New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#51 2019-10-13 13:56:48

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Nuclear power is safe

So, I think if we have robot cleaners around, dust accumulation will be pretty minimal.

Let's test that theory before we start betting lives on it. I've never seen a proper test conducted, so that's what I'd need to see to believe it.

No of course not. I gave an estimate originally for how long it would take to unroll flexible PV on Mars. Can't recall what I arrived at but Rapid Roll claim they lay 11 kw (presumably max capacity) in 2 mins. I think on that basis it would take a few sols, maybe 3 or more. But feel free to assume10 sols. That's no problem at all.

I see. So, no matter what, building a megawatt-class power plant is unlikely to be done after a day's work. That was my point. I'd wager that all of their power cables were also pre-fabricated. That would not be how I would build any power plant that I don't know the exact dimensions of until I actually arrive onsite. I would arrive with general plans and general layouts, meaning I know how far the power plant needs to be from the giant rocket that brought it there, I know what gauges of wiring I need for the maximum permissible power transmission distances, all of my power transfer and conditioning equipment is tested and ready to go, etc.

I don't think the terrain will be a big issue. The terrain will be fairly flat. The robot rover might well be moving more slowly than a big tractor on Earth.

This needs to be tested.

I think NASA has already identified potential landing sites on Mars which meet both criteria in Accidia Planitia/Amazonis Planitia

Has anyone sent a probe there to verify the availability of the water and characterize the salinity and other characteristics of any dissolved solids in the water?

You seem determined to ignore the fact it survived for 50 plus more times than its planned life! If so, I can't help you.

No Louis, I'm determined to get you to acknowledge what actually killed it. The solar panel didn't malfunction. The electronics didn't malfunction. It was simply starved of sufficient photon power and that was what it needed to live. That didn't happen with the nuclear powered rover, obviously. We have nuclear powered satellites and experiments that have been in operation longer than I've been alive. We can't make that same statement about solar powered spacecraft.

I accept you have not suggested that insolation levels will drop to zero but other pro-nukers here have. But what do you think insolation drops to in a worst case dust storm scenario. Again, the nuke community seem reluctant to discuss that. From my researches it seems that a figure of around 36% is the lowest. And that seems to translate (with extra dust accumulation in dust storms) to a figure of around 20% as the lowest for actual PV generation as a % of the norm. I have never seen any records to suggest that such low points last longer than a few sols. I think that's because dust storms are self-regulating - whilst initially they act like a heat trap, beyond a certain point they being to reduce the atmospheric temperature and so the storm subsides.

If the power output drops below what's required to make enough propellant to come home, then I don't really care about what the solar insolation levels are. From my point of view, it's not an academic curiosity. As a mission planner, I would demand that no matter what power technology is used, that I have a mathematical assurance that my people are coming home as long as there equipment doesn't malfunction. I will demand test results from proper testing of any potential solution presented. Is that a clear enough answer?

I am not suggesting megawatt fluctuations in power input as I am proposing a v. large amount of battery storage.

Have you done the calculations to determine how many tons of batteries are required to buffer megawatt-level power fluctuations?

If you have, could you share your calculations with the rest of us?

Well quite...but it may not have been you but pro-nuclearists here have referenced how long it takes to create a solar farm on Earth as an indication of how long it would take on Mars. Even if we didn't use ground flexible PV we could string it on wires on Mars due to the benign weather.

Well, at least we're not talking about laying our power provisioning solution in the dirt anymore, so I guess that's progress.

Abrasion did not seem to greatly affect the performance of the solar powered rover over 14 years. The dust on Mars would feel soft to the touch - so not like bits of gravel being thrown about as on Earth.

They aren't using panels coated with very soft, and thus flexible, plastic. They're using much harder semi-conductors with protective coatings. Maybe some kind of hard plastic coating over an accordion style flexible panel would work.

Well, it's incredibly likely that they're going to weigh 1,500kg each, which would be the mass of a functional reactor with top shielding intended to reduce radiation levels received by the electric generators.

I don't really follow your argument there. As far as I can see we agree they will weigh a minimum of 1.5 tons per 10 Kwe. But those are not units that would allow humans to work in close proximity. If I am wrong on that, let me know.

I was responding to the argument about "pro-nuclearists" not knowing what things will weigh.

So far as I am aware, a photon is a photon. Yes, direct beam insolation will always be best if you have the right angle, but (assuming two planets A and B at the same distance from a star) if there is less direct beam insolation on Planet A than Planet B then, all else being equal, clearly the productivity of equipment designed to maximise direct beam capture will be less on Planet A than on Planet B. That means that simply laying PV on the ground will be less detrimental to electricity production on Planet A than would have been the case if there was as much direct beam insolation as on Planet B.

If many of the photons are striking objects (dust in the atmosphere) that absorb some of the total energy delivered by the Sun before they reach the array, then you have lower insolation levels / lower maximum power conversion levels below the dust in the atmosphere. That said, you still have energy being transmitted to the surface. I've never argued that point, only that it increase the mass and size of the array required and it's not inconsequential given the total power requirement.

Well as I have said elsewhere, no nuclear facility anywhere on the planet could get private insurance against third party claims on the open market. The verdict of the open market is normally pretty sound. That suggests to me that nuclear power has not been discriminated against but mightily indulged ie in every country where it is allowed to operate it does so with a state guarantee to pick up the tab if things go wrong (as we see in Japan where it is the state picking up the tab for all the homeless people and loss of agricultural and other production).

"Anywhere in the world", huh? Is America "anywhere in the world"? You don't use Google much before making claims, do you.

If you have figured out how to use the Sun to generate multiple gigawatts of power in an area roughly a square mile in size, then I'm sure the Japanese will give you any reasonable amount of money you could ask for. Short of covering the entire country with solar panels, solar power couldn't begin to provide the amount of energy they consume there.

Anyway we shouldn't read across between the two planets! I have never said that nuclear power could not be used on Mars Mission One. I have said it is not as good an option as solar.

Well, some of us think assured power is better for mission planning than opportunistic power.

Well there you go, we can agree! Infrared PV panels are unlikely to be much help on Mars.

Great, but to me this has never been about agreement or disagreement.

I'm a pragmatist. If suction uses too much power, use blowing. Have the PV rolls laid out one against the other then a metre gap for the rover to pass down. It could have angled blowers on either side blowing the dust accumulation forward of the rover which would then scoop up most of the dust using a mechanical system, rather than suction. Once full, the rover could deposit the rover could deposit the dust in a dedicated bin which would be periodically transported out of the location and deposited e.g. in a small crater.

Pragmatism is good.

Speaking of that...

Why couldn't we just put the panels on an A-frame so we could blow down the panels that way?

Instead of robots that constantly mill about a solar farm, why couldn't we just run CO2 lines across the top of the A-frame to give the panels a spray whenever they need it?

I'm fascinated with robots, too, just not to the point that I'm willing to build in needless weight, complexity, power consumption, and potential problems to a solution. Sometimes simpler solutions truly are better.

I am giving you the minimum requirement for Mission One. Of course, if only for failsafeness you are going to design them to last 4 years, I would suggest.

Now we're thinking like a mission planner.

I certainly don't think we should be trying to design a long life PV system for Mission One. Mission One is all about establishing the base.

I do. Mission One is about proving that we have what it takes to live there. The ability to maintain and use robust power provisioning systems is part of that "proof".

Mission Two will have habs and rovers available. So Mission Two, assuming it was also a six Starship mission, will have more room available for other cargo. I would certainly be looking to taking more PV and longer-life PV at that. Energy is the basis of human survival on Mars, so it is a priority A cargo. I am fairly confident that within a decade we could be looking at shipping out automated PV panel manufacturing equipment to utilise ISRU materials in making PV panels. More than that, within a few years after the Mars Community will be able to 3D print, using Mars ISRU materials, the PV panel manufacturing equipment itself. That will essentially make Mars energy-independent.

If you can't execute Mission One with 500t of cargo and have a really good head start on Mission Two, then maybe the plan isn't very good.

Mission Two is only 2 to 4 years away. I wouldn't count on too much engineering magic happening, with respect to systems redesign from lessons learned, in that period of time. It's better to go with what you'll need to begin with. That's why you test first and then deploy. A reliable power provisioning system seems like a really hard requirement for all missions.

I accept this is not verified yet. This requires further investigation. I am a bit puzzled by your use of "space rated". What does that mean? Does it mean a battery pack operating in a space vacuum? Well if so, that's not necessarily what we are talking about with the Tesla batteries.

