New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#201 2023-02-28 15:17:19

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,988

- Website

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

Oh, most of America would be screwed, the heartland has the Mississippi watershed to get around on. It's east and west -- particularly west -- coast that will struggle, though the east has good connections into the heartland.

Th, I'm pretty confident this was a human. Unless the council has got early access to GPT4 or something.

Regarding freight, I've mentioned before the idea of push on pull off ferries. Just pull the loads off and hook them up straight away to the lorries. Means not having to have a lorry cab and driver held up doing nothing, just the chassis to hold the container. If we brought our rivers and certain canals (e.g. the Aire and Calder) back into use, I don't think anywhere would be more than 20-30 miles from a ferry port. Enough for them to be hauled using electric, or compressed air.

Regarding cycling, we have an abundance of bridleways and byways that could be paved. As long as cyclists can accept passing the occasional tractor they would allow us to quickly build quite a good network. And of course, suburban streets are typically quiet and low speed, so a lot of places just need a map to guide riders.

Use what is abundant and build to last

Offline

Like button can go here

#202 2023-03-02 11:25:28

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,122

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

https://www.yahoo.com/news/heat-pumps-t … 00177.html

This is for Terraformer ...

Not sure there is a good fit, but it appears there might be funds for a makeover, if the citizens are prepared for the "opportunity" ahead of time.

The Telegraph

Heat pumps have triggered a revolt against Net ZeroMatthew Lynn

Thu, March 2, 2023 at 10:45 AM ESTWhitby village

A knock-on the door. A quick inspection of the premises. And then, before you know it, a group of uniformed men have taken over the house and started dismantling it piece by piece.

It might sound like an extract from an early draft of George Orwell’s 1984. In fact, it was the plan for Whitby, targeted as the government’s first “Net Zero village”. An entire community would have all their heating systems ripped out, by force if necessary, and replaced by hydrogen or heat pumps. But, in this case, there was a twist. The villagers protested so much that the project was scrapped. And yet surely that is proof that we should go a step further – and scrap all the top-down Net Zero targets.

There are probably worse fates than being selected as a Net Zero village. You might be chosen as the site of a new reservoir perhaps, or right in the line of HS2. But the list is not a very long one. As part of its drive to hit its grand-sounding climate pledges, the government is planning to make a handful of villages laboratories for testing out new green technologies. Under the plan, traditional gas and electric heating systems would be switched off and replaced with hydrogen or heat pumps. If anyone objects, that’s just tough. If necessary, engineers would enter their house by force, rip out the old boiler, and replace it with a new one.

Here’s the problem, however. The residents of the villages on the shortlist for the honour turned out to be less than enthusiastic about the experiment. And who can blame them. No one really wants to rely on a heating system that is largely unproven to get them through the winter (it is chilly in Cheshire around January, in case no one had noticed). If it needs to be tested, it should be done in a few houses first, not in a whole village. Nor do they want to be forced to install a heating system that might turn out to be ridiculously expensive, ineffective, or quickly overtaken by superior technology.

In reality, the revolt against the hydrogen village neatly illustrates that when green technologies are rammed down our throats we don’t like it very much. Heat pumps? Despite massive subsidies, there is very little demand, possibly because they don’t work very well. Electric cars? Even with the tax breaks on offer, sales are now falling again, with the AA finding last week that only 18 per cent of us plan to buy electric next time, compared with 25 per cent last year, possibly because costs have risen and there aren’t enough chargers. Windmills on the local farmland, or local nuclear generators? No one actually wants them in their community.

The list goes on and on. It is very easy for politicians to make virtue-signalling pledges at climate summits. They can promise to ban petrol cars or gas boilers or whatever the issue of the day is. But when they try to implement that decision, it is done so poorly, and with so little planning, popular opposition kills it off.

There is nothing wrong with switching to greener energy, but it needs to be done voluntarily, because the technology is cheaper and better, not as part of a centrally planned system that rips up people’s homes without their consent. That is the real lesson of the Whitby revolt – and the government should take account of it before launching the next ridiculous target.

(th)

Offline

Like button can go here

#203 2023-03-02 11:52:44

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,988

- Website

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

Windmills on the local farmland, or local nuclear generators? No one actually wants them in their community.

As ever, the Telegraph considers only its readers to be people. Onshore wind has majority support. A few dozen people out of a town of thousands complaining about something doesn't mean "no-one wants it". And as I believe I've said before, we have local nuclear generators here... I just wish the electricity was sold at cost to those on the local (132kV) grid as an enticement to support it.

The "centrally planned system" objection is pretty dumb. Gas networks are centrally planned. Electricity networks are centrally planned. I suspect these people would complain about streets being ripped up for heat networks, even if it's not compulsory to switch. Though I agree it shouldn't be mandatory -- if some people want to pay through the nose to heat their homes, they should be allowed to. Just build the network and connect homes as people choose. Possibly without even replacing their boiler -- if the water could be preheated to say 30c from a lukewarm heating network, that still saves quite a lot of gas, and makes the step to a full heat pump system smaller.

Anyway. I volunteer my town as tribute.

Use what is abundant and build to last

Offline

Like button can go here

#204 2023-03-02 12:03:30

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,122

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

For Terraformer! I had hoped you might be willing consider this situation as an opportunity rather than something to be avoided.

However, there is a ** lot ** between your brave statement here in a US based forum, and the folks who can make things happen in your community.

I have no idea what the correct/optimum/least-risky next step might be, but I hope you will take it, and let us know what happens.

I don't see any downside, and there would appear to be plenty of upside.

(th)

Offline

Like button can go here

#205 2023-03-02 12:06:46

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,988

- Website

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

Forcing people to switch isn't an opportunity to be embraced... just build the networks and let people switch over as they get sick of their gas bills.

Use what is abundant and build to last

Offline

Like button can go here

#206 2023-03-02 12:11:10

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,122

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

For Terraformer re #205

Talking here on the forum will accomplish very little. The next step would appear to be for something to happen in the realm of communications with people who might be interested in a project to install a system. Your preference for allowing local folks to buy in or not seems reasonable to me. Someone other than you needs to be brought in, or (it seems to me from this vantage point) that nothing is going to happen.

(th)

Offline

Like button can go here

#207 2023-03-03 08:21:45

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,122

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

For SpaceNut .... the suggestion below came from a post by Calliban in a topic about kitchens on Mars...

It seems to me that some (all?) of this vision might apply to Earth, with adjustments here or there to account for differences in available materials.

One way of keeping the power on during dust storms on Mars would be to have a pit full of hot crushed rock, capped off and pressurised with CO2. The pit would be heated using solar collectors, which would blow pressurised CO2 through the steel tubes of trough collectors. Heat is withdrawn from the hot rock using an oil filled heat exchanger. This transfers heat to an oil-steam heat exchanger, which then raises steam to generate power. The powerplant would operate continuously 24/7. When a dust storm hits and solar intensity goes to zero, the heat exchanger would continue drawing heat out of the hot rock. Steam quality would gradually drop as temperature drops. But the rock pit could be sized to store weeks of power in the form of heat. On Mars, conditions are generally quite dry. Maybe we could use a hill or rocky outcrop as a natural thermal store. The upper regolith would serve as insulation.

(th)

Offline

Like button can go here

#208 2023-03-03 20:50:49

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,780

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

We do have the rocks and we know that CO2 under cryogenic is a great means to gain energy as these are the working media used to store the received or captured concentrated solar.

This is also a do able for mars as well as we can during the night for mars use the days heat store in the rocks to cause the cryogenic co2 to create power during the evening. Once it goes past the turbine it re-cooled by the natural mars nigh time temperature for reuse.

