New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#301 2022-05-04 09:21:27

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,278

Re: Internal combustion engines for Mars

For Calliban re radiator ...

At 700°C, that radiator would need to be 2.5 x 2.5m, ignoring conduction losses into the vehicle.

Please add detail ... we only (appear to) have 2 dimensions given in the specification.

I'm assuming there are pipes into which the sodium flows, separated by sections of flat metal.

Detail: between episodes, the sodium will solidify in the radiator pipes. It this intended to be a one-time-usage emergency backup?

If so, would maintenance / remanufacturing consist of melting the entire device down and separating the elements for re-use?

I like the automatic safety feature for the base station. It would (of course) not be available to the mobile units.

(th)

We need a design that assures that fuel cladding remains intact following any reasonably foreseeable malfunction. Otherwise, a malfunction could leave us with a toxic mess to clear up. This could be provided by liquid sodium flowing through a radiator driven by natural circulation. If the cooling circuit opens by melting plugs, then you have a passive activation that would occur without any operator action. It would be irreversible and would write off the asset, but would maintain the core intact.

No operator being present for refilling is a bit of a problem. Maybe propellant line insertion could be automated?

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#302 2022-05-04 09:50:49

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,677

Re: Internal combustion engines for Mars

For Calliban re #301

Thanks for expanding a bit on your basic ideas!

The automation of a delivery hose is well under way on Earth. Commercial offerings are definitely in discussion.

For SpaceNut ... please keep a watch for announcements along those lines. Science Fiction has had them for decades, and I'm not sure what I am thinking about is from science fiction or advertising of actual products.

I ** think ** Tesla has plans for automated plug capability, and a few beta sites may exist. i'm just not sure.

In any case, it is definitely needed for the Mars mining operation.

The same is true for GW Johnson's on-orbit refueling system.

GW, like you, started from an assumption there would be people on the scene, because that it how it has always been done, but we are now in the age of remote manipulation, and have been for several decades in satellite designs.

(th)

Offline

Like button can go here

#303 2022-05-04 20:14:33

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,062

Re: Internal combustion engines for Mars

I sort of described its use as well as the turbine for the equipment for the 1 meter regolith water gathering as calliban had suggested that the air intake might make use of a turbine to get a greater level of co2 gathered.

Lets we forget the earth engines are of all different cylinder sizes so sizing of a mars engine will work the same in the design of power to make use of in the variety of uses that we will have,

The cylinder is 1 bar of air an the ration of that air is related to 14.7 psi so we are using 14.7 parts to 1 part fuel in the cylinder. So while we are making use of high pressure tanks for the mars gasses we are only still looking to send in a near 1 bar solution for creating rotation power whether its by a turbine of a piston makes little difference in the end.

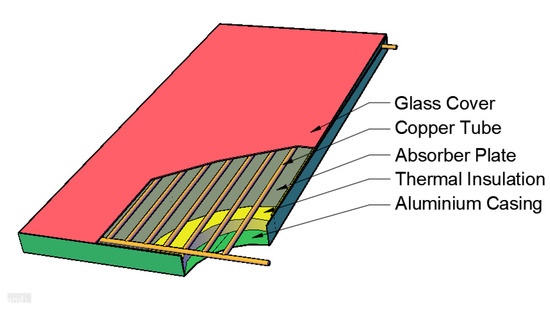

As far as radiators we have the KRUSTY design which will work, I gave a refrigerators style but we can also use a flat plate solar collector as the electronic heat-sink design as well.

The flat plate we would alter as we do not need the glass and we can use thinner metal with holes in it to make the plate radiate the heat that enters through the tubing.

Offline

Like button can go here

#304 2022-07-12 06:40:41

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Internal combustion engines for Mars

MIT design for Mars propellant production trucks wins NASA competition

https://www.marsdaily.com/reports/MIT_d … n_999.html

Using the latest technologies currently available, it takes over 25,000 tons of rocket hardware and propellant to land 50 tons of anything on the planet Mars. So, for NASA's first crewed mission to Mars, it will be critical to learn how to harvest the red planet's local resources in order to "live off the land" sustainably.

On June 24, NASA announced that an MIT team received first place in the annual Revolutionary Aerospace Systems Concepts - Academic Linkage (RASC-AL) competition for their in-situ resource utilization (ISRU) design that produces propellant on Mars from local resources instead of bringing it from Earth.

Their project "Bipropellant All-in-one In-situ Resource Utilization Truck and Mobile Autonomous Reactor Generating Electricity" (BART and MARGE) describes a system where pairs of BART and MARGE travel around Mars in tandem; BART handles all aspects of production, storage, and distribution of propellant, while MARGE provides power for the operation. After presenting their concept to a panel of NASA experts and aerospace industry leaders at the RASC-AL Forum in June, the team took first place overall at the competition and was also recognized as "Best in Theme."

"Previous ISRU concepts utilized several different small rovers and a fixed central plant, but MIT's BART and MARGE concept is composed of essentially just two types of fully mobile, integrated large trucks with no central plant," says Chloe Gentgen, PhD candidate in the Department of Aeronautics and Astronautics (AeroAstro) who served as team lead for the project. "The absence of a central plant enables easy scalability of the architecture, and being fully mobile and integrated, our system has the flexibility to produce propellant wherever the best ice reserves can be found and then deliver it wherever it is needed."

