New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#26 2023-05-24 01:44:11

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,291

Re: Limestone-based Thermal Battery

Hold off buying anything until we have a settled design. It may be worth restarting the vid comms such that we can discuss this face to face. I will be on leave next week, so will have some time to put into this project.

Last edited by Calliban (2023-05-24 01:46:45)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#27 2023-05-24 06:18:10

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,976

Re: Limestone-based Thermal Battery

For Calliban re #26

Thanks for your encouragement of the flow in this topic!

It is possible to set up a temporary Zoom at any time, if one is needed. The only limitation of the free version is a 40 minute time out, which can be easily dealt with by starting a new Zoom. The mechanism we have used to coordinate Zoom conferences is still available and still working.

In addition (thinking aloud) I am a member of three other groups who use video conferencing, and one of these uses a facility called "gather" that has a free version that works well without the timeout.

A design that is within the reach of ordinary citizens should be of interest to DoItYourself magazines, and possibly even to an established publication such as Popular Mechanics.

(th)

Offline

Like button can go here

#28 2023-05-24 14:05:31

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,291

Re: Limestone-based Thermal Battery

This may be of interest concerning the S-CO2 cycle.

https://dspace.mit.edu/handle/1721.1/17746

The paper concerns large powerplants. Given the pressure that S-CO2 requires for efficient operation, I wonder if a steam cycle would be technically easier for a first demonstration? Worth thinking about.

The original Stanley steam cars were piston driven. By the time steam turbine technology was sufficiently advanced for a vehicle, gasoline had displaced steam entirely. A gas turbine driven car was developed by Rover in 1950. Despite its theoretically superior power-weight ratio, GTs never went any further as engines for road vehicles. I am uncertain as to why this would be.

Last edited by Calliban (2023-05-24 14:36:36)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#29 2023-05-24 15:14:04

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,447

Re: Limestone-based Thermal Battery

Calliban,

We should hold a meeting on design specifications, materials selection, and any compromises we make in the name of practicality and cost. What we end up with needs to be something that someone with a home workshop person can reasonably fabricate. If that's doable, then it bodes well for the ultimate ability of a company with more resources to mass manufacture and roll out the technology. I can get some outside help from professionals with commercial / industrial machining and welding equipment, but the more I can do myself, the better.

Offline

Like button can go here

#30 2023-05-24 17:25:38

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,284

Re: Limestone-based Thermal Battery

Thank you point out my error for post 19 and making them so in yours that followed kbd512.

