fuel energy consumption. The present fixation on burning hydrocarbon fuels for transport has been thoroughly unhelpful and has resulted in no practical solutions. If we had a magic wand to wave to electrify all vehicles, that would result in an 8% to 10% reduction of the hydrocarbon fuel energy presently consumed, at most. If the cost of doing is changing every other aspect of how energy is produced and consumed, then that's a bridge too far.

Prudent Methodology for Employment of a New Engine or Fuel

When the US military considers using a fundamentally new type of engine or fuel, they follow a logical progression of applications of the new technology.

1. Stationary power plants and portable electric generators - power-to-weight can largely be ignored, so only efficiency matters greatly

2. Ships, tanks, or other large vehicles - power-to-weight ratio is far less critical than overall efficiency

3. Smaller vehicles such as trucks and other utility vehicles - power-to-weight is more important

4. Light aircraft - power-to-weight starts to become a significant factor in the usability of the vehicle

5. Heavy aircraft - power-to-weight is of critical importance

The reason that logical progression exists, is to minimize developmental risk or maximize the probability that the engine or fuel is suitable to task. If you can power a portable generator, then you can try running your new engine or fuel in a large vehicle such as a ship or main battle tank or armored personnel carrier. If power-to-weight ratio is still sufficient, then maybe it's suitable for light vehicles that require lighter engines to, you know, remain light. If the new engine successfully powers a fleet of light vehicles, then perhaps the same basic technology in a weight-optimized format could also power a light aircraft like a drone or lower performance utility / observation aircraft. At that point, assuming development has cemented the engine's requisite reliability / durability / power-to-weight, then and only then will the engine be used to power a heavy aircraft such as an attack helicopter or long range cargo transport.

Along the way, you discover that certain engines and fuels, which may be suitable for less demanding applications, don't work so well when you attempt to apply them to applications where power-to-weight and reliability become increasingly critical to the general usability of the vehicle. That automatically excludes solutions which have insufficient power or unmanageable weight. That's why we gave up trying to power long range strategic bomber aircraft using onboard nuclear reactors. Until the aircraft was scaled-up past the point where it made sense for a strategic bomber, the weight of a properly shielded reactor was unmanageable.

Materials Suitable for Thermal Energy Storage

All great in theory, kbd512, but how and why does that apply to energy storage?

To answer that question, we must ask another question:

What are the most important qualities or attributes of a bulk energy storage medium?

1. It must be affordable and abundant so that it can be deployed at truly a massive scale. This implies, water, salt, rock, sand, and CO2, with steel and concrete storage containers. There are no other "more abundant" materials that you can extract from the natural environment with minimal processing and ease of shipment. Steel and concrete are the only structural materials we produce in sufficient quantity to actually matter, with all other types of metal combined being a very distant second to steel. Steel and concrete also happen to be the lowest cost structural materials suitable for storing thermal energy.

2. An energy storage material must not experience any significant degradation over periods of time measured in decades, because it must match the design service life of a prototypical thermal power plant, which is 75 years. Preferably, the material used would be endlessly reusable and would not degrade at all over time. Solid rock will ultimately crack from thermal cycling, but salt and sand are generally thought of as "forever materials", at least until you achieve temperatures that would melt steel.

3. The energy storage medium must be endlessly recyclable without significant loss of material, because this ultimately ties back to the energy storage capacity of the material being used. It cannot generate massive amounts of toxic waste for us to contend with, either, because our ability to recycle materials and contend with toxic waste is rather limited. Most toxins are diluted with sufficient volumes of water. They don't actually "go away" and are not "rendered harmless", they're simply dispersed to the point of being survivable by most living things. For a simple singular metal such as Aluminum, meaning a bar of a particular Aluminum alloy, we can recycle that quite readily and easily, and it's thermodynamically very advantageous for us to do so.

If you have paper-thin strips of Aluminum metal coated with a sticky and typically toxic electrolyte substance, sealed inside a steel container, with Carbon and Copper, then our ability to efficiently recycle Aluminum transformed into an electrochemical battery cell, immediately drops off a cliff. The batteries will come to the recycling center in all different shapes and sizes, and they're typically coated in plastic glued on top of the steel container surrounding the battery cell, so there's no simple electro-mechanical machine we can employ to cut open the battery at one end, remove the "jelly roll" of Aluminum / Copper / Carbon / electrolyte material, unravel the jelly roll, chemically remove the electrolyte, separate the anode and cathode materials, and then dump our strip of cleaned Aluminum alloy into the melting pot to be recycled.