By "space-rated", I mean something that can actually work in space at all or without unacceptable operating characteristics. The battery cells themselves can work in space without modification, but that's about it. Nothing else will be common between a land motor vehicle battery pack and an aircraft or spacecraft battery pack. For starters, the cell packaging will be completely unlike what you see in electric cars. The mass of the battery pack in the car is in no way representative of the mass required to provide thermal regulation in space or other near-vacuum environments where the only way to get rid of heat, even if you put it in its own temperature-controlled habitat (which will still be much heavier than a design that simply properly regulates the temperature of the pack), is by radiator. If a cell in a car short-circuits, you get out of the car. If a cell short circuits in space, then you just lost part of your energy storage supply and may have more serious problems to contend with. You could also think of "space-rated" as workmanship standards as well. NASA publishes workmanship standards for electronics and electrical components. Practices considered acceptable for motor vehicles fail to pass muster for aircraft and spacecraft, generally because the two operating environments are very different.

So, just because Tesla designed a battery pack for a car doesn't mean a battery pack in an aircraft or spacecraft will have equivalent dimensions or weight. In fact, that's almost never the case. That said, all aerospace subsystems designers go to extreme lengths to economize on weight and volume, while maintaining some specified set of operability and reliability characteristics.

Here's a simple but dramatic example of how different cars are from aircraft. In a car, if the throttle cable snaps, the throttle body or carburetor closes, effectively shutting off the engine so the car can roll to a stop. In an aircraft, it the throttle cable snaps, the engine goes to wide open throttle. On the ground, the most prudent thing to do if you loose control of the engine's throttle mechanism is to shut it down. If you do that in any sort of powered aircraft, then the aircraft starts falling out of the sky. If you're not near an airfield or some other place that you can actually land, well, the results are pretty obvious. Most people I know would consider reverting to WOT in a car, should the throttle cable ever snap, to be suicidal. However, in an airplane going to WOT gives you power to climb to avoid terrain and you can still land by cutting the engine just prior to landing. From that example, it should be fairly evident how different design requirements drive different operating characteristics and therefore different designs.

In the above example, the design difference doesn't come with any substantial weight penalty because the design is just a spring moving the throttle valve in different directions. In the case of a battery pack that you don't want the rest of the cells in the pack to catch fire or explode just because one cell in the pack short-circuits, well, you'd better have enough material between the individual cells to prevent that from happening. I've seen Tesla's car and home battery packs. They're designed for maximum volumetric density, not protection of the pack from major malfunctions of individual cells in the pack. So, that design characteristic will clearly have to change. In practical terms, that increases the weight of the pack and to a somewhat lesser extent, the volume of the pack as well.

Again, I need to know what you mean by "space-rated". If you mean "floating in space by itself" then that is not what I mean. I am talking about a methox generator on the Mars surface in a pressurised hab.

Post a link to an internal combustion engine of some kind that works in a vacuum environment. I've already done that and have written at length about how important this technology is. ULA has done a lot of work on this. They took an in-line 6 cylinder piston engine from a race-car that previously made hundreds of horsepower and the space-rated version of the same engine makes about 27hp, so the de-rating required for use in a vacuum was by a factor of more than 20 (I forget if the original made 600hp or 700hp). So, can you actually run a combustion engine in space? Absolutely. Will it be anywhere as small or lightweight as an automotive engine producing equivalent power? Not even close. Even using LOX/LH2 boil-off from a Centaur upper stage for cooling the engine, they had to massively de-rate the power output of that engine to preclude melting the Aluminum block / heads / pistons. ULA's IVF (Integrated Vehicle Fluids) technology happens to require less mass than equivalent Lithium-ion batteries to provide equivalent power and results in less loss of propellants to boil-off, even while siphoning off boil-off for powering the engine to keep the LOX/LH2 cold and pressurize the propellant tanks, then insulation and batteries.

Well when the human passenger Starship comes in there will be Starships with radio beacons already landed and the HP Starship will be able to get a lock on a precise landing position from them. I don't think it's just inertial guidance and terrain maps. I think it's laser guidance systems and Mars statellite coms as well.

You have to land the cargo somewhere with water first, don't you?

If your inbound trajectory was substantially off-nominal, then no matter how precise your reentry guidance is, you may not land anywhere near where you intended to land. I'm talking about making mid-course trajectory corrections using positional info from orbital satellites so that you're already in position for a nominal reentry. After that, then yes, having an ultra-precise laser terrain map would be stellar.

Do you get the sense yet that there's a lot of pre-requisite and setup activities required to pull all of this off and make it look easy?

I think the energy system for Mission One is essentially expendable (although I don't expect it to be expended)

I think that kind of thinking leads to flags and footprints. Some of us don't want flags and footprints. We want to go to stay, building up capabilities and infrastructure with each successive mission until we can sustain a colony on another planet.

Maybe, but never underestimate the power of powerful lobbies.

This is why the USA has ended up with the silly situation of having a really top notch successful rocket company - Space X - that is not being backed 100% by NASA because American pork barrel politics has ensured NASA is glued to some underperforming industry giants.

Well, you got me there. I'm not sure what we can do about this, either. Congress seems determined to prevent NASA from actually doing anything worth doing.

Much more the latter. I suspect it's less packaging with an aerogel hab than with anything out there on the surface.

In terms of overal mass, I think it's not a huge percentage.

Again, you have to get rid of the heat somehow. Putting the batteries in pressurized enclosures doesn't remove that requirement, it just makes the overall solution heavier than it needs to be. Air, even pressurized air, is a lousy thermal conductor compared to water or metal. That's why automotive engines are cooled using water / air heat exchangers (radiators). Given their power densities, there's no practical way to remove the heat using air alone. Insulation is good at maintaining temperature, which could certainly help with proper thermal regulation, provided you had a very effective thermal management system with radiators, liquid coolants, and pumps to remove the heat associated with charging and discharging. In the end, you're either going to be charging or discharging which will keep the battery pack warm (provided the rate isn't too high), using coolant loops and radiators to prevent overheating (at high loads or fast charging), or supplying external power to keep the battery warm (exactly what they do aboard ISS using heater plates under the ORU's). All of that substantially increases the weight of the battery pack.

The mass tonnages for cabling of KP units are not disastrous. But I do wonder about labour time required by the Mars pioneers and especially any EVA activity.

The labor time to set everything up will be substantial no matter what solution is selected. Any belief to the contrary is naive at best. It's going to take real work to deploy everything. There won't be any "easy button" to press and have everything deployed. However, the simpler solution tends to be the one that works best, more often than not. In practical terms, that means deployment by hand, using hand tools.

When astronauts repaired the Hubble Space Telescope, they didn't use robots. There were already robots welding car bodies in factories and whatnot at that time, but it made far more sense to use humans to handle delicate and intricate tasks that would require years of testing and debugging of computer software programs to ensure that those tasks could be successfully completed by a robot. Despite the fact that NASA put a humanoid robot aboard ISS, it served very little purpose and was functionally useless for its original design goals, namely assisting humans on spacewalks for repair of the space stations external components. NASA is still tooling around with it. In all probability, if we go to Mars in 2024, none of that will change. Therefore, humans will be deploying everything required to provide power. Naturally, they'll be using tools to make those tasks easier.

As for deploying a flexible PV drum - well I think the cargo hold would be further down...maybe 40 metres? Then you have a cantilevered chute...that might get you another 25 metres down...so a 15 metre oblique drop on to an inflatable air bed. Why not? Experiment!

Everything you just proposed there requires far more testing to be sure the result doesn't damage the cargo than simply lowering something by rope to the surface of the planet. The solution won't be any lighter, any less complex, nor any more reliable than a lightweight nylon rope. We solve these problems every day here on Earth by tying things to ropes. No experiments need to be conducted to know for a fact that a rope will work and require very little setup or fussing with the equipment will be required. We're so sure that ropes work that we have humans dangling from them every day of the week for various construction, rescue, and recreational purposes. As long as you don't exceed the load rating of the rope, it's going to work.

Well I think that is what is at issue at the moment. I am not saying I accept your figures on batteries. We all know NASA doing things the least efficient and most expensive way...I am still laughing about their $400 billion figure for a Mars Mission back in whenever - 1980s? - probably be a trillion dollars now in 2019 money. They went to every department and said "If money was no object what would you like to give us for a Mars Mission..."