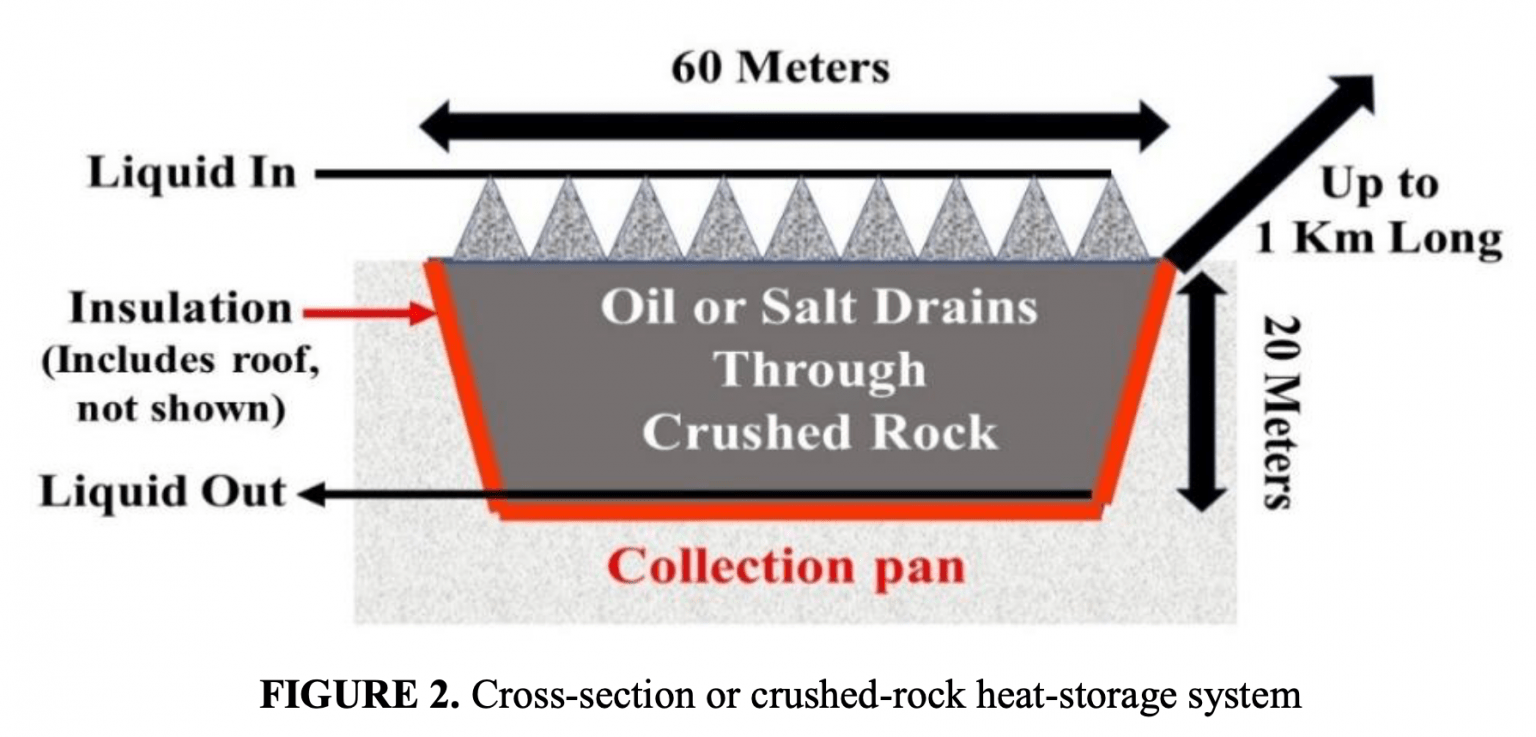

In the thermal storage topic, the grains or small rocks are placed into an oil to reduce the air within them and allow for a better level of conduction for heating.

I am thinking that a ready make tank could be a natural gas or propane hot water tank as a base to build from.

For a car we will need a small 12v battery and recharge circuit to power up the cars systems for a short period of time to allow for the limestone battery to come online.

This battery seems to be scalable as well for vehicles that would need less and could also be part of my home thermal solar concentrating system that would have wood heat as a backup to store energy with in it.

Something else to remember is the main turbine generator will be a wild mode AC cycle since the air pressure of the co2 at full battery temperature will be higher than at low battery temperatures and the turbine will not be at 60 cycle so we will need a temporary battery buffer and rectifiers to make it regulated for use. Then there is the motor drive circuit that if its 3 phase vs single changes the motor sensing and driver circuit.

Also, if we do this, we can also add in breaking power regeneration to the mix and extend the distance even further for the limestone battery.

Offline

Like button can go here

#31 2023-05-25 20:51:02

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,284

Re: Limestone-based Thermal Battery

The making of the heat storage and exchanger assembly with the converting elements are going to be literally dependent on the space allotment that we might make use of for the distance efficiency that we might be able to achieve.

One could imagine the co2 in the tubing with the limestone poured around inside the tank.

Of course, if we only have a square or rectangular area to make use of it we might need to change the method of the tank and exchanging methods.

You can think of a heat exchange and storage combination as having a transformer like winding function..

Offline

Like button can go here

#32 2023-05-25 21:34:46

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,976

Re: Limestone-based Thermal Battery

Nice find!

SpaceNut re Post #31

For those who might be curious, SpaceNut found that image at:

https://weldingweb.com/vbb/attachment.p … 1455899261

SpaceNut, a home/garage/basement project would be something along the lines of what you showed us.

Your mention of a square or cubical form seems advanced to me. At this point, it will be a miracle if anything more than hot air comes out of this project.

A cylindrical shape of a 5 gallon can would be an excellent place for a home/garage/basement builder to start.

That copper coil you showed us reminds me of a TV series on distilling spirits. The impression I got from watching a few episodes is that there are parts of the US where such copper coils are quite common.

Please keep looking for ideas like that !!!

Reminder ... the heating system would (presumably) be electric, so perhaps a parallel coil containing electric heating wire would be possible. Because electric resistance heaters can (and do) fail after many start-stop cycles, a design that allows the heating elements to be replaced easily would seem advisable.