In actual practice, we end up shredding those electrochemical batteries using an industrial shredder, and then using a lot of very toxic chemicals and high temperatures to extract the mess of different metals and other materials contained therein. The purity of the extracted metals is insufficient to make a new battery of the same type, unless a lot more energy and processing is done to increase the purity of the extracted / recycled metals back to what is readily obtainable from virgin metals refined from ores. That is why battery recycling is so limited, and so ineffective. More energy and more technology is required to recycle them than is required to create them from scratch. The same issue applies to most photovoltaics and wind turbines. The CIGS photovoltaics are one possible exception, but they have shorter service lives, produce less power output than Silicon-based photovoltaics, and are not very durable on their own.

The Lead-acid batteries that are commonly recycled, at rates of 95%+, are easy to recycle for several reasons. They use liquid Sulfuric acid electrolyte, not "jelly" or "paste" electrolyte, there is no "jelly roll" in a Lead-acid battery because they contain much thicker flat "waffle plates" of pure Lead, and all of them come in very similar packaging formats that tend to be quite large and easy enough for a human or machine to pick apart, which makes extracting the metal contents of a Lead-acid cell easy and advantageous to do. Anyone who has worked on a car before has probably messed with extracting the components of a Lead-acid battery at some point, if they worked on the old style batteries that were user-maintainable. I would use the Lead for fishing weights, and knew of other people who used them to make their own ammunition for target practice. The problem, of course, is the relatively short service life of Lead-acid batteries, the low energy density per unit weight, therefore the extreme quantities of Lead that would be required to put enough electrical power storage onto the grid to matter. The other obvious downside is the fact that Lead is toxic to humans, so a Sulfuric acid leak from a cracked case would cause Lead contamination of groundwater from leaking batteries by leaching some of the Lead from the electrode plates. Gallium-Arsenide photovoltaics have the same problem of leaching Arsenic from cracked photovoltaics, and most of the chemical loss happens during the first month or two after it cracks.

4. The energy technology must not be subject to the sorts of malfunctions that all electrical and electronic devices are subjected to. For example, you can't "hack" a tank of molten salt, because there are no network-enabled electronic control mechanisms that regulate the flow of the salt through the power plant, because no such devices are required or in any way helpful. Electrochemical batteries, photovoltaics, and wind turbines include failure points that can shut down the entire plant, even if there is no actual problem with the input energy source.

If an energy generating or storage system is only manageable when all the control electronics function correctly, then it will ultimately malfunction and fail in a catastrophic way. The nature of our universe is very unkind to electronics, even if hackers keep their grubby mitts off the system that keeps them alive. I don't mean that the control system can cause a blackout, I mean that the batteries store sufficient energy that they can fry all the other electronics attached to the grid, because they can generate a multiple of the amount of energy flowing through the grid. The grid itself might be just fine following such an event, but all the attached devices, which are largely electronic these days, probably won't be fine. If such were not the case, then the Tesla PowerWalls we have attached to our home would not have such an elaborate multi-stage voltage regulation setup between them, the grid-tie, and the rest of the house.

The control systems that regulate power output onto the grid can and will "clamp down" on the power being regulated, but not before it does serious damage to all the grid-attached electronics. The reason this is not a well known issue today is that there are no grid battery storage devices operating at the gigawatt scale to cause this type of issue. Alternatively, we will require a gold-plated grid with dramatically greater control. When you have batteries storing multiple gigawatt-hours worth of power for a major city, this problem will inevitably do serious damage, probably not to the grid itself, but to all the individual reasons for having the grid to begin with.

