New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#126 2017-02-06 08:31:48

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,490

Re: Moon mission today - Dragon & Mars hab

Many of us living in the Mountains of the West experience the BP depression already. I live at ~6,000 ' msl. Granted, that's not what you were saying, but using pressure cookers is pretty easy.

Offline

Like button can go here

#127 2017-02-06 09:44:16

- elderflower

- Member

- Registered: 2016-06-19

- Posts: 1,262

Re: Moon mission today - Dragon & Mars hab

I live at sea level (plus a couple of meters). We use a pressure cooker regularly.

You would need a secondary containment in a pressurised hab or in a space vehicle so that an unscheduled venting of the pressure cooker would not do a lot of damage. You cant vent it overboard due to the unaccounted reaction on a space vehicle, although you might on a planet's surface if you didn't mind a bit of contamination.

Offline

Like button can go here

#128 2017-02-06 10:45:58

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,144

- Website

Re: Moon mission today - Dragon & Mars hab

When I looked at hab and suit atmospheres as a sort of package deal (posted over at "exrocketman", I got habitat atmospheres from 0.6 to 1 bar at 30% oxygen, and suits that were ~3 psi pure oxygen.

I could not eliminate the pre-breathe time without going to 40+% oxygen in the nab, which is a real fire hazard. NASA thinks 30% oxygen is safe enough, so I used that. 1 bar in the hab goes with just over 3 psi in the suit.

Something close to 1 bar, even as low as 0.6 bar, should be OK for cooking in an ordinary pot.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#129 2017-02-06 11:17:42

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,380

- Website

Re: Moon mission today - Dragon & Mars hab

You don't need 1 bar pressure on Mars. It just creates an obstacle to decompression to suit pressure. Apollo used 5.0 psi with 60% O2 and 40% N2. Skylab used the same. It worked. And most importantly that pressure meant zero pre-breathe time to get in an Apollo spacesuit. Even Denver or Boulder does not have 1 bar pressure.

Shuttle operated with 1 atmosphere pressure. ISS now operates with 1 atmosphere pressure. This requires 17 hours of oxygen pre-breathe to flush out nitrogen from blood before decompressing to 4.7 psi of an EMU suit. Apollo didn't require oxygen pre-breathe because their spacecraft and Skylab habitat operated at much lower pressure.

Offline

Like button can go here

#130 2017-02-06 17:38:05

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,460

Re: Moon mission today - Dragon & Mars hab

Sticking with what works for fast transit is what we will need on mars if any structure does get hit when we are in it, the same goes for a suit rupture we need to be able to survive..

I here Orion is getting a new toilet system for use when it starts flying, what do we have onboards the dragon v2 that we will ride and then I hope the one for mars is better still as we will need it.

Offline

Like button can go here

#131 2017-02-06 19:31:46

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,499

Re: Moon mission today - Dragon & Mars hab

Any bets on whether or not Orion's toilet costs more or less than 30 million dollars?

In an alternative universe where tax payers were respected, we'd have the privilege of naming the first mission capsule since we've pretty much paid out the @$$ for this thing. I can't decide between Orion's Throne and Expensive Sh*t!

Offline

Like button can go here

#132 2017-02-07 11:41:55

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,144

- Website

Re: Moon mission today - Dragon & Mars hab

I'd take your end of the bet.

The $1200 coffee pot on the P-3 Orion had to meet unnecessary requirements like 6 gee any axis, salt fog, 40-foot drop, fragment impact, etc. That's why it cost so much. On a max 2.5 gee straight and level transport lost if shot at by the enemy.

A Mr Coffee, a roll of duct tape to lash it to the table, and a bungee cord cord to hold the pot in place if the plane made a sudden uncoordinated maneuver, would have sufficed. And made the same or better coffee. For about $35 from any hardware store in America.

Same idiot story for the $300 military grade hammer that could by spec never fail at -65 F in Alaska. For $300 you can buy an awful lot of $3 hammers at any hardware store in America.

And don't get me started on the $700 toilet seat in the P-3.

Point is, the government demonstrably doesn't know its collective ass from a hole in the ground when trying to specify design requirements. Military, NASA, any other agency, doesn't make any difference. This comes from the writing of RFQ's by people who know next-to-nothing about what they are trying to buy. If the smarts were in the government lab, then what do they need R&D contractors for? QED.

Orion is Apollo-on-steroids and too heavy and costly to use precisely because it was specified to be a scaled-up Apollo, just with electronics updated from 1960's technology. The spec writers didn't know any better. The contractors did, but the smell of a gravy-train program overwhelms ethics at best. The CST-100 does almost the same job for a lot less weight, and somewhat less cost. The Dragon v2 is both lighter and a lot less costly. In both cases, these were less-specified by the government.