Do we all know that, or is that simply a blanket statement about what you believe without much demonstrated knowledge of the engineering behind what actually works?

I do math but only off the back of other people!

I am not a religious Muskite, I am a Marsite. Musk is the best bet for Mars at the moment. But I backed Space X at an early stage when they were back on Kwajalein in the Pacific trying out the Falcon 1. They always seemed to me to have the right stuff.

I don't believe any single company is a "best bet" for going to Mars. It's going to take a lot of cooperation and teamwork to get there.

I think Ryan MacDonald ("Martian Colonist") in his latest video is right...Starship development has been phenomenal. If you get Starship right, then Mars colonisation is really just a lot of boxes to be ticked. The energy system is the big tick, but I think you will find in time that solar delivers that big tick.

I want to see one launched into orbit before I become a true believer.

Well we know at a minimum that PV panels can survive for 14 years on Mars and still deliver close to optimal power. I've not evidence Space X have a feasible energy system plan, but equally I can't imagine Musk would be so daft as to produce top of the range world class rockets in pursuit of his Mars dream but forget about the energy system for the base and propellant production system. Let's at least allow he will be focussed on that along with a lot of other things.

In the battle between enthusiasm and engineering, engineering tends to win every time. I haven't seen a propellant plant or a power system, even presented in a PowerPoint presentation with a scale engineering model. So, as much as I applaud his herculean efforts to build a rocket that can take people to Mars, all of those other things I wrote about still have to be designed / developed / tested first. Typically, radio silence on all of that stuff means there isn't anybody working on it. It's just an idea in someone's head.

This makes no sense to me. You've already said the ATK space-rated systems are way too fragile for the Mars surface. So why do you want proof of something that works "in space". Surely we need to have something that works on Mars.

No, Louis, I've stated that ATK's silicon-wafer-based solar cells are too brittle for rough handling. They're very hard, so they don't scratch easily. Dropping those would be entirely out of the question. Anything beyond a 5g acceleration is guaranteed to produce damage. It's in their product brochure, so you can go read about it. They're pretty heavy, though, which is why I started looking into Ascent Solar's much lighter thin films. Affixing a copper backing plate onto the wafers to prevent them from shattering makes them more bendable / tolerant of rough handling before they break, but also makes them heavier than they were to begin with. The power density of thin films is nothing to write home about compared to ATK's panels, but they're also a LOT easier to handle because they're less prone to damage and don't require as much in the way of stiffening to deploy into a usable array.

The thin films are more resilient because they're inked plastic with ink-jet / 3D printed photovoltaic cells and electrical interconnects, but with those we have an issue with the plastic substrate and protective plastic coating (their solar cells are laminated between sheets of plastic for outdoor use here on Earth) being very soft, which is what makes it so flexible. They do have a minimum bend radius which is dictated by the thickness of the plastic lamination. The thicker plastic is harder and more durable, but less bendable.

I looked at some pictures of what our soldiers did to Ascent Solar's thin film panels in Afghanistan. Basically, the plastic was crazed from scratching from the fine abrasive sand. They lay their panels in the dirt (hence my repeated objections to laying solar panels in the dirt), dust them off and roll them up to store them in their packs before leaving, and over a period of a 6 month deployment, that managed to scratch the plastic, turning it from a nice clear coating to a milky white. Maybe we can clean them and then employ some kind of liquid epoxy to "un-craze" them, just like we do with headlights. I've used that stuff and it actually works. So, maybe that's a solution that would work (obviously needs testing).

Your 79 ton battery figure takes me close to the 160 tons figure for KP units but not sure it takes it over.

If there's a way to reduce the mass of the battery packaging that's been tested and proven to work, I take no issue at all with lighter batteries. My exact point is that that's what we'd need to make solar and batteries work acceptably well, along with improvements to protective coatings for the photovoltaic panels. Only NASA is devoting significant resources to working on this. They stopped work on thin film arrays some time ago. JAXA is the only agency that seems to have done significant follow-on development work because the technology was attractive for the type of robotic exploration goals their agency devotes money to. Tesla only does work on silicon wafer based arrays. There are precious few utilities doing significant work on thin film, so development has been mostly limited to academia. There is a significant commercial market for very small thin film rollup panels for recreational purposes, mostly for charging cell phones / tablets / flashlights / etc.

I've already done the math on what ATK type solar arrays would weigh for a 1MW continuous power requirement. It doesn't compare favorably with nuclear power, even if we select a landing site that favors solar power. Even if you had 500t of cargo to play with, more than half of the delivered tonnage would be devoted to power production and storage using existing photovoltaic and battery technology. That's when I started looking into thin film arrays. I stopped looking at thin film when it was apparent that the dust was going to unacceptably degrade the panels. Since the company making those panels is actively working on that problem, I can only presume that the problem is real and hasn't been solved yet. If there are new developments, then post links to those.

But I think one could increase the propellant facility and reduce the battery tonnage accordingly and so come under your figure for KP of (at least) 160 tons. Because of course, you haven't said yet how you would activate fins on the Starship...would you be using batteries?

If you have to increase the mass of the power conditioning equipment or the production capacity of the propellant plant, you're still just trying to make up for the fact that you can't design a power production solution with equivalent mass to nuclear power. You're also complicating the development and operation of the plant, along with the overall solution.

Have you given any thought to the mass of the drilling equipment and water transport / storage solution required to produce water to make propellant?

Offline

Like button can go here

#52 2019-10-13 15:32:46

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,634

Re: Nuclear power is safe

Louis wrote:So, I think if we have robot cleaners around, dust accumulation will be pretty minimal.

Let's test that theory before we start betting lives on it. I've never seen a proper test conducted, so that's what I'd need to see to believe it.

The issue is that the energy cannot be gotten back for the period of time that the dust was on the panels. That no amount of cleaning gets the energy back that is not created by them to store. Changing the amount of panels to compensate for the levels of dust means that in winter you do not have enough and in summer you have to many when all is said and done with the design connections which means we now need to cover or disconnect panels when getting to much power from them so as to not damage the batteries or the circuits which charge them.

Louis wrote:I accept you have not suggested that insolation levels will drop to zero but other pro-nukers here have. But what do you think insolation drops to in a worst case dust storm scenario. Again, the nuke community seem reluctant to discuss that. From my researches it seems that a figure of around 36% is the lowest. And that seems to translate (with extra dust accumulation in dust storms) to a figure of around 20% as the lowest for actual PV generation as a % of the norm. I have never seen any records to suggest that such low points last longer than a few sols. I think that's because dust storms are self-regulating - whilst initially they act like a heat trap, beyond a certain point they being to reduce the atmospheric temperature and so the storm subsides.

If the power output drops below what's required to make enough propellant to come home, then I don't really care about what the solar insolation levels are. From my point of view, it's not an academic curiosity. As a mission planner, I would demand that no matter what power technology is used, that I have a mathematical assurance that my people are coming home as long as there equipment doesn't malfunction. I will demand test results from proper testing of any potential solution presented. Is that a clear enough answer?

The fact that these panels are laid on the unprepared ground means that they are no collecting the best light on each section of them and that pressure from the robot cleaner can cause the panels to break. These robots also will be using up energy to keep them clean daily as well if thats what we think is needed. The covering on panels when energy is to high to process means we now have another issue for against laying them on the ground as well will need to have a robot that is designed for dusting to also have another ability to go and disconnect then or cover them from the array grid. The continual adding of panels to make up for the lower levels is not a solution even when somewhat predictible and measureable.

Batteries that go bad from the cold when the panels do get enough light to create power these panels will go bad since they are trying to power a short which burns out the connections within the panels. Then if this does not happen to get damaged the circuits in between will which we will not be able to fix..

Offline

Like button can go here

#53 2019-10-13 15:45:58

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,634

Re: Nuclear power is safe

Louis wrote:You seem determined to ignore the fact it survived for 50 plus more times than its planned life! If so, I can't help you.

No Louis, I'm determined to get you to acknowledge what actually killed it. The solar panel didn't malfunction. The electronics didn't malfunction. It was simply starved of sufficient photon power and that was what it needed to live. That didn't happen with the nuclear powered rover, obviously. We have nuclear powered satellites and experiments that have been in operation longer than I've been alive. We can't make that same statement about solar powered spacecraft.

We learned how to cheat the rovers power needs in winter is why we were able have a rover live so long which was by angling its panels towards the sun to get extra energy that was not there to keep it from freezing if left in a flat level condition.