5. Environmental factors cannot significantly alter the ability of the energy generation or storage medium to continue operations at all. All photovoltaics and wind turbines experience near-vertical drops and rises in power output when some event such as a cloud passing overhead or a lull in the wind occurs. This de-facto mandates the use of very large and powerful electrochemical battery banks, else the grid crashes whenever demand exceeds supply or supply significantly overshoots demand (this scenario can be dealt with by dumping the power into the ground, but then that power is wasted). Since this can and does happen multiple times per day, it sets hard limits on the scalability of any solution based upon photovoltaics, wind turbines, and batteries. No present electric power grid is designed to handle gigawatt or terawatt scale power fluctuations. The cost of upgrading the grid to handle such events is a multiple of what the grid presently costs the consumers of that energy. The grid can handle gigawatts of power flowing through it, but you cannot add or subtract several gigawatts of power at the speed of flipping a lightswitch, else the end result is either no electric grid or no working devices attached to said grid. This dictates that sudden onset events like a lull in the wind or cloud passing by, has virtually no impact on the output of the electric grid.

More Realistic Energy Distribution and Storage Solutions

Only thermal engines and thermal energy stores can supply power in the manner addressed by the 5 points listed above. Of all the materials available for storing large amounts of thermal energy, only molten salts or crushed rock or sand are sufficiently chemically stable when heated to not degrade or strongly react with their storage container.

Rather than the endless attempts to overturn the basic physics of energy storage, I propose we start working with natural principles. We only have one area of America where we can generate significant amounts of energy. That happens to be the otherwise sparsely populated and rather barren Midwest, because it contains an expansive desert climate region wherein the Sun is almost always shining, even during the winter. That area of the country also happens to contain staggering salt reserves. Rather than shipping salt in from the other side of the planet, we will "mine" our own salt by scooping it off the ground from that part of our country. If there are any impurities requiring removal, then we're going to do it there using highly concentrated solar thermal power from fresnel lenses that Terraformer has mentioned several times. We will also use solar thermal heat to start melting metal to create the support structures and solar troughs to collect and store thermal power. We'll start with imported or US manufactured Pig Iron, and finish with cold-rolled steel sheet and tubing. Pig Iron requires coal, at least for now. Over time, we will collect enough recyclable steel that burning more coal won't be required. As-is, most American steel products derive from recycled steel.

In short, we will have a vertically-integrated factory that both produces the raw materials and resultant structures to collect and store solar thermal power. At a national level, both power and industrial manufacturing must become one and the same. Only light industrial activities can take place in areas that don't produce their own power. That makes the energy producing and generating infrastructure independent, rather than co-dependent upon many other factories and nations or imported fuels. As long as the Sun keeps shining, which I have good reason to believe is astonishingly reliable, such a system will continue to pay us back so long as we're intelligent enough to accept its importance. Whenever a solar thermal power plant's service life concludes or it has been damaged by the environment, the scrap materials will be shipped back there for recycling into new solar thermal power devices or other products.

After the electric grid has been replaced with a sufficiently large "solar thermal engine" to power the entire country, the next logical step is synthesis of storable hydrocarbon fuels to power transport. This will involve desalination and CO2 extraction from sea water. The salt will be kept for additional energy storage. The fresh water will be pumped via pipelines around the country, as tahanson43206 has suggested, to replenish local aquifers, irrigate crops, and to cover human consumption.

HVDC power lines will distribute power across the entire country, with the electrical energy being dumped into locally operated molten salt storage tanks that power their own local sCO2 gas turbines. The end goal will be to ensure that every city or town has enough thermal power to continue generating electricity for about a week, even if the HVDC cable was suddenly cut or rendered inoperable. The primary advantage to doing this is that the requirement for realtime load management across expansive regional electric grids can be offloaded to a more localized level. There is no need to balance load and generation across dozens of power plants, to within a millionth of a second. The local molten salt storage tanks are acting as difficult to over-power or under-power buffers that absorb excess power or operate without any power input over significant periods of time. By eliminating local coal / gas / photovoltaic / wind turbine power plants, local land reverts back to more natural uses. We'll collect all the trash generated by those failures to recycle what we can.

This electrical power distribution and buffering scheme does an end-run around centralized computerized control stations. No computer is required because microsecond-to-microsecond control of the HVDC input is superfluous. It's heating up a salt tank for a "mini grid" that only spans a single city or town or county. The local power operator only monitors the temperature of their local molten salt storage tanks. When the temperature is nominal, they pick up the phone, call the solar thermal engine operator back in the midwest, and tell them they have enough stored thermal power to last another day or week. The solar thermal engine operator throws a switch to turn off the supply to Township A. That process is then repeated for City B, and so on.

