New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1226 2022-03-22 09:14:53

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Large scale colonization ship

I could list other navy ships sunk in various wars. Wikipedia: United States carriers sunk. 5 fleet carriers sunk during World War 2, 1 crippled, and several others. Passenger ships have large water-tight compartments, not individual cabins. That's what I did with this ship. Pressure compartments, subdivided into 2 subcompartments, with 8 cabins per subcompartment. However, your suggestion of a light pressure containment for individual cabins that would have to be replaced if ever used, does sound like a good one. As I said, putting a sheet of Teflon FEP film either on one side of the mineral wool, or both, or down the centre, would accomplish that. Upper bunks have to be supported somehow other than from the lower bunk, so lower bunks can be pushed together to form a queen size bed. Expected use is a family with two parents plus children; the married couple could sleep together. Like the photograph I've posted a few times. Problem though is the cabin door has to seal shut. Upper bunk supported by the wall and able to fold into the wall is something I took from a sleeper couch of a passenger railroad train.

And air will be exchanged with the corridor, so vents to the corridor will have to seal shut as well. I didn't put any oxygen recycling in common areas such as dining room, kitchen, laundry, bridge, or gym. Air from the gym would be routed by fans directly into a greenhouse, so the sweaty air won't go to the rest of the ship. Plants would appreciate increased CO2.

I said one locker with emergency equipment at the base of each spoke. And the locker would be the size of a closet, but not walk-in. There are only 16 pressure compartments with standard cabins, one pressure compartment with crew cabins, almost identical to standard cabins, and one pressure compartment with luxury cabins. How far would one of the spokes be from each? Again assuming ever bunk has a rescue ball with breathing mask.

Building a VR simulation of this ship is a great idea. We have discussed it before. I said I would like to do exactly that. I had looked at building a simulation using Unreal Engine, but that's harder than I thought. The editor tools are too crude to do what I want, it requires building models with Blender and importing those models into Unreal Engine. A massively online game engine would allow many people to interact with each other within the simulation.

Portholes: I only want to put one in each cabin. No windows for any dining room, kitchen, bar, laundry, gym, infirmary, bridge, brig. The bridge would use monitors.

Offline

Like button can go here

#1227 2022-03-22 10:23:00

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,100

Re: Large scale colonization ship

For RobertDyck re portholes....

This is not intended as criticism ... kbd512 has been trying to help you to understand what a rotating environment would be like.

So far he does not appear to have succeeded. I probably won't either, but I'll try.

Think about your experience as a child, riding on a Merry-Go-Round. Those used to be popular in years past, and hopefully you got to ride one.

In order to see the outside world, you had to fix your eyes on a point, and rotate the eyes or the head to keep focus.

Without doing that, the porthole would look like the ancient Star Trek screen saver, except the "stars" would be going sideways instead of coming at you.

We've discussed this before, but like so many things, it doesn't sink in the first or second or even the third time.

(th)

Offline

Like button can go here

#1228 2022-03-22 10:54:22

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Large scale colonization ship

(th): You're not getting the point. Moving stars are not that big an issue. You'll get used to it. Being shut in a metal can with no windows is highly restrictive. Lack of windows is a much greater problem. Here's a GIF from the movie "Passengers". It shows the character played by Jennifer Lawrence looking out a window. Yes, this ship rotates at 1 RPM, ours will be 3 RPM. Because of the position of windows, stars appear to move up while in ours they'll appear to move to the side. The male character started in a small cabin with no window, but they moved to the biggest and best suites. This gives you an idea.

Offline

Like button can go here

#1229 2022-03-22 11:53:59

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,100

Re: Large scale colonization ship

For RobertDyck re portholes ....

Your point about the human desire to look outside seems reasonable, for sure.

However, folks traveling in submarines for months at a time do not have a view outside, nor (I expect) do they want a hole in the pressure hull to satisfy their curiosity about fish they may be passing.

A compromise is to use high definition LED screens with displays driven by input from the free-flying observatory we've discussed before.

I think putting a porthole in a pressure wall is a practice that safety engineers will question.

Airplanes ** do ** have portholes, and those ** are ** pressure walls, but why take the risk, when high definition displays can satisfy the human need and cost a whole heck of a lot less.

Please prepare to add another decision to the flow.

We have a firm idea of what the pressure panel on the exterior of the habitat ring will look like.

We need further definition of format of the panel (ridges or not) and ultimately, the mass, so we can begin to deduct from the 5000 tons of the entire vessel.