Dust covered panels made the level drop even more such that they could not get enough even when angled...

Offline

Like button can go here

#54 2019-10-13 16:30:45

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,634

Re: Nuclear power is safe

Louis wrote:Abrasion did not seem to greatly affect the performance of the solar powered rover over 14 years. The dust on Mars would feel soft to the touch - so not like bits of gravel being thrown about as on Earth.

They aren't using panels coated with very soft, and thus flexible, plastic. They're using much harder semi-conductors with protective coatings. Maybe some kind of hard plastic coating over an accordion style flexible panel would work.

These are glass panels with the thin layer film applied to the under side placed onto a metal backer or they are build on the metal backer in a larger meter panels with the glass topping the cells once connected from the circuits that are made from.

Go to the local dollar store and buy a solar lawn ornament led light for the walkway and take it apart...

The panels that atk makes are mounted on a metal backer with kevlar fabric between them to make them fan or hinge to fold outward...

Offline

Like button can go here

#55 2019-10-13 16:53:50

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,634

Re: Nuclear power is safe

Found the ATK baseline here

http://fiso.spiritastro.net/telecon16-1 … 2-1-17.pdf

pg 17 for the 10kwh size reactor

Solar version:

• 4X 5.6m Ultraflex arrays

• Daytime ISRU only (1098 days to produce 4400 kg LOX*)

• Requires 4X 7.5m arrays and 1100 kg Li batteries for day/night ISRU ops excluding dust storm (527 days to produce 4400 kg LOX*)

The reactor needs no batteries but some would be of benefit for surge requirements...as loads go on and off...

The time for production is to close as we will want grace time to make sure that we have enough fuel. 480 days was indicated elsewhere.

Offline

Like button can go here

#56 2019-10-14 17:46:17

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Nuclear power is safe

Of course robot cleaning of PV panels must be tested. There are specialist machines already on the market or designed for PV on Earth...

https://www.youtube.com/watch?v=uMZ1zqEo6nA

https://www.youtube.com/watch?v=HGXOaTe0e7k

...adaptations for Mars need to be developed.

I see. So, no matter what, building a megawatt-class power plant is unlikely to be done after a day's work. That was my point. I'd wager that all of their power cables were also pre-fabricated. That would not be how I would build any power plant that I don't know the exact dimensions of until I actually arrive onsite. I would arrive with general plans and general layouts, meaning I know how far the power plant needs to be from the giant rocket that brought it there, I know what gauges of wiring I need for the maximum permissible power transmission distances, all of my power transfer and conditioning equipment is tested and ready to go, etc.

Well, I would agree it won't be installed in a sol. But the advantage of the Mars PV approach is that effectively the PV system is working from Sol 1 because the Starship PV fins can begin powering up the batteries on the Starship. That can be swiftly followed by robotic ATK-style fan units on wheels that could be located in the lower cargo hold and move out even before the upper cargo hold is opened up or before the crew have adjusted to the 0.38 gravity. Maybe you'd begin unloading and laying out the flexible PV after 5 sols. Allow 10 sols - laying maybe 5000 sq metres per sol. You'd probably need a couple of robot rovers to install the PV.

My view is that the already landed Starships and satellites will enable Mission Control to identify the human-passenger Starship landing location and also the base location, with centimetre accuracy.

This needs to be tested.

We are agreed on the need to test any PV installation equipment.

Has anyone sent a probe there to verify the availability of the water and characterize the salinity and other characteristics of any dissolved solids in the water?

I am a great fan of scepticism but not insane levels of scepticism! What could all these water ice "signals" be if not water ice? These signals relate to millions of square miles on Mars. In places, IIRC, there are exposed water ice glaciers and presumably the signals essentially match the buried water ice. The "signals" relate to several (5 or 6 I think) methods of assessing the presence of water.

I don't think salinity or other contamination would prevent processing of water.

No Louis, I'm determined to get you to acknowledge what actually killed it. The solar panel didn't malfunction. The electronics didn't malfunction. It was simply starved of sufficient photon power and that was what it needed to live. That didn't happen with the nuclear powered rover, obviously. We have nuclear powered satellites and experiments that have been in operation longer than I've been alive. We can't make that same statement about solar powered spacecraft.

As far as I know, no nuclear powered rover has ever survived as long as 14 years on Mars.

If the power output drops below what's required to make enough propellant to come home, then I don't really care about what the solar insolation levels are. From my point of view, it's not an academic curiosity. As a mission planner, I would demand that no matter what power technology is used, that I have a mathematical assurance that my people are coming home as long as there equipment doesn't malfunction. I will demand test results from proper testing of any potential solution presented. Is that a clear enough answer?

I agree with your general point but I note that you give no view on what is the lowest insolation drops to (as a percentage of the norm) during a worst case dust storm scenario. You seem a clever guy so I am presuming that's not because of ignorance on your part.

Have you done the calculations to determine how many tons of batteries are required to buffer megawatt-level power fluctuations?

If you have, could you share your calculations with the rest of us?

Your criticism of my battery tonnages is fair. I was being over-optimistic I would say, although I would dispute the way you reference space-rated batteries (I think it is more sensible to reference the best Tesla used on Earth).

Well, at least we're not talking about laying our power provisioning solution in the dirt anymore, so I guess that's progress.

Nope, I am not saying I have abandoned the idea of a simple roll out on the ground. The "dirt" is in your imagination. We're probably talking about flat rocky outcrops with some dust. But I would also say it would not be that difficult to create automated systems that either elevate the PV roll or angle it. These systems could respond to PV input and automatically deploy.

They aren't using panels coated with very soft, and thus flexible, plastic. They're using much harder semi-conductors with protective coatings. Maybe some kind of hard plastic coating over an accordion style flexible panel would work.

I am struggling to find anything on the internet that supports this claim. Do you have a citation?

If many of the photons are striking objects (dust in the atmosphere) that absorb some of the total energy delivered by the Sun before they reach the array, then you have lower insolation levels / lower maximum power conversion levels below the dust in the atmosphere. That said, you still have energy being transmitted to the surface. I've never argued that point, only that it increase the mass and size of the array required and it's not inconsequential given the total power requirement.

Well I follow what you say, but if laying on the ground allows you to use a very low mass system, that means increasing the area is not necessarily a bad thing. It's a trade-off of course, but you have to look where the advantage lies. Rapid Roll is a v. low efficiency system by the way (6%) but researching some more, there is not reason why flexible PV couldn't be much higher, 20% or more. It would in Earth terms be v. expensive probably but that is of little import when it comes to Mars Mission One.

Well, some of us think assured power is better for mission planning than opportunistic power.

Well, some of us think the power system needs to be assured, low mass and low labour input.

Pragmatism is good.

Speaking of that...

Why couldn't we just put the panels on an A-frame so we could blow down the panels that way?

Instead of robots that constantly mill about a solar farm, why couldn't we just run CO2 lines across the top of the A-frame to give the panels a spray whenever they need it?

I'm fascinated with robots, too, just not to the point that I'm willing to build in needless weight, complexity, power consumption, and potential problems to a solution. Sometimes simpler solutions truly are better.

An A frame solution might be good and yes, I like your elegant CO2 spray solution. Maybe integrate the frame with flexible light weight PV and then use a simply lock mechanism to put the frame up. It could be robotised, I'm sure.

Now we're thinking like a mission planner.

I always think like a mission planner! lol - a creative one.

I do. Mission One is about proving that we have what it takes to live there. The ability to maintain and use robust power provisioning systems is part of that "proof".

Indeed, but I wouldn't want to jeopardise a Mars Mission One solution by increasing sytem mass 50% to prove long term capability.

Once you have your habs and battery systems there, bringing some additional PV for Missions 2 and 3 is not problematical. That said, I am just taking a precautionary approach. I don't actually think it's very likely that the design life for Mission 1 PV system will be 4 years. It's just that it's output will probably be declining faster than with the later systems we put in place.

One good thing about Musk's plans is that, with the Starship, you can increase crew numbers each mission without having to increase propellant production. Just guessing, but you could probably go up to 25 crew before you needed an additional Starship, and I imagine 25 will take care of the first three missions (2024-2030). So you can stick with your propellant production facility and a general energy requirement of 1 MWe or lower. You don't have to step up significantly each mission. That means that for Missions 2 and 3 you can concentrate on other priorities like 3D printers, 3D construction equipment, raw materials, spare parts, more accommodation habs and farm habs. At the same time you can augment the PV power system.

