New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#101 2023-01-10 21:29:25

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Synthetic or Natural Fuel Produced using Solar Power

here is the plastics to molecules topic Flash Pyrolysis that contains my post of conversion to petrol.

The basics have to do first with plastic type selection and making the container small in size more like chips to place inside a sealable container that can be filled, and all air removed from it before sealing. The reactor container is then heated by any means to near the 500c temperatures to cause the plastics to break down where the outgassing is fed via a valve to a filter and bubbler suppressor into a tank for future use. Some of these are liquid in plastic types while others as a gas that is output from the reaction.

Offline

Like button can go here

#102 2023-01-11 17:49:53

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,398

Re: Synthetic or Natural Fuel Produced using Solar Power

tahanson43206,

Photoelectrochemical methods to break down plastics are scientifically interesting, in much the same way that the photovoltaics first invented in 1883 were scientifically interesting way back then. About a century later, we had some of the first commercially viable implementations, assuming cost wasn't too much of a factor. I see perovskites and nuclear fusion in much the same way. 50 years from now, both might be quite practical ordinary / everyday technology, quietly doing what they do best. For now, they're scientific curiosities with potential but not promise. Steel and concrete are promises. There are artifacts of concrete and steel made thousands of years ago which are still present and still functional, even if they're only used as museum pieces.

There's a lot of this pie-in-the-sky type high-tech stuff. If and when it could work at significant scale, then yes it would really be something to behold. In case you hadn't noticed, we still have steam locomotives hauling people and freight. Are there much better ways to do it? Sure. The advantage is that the steam-powered choo-choos have already built, scrapping them for "something better" means spending mad money for "new toys" that probably require the consumption of more fuel by the barrel, we know exactly how the existing ones work and fail, and the old ones can be repaired at reasonable cost. If the new one requires a supercomputer to move forward on the tracks, then however theoretically great it is, and I'm sure it is great in its own way, then it's a brick the moment the gadgets quit working. This is something you learn the hard way in the military. Over-reliance on advanced technology is it's own form of inefficiency when the technology is not available. We already know that computers will fail and they will be non-repairable, which means more money for more gadgets on another brand new train. It's an endless consumption cycle, which is the greatest form of inefficiency. Sometimes the old ways are best, because they are so timeless. At some point, you have to get off that merry-go-round and stop playing pointless shell games with money, labor, and energy.

Back in the 1980s when I was a kid, I had a couple of neighbors with photovoltaic panels on top of their homes. In relative dollars, ignoring total output and focusing on what they were used for and how much power was required, because 1980s homes tended to consume less electricity as a function of total overall usage (very few computers or other electronics gadgets, TVs were not on 24/7, a few homes had microwave ovens, small fridge, some lights that were usually turned off, small central AC unit were the norm by that time, and a corded telephone), cost was about the same. Overall PV efficiency wasn't substantially worse than what it is now, they simply had fewer panels because they were more expensive per panel, but they weren't using that much electricity, and they achieved what they were after with what they could buy. I knew one system cost about $30,000 (because the guy who owned the house told my father that's what it cost him; my father thought it was neat but didn't have $30K to cough up), which was a lot back then. However, multiply by 2.72 (1986 to 2022 inflation) and it was $81,600 in today's money (about what my parents' house cost back in 1984), which is considerably less than we paid for our system. Obviously, we were able to get more for our money because manufacturing costs dropped (labor and red tape rose to make up the difference), but the tech is fundamentally the same as it was back then. I could be wrong, but he told me what it was and I think it's the same kind of panels we have on our roof (without the fancy on-panel micro-inverter electronics, which didn't exist back then, so far as I'm aware- maybe NASA had something like that). From then (when I was a child) until I had our own photovoltaics installed (over age 40 now), in relative terms my neighbor and I spent roughly equivalent money to achieve a similar result. We pay the loan on the panels, rather than a (sometimes wildly) variable and rather high bill to the electric utility (it probably still goes to them anyway). I received 1 cheque from the utility company here in Houston, a grand total of 1 time since install, for a few dollars and cents (excess power generated by my array).

For those who don't know, I make a living off of implementing forecasting technology for supply chain management. I'm not against computerization when there's no other practical way to make a machine or process work. A Space Shuttle needs a computer and cannot function the way it does without one. Whatever concessions have to be made to reliability and maintainability are baked-in and there's no way to separate the rigor from the end result there. I do question the need to put a computerized control system into nearly every appliance, vehicle, and home made these days. I think it's counter-productive.