The local footprint of the power generating infrastructure is limited to their HVDC interconnect, molten salt tank farm, sCO2 power turbine, and electric generator. If we're worried about local storage capacity, then we add more salt using the pile of salt accumulating at the solar engine farm in the Midwest due to water desalination used to make hydrocarbon fuels and fresh water. Local natural gas lines will supply backup thermal energy, as required, to directly power the sCO2 turbines if something untoward happens to the HVDC interconnect. Other parts of the country may have some of their own local solar thermal power generating infrastructure deployed where it makes sense, but the idea here is to provide highly reliable energy at the lowest possible cost, minimize pollution through drastic simplification of the power generation / distribution / storage infrastructure, and minimize land degradation associated with clear-cutting and paving over of local fields to make way for photovoltaics and wind turbines.

There's more to add to the detail level of the plan, but that's for later posts.

Offline

Like button can go here

#194 2024-04-18 17:30:59

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,616

Re: Thermal Energy Storage

Nicely done Kbd512

Much like the argument I would not like to need to pay a company to provide my energy needs since I have property that I can build a solution to this rather than a town or city sized or larger system.

One of the things that a grid provides is the surge currents that a flat system cannot provide with an inverter unless it's much larger than what is required to handle the average levels that the power company indicates on the daily billing.

With this I understand that I need to have a system that creates the heat to be able to store it for later and that means knowing how great it needs to be in size is via knowing how much it needs to deliver for use.

Also, if the source is gone or not available it needs another source making it a hybrid system to create heat to make the common storage possible.

Offline

Like button can go here

#195 2024-04-19 04:46:10

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Thermal Energy Storage

Kbd512, that is an excellent post. The analysis carried out here demonstrates that heat energy storage is the key enabling technology that allows intermittent renewable energy to supplant hydrocarbons as grid electricity sources. No other storage technology can be built at the scale needed. We can divide heat storage into two categories: (1) Grid energy storage, where heat is stored for the purposes of generating electricity. (2) End use energy storage, where heat is the desired end product and is stored where it is needed. Both sets of technology have applications.

For the first, S-CO2 power generation cycles appear to make grid energy storage far more practical, as they are efficient and compact. Steam powerplants could also be used, but even supercritical cycles are less efficient than S-CO2 operating at the same temperature and power cycle machinery is bulkier and more costly. The problem is that no one appears to be commercialising S-CO2 at the scale needed. And the concept is most attractive when developed in conjunction with district heating. Few localities want to cough up cash for that either.

End use heat storage has lots of applications. But it is only really useful to grid operators if they have the ability to switch loads on and off at will. For large power consumers that could be arranged. For millions of smaller ones it is a tricky problem. End uses couod be controlled through a web connection. But that sort of application would make the grid vulnerable to hacking.

Regarding the problem of thermal shock: This would indeed be a problem for storage of heat in rock if we were using it to support structural loads. The poor thermal conductivity of rock aggrevates the problem because it will result in steep temperature gradients. It is not a problem if heat is stored in crushed rock which is kept in a steel silo. I don't think we would particularly care is individual lumps of rock cracked under that circumstance. Thermal shock is a problem for steels, especially thick sections. In sensible heat thermal stores, this would limit the permissible rate of cool down and heating. One advantage to using calcium nitrate as a thermal storage material, is that it can be kept at constant temperature and heat is absorbed and released by phase change. However, as the salt freezes around heat exchanger tubes, thermal gradients will reduce the rate of heat flow into the heat transfer fluid unless there is an increase in temperature drop. That is pain as it realistically means we will be dealing with a large temperature gradient between the salt and the hot CO2 gas. There are probably design solutions that will solve this, but it needs some consideration.