The panels need to be welded to beams ... I'm not sure what the correct term is, but an aircraft designer would be conversant with the technology. Your vessel is going to look a ** lot ** like an airliner to a designer.

We need to (try to) bring someone with those credentials into the discussion.

If there ** is ** such a person within range of these posts, please read the Recruiting topic for procedures to help.

(th)

Offline

Like button can go here

#1230 2022-03-22 12:29:26

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Large scale colonization ship

Ohio class ballistic missile submarines have a tested depth of 800 ft (240 m). Pressure at that depth is 23.78 atmospheres = 24.09 bar = 349.42 psi. Our ship will operate at 1/2 atmosphere against the hard vacuum of space. Massive difference. Furthermore, ocean water at that depth has minimal light. If the water is turbid, you won't see beyond the glass of the window. Again, massive difference.

By the way, windows of aircraft have round edges. They aren't rectangular, don't have corners. That's to prevent a point of stress in the hull. One episode of "Mayday" was about an early pressurized airliner. It did have rectangular windows. The corners created stress in the hull, the crack started a rupture, pressure ripped the thin sheet aluminum alloy open. Our hull will use isogrid, so the risers will act as rip-stop. But still, windows should have rounded edges, either circular portholes or rounded like windows of an airliner.

Commercial jet airliners fly at 30,000 feet or higher. At 30,000 feet assuming surface temperature of +15°C (+59°F), pressure is 0.30 atmospheres. Western aircraft reduce cabin pressure to equivalent of 7,000 feet, so 0.77 atmospheres. That means pressure differential is 0.47 atmospheres. Aircraft are designed to keep you comfortable at 37,000 feet, pressure is 0.21 atmospheres, so differential is 0.56 atmospheres. So aircraft operate at the same hull pressure as our ship.

Offline

Like button can go here

#1231 2022-03-22 12:51:27

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Large scale colonization ship