I think energy systems need to be fundamentally simple in order to be reliable. Whereas others may believe covering large swaths of the planet with some manner of semiconductor electronic devices like photovoltaics or composites wind turbine blades larger than an airliner's wing is is the way forward, I do not. Steel and concrete are durable and fairly permanent in nature. They demand one-time energy investments over a human lifetime, and thereafter with modest maintenance they continue to function about as well as they did the day they were made. An energy system that's in a constant state of flux cannot be said to be reliable and durable. To the extent that we can use intermittent energy, it should immediately be converted into a storable product that does provide reliable on-demand power for whatever use is required.

Offline

Like button can go here

#103 2023-01-11 18:49:58

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,750

Re: Synthetic or Natural Fuel Produced using Solar Power

For kbd512 re #102

Thanks for the realistic sounding (to me for sure) evaluation of the announcement of research to improve treatment of plastics.

It seems possible there will be something to see in 50 years. Research has to start somewhere.

(th)

Offline

Like button can go here

#104 2023-02-16 04:40:35

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,279

Re: Synthetic or Natural Fuel Produced using Solar Power

Another presentation detailing the (probably) insurmountable resource problems that will impede the green transition if it is based upon PV, wind-electric and electrochemical batteries.

https://m.youtube.com/watch?v=sgOEGKDVvsg

This is essentially a problem imposed by the low power density of wind and solar energy. The powerplants are huge for the amount of power they produce. Whilst solar thermal power does not solve the problem entirely, it does at least shift materials demand from rare exotic elements, to abundant concrete and low alloy steels. These are resources that do not have imminent supply bottlenecks and can be recycled relatively easily.

There are options for improving the sustainability of wind power as well. Steel towers have a fatigue life and require replacement after 20-30 years. But this is hot rolled low alloy steel that can be recycled. Concrete plinths can be reused, although cyclic loading will eventually lead to cracking. Fitting plinths with load spreading steel caps would extend their life. For small and intermediate sized turbines, wooden laminates could replace carbon fibre in blades. Stone or brick towers could be used for onshore wind turbines. These would have much longer life as they can absorb forces compressively. We have wind mill towers in European countries that are many centuries old.

The turbines themselves could be fitted with hydraulic pumps or air compressors rather than generators. Multiple hydraulic turbines could then power a single generator on the ground. Hydraulic turbines could store limited energy in hydraulic accumulators. Hydraulics could be used to power machinery directly, without generation of electricity. In the past, factories were often powered by line shafts that conveyed mechanical power from a water wheel or steam engine. Machines drew power from the shaft using a belt. The problem with this arrangement was that line shafts required a lot of maintenance, they lost power due to friction and they constrained factory layouts. Hydraulic power would reduce all of these problems.

If offshore turbines produce compressed air rather than electricity, then undersea compressed air energy storage can be integrated into the generation cycle. There are also hybrid options, where wind turbines compress air which then feeds a gas turbine. The turbine then generates twice as much power from the same quantity of natural gas. This works because the energy consumed by the GT compressor, is actually half to two thirds that produced by the gas turbine. Eliminating compressor work allows the GT to double its power output.

Using wind turbines to generate compressed air works best if we build district heating systems. As air compresses it gets hot. As it expands it gets cold. Typically, CAES schemes either discard compressor heat or have looked at ways of storing compression heat, such that it can be used to reheat air during expansion. But this adds cost and complication. The temperature of recovered heat is too low for efficient heat transfer without very bulky air heat exchangers. If we could recover compressor heat for district heating and use the expansion temperature drop for refrigeration purposes, we achieve high overall exergy efficiency whilst avoiding the need for a large thermal storage and reheat capability. Wind powered CAES would work best for coastal towns, where there is both a concentrated heat load and opportunity for undersea CAES. A town or city with a compressed air supply can also attract industries that use compressed air for tools, machinery or metalurgy.

In the past, I have looked at options for transportation that involve transporting solids in capsules or barges through water filled pipelines or ditches. Energy costs are comparable to rail, though transportation speeds are lower. Wind power can be used to drive this directly. The wind turbine shaft is connected to a vertical shaft using a bevel gear. At the base of the turbine, the shaft drives a water pump, that pushes water through the pipe or ditch at 1-2x human walking speed. The barges or capsules are carried along with the flowing water. This provides us with a low tech transportation option that can be constructed from very abundant materials and can carry goods very cheaply between population centres.