Basically, over-spec is the source of all the waste.

GW

Last edited by GW Johnson (2017-02-07 11:44:31)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#133 2017-02-07 13:09:46

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,380

- Website

Re: Moon mission today - Dragon & Mars hab

I spoke to one engineer from Boeing who told me not to believe the price of the hammer or toilet seat. These are ways to hide the cost for black projects. And Boeing deliberately overpriced their work for ISS to recover money for YF-23. The Advanced Tactical Fighter was run as a traditional air force competition. Lockheed-Martin and Boeing both built prototypes, which competed at a fly-off. The YF-22 and YF-23; the "Y" designates prototype. Lockheed-Martin won, when it went into production the "Y" was dropped to become F-22. The YF-23 lost, so Boeing did not get the contract. Boeing wanted money for their efforts, so deliberately overpriced work on ISS to do that. Just like a black project. I don't know if Boeing received some money for YF-23; if they did, their corporate executives didn't think it was enough. So they gouged their work for ISS.

Apparently someone in the bureaucracy did learn. For the Joint Strike Fighter, instead of running it as a "Y" project, it was run as an "X" project. Which means development and construction of prototypes were paid for by NASA under their "X" program: X-32 and X-35. Lockheed-Martin again won, X-35 became F-35. But this time since X-32 was paid for through the "X" program, Boeing didn't need to hide cost in something else.

Offline

Like button can go here

#134 2017-02-07 13:10:28

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,490

Re: Moon mission today - Dragon & Mars hab

As someone on the receiving end of Government Specifications about 55 years ago, I can speak volumes about what the Powers that Be expect a simple grunt infantryman to carry--just because they "might need it." A generation earlier, Guys were so loaded down with packs and weapons and ammunition dropped off the landing craft into deep water at Normandy, and never came back up. Utterly stupid to have guys carrying extra clothing, mess kits, canteens, shelter halves, gas masks, huge amount of ammunition trying to get ashore through deep water from the landing barges. All that's really needed: weapon, double to triple load of ammo, rations for 36 hours, and water. That way they might live long enough to eat the rations.

Same reasoning applies to the Orion capsule which became too heavy to launch into LEO using an Ares I. I have a friend recently retired from Ames/Moffitt Field as a NASA engineer who wrote me saying that the original system would have worked had the capsule not grown to monstrous proportions, forcing him to recommend cancellation. NASA = Overpriced, Overweight, and Overdue.

Last edited by Oldfart1939 (2017-02-07 13:21:43)

Offline

Like button can go here

#135 2017-02-07 13:15:24

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,380

- Website

Re: Moon mission today - Dragon & Mars hab

In the 1990s, there was also a special tool to remove the ray-dome for radar on F-16 fighters. It turns out this $800 custom tool was nothing but an Allen wrench with a fancy handle. Traditionally an Allen wrench is an extruded piece of steel bent into an "L" to form the handle. But today you can buy an Allen wrench with a fancy plastic "T" handle. Here's one from a major hardware store, list price $2.98...

Offline

Like button can go here

#136 2017-02-07 13:36:48

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,380

- Website

Re: Moon mission today - Dragon & Mars hab

Also realize the Orion spacecraft was developed to launch on Ares I. That launch vehicle had a major problem: vibrations. Shuttle launched with 1.67 million pound external tank, gross lift-off weight, including tank. And the orbiter had a gross lift-off weight of 240,000 pounds, including orbiter and propellant, but not including payload. Then there's the payload. Without all that weight to dampen vibrations, the single solid rocket booster produced so much vibration that astronauts could not see their instruments. Yes, there were efforts to deal with this. All efforts were lame. But my point is Orion was designed to be extra big and heavy in an attempt to dampen those vibrations, make Orion usable when launched on Ares I. Yes, Ares I had a liquid upper stage, but it certainly wasn't enough.

When Constellation was cancelled, so was Ares I. The manufacturer tried to revive it, but Congress did not permit it. Good riddance to bad garbage. But now we're stuck with an Orion capsule that is far too heavy for the job.

Offline

Like button can go here

#137 2017-02-07 14:37:26

- Tom Kalbfus

- Banned

- Registered: 2006-08-16

- Posts: 4,401

Re: Moon mission today - Dragon & Mars hab

Yep, build something and throw it away!