(th)

Offline

Like button can go here

#33 2023-05-27 20:36:27

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,284

Re: Limestone-based Thermal Battery

I was thinking today about the shutoff of the thermal system and it's what we would call a bypass system.

The inlet side of the co2 to the tank holding the thermal heat source would require a check valve for co2 direction flow from a low to high pressure boost from the heat inside the chamber. Just before that we place the bypass valve to connect to the outlet side of the thermal tank.

Of course, the output side also has a check valve as well to continue the pressure direction where the bypass connects to. Since the pressure will drop for the section inside the tank there will be no flow to feed cold co2 into it as its being sent around it and since the check valve will block it coming back in from the opposite side the total will come to a state of equilibria pressure after a short time.

Dropping thermal energy loss and to start the bypass is removed and flow starts back into the thermal tank where it will start to expand and produce power.

Offline

Like button can go here

#34 2023-05-27 20:45:42

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,976

Re: Limestone-based Thermal Battery

For SpaceNut re #32 Nice to see you engaged with the topic!

The words you used can go with images. You can make a hand drawn sketch and take a picture of that. RobertDyck has shown how to do that, years ago, in the Large Ship topic.

Let's try to move beyond just words.

i'd like to see your layout for a system able to light a 100 watt bulb for an hour.

(th)

Offline

Like button can go here

#35 2023-05-27 21:16:39

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,284

Re: Limestone-based Thermal Battery

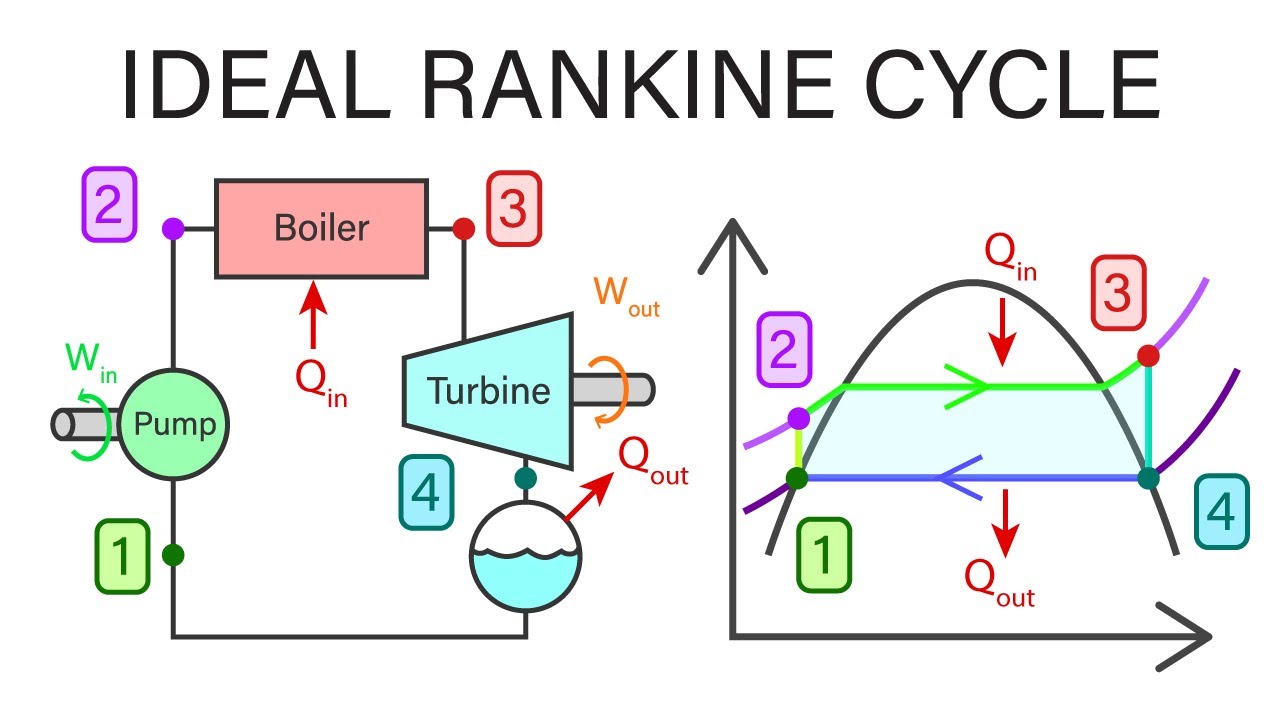

This is a modified steam plant design or Rankine heat engine and that of a AC unit in that we are reversing the pump connection to make it a turbine for power creation..