Last edited by Calliban (2023-02-16 05:29:13)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#105 2023-02-16 05:43:59

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,988

- Website

Re: Synthetic or Natural Fuel Produced using Solar Power

Hmm. My canal related thinking has been along the lines of autonomous canal boats to bring the network back into use. Doesn't matter that they travel at 4mph and only carry a truck's worth of cargo if the labour costs are nil.

We're not going to build a society of abundance on a basis of scarcity.

Use what is abundant and build to last

Offline

Like button can go here

#106 2023-02-16 08:12:36

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,750

Re: Synthetic or Natural Fuel Produced using Solar Power

Readers of this topic would have reason to expect to find posts about production of synthetic or natural (biological) fuel produced using solar power.

Calliban's post #104 adds support for the idea of using solar thermal power, by showing the advantages of the materials for both short and long terms.

Restoration of the use of canals using robotic barges is a concept that is both new and interesting, and it deserves it's own topic.

My guess would be that in some regions were canals were popular in the past, they may exist only as occasional public displays where generous local residents have maintained small sections of them, such as locks.

I would definitely be interested in seeing a topic dedicated to restoration of canals using automated barges, where that is feasible because canals have been maintained.

To return this topic to it's intended focus, I am hoping NewMars members will post reports they may find of ventures along the lines originally imagined by kbd512.

Investment is required to build and to operate a solar powered plant to make synthetic fuel. A major German corporation has undertaken a synthetic fuel venture in Chili (if memory serves). The intention (as I recall) is to provide truly green carbon based fuel for their high end vehicles. If the concept of making synthetic fuel using solar sourced energy is to succeed, there must be a market for the product, and the costs of the investment must be spread over that market so that there is a return.

I'd like to see this topic lead the reader toward an explanation of how that might be achieved.

The support of solar trough energy collection is a step in that direction.

(th)

Offline

Like button can go here

#107 2023-02-16 20:28:13

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Synthetic or Natural Fuel Produced using Solar Power

Thermal energy collection approaches 50 to 70% efficiency but the temperatures require a very large footprint to generate sufficient heat to cause turbines for steam and even higher for melting of sodium salt for heat storage for later use.

Offline

Like button can go here

#108 2023-02-18 17:56:00

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Synthetic or Natural Fuel Produced using Solar Power

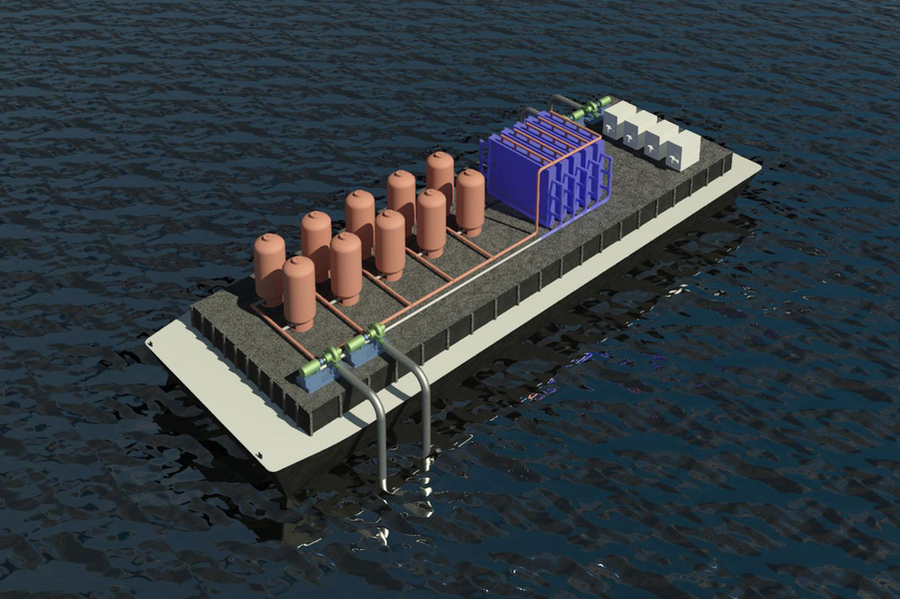

Thank you find this research

How to pull carbon dioxide out of seawater

A new method for removing the greenhouse gas from the ocean could be far more efficient than existing systems for removing it from the air.

The existing methods for removing carbon dioxide from seawater apply a voltage across a stack of membranes to acidify a feed stream by water splitting. This converts bicarbonates in the water to molecules of CO2, which can then be removed under vacuum. Hatton, who is the Ralph Landau Professor of Chemical Engineering, notes that the membranes are expensive, and chemicals are required to drive the overall electrode reactions at either end of the stack, adding further to the expense and complexity of the processes. “We wanted to avoid the need for introducing chemicals to the anode and cathode half cells and to avoid the use of membranes if at all possible,” he says.