Offline

Like button can go here

#138 2017-02-07 17:14:39

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,144

- Website

Re: Moon mission today - Dragon & Mars hab

RobertDyck:

As I recall, the solid that was the Ares 1 first stage was a 5-segment upgrade to the shuttle 4-segment SRB. The source of the thrust oscillations (also pressure) is a combustion instability excited by the longer resonant length, but not strongly enough to grow without bound.

The real cure for combustion instability in a solid is to change something about the internal geometry, flow pattern, or propellant. They already have 20% aluminum, which is about as much as you can have. The condensed Al2O3/C particulates do provide damping.

They elected not to treat flow pattern or geometry. That left only massive payload to absorb the vibration. Which also is hope that the oscillation will never choose to grow unbounded to a motor explosion (the more common outcome).

Essentially the very same 5-segment motor is the SRB for the SLS. Being coupled to the massive core and upper stage plus payload damps the effects of the objectionable vibrations without eliminating them. But the fundamental instability is still there. Nothing has really changed. I would NEVER EVER man-rate such an abortion myself.

ATK/Orbital talked them into accepting this situation long ago as Ares 1 / Constellation. They have a vested interest not to fix it, since that is expensive and a start-from-scratch redesign. And NASA is still so incredibly stupid about solids as to accept the situation. There is still no one at NASA who ever actually built a solid, not in all these decades.

The solid SRB's used on Atlas-5 and on Delta-Heavy had no such problems. Had to be reliable for the commercial market, and also not shake the paying payloads to pieces. Surprise, surprise, as "Gomer Pyle USMC" might say.

Amazing what government gravy train pork programs will buy, ain't it?

All that being said, we'll have SLS's available (eventually) for several years, at a launch rate of 1 every year or two. We can use them for this-and-that not launchable by anything else, I suppose, in spite of the horrific expense. But if it was my decision, I would NEVER, EVER risk a crew on one, not with that SRB design.

GW

Last edited by GW Johnson (2017-02-07 17:22:17)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#139 2017-02-08 01:42:59

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,499

Re: Moon mission today - Dragon & Mars hab

As someone on the receiving end of Government Specifications about 55 years ago, I can speak volumes about what the Powers that Be expect a simple grunt infantryman to carry--just because they "might need it." A generation earlier, Guys were so loaded down with packs and weapons and ammunition dropped off the landing craft into deep water at Normandy, and never came back up. Utterly stupid to have guys carrying extra clothing, mess kits, canteens, shelter halves, gas masks, huge amount of ammunition trying to get ashore through deep water from the landing barges. All that's really needed: weapon, double to triple load of ammo, rations for 36 hours, and water. That way they might live long enough to eat the rations.

Rations and mess kits? Did their officers think they were going to stop to have a picnic on the beach with mortars, artillery, and machine guns raining steel down on them?

If you're drowning, carrying extra ammo won't help you. The only thing that would've saved some lives at Normandy was arming all the assaulters with M1 carbines and a normal ammo load. Anything heavier than the carbines should've been mounted on small boats circling off shore so that the boat crews could provide suppressive fire for the assaulters. The boats would run race tracks parallel to the beach, on either side of the landing ships, continuously firing M2 machine guns at the German positions.

No one in the assault group would have had helmets, packs, or tools except for wire cutters, knives, and grenades or small satchel charges. Everyone in the assault group also would've had one bandage and tourniquet in each pocket. If something gets blown off or perforated, your team mates always have something to use to stop the bleeding. If your head gets blown off, then you obviously weren't using that anyway.

Many thanks to the brave young men who defeated the Nazis on our behalf. There was an awful price to be paid for that victory and they willingly paid for it.

Offline

Like button can go here

#140 2017-02-08 02:48:51

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,380

- Website

Re: Moon mission today - Dragon & Mars hab

GW: I could argue for liquid boosters using F1-B engines instead of advanced solids for SLS block 2B or 2. However, block 1 and 1B are committed to use 5-segment SRBs. Is there an internal geometry pattern change that could fix it? I suspect they chose internal solid fuel geometry for optimum burn rate.

Last edited by RobertDyck (2017-02-08 04:04:53)

Offline

Like button can go here

#141 2017-02-08 11:07:52

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,144

- Website

Re: Moon mission today - Dragon & Mars hab

My goodness! I haven't seen those illustrations in decades. Brings back a lot of memories.

What they used on the shuttle SRB's was a segmented form of the "tubular" in the upper left corner. The more modern name is segmented cylindrical grain. If the length is about 1.6 times the grain OD, this is a "rainbow neutral" burn with both ends burning.

Max to min surface is around 20%, which means pressure and thrust vary a lot more than that, depending upon burn rate exponent. The segment dimensions were set by how big a mix could be made and cast, because you must cast from 1 mix to get consistent performance. But you cast a segment and a slew of small burn rate verification motors from each and every mix.