Gentgen led an interdisciplinary group of undergraduate and graduate students from MIT, including Guillem Casadesus Vila, a visiting undergraduate student in AeroAstro from the Centre de Formacio Interdisciplinaria Superior at the Universitat Politecnica de Catalunya; Madelyn Hoying, a PhD candidate in the Medical Engineering and Medical Physics program within the Harvard-MIT Program in Health Sciences and Technology; AeroAstro alum Jayaprakash Kambhampaty '22, rising MIT senior Mindy Long of the Department of Electrical Engineering and Computer Science (EECS); rising sophomore Laasya Nagareddy of the Department of Mathematics; rising junior John Posada of AeroAstro; and rising sophomore Marina Ten Have of EECS.

The team was formed last September when interested students joined the project. AeroAstro PhD candidate George Lordos, who founded the MIT Space Resources Workshop and who has led or advised all MIT NASA competition teams since 2017, was a mentor for the project team. Jeffrey Hoffman, professor of the practice in AeroAstro; and Olivier de Weck, Apollo Program Professor and professor of astronautics and engineering systems in AeroAstro, served as faculty advisors.

"One year ago, the MOXIE experiment led by Dr. Michael Hecht and our team's advisor, Professor Jeffrey Hoffman, produced the first oxygen on Mars. Today, we are on the cusp of orbital test flights that will bring us closer to the first human mission to Mars," says Lordos.

"As humans venture to other worlds, finding and utilizing local water and carbon resources will be indispensable for sustainable exploration of the solar system, so the objective of our MIT team's concept is an exciting and topical technology."

The MIT team addressed the RASC-AL theme "Mars Water-based ISRU Architecture," which required delivering the target 50 tons of propellant at the end of each year and the ability to operate for at least five years without human maintenance. A few other constraints were placed, chief among them that teams could rely on one or more landings of 45 tons of mass and 300 cubic meters of volume on Mars, leaving it to university teams to propose an architecture, budget, and a flight schedule to support their mission.

They developed a comprehensive Mars mission architecture and defined a comprehensive concept of operations, from a precursor ice scouting and technology demonstration mission in 2031 to the main propellant production, storage, and delivery mission in 2036. BART is an end-to-end "ice-to-propellant" system that gathers water from Martian subsurface ice and extracts carbon dioxide from the red planet's atmosphere to synthesize liquid methane and liquid oxygen bipropellant. These are then stored onboard at cryogenic temperatures until delivery directly into a rocket's propellant tanks.

BART is accompanied by MARGE, a 40 kilowatt electric mobile nuclear reactor based on NASA's Kilopower Reactor Using Stirling Technology project (KRUSTY, which also inspired the MIT team's name) that generates power from nuclear fission to support long-duration operations on distant planets.

For the team's proposed mission, four tandems of BART and MARGEs will roam the region known as Arcadia Planitia at the mid-northern latitudes of Mars following a prospecting rover named LISA (Locating Ice Scouting Assistant) in search of accessible ice to use for propellant production. The entire system has 100 tons of storage capacity and can produce 156 tons per year, against a demand of 50 tons per year, and requires only three landings.

Another discussion on fuel

and building large smelting production

Combustion engines ... - ... on Titan and Mars

https://newmars.com/forums/viewtopic.php?id=3515

Last edited by Mars_B4_Moon (2022-07-12 06:42:02)

Offline

Like button can go here

#305 2022-07-12 17:31:26

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,062

Re: Internal combustion engines for Mars

thanks for the post on the use of a 40kwe version of a mobile reactor and drilling water to fuel units as this needs to go in a few more topics.

Offline

Like button can go here

#306 2023-02-26 17:16:32

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,062

Re: Internal combustion engines for Mars

This was intended for post 10 of the topic update edit but here it is in a new post or in this case a repeat.

This post includes a link to a video about torquing the head gaskets in a Suburu.

It was posted by SpaceNut in Housekeeping...

SpaceNut wrote:Just now got error with cellphone edit post for a link on Subaru head gasket video

https://youtu.be/o7p_fWXqoSE(th)

Offline

Like button can go here

#307 2023-03-26 13:01:47

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,062

Re: Internal combustion engines for Mars

The question keeps bugging me as I know that we use energy in a non-average mode all the time and that due to the grid and how others are using their own we end up with a more stable with peak loading on the grid.

How Many kWh Per Day Is Normal? Average 1-6 Person Home kWh Usage

Here is the total US residential electricity consumption of 118.2 million US homes:

All in all, we use 1,267 billion kWh of electricity per year. The total cost of this electricity is $219.34 billion annually.

We spend 214.2 billion kWh (16.9%) on air conditioning.

We spend 186.9 billion kWh (14.8%) on space heating (usually on heat pumps).average home will use 10,720 kWh of electricity per year. That comes to 893.33 kWh per month, 205.59 kWh per week and, finally, 29.37 kWh per day

I just got my electrical bill and my daily use for the last month was double the above with just an electric heater to keep the home at 55 to 60 F. Normally its down near that amount when warm as we do not use AC just fans.