The team came up with a reversible process consisting of membrane-free electrochemical cells. Reactive electrodes are used to release protons to the seawater fed to the cells, driving the release of the dissolved carbon dioxide from the water. The process is cyclic: It first acidifies the water to convert dissolved inorganic bicarbonates to molecular carbon dioxide, which is collected as a gas under vacuum. Then, the water is fed to a second set of cells with a reversed voltage, to recover the protons and turn the acidic water back to alkaline before releasing it back to the sea. Periodically, the roles of the two cells are reversed once one set of electrodes is depleted of protons (during acidification) and the other has been regenerated during alkalization.

This removal of carbon dioxide and reinjection of alkaline water could slowly start to reverse, at least locally, the acidification of the oceans that has been caused by carbon dioxide buildup, which in turn has threatened coral reefs and shellfish, says Varanasi, a professor of mechanical engineering. The reinjection of alkaline water could be done through dispersed outlets or far offshore to avoid a local spike of alkalinity that could disrupt ecosystems, they say.

So we can make the fuel while at sea and then transport it to shore piping to bring it to the customer for less.

Offline

Like button can go here

#109 2023-02-18 20:08:58

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,398

Re: Synthetic or Natural Fuel Produced using Solar Power

Sounds like a plan to me.

Offline

Like button can go here

#110 2023-02-19 15:56:21

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Synthetic or Natural Fuel Produced using Solar Power

We also know that we can create a floating solar array on the ocean as well and do not require a nuclear plant though it would be feasible for the small reactors that we can now build.

Offline

Like button can go here

#111 2023-02-21 20:26:45

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,750

Re: Synthetic or Natural Fuel Produced using Solar Power

This article is about Porche investing in Texas to make artificial fuel ... it may describe the energy source...

HIF says the Texas plant will produce its first e-fuel in 2027, initially 14,000 barrels per day, or 200 million gallons annually. It plans to make synthetic e-methanol, e-gasoline and e-liquified petroleum gas. Asked how the fuel will be used, HIF said, “The products can be sold anywhere in the U.S. and are considered ‘drop-in’ fuels because they can be used by existing infrastructure and engines. They have the highest value in places that also have economic rewards for low-carbon alternatives.”

HIF says the best such carbon market is in California, which like Europe has 2035 as a fossil fuel deadline for new cars. New York, New Jersey, Washington State and Massachusetts are following California’s lead, and other states are taking parts of California’s plans. In a statement to Jalopnik, HIF said its e-gasoline could keep the huge number of internal-combustion cars in those states running on near-carbon-neutral fuel after 2035. In a statement, the company said, “California’s prohibition on internal-combustion vehicles is on sale of new vehicles. E-fuels can be used by existing vehicles until they reach the end of their useful life, thereby providing a decarbonization pathway for existing infrastructure, a complement to electrification of new infrastructure.”

Porsche agrees with this. In a statement sent by research and development spokesperson Hermann-Josef Stappen, Porsche said, “There will remain a high demand for CO2-reduced fuels for the existing car fleet well beyond 2030. Besides in the existing car fleet, e-fuels can also be used in other transportation sectors such as aviation, shipping, trucks, heavy duty and construction machinery to reduce carbon emissions. Therefore, we see a huge potential for the use of e-fuels.”

(th)

Offline

Like button can go here

#112 2023-02-22 00:49:13

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,398

Re: Synthetic or Natural Fuel Produced using Solar Power

If we're going to ban fossil fuels by 2035, as all of these news articles indicate, then where in the Sam Hill is the 700% to 7,000% increase in investments into metals mining and refining?

It doesn't matter if we're talking about banning private cars entirely. If the metals mining ain't there, then this supposed transition ain't happening. Without that metal, what are we transitioning to, the Stone Age? I can't find these magic investment dollars anywhere. They're simply not there. It takes an average of 16 years to bring a new Lithium mine online, which means we needed to start the process to bring these new metals mines online back in 2019 for them to be producing metal by 2035.

Look at this chart. Tell me where all that new investment money went:

All the major auto makers, including Tesla, are already hitting capacity constraints on Lithium, Cobalt, Copper, and other metals. They're not the only ones. Has anyone else payed attention to metals prices within the past year?

At this point, claiming we're going to ban fossil fuels is a bit like claiming that we're going to ban farming or breathing.