Of course, the boiler is the thermal tank.

The point 2 and 3 are the connection of the additional plumbing for the bypass.

The pump is the car radiator for cooling instead.

Here is the AC

We are making use of the vehicles radiator to condense the co2 pressure back down so that we can make the next cycle under operation. Instead of a compressor it's a turbine.

Offline

Like button can go here

#36 2023-05-28 18:33:25

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,284

Re: Limestone-based Thermal Battery

I sort of dislike all the difference in the diagrams that we have as the scales are all different to those that we are looking to make use of.

Ideal gas law: PV = nRT

P: Pressure

V: Volume

n: number of moles

R: product of Boltzmann constant and Avogadro constant (8.314)

T: Temperature

n = PV / RT

Any gas follows a law P V = n R T where P = pressure (pascals) V = volume (m^3), n is the number of moles (44g for CO2), R is a constant 8.3145 J/(mol K) and T is the absolute (kelvin ) temperature. Alternatively 44g of CO2 occupies 24 litres at room temperature/pressure. The volume decreases linearly with pressure and increases linearly with absolute temperature.

https://www.engineeringtoolbox.com/carb … _1254.html

https://highperformancehvac.com/boiler- … pe-sizing/

Flow Rates – Boiler Piping Flow & Pipe Sizing Chart

Pipe Size Flow Rate for Copper Flow Rate for Steel

½” 1 ½ GPM (Gallons per Minute) 2 GPM (Gallons per Minute)

¾” 4 GPM (Gallons per Minute) 4 GPM (Gallons per Minute)

1” 8 GPM (Gallons per Minute) 8 GPM (Gallons per Minute)

1 ¼” 14 GPM (Gallons per Minute) 16 GPM (Gallons per Minute)

1 ½” 22 GPM (Gallons per Minute) 25 GPM (Gallons per Minute)

2” 45 GPM (Gallons per Minute) 50 GPM (Gallons per Minute)

2 ½” 85 GPM (Gallons per Minute) 80 GPM (Gallons per Minute)

3” 130 GPM (Gallons per Minute) 140 GPM (Gallons per Minute)

4” 300 GPM (Gallons per Minute)

Offline

Like button can go here

#37 2023-05-28 19:52:17

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,976

Re: Limestone-based Thermal Battery

For SpaceNut re new posts and topic in general ...

First ... am I correct in thinking you are planning to omit a pump to move liquid through the system?

Second ... the examples you provided seem to me to be on the large side, far greater than a simple little demonstration system we members could build in our homes or garages.

I'm trying to encourage moving toward a practical, achievable, affordable Real Universe concept that will show what this forum can accomplish when it puts it's collective mind to the problem.

An old electric oven filled with bricks is a perfectly reasonable energy store for a demonstration project.

I've offered a goal of lighting a 100 watt bulb for an hour. That should be achievable for a few hundred monetary units, and a few months work.

The idea of using a turbine seems high scale to me. A simple model steam engine would be a practical solution that would work with steam or with another hot gas as the working fluid. That motor needs to drive a generator to produce that 100 watts, but the bulb won't care if the current is DC, so an old automobile generator might work.

My guess is that you are going to discover you need a way to control the flow of fluid through the Thermal Energy Store. The energy produced by a given volume of working fluid is going to decrease at a predictable rate as time passes and energy is drawn off, so (it seems to me) the amount of working fluid is going to have to increase to compensate.

(th)

Offline

Like button can go here

#38 2023-05-29 09:22:14

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,284

Re: Limestone-based Thermal Battery

The first image does not contain a radiator or condenser shown by the liquid bubble that we would use for a car power train so until loop length and pressures are created for application we may or may not need the additional pump.

The second is an actual cars system where the evaporator is the section within the hot limestone container and the compressor is changed to a turbine to create the motion for spin via the gas expansion that heat will cause.