This accounts for no energy for a vehicle or other concerns in which we might want some for use.

Of course, a solar thermal and storage would change that but still not all would be solved.

From a solar panel energy provider How Many KWh Does A House Use Per Day: Ultimate Guide

Numbers that raise a question for what is average... Meaning that the real energy is most likely higher.Other things to consider are not all homes are of equal insulative quality and not all homes see the same cold or heat of the seasons.

Also, since cars would need to be all electrical to get a real total and all I have is the hybrid and gasoline to make use of then let's see if we convert to a gas source for the electrical how that will look.

Conversion: Kilowatt Hour to Gasoline Gallon Equivalent with numbers that if I feed that little amount of gas into a generator would fail to produce the electrical one would get.

1 kWh = 0.029678483099753 gge

Most references on how much gasoline a generator uses report averages of three-quarters a gallon per hour at normal load.

So if we look for a generator that produces 2kw then we have the bare minimum looks like 4 hrs on a gallon. Which is a far cry from a 24 hr clock and then you need several of them to allow for cool down cycles so as to not destroy them.24 hr x 1.5 kw = 36kwhr daily required at $4 a gallon x 6 for the day = $24 a day... 30 day average = $720 a month ouch as that is really high an add to that the vehicle which is $60 a week brings the fuel cost to $960 for everything.

Sure, other fuel types will be just different numbers, but they are still too high...

So how much oxidizers do we need and what is it energy cot.

Offline

Like button can go here

#308 2023-03-26 14:16:40

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,677

Re: Internal combustion engines for Mars

For SpaceNut re #307

Thanks for the reminder that our readers need to see the results of previous work in this topic, from time to time. Otherwise, it is natural for memories to fade, to the point that even something as basic as the amount of oxidizer needed is up for question.

To remind everyone (as is thoroughly documented in this topic, which has reached over 300 posts) ...

Carbon dioxide is abundant on Mars

The most efficient possible way to store energy and use it when needed on Mars is to separate CO2 into CO and O2

There are numerous ways to consume CO and O2 in a variety of machines.

Recently a member of the forum discovered that work has been done to create a fuel cell that generates electricity directly by consuming CO and O2.

From my perspective, this last approach has many advantages over mechanical systems, such as the ones for which this topic is named.

Never-the-less, an Internal Combustion engine will work just fine on Mars, and we recently even confirmed the size of the storage tanks for CO and O2 that must be mounted on vehicles that venture out onto the Mars landscape using this energy supply.

If you have time and would be willing to take this on, please research the topic and find the references where this solution is worked out.

(th)

Offline

Like button can go here

#309 2023-03-26 14:22:40

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,677

Re: Internal combustion engines for Mars

For SpaceNut re topic ...

A nice addition to the topic, if you have time and the effort seems worth while, would be to work out a table of tank sizes for machines that would be used on Mars to travel, or to do work.

We've established the size of the storage tanks, and that information is posted in the forum, but I have already forgotten which molecule is twice the volume of the other. In any case, regardless of which molecule requires twice the volume of the other, the vehicle MUST have onboard storage for CO and O2 as gases. Making liquids is energy expensive and totally unnecessary for any but the most extreme of expeditions.

I'm hoping someone in the forum membership will be willing to create a table of tank sizes that includes energy storage and approximate vehicle range, or machine tool operating life, depending upon the application.

(th)

Offline

Like button can go here

#310 2023-05-03 19:31:10

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,062

Re: Internal combustion engines for Mars

Here is some more of what makes todays car the way that they are.

Where the Energy Goes: Gasoline Vehicles

A car using gasoline will create from 1 gallon or 6.3 lbs of fuel, 20 lbs of co2 from an approximate 14.7 ration to 1 of which if we had to carry the mass of atmosphere to burn the fuel makes for 23.22 lbs of oxygen is required. To which the total 100 lbs of air is just for that 1 gallon. Now fill the tank up for range and you now have something that will be why conversion to other source of energy is a challenge.

Then again a new heat engine design is in process of determining values

Here

Offline

Like button can go here

#311 2023-06-14 17:19:03

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,278

Re: Internal combustion engines for Mars

The Martian atmosphere is so thin that air resistance just isn't an important consideration in ground vehicle design. This is especially true when considering that the rough nature of the surface limits ground vehicles to typical 1st gear speeds on Earth. Instead of liquefying gaseous fuels like H2, we could keep them in big spherical fbre reinforced balloons attached to the roof of a vehicle. Hydrogen contains 11MJ/m3 at 1 bar at 20°C. A spherical balloon 6m in diameter could carry some 1.224GJ of pressurised hydrogen at 1 bar. That is equivelent to 9.2 gallons of diesel. At -20°C, that would increase to 10.65 gallons equivelent. On Mars, a vehicle should get about 3x its Earthly eange on similar terrain. So 10.65 gallons of Mars is equivelent to 31.93 gallons on Earth. That is equivelent to a full SUV fuel tank. Oxygen would be needed in only half as much volume, since H2 + 0.5O2 = H2O.

The advantage of hydrogen is that electrochemical efficiency is 80% or more. Without needing to liquefy it, lightly pressured hydrogen could be a very economic fuel on Mars.