The variation of burn rate from mix-to-mix inherently means that not all your segments burn out at exactly the same time. You have to be very careful in your selection of actually as-cast-achieved burn rates in the left and right stacks, so that the thrust time traces balance way down into tailoff left and right, or else the induced yaw moment will exceed vehicle control torques.

The simple cylindrical geometry brings the organ-pipe quarter wave mode of oscillation to mind. About the first 2 or at most 3 modes are of greatest susceptibility in practice. But there are radial and circumferential modes as well, including some modes in the slots between grain segments. These lengths and natural frequencies change with grain burnback, but the longitudinal modes do not. They are the highest risk.

There is an even better grain design than that, which is more neutral burning at about half the variation percentages, and yet still easy to cast, and in longer segments, too. Its neutrality is also far less sensitive to being thrown off at the wrong L/D proportions. It is called the "keyhole slot", and flew very successfully as the ASALM-PTV booster. It's basically the segment grain with a slightly smaller bore and one slot from bore-to-case on one side only. Ideal L/OD is about 2.4-ish, but it's still pretty neutral at 3 or even 4, as good, or better than, the the rainbow-neutral segments.

It has the same risks for longitudinal mode instability as any full-length bore design does, but is just as easy to cast as the segment grain. The tooling is nowhere near as complicated as for the other illustrations you provided. The longer L/D of the basic grain design means for the same overall case length you can have fewer joints. The slot helps relieve some of the grain stress upon cold soak-out, too.

The only downsides are (1) the flow coming down the slot eroding case insulation along that location, and (2) eroding the nozzle lip because it's not a straight shot for the hot, particle-laden gas flowing into the nozzle from that slot. You just compensate with extra sacrificial insulation in those locations.

It's the hot, particle-laden gas physics that NASA has no real experience with. All their liquids burn very clean, no two-phase effects at all. But solids are heavily two-phase, even with no aluminium at all. This is why it is utterly stupid to have more than one O-ring seal at a joint in a solid. But that's another, different, story.

GW

Last edited by GW Johnson (2017-02-08 11:20:00)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#142 2017-02-08 11:54:49

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,460

Re: Moon mission today - Dragon & Mars hab

Offline

Like button can go here

#143 2017-02-08 14:27:10

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,380

- Website

Re: Moon mission today - Dragon & Mars hab

GW: I was thinking of something like a partial baffle. Say a bulkhead at the segment join between the 4th and 5th segments, with a hole in the baffle the diameter of the unburnt bore. The purpose is to shorten the "organ pipe" length, separating it into two harmonic pipes, each with shorter wavelength. The problem with that is it will have no effect until solid propellant is at least partially burnt. Another option is a 3D shape at the segment join, with a cone deflector in the bore. The reason for a cone shape is to create laminar flow, to minimize exhaust restriction, but again separate the "organ pipe" into separate segments with shorter wavelength. The problem is that requires solid propellant have a gas flow path around this obstacle, which creates a burn face that changes thrust profile.

We'll get what we get. NASA will push forward with SLS block 1, launch EM-1. Every launch so far has had a last-minute delay, so I expect EM-1 will too. If EM-1 launches Sunday December 11, then the time from announcement to first launch will be the same as Saturn V. So all the time and money spent on Ares V has been lost/wasted.

Offline

Like button can go here

#144 2017-02-08 20:01:16

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,144

- Website

Re: Moon mission today - Dragon & Mars hab

Interesting idea, your baffle. Put it forward at the 1-2 or 2-3 joint where the massflow through the baffle is far less than the motor massflow, and you can use a smaller port in the baffle plate, one actually smaller than the as-cast bore diameter. But nowhere near choked! It won't fully isolate the two chambers, but it will reduce response across the baffle plate. It's a hellish environment, but could be done with a well-insulated steel plate, I think.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#145 2017-02-08 20:50:48

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,460

Re: Moon mission today - Dragon & Mars hab

Baffles are also used in water tanks to stop sound capitation from occuring.

They only have to last for part of the burn cycle as the internal pressures drop a bit more than half way in the burn to orbit.

I am sure we captured this in the SRB topics....