After you have spinning motion sure we can connect to that any sort of power generating system that one can want AC or DC in the form of an alternator or larger. That spin is going to be wild as it's not going to be a steady sate fixed cycle as pressure will rise and fall as the diagram shows in the first image. The larger that rise and fall is the greater values will be for the rpm of that motion.

Wattage much like all things require 2 values for creation and the fixed values we make use of is voltage in that equation. Where current is related to that rpm spin rate for the purpose of maximum loading of the generating circuit.

Also, an alternator voltage value is derived from the voltage being supplied to the regulator in the alternator which for a car is 12v and at 1,000 rpm we are putting out wattage for use but not its maximum, as that will take closer to 3,000 rpm to get the full amperage from the alternator. An alternator with no supply voltage to the internal coil will not put out any voltage or wattage no matter how fast it spins.

Offline

Like button can go here

#39 2023-05-29 09:54:37

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,976

Re: Limestone-based Thermal Battery

For SpaceNut ....

Thanks for adding to the automobile vision for this topic.

An automobile implementation is out of reach for members of this forum.

Please develop a demonstration solution that members of this forum can build at home or in the garage.

I've offered a goal of 100 watts illumination for an hour. That may be out of reach but a study might reveal it is possible.

This forum has been producing grand visions for over two decades. There is now an opportunity to direct all that creative energy toward something that could actually happen in the Real Universe!

(th)

Offline

Like button can go here

#40 2023-05-29 12:58:28

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,284

Re: Limestone-based Thermal Battery

Even a bicycle can produce 250w for a short period of time pedaling at 60 rpm's from a 12 v car alternator the issue is you must get motion from a device that is inside the pressure system from the heat causing expansion and dropping as a result of cooling to the working fluid which is co2 rather than water as steam. Also, the item which does the turning is not the alternator as it's a turbine shaft or in some cases a reverse connected pump such as a power steering unit that will be coupled or connect to the alternator shaft.

Pressure is also related to the volume of the working fluid and that means length as well as diameter of the pipe that is inside the heating drum of limestone.

A CO2-driven turbine like those described in the Science paper skips the liquid phase entirely with what's called the Brayton cycle. "It uses a gas phase throughout, so you really end up with a better use of energy," says Levi Irwin, a DOE contractor, and author of the paper. Carbon dioxide also compresses more easily than water. That means you can pack more energized (heated) CO2 in a smaller volume. Irwin's paper proposes heating and compressing CO2 until it enters a supercritical state in which it is a bit like a liquid and a bit like a gas. "This lets you push energy through a turbine at 10 times the rate of steam," Irwin says. Vrooooom!

This makes a supercritical CO2 generator 30 percent more efficient at converting energy into electricity,

Turbines can use CO2 to cut CO2

https://energy.wisc.edu/industry/techno … s-turbines

Offline

Like button can go here

#41 2023-05-29 13:25:53

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,976

Re: Limestone-based Thermal Battery

For SpaceNut re Post #40 and the topic in general!

Thanks for a hefty boost to move this topic along.

One approach might be to work backward from the goal .... Can you compute the electrical (and mechanical) components needed to deliver 100 watts for one hour?

With that information, you'll be able to determine the rotational input to the generator that the Thermal Energy Store must supply.

Is CO2 a practical fluid for a home project?

Water is clearly suitable for small scale projects such as this one.

Please see if water could provide the fluid needed.

This project is going to be difficult enough to build without bringing exotic materials into the system.

(th)

Offline

Like button can go here

#42 2023-05-30 06:59:59

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,976

Re: Limestone-based Thermal Battery

https://en.wikipedia.org/wiki/Watt_steam_engine

Introduction

In 1698, the English mechanical designer Thomas Savery invented a pumping appliance that used steam to draw water directly from a well by means of a vacuum created by condensing steam. The appliance was also proposed for draining mines, but it could only draw fluid up approximately 25 feet, meaning it had to be located within this distance of the mine floor being drained. As mines became deeper, this was often impractical. It also consumed a large amount of fuel compared with later engines.[3]

The editors of this Wikipedia article have assembled a great deal of history and insight about development of steam power.

I am proposing that the current topic use steam as a working fluid for a model of the idea encompassed in this topic, so that a demonstration system is within the means of the members of this forum.

As i understand the history, the first (of many) improvements made by James Watt was to move the steam condensation activity of the early steam engine to a second cylinder, so that the primary cylinder could remain hot. If I understand the reports correctly, making this simple change cut the amount of coal to be burned for a given amount of work by half.