If you can't execute Mission One with 500t of cargo and have a really good head start on Mission Two, then maybe the plan isn't very good.

I have absolutely no doubt that a PV-based system (with methox generation and chemical battery storage) can deliver Mission One.

It's just that with Missions 2 and 3 you will have more cargo opportunities. Bringing in more PV power will be one priority.

By "space-rated", I mean something that can actually work in space at all or without unacceptable operating characteristics. The battery cells themselves can work in space without modification, but that's about it. Nothing else will be common between a land motor vehicle battery pack and an aircraft or spacecraft battery pack. For starters, the cell packaging will be completely unlike what you see in electric cars. The mass of the battery pack in the car is in no way representative of the mass required to provide thermal regulation in space or other near-vacuum environments where the only way to get rid of heat, even if you put it in its own temperature-controlled habitat (which will still be much heavier than a design that simply properly regulates the temperature of the pack), is by radiator. If a cell in a car short-circuits, you get out of the car. If a cell short circuits in space, then you just lost part of your energy storage supply and may have more serious problems to contend with. You could also think of "space-rated" as workmanship standards as well. NASA publishes workmanship standards for electronics and electrical components. Practices considered acceptable for motor vehicles fail to pass muster for aircraft and spacecraft, generally because the two operating environments are very different.

So, just because Tesla designed a battery pack for a car doesn't mean a battery pack in an aircraft or spacecraft will have equivalent dimensions or weight. In fact, that's almost never the case. That said, all aerospace subsystems designers go to extreme lengths to economize on weight and volume, while maintaining some specified set of operability and reliability characteristics.

Here's a simple but dramatic example of how different cars are from aircraft. In a car, if the throttle cable snaps, the throttle body or carburetor closes, effectively shutting off the engine so the car can roll to a stop. In an aircraft, it the throttle cable snaps, the engine goes to wide open throttle. On the ground, the most prudent thing to do if you loose control of the engine's throttle mechanism is to shut it down. If you do that in any sort of powered aircraft, then the aircraft starts falling out of the sky. If you're not near an airfield or some other place that you can actually land, well, the results are pretty obvious. Most people I know would consider reverting to WOT in a car, should the throttle cable ever snap, to be suicidal. However, in an airplane going to WOT gives you power to climb to avoid terrain and you can still land by cutting the engine just prior to landing. From that example, it should be fairly evident how different design requirements drive different operating characteristics and therefore different designs.

In the above example, the design difference doesn't come with any substantial weight penalty because the design is just a spring moving the throttle valve in different directions. In the case of a battery pack that you don't want the rest of the cells in the pack to catch fire or explode just because one cell in the pack short-circuits, well, you'd better have enough material between the individual cells to prevent that from happening. I've seen Tesla's car and home battery packs. They're designed for maximum volumetric density, not protection of the pack from major malfunctions of individual cells in the pack. So, that design characteristic will clearly have to change. In practical terms, that increases the weight of the pack and to a somewhat lesser extent, the volume of the pack as well.I accept this is not verified yet. This requires further investigation. I am a bit puzzled by your use of "space rated". What does that mean? Does it mean a battery pack operating in a space vacuum? Well if so, that's not necessarily what we are talking about with the Tesla batteries.

I accept the technical points you make but I have been reading up on space-rated batteries and that does specifically refer to (a) vacuum conditions and (b) huge temperature range that you get in orbital conditions. That definitely doesn't relate to what I am talking about which is batteries in pressurised and temperature controlled conditions (either on the Starship or in dedicated vehicles and habs on the surface). I accept that means some energy use or "loss" if you prefer. But not a huge amount I think.

Post a link to an internal combustion engine of some kind that works in a vacuum environment. I've already done that and have written at length about how important this technology is. ULA has done a lot of work on this. They took an in-line 6 cylinder piston engine from a race-car that previously made hundreds of horsepower and the space-rated version of the same engine makes about 27hp, so the de-rating required for use in a vacuum was by a factor of more than 20 (I forget if the original made 600hp or 700hp). So, can you actually run a combustion engine in space? Absolutely. Will it be anywhere as small or lightweight as an automotive engine producing equivalent power? Not even close. Even using LOX/LH2 boil-off from a Centaur upper stage for cooling the engine, they had to massively de-rate the power output of that engine to preclude melting the Aluminum block / heads / pistons. ULA's IVF (Integrated Vehicle Fluids) technology happens to require less mass than equivalent Lithium-ion batteries to provide equivalent power and results in less loss of propellants to boil-off, even while siphoning off boil-off for powering the engine to keep the LOX/LH2 cold and pressurize the propellant tanks, then insulation and batteries.

Again, not disputing your technical expertise, just the idea that batteries will be in a vacuum.

You have to land the cargo somewhere with water first, don't you?

If your inbound trajectory was substantially off-nominal, then no matter how precise your reentry guidance is, you may not land anywhere near where you intended to land. I'm talking about making mid-course trajectory corrections using positional info from orbital satellites so that you're already in position for a nominal reentry. After that, then yes, having an ultra-precise laser terrain map would be stellar.

Do you get the sense yet that there's a lot of pre-requisite and setup activities required to pull all of this off and make it look easy?

Well I don't think there's any doubt we'll have the ultra precise terrain map. I believe there are issues regarding laser and radio signalling on entry and descent. Not trying to minimise those but landing accuracy has been improving over the decades.

I accept accurate landing is a big challenge, to which I think a bold organisation like Space X can rise. There was a suggestion the Starship will do a planetary pass around Mars (as well as on the return to Earth) - maybe that would help.

I think that kind of thinking leads to flags and footprints. Some of us don't want flags and footprints. We want to go to stay, building up capabilities and infrastructure with each successive mission until we can sustain a colony on another planet.

Well the very phrase "flags and footprints" makes me want to reach for my delete button! No, there is no doubt that we should have a long term plan for settlement of Mars (to be followed by a long term terraformation plan). We just differ on which is the best system for Mission One.

Again, you have to get rid of the heat somehow. Putting the batteries in pressurized enclosures doesn't remove that requirement, it just makes the overall solution heavier than it needs to be. Air, even pressurized air, is a lousy thermal conductor compared to water or metal. That's why automotive engines are cooled using water / air heat exchangers (radiators). Given their power densities, there's no practical way to remove the heat using air alone. Insulation is good at maintaining temperature, which could certainly help with proper thermal regulation, provided you had a very effective thermal management system with radiators, liquid coolants, and pumps to remove the heat associated with charging and discharging. In the end, you're either going to be charging or discharging which will keep the battery pack warm (provided the rate isn't too high), using coolant loops and radiators to prevent overheating (at high loads or fast charging), or supplying external power to keep the battery warm (exactly what they do aboard ISS using heater plates under the ORU's). All of that substantially increases the weight of the battery pack.

I accept my knowledge of battery systems could be better! My battery tonnages were probably over-optimistic. I think for a PV system to work, the propellant production facility may need to be significantly larger. I haven't yet seen any persuasive figures on the mass for a system capable of producing 1000 tons in 600 days (approx). But given that resolves to a few millilitres per second, I am having difficulty believing it's much more than a few tons, maybe 20 tons max.

The labor time to set everything up will be substantial no matter what solution is selected. Any belief to the contrary is naive at best. It's going to take real work to deploy everything. There won't be any "easy button" to press and have everything deployed. However, the simpler solution tends to be the one that works best, more often than not. In practical terms, that means deployment by hand, using hand tools.

When astronauts repaired the Hubble Space Telescope, they didn't use robots. There were already robots welding car bodies in factories and whatnot at that time, but it made far more sense to use humans to handle delicate and intricate tasks that would require years of testing and debugging of computer software programs to ensure that those tasks could be successfully completed by a robot. Despite the fact that NASA put a humanoid robot aboard ISS, it served very little purpose and was functionally useless for its original design goals, namely assisting humans on spacewalks for repair of the space stations external components. NASA is still tooling around with it. In all probability, if we go to Mars in 2024, none of that will change. Therefore, humans will be deploying everything required to provide power. Naturally, they'll be using tools to make those tasks easier.

Well we just have to agree to disagree over whether labour time for laying the PV system would be significant - I don't agree it would.

If your energy system requires "delicate and intricate" tasks to be performed for which humans are best suited, then I think you have lost sight of the mission aims. Getting the energy system up and running is probably the biggest task facing the pioneers apart from propellant production itself and Starship maintenance/refuelling. We need to minimise the labour input.