Last edited by Calliban (2023-06-14 17:27:02)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#312 2023-06-14 17:28:06

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,677

Re: Internal combustion engines for Mars

For Calliban re #311 ...

You're off to a great start, but your post appears to be missing the oxygen to combine with that H2 ...

I seem to recall that we (forum) have dealt with this before. In that scenario, there was a volume of 1 for one of the two gases, and a volume of 2 for the other, but I no longer remember which is which.

Please add the oxygen balloon to your Mars SUV, and clarify the volume.

Doubling the pressure would solve the issue, if size of the balloon is a problem.

(th)

Offline

Like button can go here

#313 2023-06-15 10:19:47

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,379

Re: Internal combustion engines for Mars

Use Toyota's Mirai's H2 storage tank mass as a proxy, which operate at 700bar, combined weight of 87.5kg for both tanks. Mirai's pair of 700bar H2 tanks enclose a total volume of 122L / 32 US gallons, so 11lbs of Hydrogen at 700bar. Mirai's fuel cell max power output is 114kW, volume is 37L / 1.3ft^3 (3kW/L), and mass is 56kg (2kW/kg or 1.24hp/lb). You need 2 or more tanks, preferably 4 (two is one, one is none), at least as many smaller O2 tanks to store the O2 for the fuel cell and passengers, N2 tanks to pressurize the tires, plus CO2 tanks for fire suppression in the cabin and powering air tools (to change tires or work on the suspension, drill for rock samples, etc). You need at least 2 complete fuel cells, enlarged radiators to dissipate heat since they only work on radiation and a large volume of atmospheric movement through a radiator core is likely to clog the core with fine dust, as well as 2 complete life support and electrical systems.

I think you need 6 tires instead of 4 to ensure the vehicle remains minimally mobile if a tire or wheel is completely destroyed by the sharp rocks present on the surface of Mars. I don't think woven wire mesh tires will be very practical at the weights involved. Electrically heating a real off-road rubber tire is the better option. The US Army has tried various wire mesh and "tweel" concepts, but all of them have been found wanting. They work acceptably well until they're damaged, which is why you see a handful of tweels on light duty construction equipment, but then they don't work at all.

1 cubic foot / 1cu/ft^3 = 28.32L / 7.48 US gallons

Engineering toolbox says...

gaseous O2 density at 750 bars and room temperature: 43.16lbs/ft^3

gaseous O2 density at 250 bars and room temperature: 20.76lbs/ft^3

Your vehicle weighs about 1/3rd of what an Earth-bound vehicle weighs and air resistance is almost non-existent, but you're going over rough ground, which requires a lot more power, so I would expect vehicle range to be 1.5X to 2X that of the equivalent Earth-bound vehicle using the same power plant. Double the vehicle weight to account for components which keep the vehicle pressurized and ruggedized (high-strength steel chassis and suspension components, a composite pressurized cabin with radiation shielding, and big tires) and complete with proper backup systems, and then your associated range reduction makes the vehicle about as performant as it would be if operated on a road on Earth, despite weighing twice as much and operating off-road 100% of the time on Mars.

There are no free lunches to be had here. This sort of design is the lightest practical vehicle that doesn't result in occupant death if some part of the vehicle fails during operation. In addition to pressurization and storage of food / water / repair tools / communications equipment / computers / scientific instruments, the vehicle's cabin must provide some sort of radiation protection in case you're caught in the open during a solar storm. It will have a lot of intricate / delicate components like fuel cells, fuel and oxidizer transfer lines that can freeze if any moisture is present in either tank, electronic controls which require radiation hardening, etc. These Mirai vehicles were intended to operate on Earth, using high quality roads which don't exist on Mars. The same applies to any combustion engine or battery powered vehicle- without complete backups any serious problem is tantamount to your last ride.

The good news is that modern combustion engines or fuel cell and electric motor are very compact, so having a vehicle with multiple smaller combustion engines or fuel cells is less of a problem. All types of vehicles will require batteries, though. Combustion engines, H2 fuel cells, electric motors, and BEV Lithium-ion batteries all use water-glycol liquid coolant in their latest / greatest incarnations here on Earth, but that mix would freeze solid on Mars, so some kind of pressurized refrigerant gas like CO2 will be required to transfer heat to the radiator.

Offline

Like button can go here

#314 2023-06-15 10:56:45

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,677

Re: Internal combustion engines for Mars

For kbd512 re #313 and topic in general

In trying to think of a tag for your work here, I have too many choices but settled on Mirai

SearchTerm:Mirai Toyota hydrogen vehicle 700 bar tanks

I've observed that your creativity often comes in bursts that last more than a few hours, and sometimes they even last days before you've captured all the design elements and considerations needed to complete a run.

In hopes that is the case here, please consider developing your vision to include the ground support facilities.

it seems to me that your concept for a reliable, comfortable and human-protective vehicle for Mars is worth extending to the full package description, so that it can be evaluated by folks planning flights in 2024.

I just learned recently there there is another nation planning a flight, in addition to the one already in planning.

I'll set up a topic for 2024 flights, in hopes our members while post anything they find there.