The home demonstration system might take advantage of knowledge gained since 1668.

For example, heat to be stored in the high temperature store might be drawn from a cold temperature store.

The result would be that instead of venting thermal energy to the atmosphere, and thus losing the energy and having to replace it, the thermal energy would be allowed to flow into the cold energy store.

If water is used as the working medium, then there could be plastic (or similar material) tanks to hold intake water and exhaust water.

(th)

Offline

Like button can go here

#43 2023-05-30 13:38:33

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,447

Re: Limestone-based Thermal Battery

This topic was originally created to determine how to create a more cost-effective electric vehicle that was not powered by an internal combustion engine or electro-chemical batteries and computers. In the near future, I expect both liquid hydrocarbon fuels and the metals required to fabricate batteries and electronics to become even more scarce and prohibitively expensive than they already are. There are presently no good recycling solutions for Lithium-based electro-chemical batteries or electronics, and absolutely nothing remotely approaching 100% recyclability, which would be required to re-power any given sector of the global economy using low energy density sources. I do not expect such problems to be adequately addressed or resolved before people belatedly recognize and finally accept that any globally-applicable low energy density power and propulsion solutions require very cheap and very abundant and very easy-to-recycle materials and mining activities. Low energy density solutions effectively limit us to very simplistic heat engines and durable goods that last all or most of a human lifetime.

I remain completely open to discussing other solutions which might be more suitable for other purposes as well, but this entire concept revolved around creating a prototype / demonstrator unit suitable for powering a passenger car type vehicle at an affordable cost and at the scale required to truly replace combustion engines for powering the most widely used form of motorized transport.

Offline

Like button can go here

#44 2023-05-30 13:48:51

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,976

Re: Limestone-based Thermal Battery

For kbd512 re #43 .... reminder of topic focus ...

Registered: 2015-01-02

Posts: 6,758

I'm starting this thread in response to a recommendation from Calliban that we create a separate thread to discuss the topic of thermal batteries made using low-cost / low-embodied energy materials for powering an alternative type of electric vehicle that primarily uses electricity to heat up a very low cost heat energy storage medium, such as limestone, which costs $10 to $55 per metric ton.

You have the option of changing the wording of the title of this topic.

Not everyone knows this ... I only learned it recently. I'm assuming you know, but for present and future members:

If you create a topic you retain the power to change the title. Just Edit Post #1 of the topic, and the title is available.

In this case, it would make sense (to me at least) to add a qualification to the title indicating the focus is on automotive applications.

I was going on the title "Thermal Battery", in proposing we forum members could actually build a working model of a Thermal Energy storage system.

The tradition for 20+ years is for this forum to publish creative ideas but to skip the hard work of actually building something.

The Thermal Energy powered car is going to happen the same day as RobertDyck's Large Ship leaves orbit with a full manifest of passengers and crew.

It will be a proud day for this forum (and for the entire planet) when those two things happen.

(th)

Offline

Like button can go here

#45 2023-05-30 15:42:19

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,447

Re: Limestone-based Thermal Battery

tahanson43206,

I skipped straight past the, "let's try to optimize this to the nth-degree", to "I'm buying 304L and limestone", so if any of you mechanical engineers want to provide input, now's the time to do it. Calliban immediately requested that I hold off on purchasing materials to fabricate the demonstrator unit, so I assumed that he wanted to provide some kind of technical input prior to materials purchase. I don't know what that was because he never specified and hasn't posted to this topic since then.

Offline

Like button can go here

#46 2023-05-30 18:24:53

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,284

Re: Limestone-based Thermal Battery

I know that above it was intended to have a 1 meter pressure vessel but that will take up 40% of the available interior of a vehicle and since most vehicle barely ever use more than 2 occupants that might not be all that bad. I would think other shapes and sizes would be possible.

If I remember correctly a 5 gallon steel container heated for 1 hour of sand held the near 500c heat for about 3 to 5 hours falling back to room temperature for open air heating so a vacuum should be around that container to isolate, it.

tahanson43206, there will be no water in the turbine loop as that will freeze during the night when not in operation. Also, to prevent freeze one needs a mix of better than 50% glycol and heating to that 500 c I do not believe will be something we will want to do.