Offline

Like button can go here

#209 2023-03-07 18:38:47

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,122

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

This discussion may already have a baseline post ... if there is one, then this will be a duplicate.

SearchTerm:baseline geothermal technology using water

SearchTerm:geothermal baseline tech using water

https://www.energy.gov/eere/geothermal/ … xt-version

I would be interested in knowing the overall efficiency of this design.

Alternative designs are in play here in the forum.

We have at least two alternative designs, and there may be more.

A leading contender is a concept using Carbon Dioxide as a working fluid instead of water.

An alternative is liquid Nitrogen as the working fluid.

The ideal is a solution that ONLY ships electrons back and forth from the heat source at the bottom of the well.

Solutions that ship massive amounts of material back and forth are not and cannot be, more efficient than an electron or photon shipping system.

Of the liquids under consideration, one will prove to be the most efficient and cost effective in the long run.

The only entry in the sweepstakes right now is water, or it's cousin steam.

How a Geothermal Power Plant Works (Simple) - Text Version

Geothermal Technologies Office

Geothermal Technologies Office How a Geothermal Power Plant Works (Simple) - Text Version

The below is a text version of the animation How a Geothermal Power Plant Works.

This animation is meant to convey in simple terms what happens in the operation of a geothermal power plant. Aspects such as exploration, resource verification, site preparation, construction, geothermal fluid processing, and power conditioning are not shown or described in the interest of simplicity, and so the viewer can more readily grasp the basic operating concepts.

WELLS ARE DRILLED

A production well is drilled into a known geothermal reservoir. Typically, an injection well is also drilled to return used geothermal fluids to the geothermal reservoir. Hot geothermal fluids flow through pipes to a power plant for use in generating electricity.STEAM TURNS THE TURBINE

Hot, pressurized geothermal fluid, or a secondary working fluid, is allowed to expand rapidly and provide rotational or mechanical energy to turn the turbine blades on a shaft.THE TURBINE DRIVES THE ELECTRIC GENERATOR

Rotational energy from the turning turbine shaft is used directly to spin magnets inside a large coil and create electrical current. The turbine and generator are the primary pieces of equipment used to convert geothermal energy to electrical energy.TRANSMISSION - POWER LINES DELIVER ELECTRICITY

Electrical current from the generator is sent to a step-up transformer outside the power plant. Voltage is increased in the transformer and electrical current is transmitted over power lines to homes, buildings, and businesses.

(th)

Offline

Like button can go here

#210 2023-03-07 20:22:18

- Void

- Member

- Registered: 2011-12-29

- Posts: 8,999

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

Well, I have to respond with honesty. I do not like binary sports type decisions. Any number of options may exist for varying circumstances and for various needs.

But don't take offense. It is how I am. It is not how others have to be.

Eavor may use a hydrocarbon with a vapor pressure characteristic that allows boiling at a lower temperature. I continually run into this where I expose something and then I have to come back again and expose it once more.

https://www.eavor.com/

And yes, water is also an option.

But just saying, no anger.

Done

Last edited by Void (2023-03-07 20:28:37)

Is it possible that the root of political science claims is to produce white collar jobs for people who paid for an education and do not want a real job?

Offline

Like button can go here

#211 2023-03-07 21:48:33

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,122

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

For Void ... this topic has reached over 200 posts.... It is entirely possible there are posts that contain descriptions of methods of operating geothermal wells that use liquids other than water. Rather than offer sports metaphors, please simply point us to the posts that show alternatives. The discussion with kbd512 in another topic was about the relative merits of nitrogen and carbon dioxide as alternatives to water. If you are aware of existing geothermal well installations that use liquids other than water to harvest energy, please provide links to them.

Another subplot of the discussion with kbd512 was the question of where to put power generating equipment, Kbd512 is certainly right to argue in favor of a surface installation for power generation equipment, because that is the ONLY place that power generation equipment has ever been installed in the entire history of the human race (to the best of my knowledge). If in your studies of the field, you have found an example otherwise, please provide a link.

I am arguing for installation of power generating equipment as close to the source of thermal energy as possible, to reduce as much as possible the movement of mass from the bottom of the well to the top, and back down again. The ideal installation of a geothermal harvesting would ship electrons or photons up and down the well, and eliminate the movement of mass altogether.

(th)

Offline

Like button can go here

#212 2023-03-07 22:02:58

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,780

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

Of course, we can also have other liquid media types to absorb the heat that is moved away from the source to do work via natural thermal syphoning or by pumping that heat content to do work as in a much lower heat content does not steam. Freon or other hydrocarbon chains can be used, Ammonia are a couple that come to mind for a working fluid.

Heat absorbing is half of a heat exchanger to which the working fluid makes contact within to the source of heat.

You might place a simple coil of pipe inside a can to protect the unit from heat that would be too high in the hole that is made like this.

Offline

Like button can go here

#213 2023-03-08 02:39:10

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,331

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

The ideal is a solution that ONLY ships electrons back and forth from the heat source at the bottom of the well. Solutions that ship massive amounts of material back and forth are not and cannot be, more efficient than an electron or photon shipping system.

That's a quaint assertion that still categorically refuses to deal with HOW "only electrons are shipped", as indicated by the link you provided in Post #209:

How do electrons get "shipped back and forth" (in mass quantities, with voltages and currents usable to all the existing electrical or electronic machinery already built by humans, in ways that don't bring down the rest of the electrical grid from demand exceeding supply or start fires from electrical short circuits or when supply greatly exceeds demand)?

1. To start with, you need an input energy source to generate electricity:

A. All natural sources exploit photonic power the Sun (which includes wind and all plants, and therefore any animals which eat plants or other animals)

B. The heat energy that gravitation creates compacting great masses of materials together in the case of geothermal power

C. Direct gravity in the case of hydroelectric power

D. Energy contained in light or heavy atoms in the case of nuclear power, which have been fused or split, respectively

E. Energy from reactions between energetic materials such as hydrocarbon fuels and Oxygen (another form of low-output heat and light atomic reaction that involves electron shell binding without splitting or fusing any nuclei; a kind of electro-chemical reaction which alters chemical composition of the combustion byproducts- Oxygen is very electro-negative, so it binds to Hydrogen and Carbon after a catalyzing event, such as ignition)

2. You need an electric generator. Apart from hydroelectric which uses gravity, you need a thermal power source that spins said electric generator. There are no "purely electric" electrical power generation systems.

A. Photovoltaics come closest to the definition. Even photovoltaics use a massively inefficient energy conversion that takes advantage of the photoelectric effect in specific band gaps to stimulate current flow in a semiconductor. A semiconductor, by dictionary definition, is a piss-poor electrical conductor.

B. Wind turbines are externally driven heat engines that transform differential heating of the Earth's surface from the Sun (a 1% to 3% efficient conversion) into electrical power.

C. All geothermal and nuclear thermal and solar thermal power plants are classical heat engines. These systems operate on mass flow of a great mass of moving fluid, typically hot gas or steam.

D. All hydroelectric dams are converting movement of a heavy mass of water, driven by gravity, into electrical power. In terms of total cost per total output, hydroelectric is the most overall efficient because it exploits movement of a gravity-driven fluid. There is very little loss of energy since there is not much change in temperature.

E. Anytime heat engines are involved, there is inherent power loss, because that's literally baked into how heat engines create mechanical work output.

3. You need electric conductor wire.

A. You also need electrical insulators around said wire to prevent arcing and sparking between different parts of the electric generating machine or other materials in the environment, like trees.

B. The insulator could be air if the wire is high up off the ground, but in practice it will be plastics on both the supply and demand side.

C. You need voltage step-up and step-down transformers if the energy will travel any great distance between where it's produced and where it's consumed, or whenever the load is not matched to the supply (almost all cases in the real world).