(th)

Offline

Like button can go here

#315 2023-06-15 13:49:05

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,379

Re: Internal combustion engines for Mars

tahanson43206,

I've already posted numerous times about Toyota's Mirai because US DoE and NREL consider it a kind of landmark achievement when it comes to a practical fuel cell powered passenger vehicle design. It meets or exceeds a number of performance metrics DoE considers important for such a vehicle to have, in order to be viewed as a viable replacement for a combustion engine. Likewise, the Australian company named "Hysata" produces a commercialized "reverse fuel cell" design (splits water into H2 / O2) with a 95% overall electrical efficiency rating, meaning 1,000Wh of electricity in pumps out 950Wh of H2 / O2 chemical reactants on the outbound side. There will be significant further losses to compress both resultant gases to 700 bars of pressure. I would consider a 50% overall efficiency as a "big win". California rates a Tesla Model 3 at 73% well-to-wheels electrical efficiency, so achieving 50% overall energy efficiency (water splitting, gas compression, input into another fuel cell that combines H2 and O2 to generate electricity for traction motors, and then power delivered to the ground) is a good metric to use when evaluating overall energy efficiency, thus the practicality of taking said technology to Mars to use at modest scale as a common form of ground or aerial motorized transport.

The advantages are that the gases are rather light and compact at 700bar, no cryogenics are required (regardless of if it's possible, it greatly complicates storage), and the equipment to use this form of energy is no worse than gasoline on overall gravimetric power density, as well as reasonably mature at this point. Wherever possible, we should use viable commerical power generation and storage technology with tweaks made to it to account for the fact that Mars is colder than Antarctica and receives half as much solar radiation as Earth.

Similarly, the ISS uses the exact same model of commercial prismatic Lithium-ion batteries made by "GS Yuasa", that are also used on the Boeing Dreamliner, but with appropriate thermal and charge / discharge protection. NASA incorrectly assumed that Boeing understood how to use these batteries for flight applications, but the resultant battery fires aboard Dreamliners indicated that Boeing did not. That problem has since been resolved.

Each of these fuel cell powered surface vehicles is going to cost about as much as a Cadillac Escalade top-of-the-line model ($150,000) and they'll weigh about as much as GM's Hummer EV pickup truck. We'll save weight and money on a CFRP cabin using Lamborghini's "Carbon Forging" process, but the 700bar storage tanks are expensive fluoropolymer-lined filament-wound CFRP, and everything else is "doubled-up" over an ordinary Earth-bound vehicle, hence the drastic increase in weight and cost. The cabin will need to be rollover protected using an external high-strength steel tubing "exoskeleton" that you see on the newest high-dollar rock-crawler type vehicles (prevents crushing of the cabin when these heavy off-road vehicles roll / flip / drop onto rocks in off-road sporting events here on Earth).

Example of an exoskeleton frame off-road electric vehicle:

This Off-Road Electric Vehicle by Maitreya Dhanak is Sleek

Example of a real life exoskeleton frame off-road truck:

Offline

Like button can go here

#316 2023-06-15 14:27:27

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,278

Re: Internal combustion engines for Mars

One way of reducing the amount of energy required to compress H2/O2, is to carry out electrolysis at high pressure. Instead of compressing gas to 700 bar, you inject water into the cell at 700 bar. Water is incompressible. So relatively little energy is needed to do this.

But Mars has virtually no atmosphere. A big balloon mouted to the top of the vehicle, would experience very little drag, especially at low speeds. Instead of 122 litres stored at 700bar, why not 85m3, stored at 1bar in a spherical balloon? The balloon would be 5.5m in diameter, about as wide as the truck is long. On Earth, this would be inefficient because of air resistance. On Mars, air resistance is about 1% what it would be on Earth. So our 5.5m diameter balloon, would experience the same air resistance as a 0.55m diameter balloon on Earth.

The drag experienced by an object moving through a fluid, is given by:

F = 0.5 x Cd x A x rho x v^2

If v is 20mph (8.94m/s); rho is 0.013kg/m3; Cd for a sphere is 0.47; A = pi x 2.75^2 = 23.76m2.

Air resistance, F = 0.5 x 0.47 x 23.76 x 0.013 x 8.94^2 = 5.8N

Engine power required = F x V = 5.8N x 8.94 = 52W.

That is a negligible addition to total engine power. If we take a Mars SUV mass to be 3 tonnes, its weight on Mars will be 11,000N. The rolling resistance of well inflated tires on asphalt, is 0.01. On loose sand, it is 0.3. On the rubble strewn Martian surface, 0.1 is a good estimate. Rolling resistance will be

F = (M x g) x Crr = 11,000 x 0.1 = 1100. This is 190x greater than air resistance at 20mph. For air resistance to reach even 10% of rolling resistance, the vehicle would have to travel at 87mph on Mars. Not likely to happen. In fact, 20mph would be difficult over rubble strewn terrain.

Last edited by Calliban (2023-06-15 14:54:00)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#317 2023-06-15 14:39:38

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,677

Re: Internal combustion engines for Mars

For Calliban re #316

Please add the second balloon to your vision. I suspect it is present in your mind, but it has not yet shown up in the postings.

For kbd512 ... ** nice ** image to go with the external frame advice!