The desired output will require EV motor to most likely be liquid cooled for it to remain function with a glycol mx in a different radiator and pump arrangement as it is. While this radiator is a 1 atmosphere type the one for the cooling of the super-heated co2 will not be and will need as much surface area as possible to provide cooling to start the cycle over again.

Do we have the delta on the co2 entering the thermal container and exit, so that we can look at heating time for that rise. This will tell how long the hot gas has to turn the turbine as the pressure must be somewhat regulated a near constant spin. We may need an expansion chamber to make this happen before the turbine.

Offline

Like button can go here

#47 2023-05-30 19:09:06

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,976

Re: Limestone-based Thermal Battery

For SpaceNut ... re Post #46 and your support of kbd512's topic...

kbd512 just reminded me that he intends for this topic to be about an automobile, and not just about title as given at present.

I had been hoping we could move this topic toward a Real Universe demonstration, which is why I proposed water as the working fluid.

What concerns me is that if the topic remains focused upon an automobile, the chances of Real Universe demonstration are vanishingly small, right up there with The Large Ship leaving orbit on it's way to Mars.

Are you at all interested in building a small working model of kbd512's concept?

If you are , then I would be interested and perhaps other members who are handy with tools would be interested as well.

This forum has been creating terrific ideas for over 20 years, and except for Dr. Johnson, who has created a course of instruction for students wanting to learn Basic Orbital Mechanics, I don't see results from all that work.

(th)

Offline

Like button can go here

#48 2023-05-30 21:32:18

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,447

Re: Limestone-based Thermal Battery

tahanson43206,

What you're describing is a combination of the cost and expertise required to translate our ideas into working hardware. Expecting one person to fill the roles of a mechanical or aerospace engineer, an electrical engineer, a computer programmer, a machinist, a welder, a graphic designer / artist, and whatever else is required is asking for quite a lot. There are obviously some people out there with that combination of skills, but not very many.

Offline

Like button can go here

#49 2023-05-31 06:25:10

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,976

Re: Limestone-based Thermal Battery

For kbd512 re #48

Thanks for the perspective on the difficulty of making a working model of your idea.

If it takes a team effort to build a working model of a Thermal Energy Battery system, then that's what it will take.

Each NewMars member is (if I interpret hints correctly) situated in a densely populated section of the planet, where a great variety of human talent is available to be enlisted to help with a worthy cause.

In thinking about the great inventive talents of human history, I came up with Benjamin Franklin, Henry Ford, Thomas Edison ...

Each of these gents built working models of their inventions. Alexander Graham Bell had an assistant, Watson.

You've inspired me to attempt to discover the history of invention. I expect there were some inventors who did all the work themselves, and others who had teams to help. Thanks for this neat idea for a study focus!

I was ** just ** reading about James Watt ... he was (apparently) employed as an instrument maker, and he was asked to work on a model of the state-of-the-art steam engine of the time. In working on the model, he recognized that he could increase the efficiency of the engine by performing condensation of the steam in a separate cylinder. That simple idea led to an increase in efficiency of 50%. Whether Watt did the work ** himself ** is what I'm curious to find out.

(th)

Offline

Like button can go here

#50 2023-05-31 08:55:12

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,976

Re: Limestone-based Thermal Battery

As a follow up to #49, I asked ChatGPT for advice....

The transcript at the link below includes a partial history of inventors who worked with or without support teams.

In addition, the transcript includes detailed discussion of the design of a Thermal Energy Storage system.

https://docs.google.com/document/d/1lqP … sp=sharing

the critical path appears to include needing to know the steam input required by the steam engine to drive a generator to feed a load.

Here is a detail from the transcript:

To determine the energy requirement at the input of the generator, we divide the adjusted energy requirement by the generator efficiency: 333.33 Wh / 0.8 = 416.67 Wh.

The computation shown above indicates that 416.67 Wh are needed at the input to the steam engine to deliver 100 Wh output, if we assume 30% efficiency for the steam engine, and 80% efficiency for the generator.

Thus, in this scenario, the energy store must hold 416.67 Wh of available energy that would be consumed during a one hour test run.

The actual amount of thermal energy that must be stored would be greater, since the tank itself will lose thermal energy during the run, and losses will occur in the transfer from the tank to the engine.

(th)

Offline

Like button can go here