D. You need electronic control systems that can near-instantly ramp-up (implies increased capacity of the heat engine that's actually supplying the input power) and ramp-down the power (or shunt it to ground) to avoid frying electrical or electronic devices attached to the grid.

E. Electrical conductor wire materials (Copper and Aluminum) and insulators other than air or vacuum (high grade plastics and rubbers or ceramics) are some of the most energy-intensive materials known to man. The insulators are exceptionally difficult to recycle, they're bonded to the electrical conductors, and to recycle an electrical or especially an electronic machine, you must first separate all of these materials which have been permanently bonded to each other, at great labor and energy cost- often far greater than what it took to build the machine to begin with for near-complete recovery of materials.

F. Many of the materials used in electrical or electronic machines are very scarce and very expensive, so when you try to scale up this electric everything idea up to a global level, it immediately smacks into material supply constraints.

4. You need a plethora of ancillary electrical or electronic devices to direct or redirect the flow of electrons through the conductor wires, almost instantly to avoid dropping loads since electricity operates near the speed of light, after electricity is generated.

A. All of these devices, because they use electrical conductors which all have non-zero resistance values, unless they're superconductors, also have some measure of electrical resistance.

B. If electricity was so efficient, then why are there so many giant fans running at every single step-up or step-down station in existence? The short answer is that it's not. After the electrical power is generated, we lose 10% to 25% of that somewhere in the overall conversion process that consumes it to do something humans find useful. If the electrical power was generated by a heat engine of some kind, as almost all of it is, then we have a cumulative loss of around 60%, minimum. If it was generated by photovoltaics, then 85% loss, minimum. On top of that loss, we then convert about 75% of the remaining electrical power back into heat at the point of end use... All that trouble and expense, merely to do another energy conversion from electricity into thermal power.

C. This has MAJOR implications for the quantity of equipment required, total mass of all embedded materials and their energy cost, plus the cost of eventually recycling those materials because the supply is finite and scarce for many of them (anything using rare Earths or precious metals or electrical conductors, for example).

D. The electricity itself is not the problem. The major problem is everything else required to use electricity. In other words, there are "total energy system" design implications. If you need a tens of millions of 2MW windmills to assure there is always wind energy input somewhere, then the materials to do that is astronomically high, relative to what we actually produce every year. Each windmill has a power cable as thick as your leg to reduce electrical resistance losses, we'd need more Copper than all the world's known reserves just for them and all the new power transformers required to handle gigawatt power surges, not for the rest of the electrical devices uses the power, and we don't have an acceptable substitute for Copper.

We can substitute Aluminum for fixed conductors, things like bus bars that require no ductility, but the moment you start wrapping Aluminum around an Iron core, you start work-hardening the metal. This applies to all metals, not just Aluminum, but Aluminum alloy is nowhere near as ductile as Copper. Aluminum is much lighter than Copper for a given ampacity (50% better than Copper per unit weight, in fact), which is great, but the further you move a conductor away from a magnetic field, the less powerful / capable the motor or generator or transformer (Aluminum is 1.6X the volume of Copper for equal electrical resistance), or it has to become much bigger, and then the casing outweighs the internal components by a lot (the casing will be Aluminum or steel). This is the "blow harder" approach that people take who don't understand the implications of "blow harder".

Total global energy consumption (all kinds), is 19.4TW (every second of every minute of every hour of every day).

19,400,000,000,000 Watts of power <-- This is what humanity presently uses at all times

3MW onshore wind turbine, according to Copper Development Association Inc:

54% of Copper in power cables

24% in the electric generator

19% in the turbine transformer

4% in ancillary transformers for power electronics / motors

6,466,667 <-- This is how many 3MW onshore wind turbines we'd need if all of them produced 100% output at all times

30,393,335 <-- This is how many tons of Copper we'd need, just for the wind turbines

22,000,000 <-- This is how many tons of Copper we produced in 2022 (the most we've ever made in 1 year)

19,400,001 <-- This is how many we'd need at average capacity factor (they produce output about 33% of the time)

91,180,005 <-- This is how many tons of Copper we'd actually need

EV cars use 83kg of Copper. EV buses use 369kg of Copper.

124,500,000 <-- This is how many tons of Copper we'd need for the EVs based upon average per-EV Copper consumption.

Tesla alone consumes 45,000t of Copper each year.

So, between the passenger EVs and wind turbines, we've spoken for the world's entire Copper production capacity for 10 years, for the devices themselves, but absolutely nothing else required to actually use them. We mined 700,000,000t of Copper over 6,000 years. Now you want 1/7th of that total production in 10 years. It's doable with enough money and labor (which we don't have), but then you won't be able to buy any electronics gadget for the next 10 years, or you'll pay insane prices for something like the USB cable that attaches your iPhone to the wall charger.

How does $100 to $200 for a cell phone power cable sound to you?

How about someone putting a gun to your head to steal your extension cords you use to do yard work, which might cost $1,000 with the massive demand increase?

The market will respond to increase supply, right? More metaphysical woo woo.

If you add in all the devices to actually use the cars and wind turbines, now we're talking about all the known Copper reserves on the entire planet. Absolutely everything we actually know about, regardless of whether or not there's a mine established to extract it.

After we build all these wind turbines and EVs and the world can't use 1 lousy kilo of Copper for ANY OTHER PURPOSE for 10 years, which would be all the electrical machines that contain Copper, we then have to build an electric grid that can handle power surges measured in GIGAWATTS! Think we might need to build some additional power transformers to do that? What do all of those contain? Oh, that's right... More Copper. More Aluminum. More steel. More mineral oil (22kV/cm for air as the insulator vs 240kV/cm for mineral oil).

We can't recycle any of that Copper because we need to extract it to begin with. We can recycle more of the Aluminum, so that's a better proposition.

5. All devices that consume the electricity to bake bread, run the equipment that grinds the wheat into flour for baking bread, or harvests the wheat from the fields, also need to be electrical or electronic, in order to take advantage of everything we just converted electricity. Where's all the metal for those coming from? That's where we run into real trouble.

Electricity appears superficially efficient IF AND ONLY IF you utterly ignore all other implications of making every energy generating and storage system electrical / electronic. This is what you and so many other people do. You latch onto one aspect of an idea (that electricity is efficient at moving power) with no regard given to every other implication or aspect of the assertion.

Our society is not only energy-blind, it's also minerals blind and materials blind. - Professor Simon Michaux, Doctor of Science in Mining and Physics

What is Professor Michaux telling us?

We fail to consider all the other implications of our blanket statements, like "shipping electrons back and forth is the most efficient process". That singular process may be very efficient relative to alternatives. What about everything required to use it at a global scale? How "efficient" is all of that?

A Lithium-ion battery is very efficient, too. Earth moving equipment has to move 500,000 pounds of material to make each one of them.

500,000 pounds per 100kW battery * 1,500,000,000 cars that are not EVs = 750,000,000,000,000 pounds of material moved or processed

340 billion metric tons of materials need to be moved, just to make the stupid batteries for these EV cars. That'll be real efficient to do, won't it?

BTW, between the mining of the Copper and materials to make the batteries, we will entirely erase any CO2 reduction benefits for at least 20 years. The cars and wind turbines only last for 20 years. If you can't figure out the rest, then I guess you can't. We could make Lithium-ion batteries for all the mining equipment, or all the farming tractors and trucks, but then we'd have none left for all the Teslas. In short, we'll still be burning gasoline and diesel like it's going out of style.

To visualize just how ridiculous the notion of making all vehicles electric is becoming:

We just keep diving deeper and deeper and deeper into this futurism fantasy. We're investing 1/2 of the dollars into mining capacity that we invested 10 years ago, and 1/3rd into petroleum production to power all the diesel machines that go get your Copper, Aluminum, Iron, and everything else you need to support your electric futurism fantasies.