For Calliban... this could go into the Thermal battery topic, but you are ** here ** (at the moment) ... It occurred to me to ask about molten salt as a hot store, while liquid air serves as the cold store. I am offering this as an alternative to your solid limestone block, which must be drilled out to accommodate fluid lines.

Setting aside the technical difficulties for a moment, if you had liquid air as the cold store, and molten salt as the hot store, what proportion of each material would be needed to balance, so that the output is gaseous air at whatever temperature is most advantageous for an air motor.

(th)

Offline

Like button can go here

#318 2023-06-15 15:01:10

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,278

Re: Internal combustion engines for Mars

For Calliban re #316

Please add the second balloon to your vision. I suspect it is present in your mind, but it has not yet shown up in the postings.

For kbd512 ... ** nice ** image to go with the external frame advice!

For Calliban... this could go into the Thermal battery topic, but you are ** here ** (at the moment) ... It occurred to me to ask about molten salt as a hot store, while liquid air serves as the cold store. I am offering this as an alternative to your solid limestone block, which must be drilled out to accommodate fluid lines.

Setting aside the technical difficulties for a moment, if you had liquid air as the cold store, and molten salt as the hot store, what proportion of each material would be needed to balance, so that the output is gaseous air at whatever temperature is most advantageous for an air motor.

(th)

Liquid CO2 would be relatively easy to collect and store on Mars. At -70°C, CO2 can be stored as liquid at a pressure of 6 bar(a). The surface of Mars is sunny most days, all over the planet. Only during dust storms and night time is the sun obscured. We could put a dish on top of a vehicle and collect concentrated sunlight during midday. The heat could be stored in molten nitrate salt. A mineral oil would transfer heat into a boiler, where liquid CO2 would be converted into high pressure gas. Driving would take place around dawn and dusk. At night, a small heat engine would run, generating enough power to compress the cokd CO2 Martian air to a pressure of 6 bar, at which point it would luquefy.

Last edited by Calliban (2023-06-15 15:02:53)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#319 2023-08-21 19:58:03

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,062

Re: Internal combustion engines for Mars

Who would have thought that it would be possible to 3D-Printed Combustion Engine Made of Plastic

Offline

Like button can go here

#320 2023-09-02 20:17:02

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,379

Re: Internal combustion engines for Mars

Speed of Air Engine Technologies’ Delivers Performance Breakthrough - Engine Builder Magazine

The test Ford F250 uses a new piston design that resembles a golf ball. It's an engineered pattern of dimples on the piston crown that drastically improves fuel economy and power, without creating black smoke, which indicates unburned fuel in the exhaust.

Highlights before / after Speed-of-Air piston installation:

2002 Ford F250 PowerStroke diesel truck

Horsepower: 275hp at 2,800rpm (original); 565hp (new)

Torque: 525 lb-ft at 1,600rpm (original); 1,304 lb-ft (new)

Fuel Economy: 13mpg (original); 22mpg to 24mpg (w/ Speed-of-Air pistons)

New fuel economy: 22mpg to 24mpg

Exhaust opacity 4.41%, 16.77 O2; CO2 2.42% avg; NOx 360.33ppm- all without EGR, DPF, DOC, or any other after-gas treatments (will pass California exhaust opacity for trucks made after 2007)

Testing confirms fuel consumption reduction of 30% under constant load

CAT 3516 mine haul truck engine, oil-change intervals could be extended by nearly double that of a conventional engine. Based on oil samples from the SOA engine versus the stock engine, SOA reduced the soot levels in the oil by 55 percent over a period of 27 months.

The economic impact of this aspect alone saved nearly $250K in operating expenses over 18,000 hours of service life. That figure is based solely on labor and materials for oil changes, not including maintenance or repairs due to engine wear, or lost production due to service down time.

I have noticed this new technology is starting to be applied to gasoline engines as well.

Today I also watched a video from David Vizard wherein he indicated that it was possible, based upon testing done while he worked at GM, to make a 1L engine achieve 100mpg using water injection and 4-stroke cycle. One of the strokes uses heat stored in the combustion chamber to get a free power stroke from steam expansion using heat generated by the previous combustion event, so it's technically a "hit-and-miss" engine at that point. The video was not about fuel economy at all, though. The main topic of the video was running 17:1 compression on 87 octane motor gasoline, as well as up to 45 pounds of boost, hopefully not at the same time, without running an intercooler after the turbo. He said it was all about water droplet size control. I was watching a video on droplet size and hydrodynamics, and then stumbled into the video from Vizard.

Worlds cheapest and MOST EFFECTIVE octane booster - David Vizard

Offline

Like button can go here

#321 2023-09-16 17:31:42

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Internal combustion engines for Mars

GS Caltex test operates container ship running on marine biofuel

https://www.koreatimes.co.kr/www/tech/2 … 59298.html

Perhaps it will depend on what fuels the farms of Mars can grow, I think the vehicles might also be a hybrid mxiing liquid fuel or gas vehicle with fuel cell electric vehicles (FCEV) a working Biosphere even the most unusual producing any kind of chemical or organic production will be a huge break through. Robots and a farm of animals might even have a working combustion engine before the human arrives.