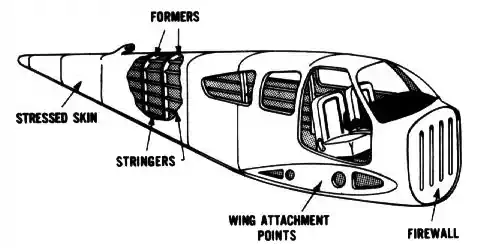

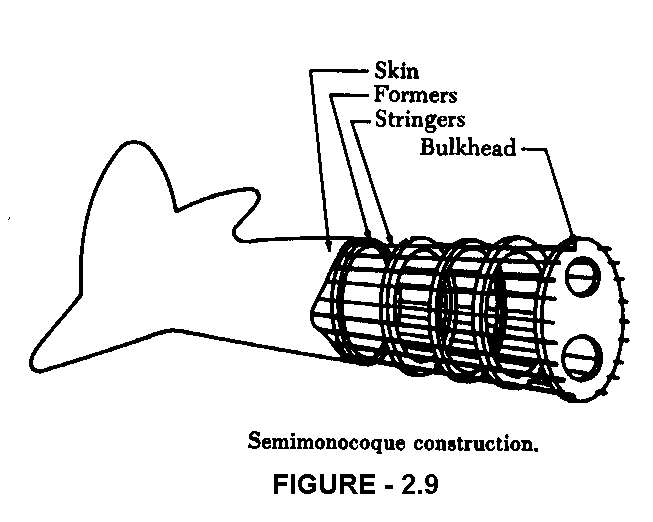

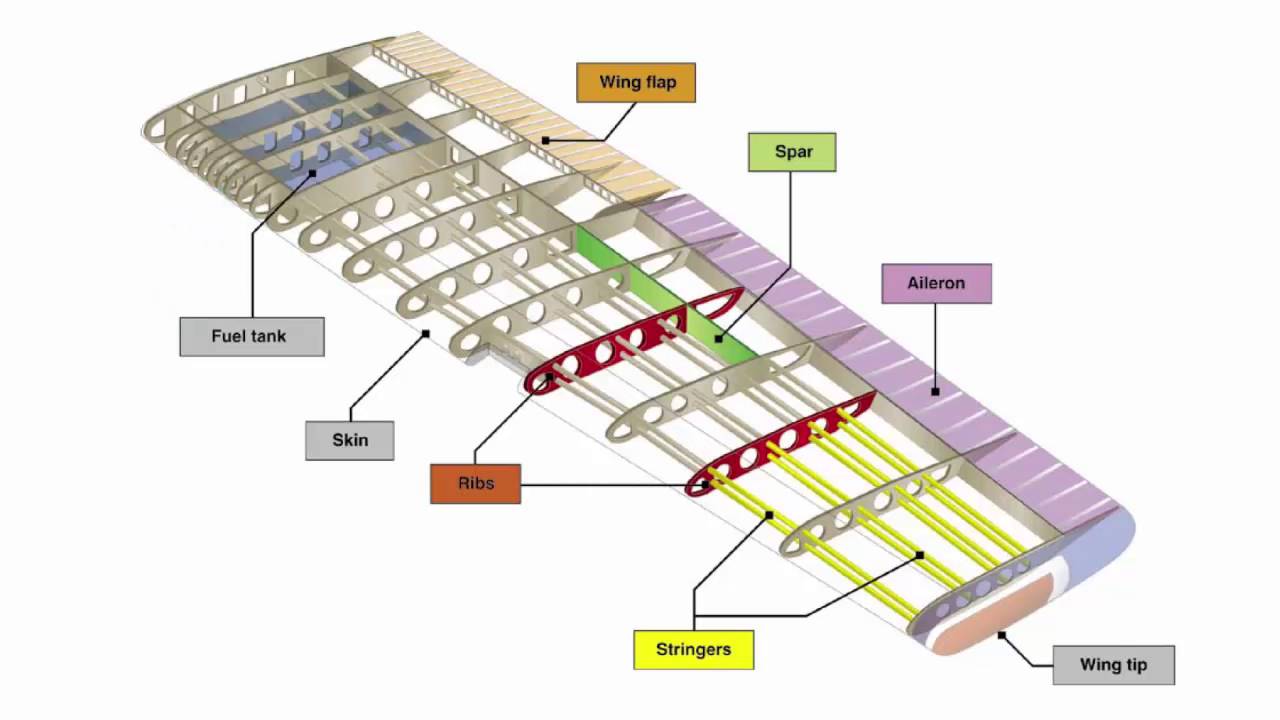

This is one reason I suggested a vaulted ceiling for areas that don't have a second level. The vault (3D arch) applies tensile stress, not sheer. Sheet metal has great tensile strength, not so much compression or sheer. Hmm. If we're using steel alloy, could we use sheet steel without isogrid? Aircraft use sheet aluminum alloy. But they do have ribs or frames and stringers (aka longerons).

Offline

Like button can go here

#1232 2022-03-22 13:23:05

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,100

Re: Large scale colonization ship

For RobertDyck ... re #1231

Thanks for the assistance with terms! The terms I was looking for are "formers" and "stringers"

I expect your engineering assistant is going to recommend you design "formers" and "stringers" for the skin panels to weld to. Furthermore, I expect your engineering assistant will recommend you weld the panels ** inside ** the "formers", to increase strength. The exterior of the panels will (hopefully) be covered in foam insulation to a thickness of one meter or so. No one is going to see the "formers".

In the inside of the ship however, the inspector (during assembly) and the crew during flight, are going to want to be able to inspect the skin at every point.

That is why (per GW Johnson recommendation) I'm assuming (hoping) you've planned for at least two meters between the pressure hull and the walking surface in the cabins and corridors.

Hopefully you've accepted the recommendation to avoid foot traffic on the exterior facing skin of the pressure vessel.

(th)

Offline

Like button can go here

#1233 2022-03-22 13:53:52

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Large scale colonization ship

An aircraft requires an aerodynamically smooth skin. A spacecraft doesn't. An aircraft skin is on the outside, formers and stringers inside. For our ship, I was thinking of isogrid which has risers inside the skin. However, some modules have them outside. A spacecraft uses multilayer insulation instead of foam, which is multiple layers of aluminized mylar with some sort of spacer between each layer. Outside that is the micrometeoroid shield. Some modules use orthofabric, same as a spacesuit. Leonardo module uses thin sheet steel. But yea, the pressure hull is inside. However, no there isn't a 2 metre gap between walking surface and hull. You can lift floor panels to inspect the hull. As kbd512 recommended, a walking surface applied to the hull with a latch that pushes into the centre of a node where risers meet, and latch with a quarter turn. kbd512 suggested sheet metal and weld formers and stringers directly to the sheet metal. Simpler and less wasteful manufacturing technique. The floor is a cylinder around the circumference of the ring, but we may still need stiffeners to prevent bulging. Isogrid uses triangles, and works very well for stress from any direction. Orthogrid uses rectangles, which is stronger in the direction of the risers. ULA is considering changing to Orthogrid because risers can be longitudinal along the length of the stage, providing more strength in the direction of thrust. Orthogrid also means more straight lines when the automated milling machine carves out the gaps between risers. If we weld formers and stringers directly to the sheet steel skin, that would work better as an orthogrid.