Offline

Like button can go here

#113 2023-02-22 20:20:25

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Synthetic or Natural Fuel Produced using Solar Power

I know we will actually make use of the collected recycling that we are not sending to China any longer since its mostly now ending up in the ground as they want to get big $ for what they have to recycle.

Offline

Like button can go here

#114 2023-02-22 21:29:29

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,398

Re: Synthetic or Natural Fuel Produced using Solar Power

SpaceNut,

Someone like you or I or perhaps a small town could benefit from small scale local recycling efforts using scrap materials. It would result in some part time jobs and greater materials abundance for home use. However, we are not going to drastically alter the energy sources that power America using recycled scrap metal. There are no shortcuts and no ways around this problem, given the stated goal.

You remember all that scrap metal Americans turned in during the metal drives to help our war efforts during WWII?

Almost none of it was usable in the war effort because it was contaminated and of poor quality to begin with. Great energy and effort was expended, but it's one more example of conflating activity with accomplishment. That is why bubble gum wrappers, beer cans, tin soup cans, and old plywood will not "Repower America". There's not nearly enough of it, the quality is questionable at best, and apart from being another "feel good" measure like the WWII metal drives, it will invariably cost more than its worth.

No free lunches means just that. There are no cheap-and-easy solutions to be had. Some solutions are outright unaffordable while others are moderately feasible. There is no "subjective truth" here. Only certain interpretations of the world are survivable. Far fewer interpretations produce desirable end results.

Offline

Like button can go here

#115 2023-02-23 03:30:43

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,988

- Website

Re: Synthetic or Natural Fuel Produced using Solar Power

What sort of quality is needed for things like flat plate solar collectors?

If we run low on liquid fuels, there will be plenty of scrap metal available in the form of cars... Going out on a limb here, but I'm guessing the quality of the steel will be somewhat higher than it is in tins.

Use what is abundant and build to last

Offline

Like button can go here

#116 2023-02-23 17:19:50

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,398

Re: Synthetic or Natural Fuel Produced using Solar Power

Terraformer,

If there's no fuel for cars, since the fuel for cars and trucks and ships doesn't come from different sources, that means... finish that sentence for me. Recycling cars involves lots of giant diesel fueled machines. There are no solar powered cranes or wreckers to tow off the cars, nor will we be pushing all of them to the scrap yards. If you can't figure out why, then try pushing a car a mile or two on a level surface.

America's 2021 production of cold-rolled product (coil and slit coil) was 87 million metric tons. Global crude steel production was about 1.958 billion metric tons. I believe I was asking for something like 150 million metric tons of cold-rolled product. That's doable over 10 years, and certainly doable over 20 years. I was also asking for cold-rolled product for the steel support structure, which is strictly speaking, entirely unnecessary. The finish on the support can be very crude and it makes no difference to the performance of the mirror, but we're keeping this machine for at least 1 human lifetime. As long as I can hot-dip it in Aluminum, like a vehicle's exhaust system, and have a nice smooth surface finish for final polishing, that's all I need.

If you're asking whether or not I absolutely need cold-rolled, then the short answer is no. I really really want it, but with another building to remove the mill scale and some very modest surface prep, surface finish of acceptable quality could be achieved. I was hoping to only require rolling and stamping and Aluminum hot dip equipment. This could be the cheaper option for the quantity of steel I'm asking for, since hot rolled is considerably cheaper than cold rolled. It would be $128.85B USD for the 150Mt of 2mm A36 hot rolled. Cold rolled would be $164.25B. The difference is small, about $35.4B USD, but then we need to know that the hot rolled product can be finished for less money. There is no similar supply constraint on hot-rolled, so if we had to roll out this solution to the entire world it would be much cheaper at that scale.

I would take the hot-rolled product, blast off the scale with wet media blasting mixed with a light oil to prevent flash corrosion, aka "vapor honing", grind to a final surface finish, stamp the reflector (it will have a "golf ball" surface stamped into it to make it stiffer), chemical cleaning, hot dip in commercially pure Aluminum, final polish to a mirror finish, clear anodize to protect the coating, and then the mirror is finished. We'll use fabric or rubber spacers for stacking, band them together with strapping, crane them onto the flatbeds using the straps, and then they're going out the door.

The support structure will be welded A36 DOM tubing, same surface prep, except painted white afterwards (makes cracks more visible). We'll need lag bolts, more tubing, and concrete pads / anchor blocks without steel reinforcement.