Offline

Like button can go here

#146 2017-02-17 18:30:45

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,460

Re: Moon mission today - Dragon & Mars hab

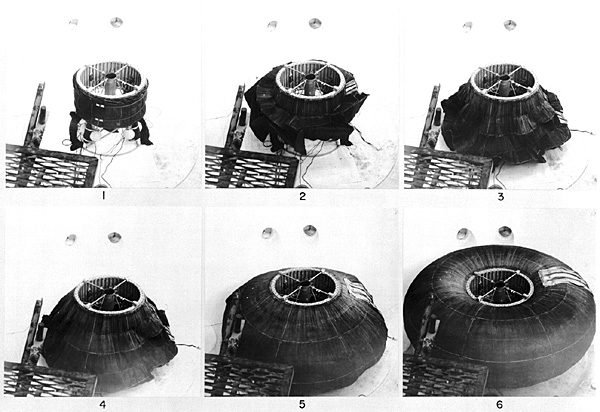

I do think that if we are going to simulate a mas base on the moon then this image does do that for a habitat.

Offline

Like button can go here

#147 2018-04-21 19:38:46

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,380

- Website

Re: Moon mission today - Dragon & Mars hab

I proposed going to the Moon with Falcon Heavy. Two launches: first delivers the lunar module to lunar orbit, the second delivers Dragon. The problem is not enough delta-V with all 3 Falcon Heavy core stages recovered. To do this, the central core stage would have to be expended. Years ago at a Mars Society convention, Elon Musk talked about a LOX/LH2 upper stage for Falcon. What would the launch mass to TLI be with all 3 core stages recovered?

Offline

Like button can go here

#148 2018-12-05 18:46:47

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,460

Re: Moon mission today - Dragon & Mars hab

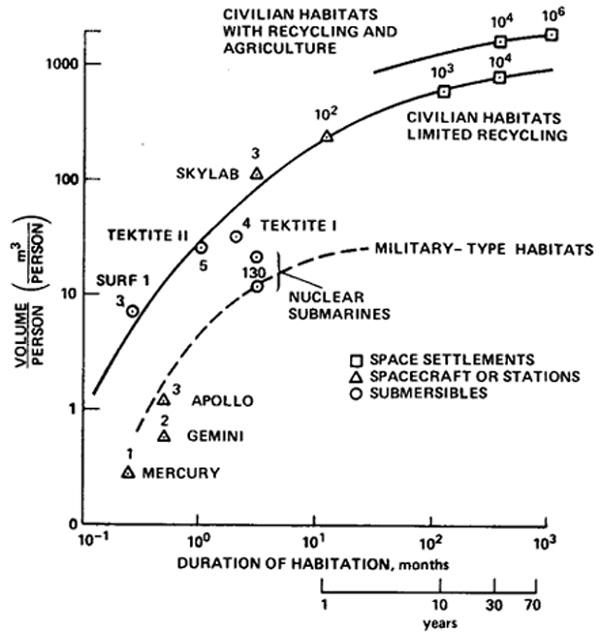

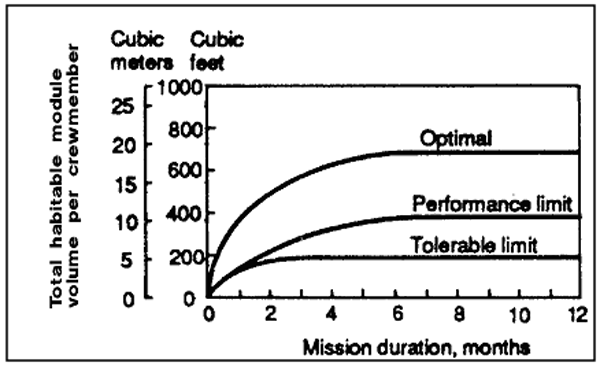

One the note of how much space we will need for a crew going to the moon or mars will be important.

What if the tuna can lander and an inflatable ring was what we sent for man to live in

Of course thats just that part of the mass for the mission to which; a Mars mission is for 18 months (540 days). 6 persons × 540 days = 3,240 person-days. And though the missionis 3 legs the total needed is 2.303 kilograms × 3,240 = 7,462 kg food to feed 6 people for 18 months.

Offline

Like button can go here

#149 2019-01-01 18:48:49

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,460

Re: Moon mission today - Dragon & Mars hab

The use of a modified lunar lander is not without its expected issues but a clean sheet has its problems as well.

I think that a cygnus might be as clean as we can go since we want a Lox/LH2 landing section and ascent stage once refilled.

Offline

Like button can go here

#150 2019-01-03 21:46:52

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,460

Re: Moon mission today - Dragon & Mars hab

https://ntrs.nasa.gov/archive/nasa/casi … 005557.pdf

LOX/Methane In-Space Propulsion Systems Technology Status ...

cube-square law, the smaller the tank, the faster the liquids will boil off.

Offline

Like button can go here