Offline

Like button can go here

#1234 2022-03-22 14:22:16

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Large scale colonization ship

One difference between a spacecraft and an aircraft: the aircraft is leaky. Commercial aircraft are made of panels of aluminum alloy glued together with epoxy, and riveted. It's not normal epoxy, aircraft grade epoxy requires specially preparing the surface, and is very strong. However, the aircraft leaks a lot of air. The reason it remains pressurized is ram air from the aircraft flying at 84% the speed of sound. At least a 777 cruises at 0.84 mach. The air from the overhead nozzle is not all clean air, a lot is recycled, but there is enough ram air to refill from the leaks. For a spacecraft, you want it sealed so it doesn't leak. A trip to Mars takes 6 months, and there's no air in space to replace what leaks. All you have is what you bring with you. So the spacecraft pressure hull must be welded, not glued and riveted.

Offline

Like button can go here

#1235 2022-03-22 17:23:38

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,100

Re: Large scale colonization ship

For RobertDyck ... thank you for continuing to work on details for Large Ship .. there are thousands to be addressed, and while we are waiting for the staff to take on some of the load, you are all we (and the ship) have to carry it.

In post #1233, you indicated you did not see a need for 2 meters of space between the pressure hull and the walking surface, but you did not indicate the amount of vertical separation you want to provide.

If you decide to provide panels in the floor, in order to provide access to the pressure hull, then those panels will need to be defined in detail so they can be procured, and they must be designed so they can be installed by remote teleoperation.

While kbd512 seems to prefer using live human beings to perform assembly, I suspect he has not priced out the cost of delivering a human being to the job site, let alone maintaining them in a healthy condition for as long as the job lasts. $20,000,000 was a going rate for a single person to visit orbit for two weeks, and I expect the price has held steady since then.

(th)

Offline

Like button can go here

#1236 2022-03-22 19:20:42

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,577

Re: Large scale colonization ship

Sounds like post 1228 needs the slow glass topic for a screen that gives the video appearance with out the added complexity of an actual hull hole giving the user and view that they should want displayed onto it.

This and also double as a communications portal for breech information, evacuation routes ect...

While man may not be doing some of the welds it could be there to operate tools that the robots can not.

Offline

Like button can go here

#1237 2022-03-22 19:25:19

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Large scale colonization ship

I notice cruise ships charge more for outside cabins with a window. One technological improvement is inside cabins have a large flat-screen smart-TV connected to a 4k high-speed camera on the ship, so it looks like a window. I have suggested such cameras on our Large Ship, and smart-TVs in every cabin. For outside standard cabins install the smart-TV over the window, and choose a TV that is transparent when turned off. So the TV appears to be an additional pane of glass. There are such TVs on the market now. The back can be made opaque so you get a clear view of the TV. How do we conduct a survey of potential customers? Would they accept just a TV? Or would they want a window? I suspect the latter, but we should do a market survey. There will be the two observation rooms on the upper deck, but is that enough? I suspect not, but let's do a survey. One way to do this is a massively online multi-user virtual simulation.

Offline

Like button can go here

#1238 2022-03-22 23:06:32

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,514

Re: Large scale colonization ship

Robert,

I have a very light weight compromise that allows the flooring material to simply "snap into place" rather than use twist-lock fasteners. If we were to sandwich polymerized aerogel between Teflon tape, then we have a floor and wall covering that is exceptionally light, exceptionally easy to install or remove, and reasonably fire resistant. The aerogel won't support combustion at all. Polymerized aerogels have superb sound deadening characteristics and these sandwich panels can pull double-duty as the pressure bulkhead between berthing compartments, and it will cushion your fall if you trip and hit the deck. It will look and feel somewhat like rubberized matting and provide good traction while not being overly abrasive. Since the covering is Teflon, it's also resistant to a wide variety of cleaning solutions.