Some of us, probably most of us, are energy-blind, minerals-blind, and materials-blind.

If we want something, we'll "just go out and get it", won't we?

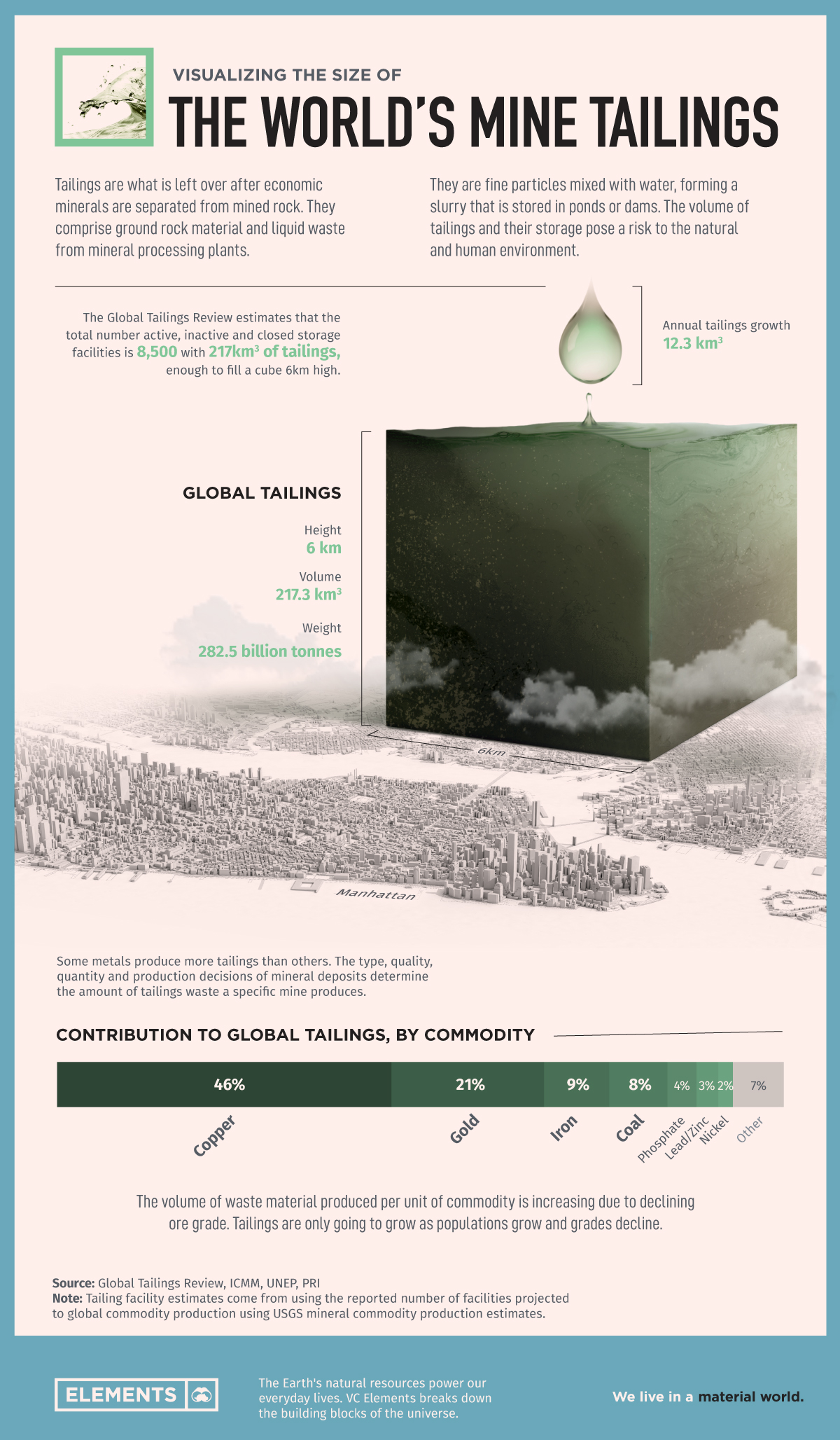

Notice how little Iron mining contributes to total mining waste, yet Iron is the most mass-produced metal on the planet by a huge margin.

Copper, on the other hand, contributes almost 50% of all the mining waste / tailings.

Aluminum, which is exceptionally easy to get in raw ore form, still consumes inordinately more energy than Iron or Copper. That's how damn hard it is to turn Alumina Oxide into Aluminum metal.

After seeing that photo, can you understand why I said we'd need to turn the planet into a giant strip mine to make everything electric?

Offline

Like button can go here

#214 2023-03-08 03:58:16

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,331

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

When I speak about energy efficiency, I speak in terms of efficiency of the overall "big picture" process of making and using energy. We have some people who claim they want to quit burning hydrocarbon fuels. I think they're unable to accept why we use them. It's a question of extreme abundance and ease of use. Gasoline is great because it's produced in staggering quantities, it packs a wallop per unit weight only met or exceeded by nuclear processes, it's easy to store, and if we make the machinery to synthesize it, the recycling potential is endless.

The electric everything crowd can't wrap their heads around the implications of their beliefs. The machines they want to build are a mish-mash of dissimilar but difficult to separate (after initial manufacturing) materials. Either the numbers are too big for them to truly comprehend or they think magic will happen. Well, engineering is not magic and no new electric technology except computing power, which has no affect on the energy density of energetic materials, has meaningfully changed the numbers involved.

I will readily admit that air and water look "inefficient" compared to moving electricity, because the energy density is so low. The exact same energy density issue applies equally to all batteries, except that all the energy and materials to make batteries must be supplied up-front, it has to work reliably for many years, and then it has to be recycled at some point because the metals used are scarce. The amount of metal present is a tiny fraction of the amount of air and water present.

The difference comes down to what's required to convert air and water into mechanical horsepower versus electricity. The electric alternative future requires that we turn planet Earth into a toxic waste dump trying to extract all that Copper and Aluminum ore. We're already doing a bang-up job of that. The leftovers from both processes contain some very nasty stuff. The stuff that comes from rare earths mining might actually spawn some teenage mutant ninja turtles at some point.

Aluminum processing:

The majority of aluminium fluoride is produced by treating alumina with hydrogen fluoride at 700 °C: Hexafluorosilicic acid may also be used make aluminum fluoride. Alternatively, it is manufactured by thermal decomposition of ammonium hexafluoroaluminate.

Copper mining process:

Open pit mining is a technique used to extract copper ore near the earth's surface. Open pit mining is the most widely used technique of mining copper today. It is accomplished by creating and using benches or terraces to gradually reach deeper under the earth's surface.

Copper processing:

The leaching reagent (dilute sulfuric acid) is sprayed through sprinklers on top of the heap pile and allowed to trickle down through the heap, where it dissolves the copper from the ore. The resulting “pregnant” leach solution of sulfuric acid and copper sulfate is collected in a small pool.

Sulfide-ore copper mining has the potential to release numerous chemicals known to negatively affect human health, including mercury, arsenic, lead, asbestos-like fibers, and air pollution.

Chemicals are used to leach the mineral out of ore, and exposed water is forever contaminated.

We wind up with more plastic from wind turbine blades in the environment than all the silly plastic shopping bags could ever hope to accomplish.

Using air and water, we finally stop burning fuel for most forms of land transport. Air transport doesn't work without burning something.

If we try to "go electric", then we just signed ourselves up for a toxic waste dump of a planet, burning hydrocarbon fuels forever, unless all those mining machines are dragging giant Copper power cables behind them.

Where does 46% of all minings tailings come from?

Mining for Copper.