I have thought have having machines build the village and factory production before the human, I think it is important to have people on Mars yet what if the human needs an extra critical system more oxygen, extra medical supplies, more radiation protection, more fungi or funga to keep the larger human village colony working. For the moment the engine is not a first as Solar, RTG, and nuclear are means of energy generation for a robot or space vehicle, the Solar or RTG or Nuclear powered base full of robots might develop the combustion engine but without supplying the human, later the humans arrive and occupy the city and villages. When Robots have extra Oxygen to spare, Methane combustion will be process of combining oxygen with methane within a combustion chamber, such as inside the block of an engine, to produce heat and pressure, there could be use of ethane (C2H6), propane (C3H8) and butane (C4H10).

NASA's Oxygen-Generating Experiment MOXIE Completes Mars Mission

https://mars.nasa.gov/news/9474/nasas-o … s-mission/

Mars astronauts could make rocket fuel on the Red Planet someday. Here's how

https://www.space.com/mars-astronauts-r … red-planet

What would it take to build a self-sustaining astronaut ecosystem on Mars?

https://arstechnica.com/science/2023/09 … m-on-mars/

We're getting closer to bioregenerative life-support systems for astronauts.

Once Biodomes are working and producing farming a system of fauna and life and animals and flowers and plants, you might have Ethanol, Alcohol, Kerosene and other engines. We had fringe ideas for Hybrid engines, ideas for Mg/CO 2 engines on Mars, some type of burning of Iron, CH4+O2 in ICE used not only as rocket fuel, but also for internal combustion engine.

Offline

Like button can go here

#322 2023-10-09 14:15:48

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,114

- Website

Re: Internal combustion engines for Mars

What makes internal combustion engines attractive here on Earth is that we only carry the fuel aboard the vehicle. The oxidizer (the oxygen in the air) is all around us "for free". And because it is diluted with nitrogen, combustion temperatures are reduced by something near 1000 C from fuel-pure oxygen combustion temperature levels, so the mechanical design is so much more feasible.

A big part of the attractiveness is something most folks do not appreciate: the relatively-high atmospheric pressure on Earth. Thermodynamics requires that combustion take place well above ambient pressure levels, for there to be usable work done in the thermodynamic cycle. Without significant pressure rise, there is little or no usable work to be had. PERIOD!

And in order to useful, you need to extract this cycle work at a significant rate, which means you compress a significant massflow of ambient air to combustion pressures, then burn it with your fuel. At Earthly atmospheric pressures as compression inlet pressures, this is easy to do in one or only a few stages of compression, and at a MASS flow rate high enough to be useful. The atmosphere on Mars is so thin, that any compressor is going to resemble an Earthly vacuum pump: it can get the pressure up from millibars to multiple thousands of millibars, yes, but the massflow is minute!

The Mars atmosphere is a good dilution gas to solve the high combustion temperature of fuel with oxygen, yes, but is has no free oxygen. You will have to carry an oxygen supply as well as your fuel supply, and oxygen outweighs fuel by factors from 2 to 4 with most fuels. That means you carry from 3 to 5 times as much liquid for your combustion engine as you would here on Earth, and you still have to add diluent gas, or face the 1000 C-higher temperatures!

The diluent gas we need to get the temperature reduction outweighs the oxygen by a factor of 4 here on Earth. As indicated, you are not going to compress that real-time as you drive on Mars. You must compress and store the diluent gas before you go, and carry it with you, just like you must carry the oxygen, and the fuel. Using Earthly air as a guide, the stoichiometric ratio of air to fuel falls in the 17-to-19 range, for a wide variety of hydrocarbon fuels. With hydrogen, it is even higher, at 51. Even with ethanol, it is still 9.

You are looking at carried propellant masses in the factor 10-20 range higher than you are used to on Earth, to use Earthly internal combustion technologies on Mars! Maybe 52 if you go with hydrogen.

That's just the numbers, guys!

GW

Last edited by GW Johnson (2023-10-09 14:18:41)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#323 2023-10-09 14:27:50

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,677

Re: Internal combustion engines for Mars

It is always good to revisit solved problems, to be sure they are still solved.

This topic showed that CO and O2 are the most cost effective and technically superior (ie, simplest) fuel for internal combustion engines on Mars. The use of CO2 as a diluent has been thoroughly discussed, and included in the business plan.

Perhaps something has changed?

The size of tanks needed is known. The mass of fuel and oxidizer are knowable, for any given trip.

(th)

Offline

Like button can go here

#324 2023-10-09 20:25:03

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,062

Re: Internal combustion engines for Mars

Head compression is for the lowest to highest depending on fuel can be as low as 100 PSI and for Deisel 400 PSI.

https://www.apexinds.com/blog/engine-co … ested.html

This is where the head gaskets fail for the Subaru Boxer engine to the coolant from the exhaust of the spent fuel.

I would think that the least rework engines for the design for mars would be not to use a boxer but some sort of inline vertical or slant style to make it as dependable as possible. Som depending on the HP we require we can then figure in the mass for the vehicle with fuel onboard.

Typical gas tank is 11 gallons to 16 but the mass is not the same for the tank as we need to have a thicker wall for both the fuel and oxidizer as they are liquidized.