I second the motion to use high definition cameras to show the outside world to the passengers. The newest cameras and displays are so good that you almost have to press your nose to the screen to see any individual pixels. From any normal viewing distance, it's photo-realistic. The upside is that every cabin has a TV for watching movies or playing video games or participating in video calls or watching training videos. The cost of large televisions and an array of HD cameras will pale in comparison to the engineering work and hardware to put portals all over the place. The cameras have the added benefit of showing the bridge crew the space around the ship.

tahanson43206,

This ship will be permanently crewed for 25+ years. If it's too costly to send 6 construction workers to supervise assembly, then how probable is it that any corporation could afford to have 10X as many crew members permanently assigned over the ship's entire service life?

Offline

Like button can go here

#1239 2022-03-23 13:31:51

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,100

Re: Large scale colonization ship

For RobertDyck re Asteroid Source vs Earth source

In this post: http://newmars.com/forums/viewtopic.php … 39#p192639

You have suggested there might be a disagreement on sourcing of materials.

Why is there a need for a disagreement?

You are free to build additional copies of Large Ship using asteroid resources.

There is absolutely nothing (that I can see) stopping you from building as many copies of Large Ship as you want using asteroid resources.

Meanwhile, it is convenient to build Large Ship using resources available now on Earth.

Please ** do ** open a topic devoted to building Large Ship using resources you assemble from one or more asteroids. You'll need a decent sized ship to do that, so it might as well be one that was built by willing supporters here on Earth.

(th)

Offline

Like button can go here

#1240 2022-03-23 18:20:30

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,577

Re: Large scale colonization ship

Many of the raw ore sources are with some expenditure even if it takes less fuel for it to be mode and processed its still a delay in beginning the building process. It also adds to the initial upfront costs to get so that we can utilize these resources.

This is where a trade study comes in once you have the estimate BOM to make use of for what you want to build.

Offline

Like button can go here

#1241 2022-03-23 19:38:55

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Large scale colonization ship

An iron asteroid has metal, not an oxide ore. Iron, nickel, and cobalt can be extracted with the Mond process. This uses carbon monoxide. Working temperature is low, exact temperature is different for each metal. For nickel, carbon monoxide at 200°C will bind with nickel forming nickel carbonyl vapour. That's drawn into a second chamber where it's heated further, causing the vapour to break down into nickel metal and carbon monoxide. So the CO is recycled. The deposited nickel is over 99.9% pure. This temperature is so low that it can be achieved in space simply with a parabolic mirror to focus sunlight, so no fuel cost. Each metal requires greater temperature, but it can all be achieved with focused sunlight. Pressure is 1 atmosphere.

Harvesting other metals is more tricky. A group called PERMANENT has been working on a way to modify the Mond process for platinum group metals. It requires higher temperature, more pressure, and addition of fluorine gas.

Considering the size of our Large Ship, I don't see this as an additional expense, but rather a way to save money.

On the Moon, ore for aluminum is anorthite or bytownite. Ideal is pure anorthite. Bytownite is a mixture of anorthite and albite. Processing ore is similar to the Bayer to extract aluminum from bauxite ore. Bauxite is the result of a tropical rain forest extracting nutrients, bauxite is the left-overs, stuff plants don't want. No tropical rain forest, no bauxite. Bauxite can be found on Earth were there is no rain forest now, but there was millions of years ago. So we won't find bauxite in space. Anorthite and bytownite are igneous minerals, produced by volcanoes, already found on Mars and the Moon. The Bayer process dissolves aluminum oxide and silicon oxide from ore with a strong alkali, draws the liquor to a second chamber where weak acid neutralizes pH causing aluminum hydroxide to precipitate. The process for anorthite reverses that: strong acid and weak alkali. after aluminum hydroxide precipitates, the remaining process is the same. A mining company in Sweden already does this. The catch is albite mineral doesn't dissolve in hydrochloric acid. The mineral contains aluminum oxide and silicon oxide, with albite the silicon stays behind and creates a film of quartz on the grain, sealing it so it doesn't dissolve further. So anorthite or bytownite that has only a little albite will work. The process uses a lot of water. The water is recycled, but required. So the best place on the Moon to do this is a pole.

The Moon also has ilmenite ore. That's iron titanium oxide. Processing requires water and hydrogen. So again, ensure there's water nearby.