What are all mining machines powered by?

Diesel.

Why are they diesel powered?

If not, then the entire machine becomes a giant fuel tank, just like a rocket. The same would apply to powering them using air and water, with the notable exception that the only materials being consumed and then immediately returned to the environment, are still air and water.

Making steel from Iron ore produces just 9% of the total tailings waste from all mining activity, despite accounting for nearly all of the total metals production.

Why is Iron mining so much easier and so much cleaner?

All that bright red stuff you see everywhere is better known as "Iron ore". Notice that the stuff is literally everywhere. It's all Iron ore. You can throw a rock in any direction and hit the Iron ore.

It's the same reason we used coal, gas, and oil. There's so much more Carbon than there is Lithium or Lead. When the Earth was formed, no questions were asked of our non-existent green energy / electric everything people about what the correct Carbon-to-Lithium ratio would be to support their futurism fantasies. The Earth came into existence with a lot more Iron and Aluminum than Lithium or Lead. Whether or not you like that simple fact of life is irrelevant to reality. Blowing harder isn't a solution. It's a refusal to admit to reality because something doesn't work well enough to be to your liking.

Offline

Like button can go here

#215 2023-03-08 05:27:17

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,236

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

Kbd512, some really excellent posts regarding the electronic insanity that we seem to be heading into. I will respond in more detail after work.

If human beings were really sensible creatures, with long term joined up thinking, we would do things differently to the way we do. We would look at material resource constraints and come up with sustainable ways of meeting human needs. One way we can do that is to examine how energy is used in meeting needs. We can then look at what nature provides and develop solutions that work around limitations.

Human society uses energy in various forms. We use lots of heat in many different ways. We use cold heat, in refrigeration and cryogenics. We use low heat (<100°C) for wash water, clothes washing, space heating and even some cooking. We use intermediate heat (100-300°C) for baking and some industrial processes like melting polymers. High heat, (>300°C) becomes important in industrial processes, such as sintering, melting metals and reducing oxides. Turning materials into finished products almost always involves high heat at some point in the process. We need pure mechanical power in all sorts of situations. Pumping, mining, machining and processing materials needs mechanical power. Moving anything requires mechanical power. We also need chemical energy or energy dense chemicals as feedstocks to various processes. If you want to reduce iron ore to crude metallic iron, heating it isn't enough. A reducing chemical is needed that reactes with iron oxide, carries away the oxygen and reduces the oxidation state. That means a reducing gas, like CO, methane or hydrogen, that must pass through the hot ore. Finally, humans need food energy, which must also provide nutrition.

Taking the long term view, we should be looking at sustainable ways of meeting these human needs, allowing reasonably affluent lifestyles, without exhausting what nature can provide on this lonely ball of rock.

Talking very generally, nature provides us with a certain amount of ambient energy, in the form of sunshine, winter cold, wind, waves, tides, falling water, etc. These energy source tend to be intermittent both on a seasonal and daily basis, low in power density and not evenly distributed over Earth surface. These problems have consequences in terms of how we can use these energy sources productively to meet our needs. We will talk about them one at a time.

1. Low power density is exactly why wind and solar PV have such monstrous material requirements. The amount of equipment we need per unit of average power is high. So for each unit of energy harvested by these systems, embodied energy and materials requirements are high. This can be illustrated by way of comparison. A pressurised water reactor core will generate about 80MWth of power per cubic metre. Sunlight by comparison, has a peak intensity of 1kW/m2 and average flux is much lower. If wind is blowing at 10m/s (22mph), then the kinetic energy of the air moving through a wind turbine, is 60W/m2 of swept area. And the turbine will extract maybe a third of that. In terms of raw power density, wind and sunlight are about a million times weaker per unit area than a nuclear reactor. So of course the embodied material and energy of systems that harvest these energy sources will be much greater.

2. Intermittency can be both seasonal and daily. Wind and wave power produce much greater output in autumn, winter and early spring. Solar power is prevelant in the summer. In places like the UK, the sky is heavily overcast a high percentage of time and almost all of the time during winter. In many places, it will only be possible to raise high heat from the sun for limited periods at certain times of year. Tidal power produces energy in sinusoidal cycles. But tides are stronger at different times of year. Winter cold is also a resource if we desire low temperatures. In the UK, with its marine climate, it is now unusual for temperatures to drop beneath freezing for very long. It rarely gets very hot and rarely gets too cold. But on the Eurasian continent, there are larger temperature swings. Practically all of North America experiences larger annual temperature swings than the UK.

3. Location is also a limiting factor with ambient energy. This seems obvious, but it is amazing how frequently it is ignored by green tech obsessives. A wind turbine built of the English or Scottish coast, will be tapping into a much stronger resource than the same machine built in Germany. Tidal barrage power requires locations with good tidal range. Tidal streams flow through choke points, where tides stream through narrow sea straights between land. Solar flux varies greatly between different locations on Earth. Also, cloud cover complicates the situation further. Solar flux in the UK, is much weaker than in California. And a greater portion of flux is diffuse, having passed through clouds. Geothermal energy potential is critically dependant on local geology. Location can be important locally as well. Ideally, you wouldn't put up a wind turbine in the middle of town. If you live in the northern hemisphere, a solar collector needs to be south facing or on a south facing sloped roof. To use wave power, you need to be on a coast and preferably onnthe Atlantic coast in Europe.

These limitations are not negotiable. They are imposed by nature and humans must work within them. The characteristics of these energy sources mean that using them sensibly to meet human needs requires that we work within their limitations. It also means that the solutions applicable to one location, will different to those that would work in another part of the world. So what can we deduce from these facts in terms of what they mean for meeting human needs?

1. Low power density. There are really three things we can do that mitigate this problem.

Firstly, the systems that tap into a low power density resource should have low embodied energy. If you are intercepting sunlight with an average flux of 100W/m2, then the systems that intercept it should have low embodied energy per square metre and should be made from cheap (and energy cheap) materials. Easily recyclable materials are a way of doing this as well. Natural materials that don't require much processing have lower embodied energy than highly refined synthetic materials. In this way, you shorten the energy payback time of the system. Solar PV is terrible from this perspective. But low grade heat that enters a house through a window or greenhouse, is much better. A really simple system, that intercepts solar flux using a slab of concrete or stone to soak up low temperature heat, is even better. Simple systems are better than complex systems, because complexity has its own embodied energy and labour costs.

Secondly, longer lived systems have better EROI than short lived systems. This is in some ways obvious, but modern green tech pays no respect to it at all. The North Sea is full of wind turbines whose towers will need replacing in 20 years due to fatigue and salt water corrosion. The blades will need replacement in 10-15 years. Gear boxes are comparable. Solar PV plants have a 20 year name plate life expectancy. This means that all of this infrastructure must be demolished once every generation and replaced. Only part of the huge embodied materials will be recyclable. The low life expectancy and poor recyclability of modern green tech aggrevates its enormous refined metal requirements. Compare this to a late victorian greenhouse. It was built adjoining a property some 130 years ago. It's structure is cast iron and float glass. With occasional maintenance, it has provided space heating, food and extra habitation space to a house for 130 years. It will continue to do so for another century if the residents bother to maintain it. There are still working wind mills that were built centuries ago. They were made using brick or stone for their towers. Moving parts were wooden, with cast iron or steel used for gearing. These structures were built to last. Although they are not as optimised or efficient as modern machines, the EROI of a windmill that is maintained continuously for centuries, will be high. You invest energy and labour building the greenhouse or windmill once, and your grandchildren will still be using it.