I agree that the focus on replacing hydrocarbons as vehicle fuels has diverted attention away from the more pressing need of decarbonising heat and power. Vehicles are always going to be a tougher engineering challenge because they have strict requirements for energy density (range) and power density. Developing non-fossil electricity sources does give us extra breathing room in developing solutions for vehicles. Natural gas that was being consumed for heat and power could be diverted to vehicle applications. LPG can be substituted for gasoline and diesel. Whilst these aren't permanent solutions, they would reduce the urgency of oil supply limitations and allow alternative vehicle energy sources to develop over several decades, rather than being an urgent problem that we must solve straight away.

Last edited by Calliban (2024-04-19 05:14:05)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#196 2024-04-19 09:03:12

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Thermal Energy Storage

Siemens have already developed a prototype TES storage system that will generate 1.5MWe using a small steam turbine.

https://www.utilitydive.com/news/siemen … er/428055/

This concept uses sensible heat storage in crushed volcanic rock. A blower pushes air across a resistance heater, which then blows through the rock bed heating it to around 750°C. Although the references don't say as much, I assume the same blower also transfers heat from the rock into a boiler.

There is no indication of what efficiency can be expected. The temperatures are high enough to superheat steam. But for such a small system, I would be impressed if it put more than a third of the electric power used to charge it back on the busbars. But if that electric power is wind energy that woukd otherwise be curtailled, then it isn't such a bad deal. Assuming a 33% efficiency, the condenser will provide some 3MW of waste heat. This would cover the heating needs of a town the size of Carnforth for most of the year. During the peak winter months, we may have to provide extra heat using either natural gas or pumped heat from the river.

The plus side of this technology is that it is developed at least to prototype stage and can be bought off the shelf by contacting Siemens. The downside is that efficiency is lower than it could be if we had access to S-CO2 power generation technology. But we work with the tools we have. If the plant can sell baseload electricity back to the grid for 3 times the cost of the otherwise curtailled electricity used to charge it and is also able to charge a fee for the heat put into the town heat network, then it could feasibly turn a profit.

In the UK, natural gas prices are capped at £0.07/kWh.

https://energyguide.org.uk/average-cost-gas-kwh/

Suppose our storage system takes three units of electricity from the grid, puts one unit back on at £0.1/kWh and produces two units of heat (2 × £0.07). Let us further assume that purchased power amounts to 1/3rd of the stations outlay, with another third covering capital payback and the balance on O&M. To turn a proffit the station must be able to buy electricity in at £0.0311/kWh, sell it back at £0.1/kWh and sell heat at £0.07/kWh. I think it could be workable, especially considering that increasing amounts of wind piwer are now curtailled (wasted) and coukd be bought at low cost.

Last edited by Calliban (2024-04-19 09:23:11)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#197 2024-04-19 17:35:00

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,616

Re: Thermal Energy Storage

All of the systems so far are not off the shelf designs but engineered for single design use for large scale generation.

That means the supplied energy to the grid will cost you more than what we can afford to pay if not initially in the future for sure as greed sets in.

.

Offline

Like button can go here

#198 2024-04-20 07:26:02

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Thermal Energy Storage

All of the systems so far are not off the shelf designs but engineered for single design use for large scale generation.

That means the supplied energy to the grid will cost you more than what we can afford to pay if not initially in the future for sure as greed sets in.

.

True. The original MIT study that I used for my degree was looking at developing 250MWe power modules. Something like that could be developed as a standard unit that is then mass produced. One of the benefits of S-CO2 is that the high system power density and compact turbine makes the system more suitable for modularisation. We could for example make integrated power conversion modules that can be transported on a trailer. It is more difficult to that with steam, because the boilers, LP turbine and condenser are all so large. It would be difficult to integrate the power cycle machinery into a single package.

If you mean off the shelf in the sense of something you can buy as a home system, then that is a different problem. All thermodynamic systems scale up more easily than they scale down. It is possible to build home scale thermal storage systems that store high quality heat and produce a mixture of low quality heat (as hot water) and electricity. But you would need some kind of steam engine to do that. That involves a lot more complexity than you woukd face with a battery, that has no moving parts. The complexity is manageable in large systems. But it becomes more difficult as you scale down. The home may be a good place to consider end use thermal storage.

Last edited by Calliban (2024-04-20 07:31:13)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#199 2024-04-20 07:56:02

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,616

Re: Thermal Energy Storage

Here is an example of what MIT also has been designed with numbers for performance coming from it.