Everything you just proposed there requires far more testing to be sure the result doesn't damage the cargo than simply lowering something by rope to the surface of the planet. The solution won't be any lighter, any less complex, nor any more reliable than a lightweight nylon rope. We solve these problems every day here on Earth by tying things to ropes. No experiments need to be conducted to know for a fact that a rope will work and require very little setup or fussing with the equipment will be required. We're so sure that ropes work that we have humans dangling from them every day of the week for various construction, rescue, and recreational purposes. As long as you don't exceed the load rating of the rope, it's going to work.

Yes, it might require testing but not much. All these force measures are known to the experts. They'll know what systems can tolerate. Bit of bubble-wrap and off you go! A chute, fall and bounce system could work well I think.

Do we all know that, or is that simply a blanket statement about what you believe without much demonstrated knowledge of the engineering behind what actually works?

I think it's well known that's how NASA got to their $40 billion (3 decades ago money) estimate for a Mars Mission. The reason they structured it that way was they knew they would get an absurd figure and that would kill the Mars Mission. And then they could carry on merrily with their 101 different missions, all very interesting but all sucking up money. NASA was killed by interest groups.

I don't believe any single company is a "best bet" for going to Mars. It's going to take a lot of cooperation and teamwork to get there.

Well that's the good thing about Space X they seem to have the right balance between in-house focus and flexible willingness to co-operate with other organisations.

I want to see one launched into orbit before I become a true believer.

Well quite. But I do feel good about this project. My feeling is that Space X is a great combination of pragmatism and idealism.

The idealism - the settlement of Mars - provides the focus and energy for their work. But because Mars colonisation is such an overriding goal, they have minimal organisational self-regard...if Space X can't do it they are more than happy to use someone else. It's true they do a lot inhouse but that's only because that is the quickest route to Mars, not necessarily the cheapest.

In the battle between enthusiasm and engineering, engineering tends to win every time. I haven't seen a propellant plant or a power system, even presented in a PowerPoint presentation with a scale engineering model. So, as much as I applaud his herculean efforts to build a rocket that can take people to Mars, all of those other things I wrote about still have to be designed / developed / tested first. Typically, radio silence on all of that stuff means there isn't anybody working on it. It's just an idea in someone's head.

Well against that...a few months ago everyone thought that Space X were going carbon composite. Musk never let on how far from the truth that was still we saw the strange glistening Starhopper materialise at Boca Chica. And we still know NOTHING about how that turnabout occurred. Musk has told us why it is a good move but not who recommended it, who decided it on it, how long ago etc..

I simply don't believe that Musk, whose life focus is on Mars colonisation, is going to say after the first successful orbital flight of Starship "Shit! I forgot the bleedin' energy system for Mars...!" I really don't think that's how it works.

No, Louis, I've stated that ATK's silicon-wafer-based solar cells are too brittle for rough handling. They're very hard, so they don't scratch easily. Dropping those would be entirely out of the question. Anything beyond a 5g acceleration is guaranteed to produce damage. It's in their product brochure, so you can go read about it. They're pretty heavy, though, which is why I started looking into Ascent Solar's much lighter thin films. Affixing a copper backing plate onto the wafers to prevent them from shattering makes them more bendable / tolerant of rough handling before they break, but also makes them heavier than they were to begin with. The power density of thin films is nothing to write home about compared to ATK's panels, but they're also a LOT easier to handle because they're less prone to damage and don't require as much in the way of stiffening to deploy into a usable array.

The thin films are more resilient because they're inked plastic with ink-jet / 3D printed photovoltaic cells and electrical interconnects, but with those we have an issue with the plastic substrate and protective plastic coating (their solar cells are laminated between sheets of plastic for outdoor use here on Earth) being very soft, which is what makes it so flexible. They do have a minimum bend radius which is dictated by the thickness of the plastic lamination. The thicker plastic is harder and more durable, but less bendable.

I looked at some pictures of what our soldiers did to Ascent Solar's thin film panels in Afghanistan. Basically, the plastic was crazed from scratching from the fine abrasive sand. They lay their panels in the dirt (hence my repeated objections to laying solar panels in the dirt), dust them off and roll them up to store them in their packs before leaving, and over a period of a 6 month deployment, that managed to scratch the plastic, turning it from a nice clear coating to a milky white. Maybe we can clean them and then employ some kind of liquid epoxy to "un-craze" them, just like we do with headlights. I've used that stuff and it actually works. So, maybe that's a solution that would work (obviously needs testing).