Thirdly, we avoid unnecessary energy transitions. This reduces energy losses and also allows lower embodied energy and simpler machines. Solar power arrives as diffuse heat. We need low heat for space heating, water heating and cooking. Windows or simple, flat plate panels can be very efficient at gathering heat at low temperatures. They can be cooled by air or water. If we are gathering summer heat for space heating or water heating immiediately or at a later date, the only energy transition needed is sunlight to heat, carried away by air or hot water. Intermediate level heat can be gathered by concentrating sunlight. This may be more complicated. We could have purely mechanical systems, where an operator manually adjusts trough or dish solar collectors to aim them at the sun. This would involve winches and gearing. If we had a large facility, that might even be practical to do. But electronics and electric motors would be more cost effective in most applications. Where we gather concentrated solar heat, the systems involved are simpler if there are no energy transitions. If we are melting polymers at 150°C, then trough solar collectors can transfer heat to the melting vessel using pipework containing hot oil. Some high heat can be solar based as well. Dish collectors in high sun parts of the planet, can reach temperatures of up to 1000°C. This is high enough to reduce iron ore, provided we introduce a reducing gas.

Where we need mechanical power, we have a number of options. If a region has good wind power, then a vertical axis or horizontal axis wind machine can provide direct mechanical power via a rotating shaft. Victorian era factories would drive machines using belts, that drew power from a line shaft running down the workshop. We could build fractories in this way once again. Modern machines could draw power from a shaft using a clutch system, with gears to adjust speed. This would avoid the maintenance burden of belts. The shaft could even pass through a covered trench under the floor. Hydraulics may be a more elegant solution and it allows more flexibility in factory floor layout. The shaft of our wind machine is coupled to a centrifugal pump which pumps water or hydraulic oil. Hydraulic lines run along the ceiling or in trenches under the floor, with individual machines attached to the main by flexibles and driven by hydraulic motors. Wind power can be used to pump water using very simple machines with just a few moving parts. These can be made from wood, stone and carbon steels. Freight can be carried in unmanned barges floating through through pipes and ditches, at 1-2× human walking speed, simply by pumping water through them using directly coupled wind power. Solar power can raise mechanical power by heating water and raising steam. Turbines can convert power to mechanical energy. If waste heat is being used as well, efficiency is less important and low pressure, low temperature steam systems can produce direct mechanical power in the kW to MW range.

More later.

Last edited by Calliban (2023-03-08 08:07:00)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#216 2023-03-08 08:59:38

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,236

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

Continued.

2. Intermittency. This problem is particularly difficult in relation to modern electricity networks, because supply must meet demand on a second by second basis, or frequency swings will destabilise the entire grid. The conventional answers to this are grid energy storage (which buffers supply) and 'Internet of Things' which allows some aspects of demand to be controlled. But these solutions exacebate all of the complexity problems that we have been discussing here. Grid energy storage requires that primary energy be stored in some way (batteries, compressed air, pumped storage, liquid air, heat, etc) and is then converted back into electric power when demand exceeds supply. We already use energy storage to a limited extent, but an energy store is essentially a power station that sucks in electricity or mechanical power when in abundance and spitts out electricity or mechanical power when power production cannot meet demand. Storage of energy always involves losses. So more primary energy production is needed to cover the losses. And the energy store must be manufactured and represents an embodied energy and materials demand. The capital and operating costs of that extra energy production, add to the capital and operating costs of the storage system which are also added on top of the capital and operating costs of the primary renewable energy system itself. The alternative is to build a fossil fuel burning powerplant and run it when the renewable energy system is not producing enough power. Either way, you have two sets of operating, maintenance and capital costs to pay. There are also additional transmission costs, because renewable energy is usually gathered from remote locations. This is why countries with high proportions of renewable energy in their electricity mix have high power bills.

Internet of things is a way of controlling demand by switching off some appliances when power production from a renewable source drops below typical baseload requirements. But this poses a complexity nightmare, in which a grid operator must control millions of individual appliances using a web connection. That means appliances must contain computers. There must also be provisions to prevent hackers from sabotaging the system. This aggrevates the problem of growing complexity and increases the amount of electronic waste.

I think there are a number of possible solutions here. One option is simply to take as many energy consuming activities as possible off of the electric grid. If we need hot water to fill a washing machine, then stored hot water from the house supply could be used. It doesn't need to be electrically heated. Mechanical functions can be met using mechanical power harnessed locally, without conversion into electricity. This would require new ways of doing things. Before the 1980s, most houses in the UK did not have washing machines. Most towns had laundrettes where people took their clothes once per week to be washed. We could return to that arrangement. A town could pool its resources and build a laundrette for clothes washing. The laundrette would need a lot of hot water and mechanical power to wash the clothes. We could build an interseasonal hot water store to provide the hot water needed, with solar heating panels gathering summer heat. We could build a mechanical wind mill out of local stone. The laundry machines would occupy the floor space on different levels within the wind mill and would draw mechanical power directly from the rotating shaft. No electricity needed. The materials used would be stone, wood and steel.

Refrigeration can be provided using direct mechanical power as well, as it is a mechanically driven process. A small wind turbine made from wood or wood and stone, could be used to power a simple, single piston air compressor, by coupling the rotating shaft to a crank, which raises and lowers the piston rod. As the air compresses it gets hot, hot enough in fact to produce hotwater or even to heat an oven. When air expands adiabatically, internal thermal energy is converted into mechanical work and it gets cold. The compressed air can be used to raise mechanical power and at the same time, produce cold air that can cool or even freeze food. An individual house could build a small wind turbine that provides the heat needed for hot water, the cold needed for refrigeration and some mechanical power for internal appliances. But the system would work best on a community level, because heat stores more efficiently as scale increases. A community freezer could be a small insulated building, but would be most efficient if built underground. Individuals would go there to get the refrigerated food they needed that day and store it in a simple pantry.

Heat storage is more efficient in large containers, because larger containers have less surface area per unit volume. A town of village could build a community hot water tank and use summer heat to produce hotwater that is stored year round. A bath house could be attached to the store. If the store is large enough and sufficiently well insulated, very simple flat plate solar collectors could be used to gather enough heat using summer sun. The same could theoretically work for winter cold. Before mechanical refrigerators, wealthy houses would build ice pits allowing winter ice to be stored for use through the summer. Insulation was provided by the dirt. We could build cold stores on a town level. Winter cold air could be blown through the store when outside temperatures dropped beneath freezing. Cold would be stored in ice and surrounding soil would provide insulation. Storing interseasonal heat like this, only works at scale. But this is a way of keeping food cold without any electricity and with only the minimum of energy of any kind.

Cooking is something that can use stored heat. Meat and vegetables will slow cook at temperatures as low as 60°C, but 70°C is usually recommended as a safe minimum. Baking requires temperatures of at least 121°C to allow caramelisation reactions. These temperatures are low enough that they can be achieved using concentrated solar heat. Houses could cook with small solar concentrators in summer months. But solar heating works best if heat can be stored and this works better at scale. At the community level, cooking heat can be stored in insulated rock or water masses. Boreholes provide another potential option. Restaurants and food manufacturers could use stored heat for cooking. At the level of the individual house this could also work, but is more difficult because thermal losses impose the need for thick insulation. But we could use a mechanical wind turbine or solar concentrator to heat a well insulated oven. No electricity required.

In Britain, the wind provides electricity and could be used to produce mechanical power directly. Factories could be powered by wind using line shafts or hydraulics to drive individual machines. Little to no direct electricity needed. The factory and all its machines, would be dominated by stone, brick, wood and steels. No need for copper, unless we use phosphor bronze bearings. But the wind doesn't blow all of the time. How do we deal with that? The technically easiest way is to adjust work loads according to wind availability. During windy times, all machines in the factory would be working and people would work 12 hour shifts. When wind levels are lower, they would work 6-8 hour shifts. And during summer months with low wind levels, they would take more time off. To balance production with demand levels, the factory would keep higher inventories of finished goods and feedstocks than woukd be considered typical today.