Windows on our ship will be aluminum oxynitride. That's aluminum oxide with aluminum nitride, and just a touch of yttrium oxide to control crystal size. The process requires aluminum oxide fines mixed with aluminum nitride fines. As as fine as flour. Poured into a mould, heated under vacuum to 1850°C and press with a multi-ton press. That is held for 3 days, then cooled. The Moon has vacuum. The vacuum ensures no air bubbles, the press squishes the grains together so no voids. This sinters the fines. The result is ceramic, which has greater impact strength than crystal. Synthetic sapphire is crystal of aluminum oxide, greater tensile strength but impact causes it to shatter. Aluminum oxynitride will come out with a matt surface, which must be polished to optical smoothness with diamond dust.

I mentioned mineral wool as acoustic insulation. That's formed by melting rock, extruding like fibreglass batt insulation. We could do that with lunar rock. The binder would have to be imported from Earth, but the bulk would come from the Moon.

Offline

Like button can go here

#1242 2022-03-27 19:39:09

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Large scale colonization ship

The Large Ship has various cabins available. Most cabins are "standard" cabins, the same size as 3rd class in the age of steam ships, and also the same size as studio single cabins of today's luxury cruise ships. Furniture can be configured as 3rd class, or as studio single. Or an intermediate option. So here is a video that covers 3rd class on the Titanic, with focus on food. But it also describes cabins, and how much food was carried by the ship.

YouTube: Dining Third Class on the RMS Titanic

video starting at 3:54, Titanic carried:

75,000 pounds fresh meat

25,000 pounds poultry

11,000 pounds fresh fish

7,000 heads lettuce

40 tons of potatoes

36,000 oranges

13,000 grapefruit (the announcer says that's 13,000 too many)

250 barrels of flour

800 pounds tea

40,000 fresh eggs

1,200 quarts of ice cream

15,000 bottles of ale

1000 bottles of wine

850 bottles if liquor

The ship could carry 3,547 passengers and crew, although its maiden voyage carried 2,200 people, 709 of whom were 3rd class passengers.

Ticket price for 3rd on Titanic was £7, which is about US$1,000 today. At the time that was 2 months wages for the average 3rd class passenger.

3rd class passengers required a physical examination by a physician before boarding, because for the vast majority of 3rd class this was meant to be one-way ticket to America. American immigration required this examination before boarding.

Accommodations include 84 2-berth cabins with electricity, a wardrobe, and a sink with running water. Or larger cabins with up to 6 berths, intended for families or single travellers of the same sex. There were 2 baths for 3rd class: one for men, one for women. For the whole ship. 3rd class had a "general room" with wooden benches, tables and chairs, and a piano. There was also a 3rd class smoking room with a bar, again with wooden benches, tables and chairs. No upholstery because 3rd class passengers were assumed to have lice. There was a deck where 3rd class passengers could go outside to "get air". Two dining saloons, separated by a water-tight bulkhead. Chairs in 3rd class dining were again wooden, no upholstery. Due to limited dining space, passengers were assigned one of two seatings.

Menu for 3rd class on Titanic's final day:

Breakfast

oatmeal porridge & milk

smoked herrings, jacket potatoes (today well call that baked potato)

ham & eggs

fresh bread & butter

marmalade, Swedish bread

tea, coffee

Dinner

rice soup

fresh bread, cabin biscuits

roast beef, brown gravy

plum pudding, sweet sauce (that's raisin pudding, and the sauce is caramel)

fruit

Tea

cold meat

cheese, pickles

fresh bread & butter

stewed figs & rice

tea

Supper

gruel (oatmeal with way too much water), cabin biscuits (fancy version of hardtack), cheese

"supper" ended at 10:00pm

Last edited by RobertDyck (2022-03-28 13:00:09)

Offline

Like button can go here

#1243 2022-03-28 18:15:39

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Large scale colonization ship

Let's see if I can remember what a modern hotel offers as complementary breakfast:

scrambled eggs

bacon

pancakes (cook your own, pitcher of batter provided and griddle)

waffles (again cook your own, same pitcher of batter, waffle iron has a light to indicate it's done)

pancake syrup

croissant

muffins & butter/margarine

cereal & milk

orange juice & apple juice

On our space ship:

cereal & milk (skim milk powder & recycled water)

bacon weed

pancakes (cook your own)

waffles (cook your own)

pancake syrup (hot water, golden yellow sugar, imitation maple extract)

croissant (fresh baked: flour, margarine, sugar, salt, yeast, milk)

orange juice (from concentrate)

fresh oranges (as available from the one dwarf tree on the observation deck)

Offline

Like button can go here

#1244 2022-03-30 19:19:11

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Large scale colonization ship