This is close to the average homes power levels for use as the output is dependent on the power generations spin.

There are 4 troughs that create 10kw to create 200 to 300 gallons of hot water and 1 kw of electrical power with crude auto parts.

Here is another view of the troughs collecting heat energy

Sure, the working fluids are different which changes the items due to pressure as well as the heat range.

MIT develops new "reverse air conditioner" solar power system for the developing world

Parts list

pressure washer pump

Understanding How Pressure Washer Pumps Work

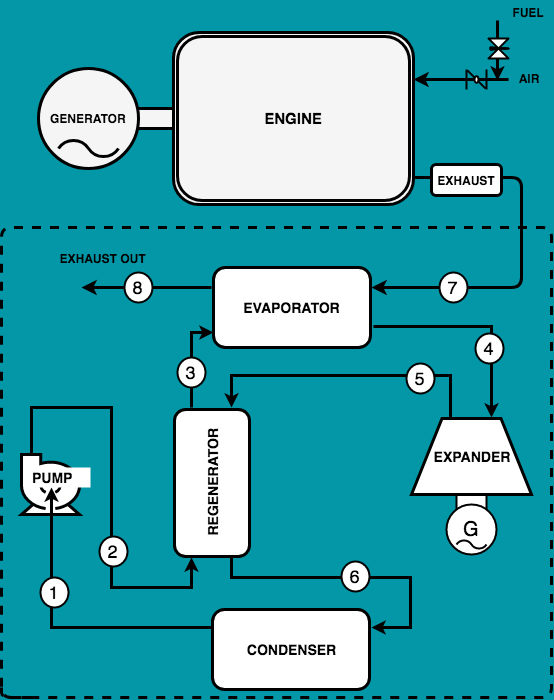

The main characteristics of a micro-utility sized for rural service providers are the following:

Target net output power: 3 kWe

Collector field: 75 m2 single-axis parabolic trough, using Miro aluminium reflectors and a Heat Collection Element (HCE) with selective coating and air-filled annulus between absorber pipe and glazing.

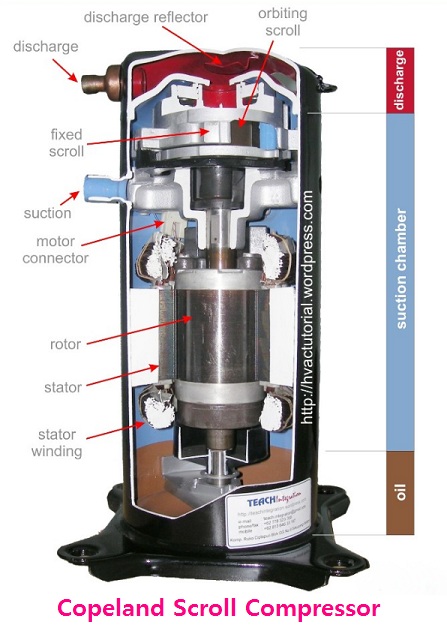

ORC: two stage expansion of R245fa using modified commercial HVAC compressors, brazed plate heat exchangers for high pressure heat transfer, and commercial HVAC tubes-and-fins air condenser for heat rejection

Here is some of the parts:

ITT BP 410-040 Brazepak Refrigerant Plate Heat Exchanger 450°F 1" NPT

Vicker V-20 Power Steering pump

Cut away of the copeland scroll compressor

https://www.researchgate.net/publicatio … plications

https://www.geothermal-energy.org/pdf/I … _Final.pdf

https://www.researchgate.net/figure/Con … _261696759

Offline

Like button can go here

#200 2024-04-20 08:25:15

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,126

Re: Thermal Energy Storage

For SpaceNut re Post #199

Thank you for finding and postings the 2012 report on MIT research in an African country, using solar power with a reverse air conditioning cycle. 12 years have passed. The concluding section of the article includes a quote of a third party calling for testing in the field over time. Please look to see if there are any follow up reports.

The engineering team set out to try to deliver a system that could be maintained in remote locations using off-the-shelf parts.

It would definitely be interesting to see how well their design(s) have fared.

(th)

Offline

Like button can go here