Wind power and solar thermal power could be used to power transportation as well. The green tech enthusiasts usually talk about hydrogen in this context. But hydrogen is a weak contender as a transportation fuel. It is volumous and producing it is wasteful of electricity, with most being lost as heat. The electrolyser also has high capital cost. Wind could power transportation directly. Historically sailing ships were the most common means of transporting goods. Wind can also drive ropeways. This is a slow, but energy efficient option for transporting goods over land. Buckets containing freight are carried by a rope that moves over pulleys attached to pylons. Wind turbines can power these pulleys using directly coupled shaft power. The rotating shaft of the turbine would drive the pulleys through bevel gears. Wind can also be used to pump water, which can carry floating barges through pipes and ditches at low speeds. This is slow compared to road or even rail. But it is an extremely simple system that uses the wind to pump water, without electricity and using only a few moving parts. Wind turbine along the pipelines or ditches would provide pumped fliw that is proportional to wind speed. They would be made from stone or brick towers, with wooden blades and nacelles, with a steel hub, shaft, gears and simple directly coupled hydraulic pump. Wind and solar thermal power can be used to power vehicles using liquefied air, stored heat and compressed air. Ships and freight trains could be powered in this way. Some smaller vehicles would be powered in this way as well.

Beyond de-electrification, we could use wind and solar power to power a scaled down electrical grid, providing perhaps half as much electric power aswe use now. We would use thermal storage and compressed air to manage intermittency. Liquefied air provides a way of storing mechanical power in a cryogenic liquid that can be stored in underground tanks for long periods if neccesary. It can be produced using compressors that are coupled to wind turbine shafts or solar thermal steam turbines, without the need to produce electricity. Stored solar heat can then be used to evaporate it and raise mechanical power on demand. Undersea compressed air storage also stores mechanical energy efficiently. Energy can be stored as heat in hot rock and used to raise steam to drive turbines. This would be 40% efficient at best, but its low capital cost and simplicity make it attractive if we can productively use the low grade heat from the steam condenser. We could build these thermal store steam generators outside towns with district heating networks.

Electricity generating wind turbines would be built on land and their towers would be compressive structures made from brick or stone. These turbines would be built in clusters or along lines. Dozens of individual turbines would transmit mechanical power to a single ground level generator that would be grid connected. This could be done by having a common rotating steel shaft within a trench, that all of the turbines along a line transfer mechanical power to. The rotating shaft then turns an alternator within a power house at the end of the trench line. Alternatively, turbines could each drive a hydraulic pump, with the combined pumped flow from all of the turbines driving a single large alternator via a hydraulic motor within a ground level power house.

It is popular these days to assume that electricity will be used to power cars using advanced batteries. Capital cost of vehicles, charging infrastructure, power transmission and extra generating capacity, all make this highly unlikely. The enormous and unsuppirtable resource requirements of an EV road vehicle revolution, appear to make it physically impossible as anything more than a part solution, if at all. However, electricity has met a large share of transportation needs in many countries for over a hundred years. It has done this by powering fixed bed, rail based transportation. Underground systems, mainline and suburban trains and tram systems, are the real but unsung electrical transportation revolution that is proven to work. They draw power directly from the grid as they use it, through overhead cables and third rails. If a transition to electric transportation is what we want to achieve, this is how to achieve it at cost that we can afford, both financially and environmentally. It the long run, we should aim to reconfigure our living arrangements to allow rail to meet all of our high speed, long distance transportation needs. This could be done using a small fraction of our existing electricity consumption, because of the extremely high efficiency of rail as a mode and the high efficiency of electric motors drawing power directly from the grid.

Last edited by Calliban (2023-03-08 11:38:04)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#217 2023-03-08 12:07:43

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,236

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

(3) Location. There are two places you should never build a wind turbine - (1) the Moon and (2) Germany :-)

It seems blatantly obvious that you shouldn't build wind turbines where there is little wind, or solar farms where there is little sunlight. You cannot build a hydro plant if you don't have a river. This seems obvious, but this unfortunate fact of life has been entirely forgotten by the green tech crowd. The problem with this group of people, is that tend to be politicos and cause junkies. They are dominated by ideological types; the trashy rejects of the political left. And they think that every problem can solved by campaigns, propaganda and ideological purity of heart. But mother nature is infuriatingly resistant to propaganda. The laws of physics are stubbonly unchangeable in the face of even the best PR campaign. You can apply corporate pressure to oil companies and make it impossible for them to develop new reserves. You can force them to pour money into wind and solar projects. But these resources don't get easier to use just because people are forced to use them. And the fact is that some locations have ambient energy resources that are exploitable, whilst others don't.

In Britain, Ireland, the Netherlands, Portugal, Greenland, Iceland, Denmark and parts of the US, there are wind power resources that could be exploited to generate mechanical and electrical power. Britain, Ireland and Norway, also have wave power resources that are untapped. In these locations, wind power could drive entire economies, within limitations. But for most of these, solar power potential is beyond crap. The US has plenty of wind and solar potential, but not always in the same places. Portugal and Spain have plenty of both forms of energy. Britain has reasonable tidal power potential, but is one of the few countries that does. North Africa has good solar potential and some wind. Parts of South America have the best solar potential of all. Rather than attempt to store this energy and ship it around, it would make sense using it where it is available. We could use concentrated sunlight in sunny places and put the industries that need high heat in those places. Places like Britain could have an edge where the energy inputs are mostly mechanical. But the point is that in a renewable energy world, we must tailor our energy solutions to the specific location.

Places that experience winter cold, can build underground freezers that store winter cold without needing heat pumps. In Britain and Netherlands, wind power can be used to keep those stores cold, as outside temperatures don't get cold enough. In many parts of the world, solar thermal plants could generate all grade of heat, electricity and mechanical power. In Britain, solar power is less viable and would be limited to low and perhaps intermediate grade heat. Mechanical power and electricity could come from wind, wave and tides. Some countries have geothermal reserves that can generate high heat and steam. In Britain, geothermal will be limited to warm water.

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#218 2023-03-08 12:25:22

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,331

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

If we think we're going to transition from hydrocarbon fuels to renewable / sustainable anything, then it's going to be based upon air, water, wood, rock, and steel. It won't be Copper, Lithium, and Sodium. If you look at the infographic I posted in Post #213, you can see that mining for Copper / Gold / Coal, accounts for 75% of all mining inputs and therefore energy, and this is what has to expand by orders of magnitude in order to electrify everything. If these people who claim they want to "save the planet", using truly want a renewable / sustainable energy system, then it's high time they quit "getting high on someone else's supply" and have their "Come to Jesus" moment, regarding the implications of their sophomoric thinking. Their beliefs are energy-blind, minerals-blind, and materials-blind. We're going to wreck the environment with toxic mining and electronics waste, which will only come from expanding mining by 1,000% or more, and somehow that's going to "save the planet". What a crock. These people haven't done the most cursory analysis to understand the implications of their behavior. Now that actual intellectuals are scoping and framing the nature of the nature of the problem, all the flaws in the pie-in-the-sky thinking are coming to the forefront.

The learning curve associated with this new energy system is going to look like the transition from street level to the top of the Burj Khalifa. I already know we're not prepared. All the expensive diversionary work on electronics and batteries has left us ill-prepared to develop the kinds of energy systems that can actually work at the scale required, which is staggering. This undertaking will be monumentally expensive, even with the kinds of low-cost / low-technology solutions I've proposed. The only real benefit is that it's minimally workable without immediately running into supply constraints.