YouTube: Titanic's Second Class Experience

Breakfast

Fruit

Rolled Oats, Boiled Hominy

Fresh Fish

Yarmouth Bloaters

Grilled Ox Kidneys & Bacon

American Dry Hash au Gratin

Grilled Sausage, Mashed Potatoes

Grilled Ham & Fried Eggs

Fried Potatoes

Vienna & Graham Rolls

Soda Scones

Buckwheat Cakes, Maple Syrup

Conserve, Marmalade

Tea, Coffee

Dinner (noon meal)

Consume, Tapioca

Baked Haddock, Sharp Sauce

Curried Chicken & Rice

Spring Lamb, Mint Sauce

Roast Turkey, Cranberry Sauce

Green Peas, Purée Turnips

Boiled Rice

Boiled & Roasted Potatoes

Plum Pudding

Wine Jelly, Cocoanut Sandwich

American Ice Cream (note: French ice cream is made with eggs)

Nuts Assorted

Fresh Fruit

Cheese, Biscuits

Coffee

Offline

Like button can go here

#1245 2022-04-03 20:08:38

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Large scale colonization ship

Following up on today's Zoom meeting. If we want to get serious on Big Ship, we should consider recruiting some experts. Someone who has worked with mini-magnetosphere. Someone who has worked with producing microbial oil. The chloroplast oxygen generator will take a lot of work; that alone is a major project. Yet it's critical to life support for a ship this large.

My ex-girlfriend from Miami owns a small consulting firm. She's still there, her website shows she's still in business. She has computer software developers who work for cruise ship companies: Royal Caribbean, Carnival Cruise Lines, etc.

https://pragmatic-systems.com

A local friend has a finance startup, and claims to have landed funding for a few multi-million dollar projects. He said he likes my technology ideas. Things for use on Earth, not space. My idea to get financing is to get a large company going with several divisions producing practical things for Earth. Then use the finances of that company to fund our space venture.

Offline

Like button can go here

#1246 2022-04-03 21:59:40

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Large scale colonization ship

Before we get ahead of ourselves, realize if we ship all parts from Earth, how many launches of SpaceX Starship will this take? Elon Musk said he hopes to get a single launch down to less than $10 million, after 2-3 years of Starship operation, but didn't take into account current launch costs. And FAA still hasn't approved even the first orbital test launch. Last high altitude launch was May 5. So how much money will this take? Do you have a way to raise that money?

Offline

Like button can go here

#1247 2022-04-04 18:50:45

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,577

Re: Large scale colonization ship

we surely would not want to use the SLS so what else would we make use of?

Falcon 9 Heavy could bring up 63 mt but we would need a new shroud fairing to be created to haul the stuff to orbit.

Offline

Like button can go here

#1248 2022-04-09 10:54:51

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Large scale colonization ship

SpaceNut: The point I was trying to make in post #1246 is we aren't at a point where we can start building the Large Ship right now. We on this forum are ambitious and have skills, but how much money? In last Sunday's Zoom call, tahanson43206 (th) strongly argued to find a company that can start manufacturing panels for the hull of the Large Ship. Now. Right now. My point is we can't afford a single launch of Starship, we certainly cannot afford all the launches required to lift all the components to build Large Ship. So we aren't anywhere near ready to start building the real thing.

My assumption was and still is that the Large Ship is dependent on SpaceX Starship to launch components and tools for construction. For one thing we will have to wait for Starship to become operational. I have also argued to use in-situ materials: harvest a Near-Earth-Asteroid for iron and other metals for steel alloy of the hull. Tom Hanson has argued that would require more time, so he wants to launch all components from Earth. Launch from Earth will be required for mechanical equipment such as life support, but I wanted to reduce number of launches. Whether you use in-situ materials or not, we don't have the money for one single launch. Besides, there's still research for several new components.