Offline

Like button can go here

#325 2023-10-10 02:24:57

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,379

Re: Internal combustion engines for Mars

2CO + O2 = 2CO2

O2 = 31.9988g/mol or 31.25mol/kg

CO = 28.011g/mol or 35.7mol/kg

CO = 10.112MJ/kg

CO / O2 Flame Temp: 3,220°K / 2,947°C / 5,336°F (very hot)

To completely combust 1kg of CO, we need 17.85mol of O2, or 571.17858g.

This yields 10,112,000J / 2,808.9Wh of heat energy. If we can convert 60% of that to mechanical power using a 3-stage sCO2 gas turbine (with inter-stage heat re-injection from the burner can's scorching hot exhaust effluent stream), then 1,685Wh of power output per 1kg of CO, or 1.571kg of combined fuel and oxidizer, or 1,072.6Wh/kg.

Suppose we need a 100hp / 74.57kW engine. We need 354kg / 0.45m^3 (788.6kg/m^3 at -191.52°C) of CO and 202.2kg / (0.18m^3 at -182.96°C) of O2 to run the engine for 8hrs at full output. If a Lithium-ion battery can achieve 200Wh/kg in an actual battery pack, then 2,982.8kg for 8hrs (assumes 100% efficiency of all electrical components). Assume that our cryogen tanks, sCO2 gas turbine, sCO2 supply, and radiator panel weighs about 350kg. Our power-to-weight ratio (PWR), inclusive of fuel / oxidizer / sCO2 gas turbine engine, is still 3.3X better than the battery alone. The electric motor, radiator for the motor / batteries / power control electronics (a much larger radiator since it operates at lower temperature, albeit probably no heavier than the radiator for the sCO2 setup), and electronic control components to regulate voltage / amperage are certainly not weightless. It's probably a safe bet that our true PWR advantage falls somewhere between 3.5X and 4X.

If future solid state batteries can match sCO2 gas turbines, then we should revisit batteries as the power source because they do work, but that seems unlikely in the near term. In another 10 years, we might have the battery problems figured out. This is reason enough to pursue sCO2 and CO / O2 combustion engines for powering heavy off-road vehicles. CO energy density is nowhere near as good as H2 or any liquid hydrocarbon fuel, obviously. That said, we don't have H2 synthesis and storage problems (embrittlement of nearly everything), hydrocarbon fuel synthesis problems (water sourcing and transformation into hydrocarbon fuel), fuel cell maintenance (rubber O-ring seals, plate seals for the stack, pump motors, check valves), or ensuring that control electronics for fuel cells or batteries can survive a major solar flare event.

To be frank, I'm far more concerned about power control electronics getting fried through overheating or radiation than I am about the durability of the batteries or fuel cells, but the charge / discharge rates of these devices for all existing space applications are very pedestrian compared ot the demand from a motor vehicle. This is a non-issue with a sCO2 gas turbine. All components are physically robust by necessity, and should be field-repairable or replaceable. I'm quite certain we'll maintain a stock of chips for computers, but rendering a vehicle non-operable due to a computer failure is ridiculous. The present cost of rad-hard chips is also ridiculous. One IBM CPU might cost as much as the entire vehicle.

I've identified austenitic ductile cast Iron, very high-Manganese steel, and 5083-O Aluminum alloy as acceptable substitutes for 300 series stainless steel, all of which confer various mechanical property advantages over 300 series, as well as cost. Chromium and Nickel are not cheap, so whatever we can do to minimize the consumption of strategic materials and obtain metal from domestic sources is advantageous. sCO2 will require the use of 300 series for the cryogen storage vessels and radiator exclusive of the piping, 625 series Inconel for the gas turbine / turbine casing / radiator piping / valves / storage tank. The reduction gearing and transmission casing will use austempered ductile cast Iron for its compressive yield strength and its ability to absorb vibration. Austempered ductile Iron is not the same material as austenitic ductile Iron, which is notable for its cryogenic toughness. Austempering adds a great deal of tensile strength to ductile Iron at normal service temperatures, which means that strength increases at lower temperatures as the crystalline structure of the material changes and becomes more brittle. You can't temper austenitic materials to any appreciable degree, which is why they don't lose ductility at modestly cryogenic temperatures- there's no change to the microstructure of the steel.

Anyway... 5083-O is the most obvious choice for the vehicle chassis, pressure vessel, and road wheels. High-Manganese steel will be used for high-stress parts like bolts / studs / nuts / suspension components / shafting / track links / pioneer tools for getting the vehicle "unstuck" (from ruts) because it's incredibly tough stuff. This characteristic will also make it difficult to machine, but it's not as soft as 300 series and performs almost as well as 300 series at cryogenic temperatures, in terms of toughness.

Inside the vehicle, we need a thermoplastic liner to absorb protons from a solar flare, probably HDPE (used in armored vehicles as part of the NBC protection systems). Any advanced electronics for sensors need similarly well-protected enclosures. We'll want a F-35 style distributed aperture system to ring the vehicle with IR cameras for driving under all weather conditions. A ground-penetrating radar system probably isn't a bad idea, either, to avoid driving over thin-walled lava tubes. Beyond that, we want stupid-simple VHF radios, like the PRC-77. Canada EMP-tested the radio and determined that it suffered no apparent damage from multiple tests. That's the level of reliability we need from our radios.

Offline

Like button can go here