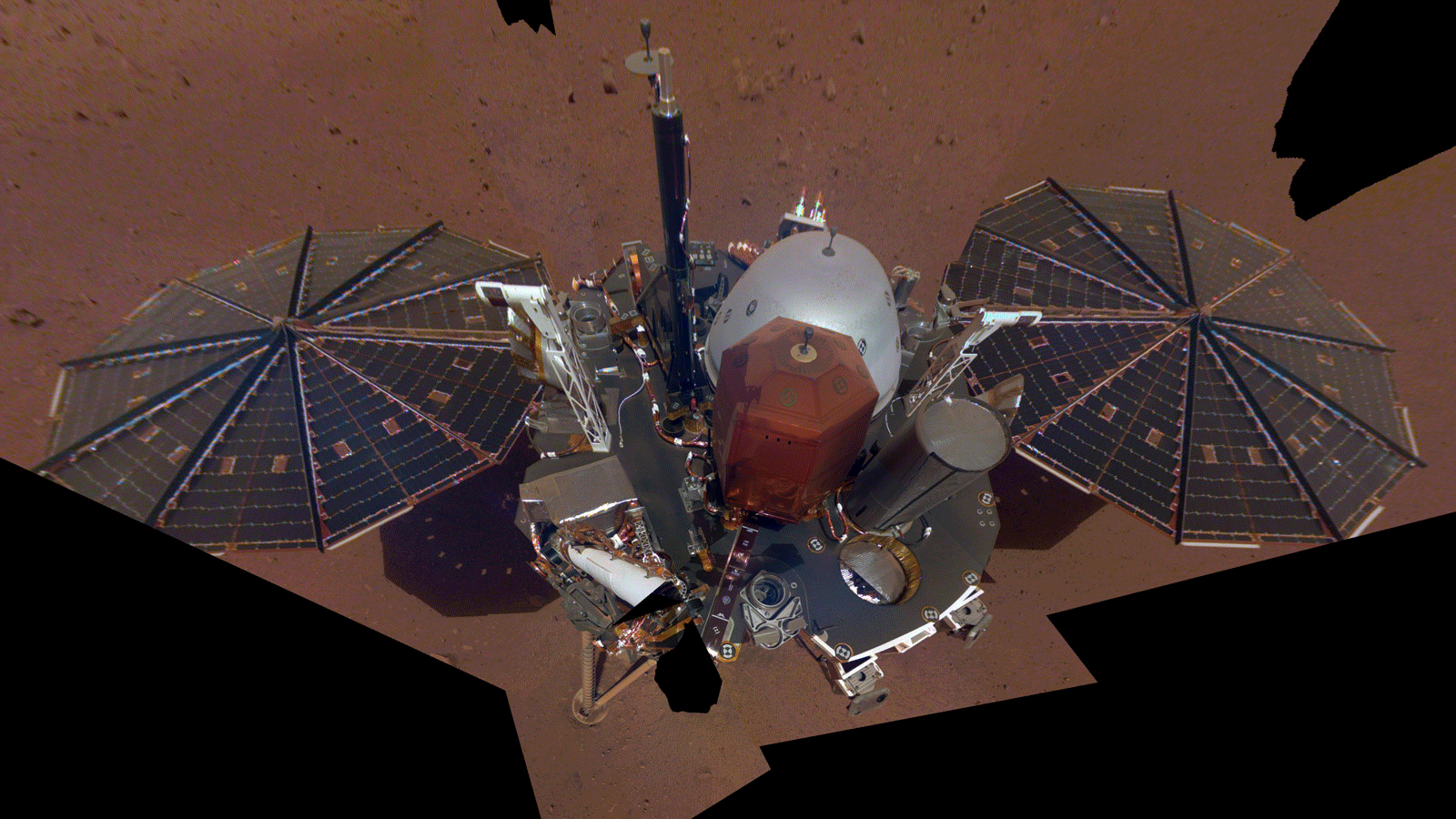

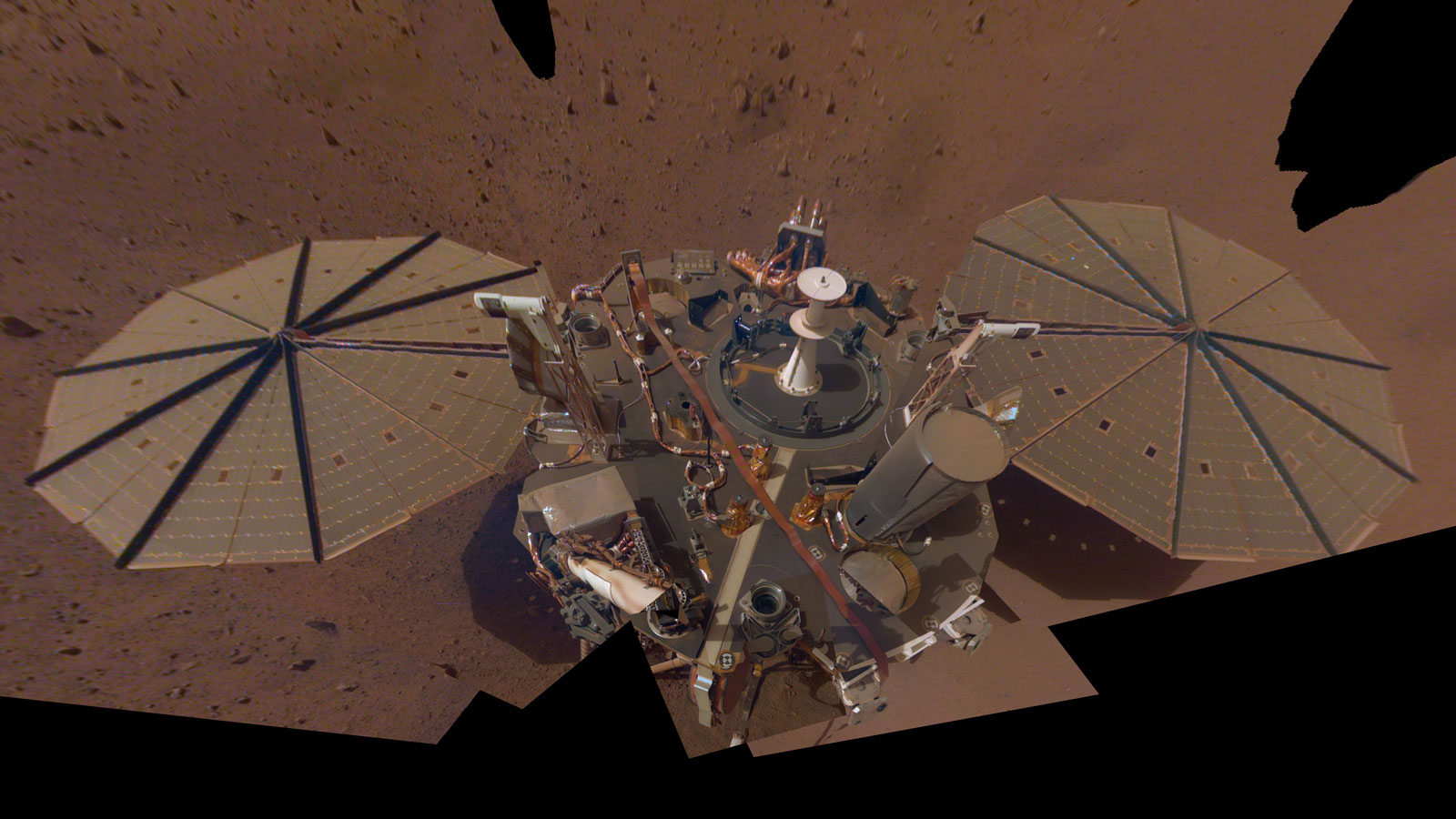

Interesting observations. ![]()

My only comment is that it won't be soldiers handling the systems - it will be trained technicians. The wind force in Afghanistan is going to be many times the wind force on Mars. As I think we agreed - all these assumptions and speculations need to be tested in a facility that replicates as far as possible Mars conditions.

If there's a way to reduce the mass of the battery packaging that's been tested and proven to work, I take no issue at all with lighter batteries. My exact point is that that's what we'd need to make solar and batteries work acceptably well, along with improvements to protective coatings for the photovoltaic panels. Only NASA is devoting significant resources to working on this. They stopped work on thin film arrays some time ago. JAXA is the only agency that seems to have done significant follow-on development work because the technology was attractive for the type of robotic exploration goals their agency devotes money to. Tesla only does work on silicon wafer based arrays. There are precious few utilities doing significant work on thin film, so development has been mostly limited to academia. There is a significant commercial market for very small thin film rollup panels for recreational purposes, mostly for charging cell phones / tablets / flashlights / etc.

I've already done the math on what ATK type solar arrays would weigh for a 1MW continuous power requirement. It doesn't compare favorably with nuclear power, even if we select a landing site that favors solar power. Even if you had 500t of cargo to play with, more than half of the delivered tonnage would be devoted to power production and storage using existing photovoltaic and battery technology. That's when I started looking into thin film arrays. I stopped looking at thin film when it was apparent that the dust was going to unacceptably degrade the panels. Since the company making those panels is actively working on that problem, I can only presume that the problem is real and hasn't been solved yet. If there are new developments, then post links to those.

I would only propose an ATK fan system to provide "early power" maybe in the range up to 50 Kws. This would be an assurance that you have power available on the surface for rover power, hab construction and so on.

If you have to increase the mass of the power conditioning equipment or the production capacity of the propellant plant, you're still just trying to make up for the fact that you can't design a power production solution with equivalent mass to nuclear power. You're also complicating the development and operation of the plant, along with the overall solution.

Have you given any thought to the mass of the drilling equipment and water transport / storage solution required to produce water to make propellant?

Nope, if I increase the propellant mass it's just because I am making adjustments and thus saving on battery mass in light of your helpful comments. Increasing plant scale won't increasing complexity significantly.

I presume the mass of the drilling equipment and water transport / storage solution will be the same for both nuclear and solar solutions, but of course for a nuclear power approach, you have to be able to drag your 1.5 ton nuclear power facility maybe 10 kms to the water mining site. That's assuming you only need 10Kwes. And when you get there, you have to make sure it's not close to any humans and then cable it up at a distance to the water mining location.

Last edited by louis (2019-10-14 17:47:13)

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#57 2019-10-14 21:11:46

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Nuclear power is safe

Of course robot cleaning of PV panels must be tested. There are specialist machines already on the market or designed for PV on Earth...

This is another of those ideas that looks great on paper, but may not work so well in practice. It's pointless complexity. Run plastic sprayer nozzles across one edge of the panels, provided you mount them on an A-frame for single-axis Sun tracking, and call it a day. It'll be far less consumptive of power, delivered tonnage, time, maintenance, and ultimately, cost. There are literally thousands of other things to devote development money and delivered tonnage to.

My view is that the already landed Starships and satellites will enable Mission Control to identify the human-passenger Starship landing location and also the base location, with centimetre accuracy.

That would be grand, but I'd settle for an assurance that the vehicle won't hit any other vehicles on the ground and that a proper reentry trajectory was set up long before the Starship carrying humans breached the interface.

We are agreed on the need to test any PV installation equipment.

Great, so let's see those test results. NASA routinely publishes this sort of information.

I am a great fan of scepticism but not insane levels of scepticism! What could all these water ice "signals" be if not water ice? These signals relate to millions of square miles on Mars. In places, IIRC, there are exposed water ice glaciers and presumably the signals essentially match the buried water ice. The "signals" relate to several (5 or 6 I think) methods of assessing the presence of water.

I'm a great fan of verification. If you need 100m of drill pipe to reach the water source, but only brought 50m, then that's a bit of a problem.

I don't think salinity or other contamination would prevent processing of water.

You'd need equipment that could handle whatever is in the water. From my time aboard Navy ships, I can promise you that what the water has in it actually matters. Trust me on this one, or don't, but do some research if you don't.

As far as I know, no nuclear powered rover has ever survived as long as 14 years on Mars.

You still can't acknowledge what killed those solar powered rovers, can you?

I agree with your general point but I note that you give no view on what is the lowest insolation drops to (as a percentage of the norm) during a worst case dust storm scenario. You seem a clever guy so I am presuming that's not because of ignorance on your part.