Offline

Like button can go here

#1249 2022-04-09 11:07:48

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Large scale colonization ship

Some new components that require research:

chloroplast oxygen generator - based on current real-life physics, and there are laboratory exercises for university undergrad (bachelor) students in biochemistry to harvest and isolate them, but with the undergrad experiment in-vitro chloroplasts only last 20 minutes. To be practical for life support, they must last months.

vacuum desiccating toilet - Russia developed one for Mir2. The core module for Mir2 became the Zvezda, but NASA insisted that toilet be removed, that a copy of the old toilet from Mir be used instead. Their concern was plumbing was too complicated. But I'm sure NASA regretted that at various times, wishing they had more efficient water recycling. We will need one that operates in gravity, and has a built-in bidet. (no toilet paper)

urine processor that is reliable - the one on ISS got clogged by calcium. Decalcified astronaut bones. And the one for our ship won't extract as much water as the one on ISS.

urine electrolysis tank - this will extract sodium hydroxide and potassium hydroxide, producing hydrogen and chlorine gas. Then recombine the gas with sodium hydroxide to form salt water, and boil dry the salt water in partial vacuum so the salt doesn't burn. Resulting salt must be food safe, with no urine smell.

water recycling shower - This was an invention by a design student in the UK. 70% of the water that goes down the drain, comes right back out the shower head. Brilliant idea, greatly reduces water consumption, and reduces energy required to heat water.

liquid soap for hand washing and body wash in showers, shampoo, laundry soap, dishwasher soap - all made from vegetable oil and either sodium hydroxide or potassium hydroxide. Result must be compatible with hydroponics, that is concentrated dirty water can be used as fertilizer.

mini-magnetosphere radiation shield - University of Washington has done a lot of work on this, but we need one that works, and the magnetic field must be compatible with our ship.

control moment gyros - must work with Large Ship. The habitation ring will act as a large gyroscope.

MCP spacesuit - I have posted many times detailed descriptions, but we need a working prototype.

intra-vehicle pressure suit for emergency - this doesn't require micrometeoroid shield, but must be durable for all conceivable emergencies inside the ship. Must be donned (put on) quickly, and able to fit a variety of crew members.

emergency ball

portable airlock

aluminum oxynitride - manufactured by a US military contractor for windows of tanks, and other military applications. Patent has expired. We must be able to make windows for our ship with this material. Transparent like glass, but much stronger, able to withstand micrometeoroid strikes without pitting or other damage.

elevator that works from 38% gravity to microgravity. I'm thinking a cog strip along the elevator shaft. You can google "cog railway", Wikipedia calls it Rack railway. A cog wheel on the elevator car engages teeth of the cog strip to lift up/down. A traditional elevator uses a steel cable with a winch at the top of the shaft. But in microgravity, there won't be sufficient gravity to pull down on the car. A traditional elevator (UK term "lift") connects the cable to lever arms that have springs to pull the lever down at the top, and out at the sides. Weight of the elevator car pulls down on the cable, which forces the lever arms up at the top, and in at the sides. If the cable breaks, the lever arms spring out to grab rails in the elevator shaft, acting as breaks. That's the safety feature. That won't work when the car experiences microgravity, so we need something else to slow the fall of the car when it's in the lower shaft where artificial gravity (centrifugal force) is significant. Something not dependant on air either. The elevator car should be pressure sealed should the shaft decompress, so a breaking system dependant on air in the shaft won't work. Something that will break the fall of the car if it moves too fast.

Docking hatch compatible with Starship - APAS was designed to allow a 125 metric tonne Space Shuttle (including cargo and propellant) to dock with a 300 tonne space station. However, inside diameter of the hatch was only 0.8 metres. We need a larger hatch, something similar to CBM. But CBM does not have shock absorbers like APAS, modules must be attached gently by a robot arm. The new NASA Docking System is an adapter for APAS to allow a lighter capsule to dock: Dragon, Orion, Starliner, Dream Chaser. And I suggest an NDS style adapter on a hinged arm to allow capsules to dock. NDS could be moved out of the way to allow Starship to dock, or attached to the large docking hatch for Dragon etc.

RCS system for a ship this large

main propulsion

cooking in ½ atmosphere pressure

details of flooring, lightweight composite walls - sound proof and able to support things we intend to attach to them

inspection drones, navigation drone, construction drones

Offline

Like button can go here

#1250 2022-04-10 03:06:12

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Large scale colonization ship

The guy with YouTube channel "Tasting History" has a video for The Titanic's Crew Member Experience

I am suggesting crew on our ship eat at the same buffet dining rooms as passengers. Titanic had separation of people into: first class passengers, second class, third class, officers, and crew. We don't need that. I have proposed a fine dining room. Luxury cabins/suites include free meals at fine dining, but everyone else could also eat there if they pay for the meal.

Ps. Rather than carving potatoes into "grape" size/shape, it's more efficient to use a slicer to cut a potato into french fries. Or breakfast cubed potatoes. Or wedges.

Offline

Like button can go here