So... Don't look up, all you futurism fantasy believers, or you might get dizzy and keel over. I wish these people well in their impossible quest to electrify everything, but they're all going to find out the hard way that it's not workable at anything close to the scale required. When they realize they've been sold a bill of goods that doesn't match what they actually received, they're going to panic first, go into denial if they haven't already, then they're going to get really angry, and finally they will learn to accept the limits of energy and materials and technology.

I have provided my warning order to the electronics fetishists as best as I know how. I knew something was deeply flawed with what we were doing, it just took me a long time to figure out what was wrong, given the fact that I had no prior knowledge. Basically, I learned a lot over enough time. I'm not an expert, but to read off numbers from geological surveys and production reports, I don't have to be. I am still an expert bean counter. I have been honest and forthright with these people. I am sincere in wanting to find a solution that actually works at the scale required, in the manner in which they wish to proceed. Their chief demand is that we not burning anything for energy, given how much of that we're presently doing. I have no real bone to pick with at this point, but it has serious and massive implications for what can serve as a workable replacement. I have touched on what workable solutions will look like (not exact solutions, which is something that people who can't generalize latch onto), I shown that no math is violated, no material constraints exist which would preclude building and operating them at the scale required, and we presently have the manufacturing base to make the kinds of machines required for an actual transition away from burning things as our primary go-to source of energy. Whether or not we have the will to move past unworkable electric / electronic solutions is another matter entirely.

Things are going to get really ugly before they get better, but eventually we will learn. I wager that we're going to have a lot of honors graduates from the School of Hard Knocks. I think most people will learn, as it becomes increasingly obvious that they can't do this the way they thought they could. I initially thought it was an impossible task to replace hydrocarbon fuels, which is why I thought the proposition was ludicrous. It turns out not to be. It turns out that you have to be very shrewd about which technologies you apply to a specific problem or problem domain. When you strip away needless complexity, drop unworkable ideas, and move past the sunk cost fallacies, you arrive at workable solutions that are affordable but still not cheap. It's a paradigm shift in how things are presently done. We operate on planned obsolescence. That won't work in the near future. The longer we delay, the more painful the transition will become. We should've started this process about 50 years ago, because we had the technology to make it work 100 years ago. There is no longer any easy way out of this predicament. Sacrifices will be made.

Anyway, that nicely sums up where we're headed to if this sustainable future plan has any chance of actually working.

Offline

Like button can go here

#219 2023-03-08 13:57:11

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,988

- Website

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

Archdruid Greer thinks northwestern europe will sink back into being a poor backwater once the oil and coal runs out.

With respect to him, I think he's forgetting about the advances of the 12th century. We may not have the vast fertile soils of China and India to support a civilisation, but we've had windmills for going on 900 years. We don't need vast amounts of human muscle power to be wealthy if we can tap vast (compared to human muscle, not compared to current usage) amounts of wind and water power.

Coal was discovered before the Industrial Revolution (in textiles) even began, so we never got to see what Britain without fossil fuels might have looked like. But it's possible to imagine an indefinitely sustainable island that uses water transport via the coast rivers and canals, powers industry off wind, and heats homes with summer sun. The oldest parts of the Chinese Grand Canal are pushing two and a half millennia; it's not implausible for Britain to one day have windmills that old, if they're built well.

Of course, I'd rather *not* drop back technologically to 1800. Even so, a canalpunk future for Britain is a *lot* better than the medieaval-at-best apocalypses we're usually given.

Use what is abundant and build to last

Offline

Like button can go here

#220 2023-03-08 15:49:56

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,331

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

Terraformer,

You didn't get to see what Britain looks like without hydrocarbon fuels because fire is the first thing that humans discovered, but your ancestors did. Your history books go back quite some ways. It wouldn't hurt to read some of their descriptions of daily life. They hunted whales and burned down nearly every tree in Britain for firewood. Since that wasn't sustainable back then, with a fraction of Britain's present population, you'd better get busy building things that last longer than 20 years.

The UK has 281 people for every square kilometer of land on the island, which equates to a patch of land about 60m by 60m for every person there. The US has a patch of land about 157m by 157m per person, and that's not a whole lot more, to be honest. We need to be incredibly land-efficient. Where you go back to technologically depends upon how quickly the people in power discover that completely replacing large parts of your energy infrastructure every 20 years is not sustainable.

Offline

Like button can go here

#221 2023-03-08 16:22:11

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,122

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

https://www.yahoo.com/finance/news/mult … 00123.html

Hi Terraformer!

Is this operation anywhere near you?

27

Rachel MillardWed, March 8, 2023 at 1:00 AM EST

Geothermal energy pioneers also want to extract lithium from Cornwall's waters - eye35 / Alamy Stock Photo

The race to develop cleaner energy has sent engineers in several directions: out to sea to plant wind turbines, to the desert to plant solar panels, and into the laboratory to try and develop nuclear fusion.

Stay ahead of the market

At an industrial site in Cornwall, however, they are looking in another direction: deep underground.Private company Geothermal Engineering has drilled more than three miles underground near Redruth, tapping into water at temperatures of up to 180 degrees centigrade.

It plans to harness that heat to generate electricity for the national electricity grid and warmth for nearby homes.

It would be the first deep geothermal power plant in the UK, when up and running as planned in 2024.

Geothermal Engineering has now raised £15m to get the project over the line, £12m of which is coming from Kerogen Capital, the private equity firm.

The $2bn [£1.6bn] asset manager has been best known for its investment in oil and gas, but is pushing into lower carbon sources and has a dedicated clean energy division, CelerateX.

Its investment into Geothermal Engineering comes amid a wider global push into deep geothermal energy as part of efforts to replace fossil fuels and cut carbon emissions.

Companies are rapidly developing new ways of drilling and extracting the warmth from deep underground, raising hopes deep geothermal could move from the niche into the mainstream.

“I think it can be very significant,” says Michael Liebreich, energy expert and chairman of Liebreich Associates, who is also chairman of the advisory board of deep geothermal developer Eavor.

“I think there's always been a strong understanding that it's a big opportunity - the challenge is how do you get it out, and how do you get it out economically.”

Deep geothermal currently makes a tiny contribution to the global energy system, with projects generally providing heat and electricity for small, local communities.

The complications, risk and expense of drilling deep underground and drawing out warmth has held the industry back, with little reason to invest heavily when other, competitive sources of energy are plentiful.

That equation is changing, however, because of efforts to diversify away from oil and gas, with billions of pounds now flowing into finding cleaner energy solutions and the price of carbon emissions going up in several economies.

Global concerns over energy security this winter after Russia’s war on Ukraine rocked oil and gas markets is also focusing minds on new solutions.

“The current situation – characterised by highly volatile oil and gas prices – provides renewed opportunities for geothermal energy to further develop as a strategic alternative in electricity generation, heating and cooling worldwide,” Irena, the International Renewable Energy Agency, said in a report last month.

New drilling techniques, including some developed through the natural gas fracking boom in the US, are also helping to push the industry forward.

In the US, for example, Quaise Energy is developing a new technique which uses super high energy laser beams to ‘drill’ through hard rock deep underground.

The company says the “radical new approach” should enable them to reach depths of up to 20 kilometres and temperatures up to 500 degrees celsius.

The technology was developed by scientists working on nuclear fusion at the Massachusetts Institute of Technology.

Carlos Araque, chief executive and co-founder, says he wants to build “clean electric generation and heat distribution plants within a short distance of every major population and industrial centre on the planet”.

In June, Quaise Energy raised $52m from companies including Techint Group, the Argentine conglomerate, and Safar Partners, US technology venture fund.

Before setting up Quaise, Mr Araque worked as a technology development manager at Schlumberger, the oilfield services company.

He is not alone in seeing the potential for assets and expertise from the fossil fuel industry to be redeployed.