Insolation levels can drop by more than 90% of "clear sky" levels during a major dust storm. The rover was producing 650Wh per day in June prior to the storm. At the height of the storm, it's panels produced just 22Wh per day. That means output was just 3.38% of clear sky levels. When the solar panels were clean, they could produce 950Wh per day.

Your criticism of my battery tonnages is fair. I was being over-optimistic I would say, although I would dispute the way you reference space-rated batteries (I think it is more sensible to reference the best Tesla used on Earth).

I'm not critiquing you, I'm asking a question. Have you done the math on this using batteries that have actually flown in space?

Tell you what, use the Orion battery packs under development for Orion as your baseline because those have substantially greater energy density per kilogram of battery pack. Each 120V 30Ah pack stores 3.6kWe of electricity and weighs 44.8kg. The pack stores roughly 80.36Wh/kg. To store 5MWh / 5,000kWh worth of power, the battery packs would weigh 62,220kg. So, as stellar as the efficiency of the cells may be, the total battery pack mass drags those numbers down substantially. One of the most significant problems noted during the Orion program was "the near impossibility of keeping the charge / discharge controller electronics cool".

If you come back with a lighter pack, then please show your work and your sources.

Nope, I am not saying I have abandoned the idea of a simple roll out on the ground. The "dirt" is in your imagination. We're probably talking about flat rocky outcrops with some dust. But I would also say it would not be that difficult to create automated systems that either elevate the PV roll or angle it. These systems could respond to PV input and automatically deploy.

The entire planet is dusty. Pitching something in the dirt that needs to remain clean to function is a bad idea. Lots of expedient solutions are bad ideas. The mass of the A-frames, made from something like CFRP or CNTRP is a trifle compared to the loss of power output and the mass of the extra panels required to make up for it.

I am struggling to find anything on the internet that supports this claim. Do you have a citation?

Please read the product literature on these products. I've posted it here. SpaceNut has posted it here. It's available.

The thin films are protected by LDPE plastic and the wafers are protected with glass. The glass doesn't craze (scratch), but it's also much heavier. It doesn't take much effort to Google "plastic headlight crazing", for example.

Well I follow what you say, but if laying on the ground allows you to use a very low mass system, that means increasing the area is not necessarily a bad thing. It's a trade-off of course, but you have to look where the advantage lies. Rapid Roll is a v. low efficiency system by the way (6%) but researching some more, there is not reason why flexible PV couldn't be much higher, 20% or more. It would in Earth terms be v. expensive probably but that is of little import when it comes to Mars Mission One.

The mass increase from dust on the panels by laying them flat on the ground will be much greater than the mass of panels on a simple A-frame, or better yet, panels on an A-frame with a single-axis tracker. Forget about cost for a second and pretend that there's a limit to the delivered tonnage.

Well, some of us think the power system needs to be assured, low mass and low labour input.

Low initial labor at the expense of on-going labor-intensive activities is generally not a good trade when you're short on labor.

An A frame solution might be good and yes, I like your elegant CO2 spray solution. Maybe integrate the frame with flexible light weight PV and then use a simply lock mechanism to put the frame up. It could be robotised, I'm sure.

Again, I fail to understand this fascination with robots.

I always think like a mission planner! lol - a creative one.

Creativity is also good.

Indeed, but I wouldn't want to jeopardise a Mars Mission One solution by increasing sytem mass 50% to prove long term capability.

Given highly variable input power, you may end up having to prove that anyway.

Once you have your habs and battery systems there, bringing some additional PV for Missions 2 and 3 is not problematical. That said, I am just taking a precautionary approach. I don't actually think it's very likely that the design life for Mission 1 PV system will be 4 years. It's just that it's output will probably be declining faster than with the later systems we put in place.

If the power system was nuclear, there wouldn't be any power output drop for decades. Long-term thinking never agrees with the overly-anxious. Here's another thought. If you kill everyone on Mission One, there may not be a Mission Two for a long time.

One good thing about Musk's plans is that, with the Starship, you can increase crew numbers each mission without having to increase propellant production. Just guessing, but you could probably go up to 25 crew before you needed an additional Starship, and I imagine 25 will take care of the first three missions (2024-2030). So you can stick with your propellant production facility and a general energy requirement of 1 MWe or lower. You don't have to step up significantly each mission. That means that for Missions 2 and 3 you can concentrate on other priorities like 3D printers, 3D construction equipment, raw materials, spare parts, more accommodation habs and farm habs. At the same time you can augment the PV power system.

If you mean that you can substitute delivered cargo tonnage for more delivered people, then yes, that's a possibility provided you can supply what they require to live.

I have absolutely no doubt that a PV-based system (with methox generation and chemical battery storage) can deliver Mission One. It's just that with Missions 2 and 3 you will have more cargo opportunities. Bringing in more PV power will be one priority.

Well, some of us disagree. We think you're better off paying for power provisioning once, rather than again and again.

I accept the technical points you make but I have been reading up on space-rated batteries and that does specifically refer to (a) vacuum conditions and (b) huge temperature range that you get in orbital conditions. That definitely doesn't relate to what I am talking about which is batteries in pressurised and temperature controlled conditions (either on the Starship or in dedicated vehicles and habs on the surface). I accept that means some energy use or "loss" if you prefer. But not a huge amount I think.

Making this point is getting rather tiresome, but you still have to get rid of the heat. Putting the batteries inside a pressurized box doesn't do that and it certainly won't save any mass. After your batteries heat up the air in your pressurized battery cabin, then you have to get rid of the heat, else the batteries still die, and the only way to do that is by using a radiator. Whether you understand it or not, there's a reason why everyone who builds batteries for spacecraft uses the same general configuration. It's not because they're all boring, uncreative aerospace engineers. This doesn't help your proposed solution at all. It only increases the mass of your power storage subsystem.

Again, not disputing your technical expertise, just the idea that batteries will be in a vacuum.

See response above.

Well I don't think there's any doubt we'll have the ultra precise terrain map. I believe there are issues regarding laser and radio signalling on entry and descent. Not trying to minimise those but landing accuracy has been improving over the decades.

To my way of thinking, this is just an infrastructure problem. If we were serious about going, then we'd have a small constellation of satellites with LIDAR, GPS, and LaserComm.

Well the very phrase "flags and footprints" makes me want to reach for my delete button! No, there is no doubt that we should have a long term plan for settlement of Mars (to be followed by a long term terraformation plan). We just differ on which is the best system for Mission One.

Agreed, but we still don't have one, do we?

I accept my knowledge of battery systems could be better! My battery tonnages were probably over-optimistic. I think for a PV system to work, the propellant production facility may need to be significantly larger. I haven't yet seen any persuasive figures on the mass for a system capable of producing 1000 tons in 600 days (approx). But given that resolves to a few millilitres per second, I am having difficulty believing it's much more than a few tons, maybe 20 tons max.

If this was such an easy problem to solve then we should have a solution by now, right?

Well we just have to agree to disagree over whether labour time for laying the PV system would be significant - I don't agree it would.

Ok, so we disagree. Big whoop.

If your energy system requires "delicate and intricate" tasks to be performed for which humans are best suited, then I think you have lost sight of the mission aims. Getting the energy system up and running is probably the biggest task facing the pioneers apart from propellant production itself and Starship maintenance/refuelling. We need to minimise the labour input.

Actually, I think it's a tacit admission that the task is not easy or simple and that glossing over pertinent details with great enthusiasm isn't going to solve any of the challenges involved.

Yes, it might require testing but not much. All these force measures are known to the experts. They'll know what systems can tolerate. Bit of bubble-wrap and off you go! A chute, fall and bounce system could work well I think.

Ever wonder why nobody has developed a similar system to transfer cargo that way here on Earth?

I think it's well known that's how NASA got to their $40 billion (3 decades ago money) estimate for a Mars Mission. The reason they structured it that way was they knew they would get an absurd figure and that would kill the Mars Mission. And then they could carry on merrily with their 101 different missions, all very interesting but all sucking up money. NASA was killed by interest groups.

Well, we've spent a lot more than that so far and still have no Mars mission to show for it.

Well that's the good thing about Space X they seem to have the right balance between in-house focus and flexible willingness to co-operate with other organisations.

Who have they successfully partnered with?

Well quite. But I do feel good about this project. My feeling is that Space X is a great combination of pragmatism and idealism.

I'll feel good about it after the first crew comes back alive.