Offline

Like button can go here

#117 2023-02-23 21:15:27

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Synthetic or Natural Fuel Produced using Solar Power

We never thought that we would have tractor trailers that were battery powered but it's now been done so having other large equipment is possible with proper design. Does it all make sense probably not but needs drives many an item that we use today.

As to how cheap a thermal air box can be, well I have seen them made of recycled soda cans painted black with in a wood box covered with even a thin film plastic. An insulated mat under the cans to stop heat being drained into the back of the enclosure. A double layer of plastic to trap more of the heat inside the flat collector box. Connect a low-speed blower or fan and now you have heat.

Thermal liquid media is a bit more complex but pex plastic tubing even on metal flashing with a thermal conductive grease or paste to improve tubing plate contact in that same wood box can collect heat for later use. Then add in temperature sensor control of pumps and valves to a storage tank and you are most of the way there.

Of course, some things work much better with a higher level of quality in materials, but will it work, yes it will.

Offline

Like button can go here

#118 2023-02-24 00:04:44

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,398

Re: Synthetic or Natural Fuel Produced using Solar Power

SpaceNut,

We had electric cars and trucks before we had gasoline or diesel powered models. They're still utterly impractical for most people to purchase and operate. The only people who think otherwise haven't bothered to count all the material inputs required for all or most vehicles to become electric. If you attempt to scale up this futurism fantasy to the human civilization level, then it will fail using existing technology. Whenever we mass produce things, they're made using existing technology, not what might become available in the future.

Evidence-free claims about the future are the favored stalling tactic of the "green energy" religious faithful. In lieu of being honest and admitting that they have no viable solutions, repeated vague assertions are made that "one day we'll have something better". I've had enough. We've spent the past 50 years and who knows how much money to make photovoltaics / wind turbines / batteries viable replacements for coal / oil / gas. 50 years later, they're still not viable. We keep paying more and more money for supposedly "better technology" that ultimately fails to do what its proponents claim it will do, if only we do this / that / the other. The only thing measurably "improved" about this new technology, is the asking price.

Metals are finite in the same way that oil / gas / coal are finite. We produced 700 million tons of Copper over 6,000 years. We burned more gas or oil or coal than that yesterday, as well as every day before, for at least the past 50 years. Hydrogen and Carbon are wildly more abundant here on Earth than any kind of metal. Whether you find that fact pleasing or displeasing is irrelevant to reality. These arguments over reality aren't helping anyone.

Exceptions don't disprove the rule. That's why we call them "exceptions", rather than "the rule". Your invention isn't going to power a city. I'm not trying to discount its utility to you, personally, and I think it's great that you're so industrious, but its ability to enable at least most of us to continue to enjoy our present quality of life is practically nil. We need far less emphasis on attempting to prove that something can be done, and a whole lot more focus on the most practical ways of doing things.

Offline

Like button can go here

#119 2023-02-24 19:48:07

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Synthetic or Natural Fuel Produced using Solar Power

Those unconcerned about the sticker will not care about the cost of materials or anything else related to making them possible which is sad but true.

Seems we need not small or micro but nano sized nuclear for the general public to make use of. Sure, a community that makes use of the waste heat and electrical for all of its population is a fine for a utopia but so is the current town water and sewer which fail since you are infrastructure that you cannot even use.

Offline

Like button can go here

#120 2023-03-03 18:17:13

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,750

Re: Synthetic or Natural Fuel Produced using Solar Power

Speaking of folks not concerned about the sticker price, here is a report about the US Air Force wanting synthetic fuel...

https://www.yahoo.com/finance/news/air- … 00957.html

Popular Mechanics

The Air Force's Modular Reactor Will Create Jet Fuel Out of Water and AirSébastien Roblin

Fri, March 3, 2023 at 11:40 AM ESTUSAF's Reactor Creates Jet Fuel Out of Water, AirParsa Tavakoli / EyeEm - Getty Images

The New York-based startup Air Company has been awarded $65 million by an Air Force Defense Innovation Unit for a project known as SynCe to install a Carbon Conversion Reactor that promises to create synthetic jet fuel out of water and carbon dioxide in the air we breathe.Sustainable aviation fuel (SAF) isn’t an entirely new thing—back in December 2006, a B-52 bomber flew for 7 hours on a 50/50 blend of traditional jet fuel and a synthetic fuel called Syntroleum produced using the Fischer-Tropsch process. According to the International Air Transport Association, by 2022, over 450,000 commercial flights by 50 airlines had used SAFs in part—though they tend to be 2 to 4 times more expensive than traditional fossil fuels.

But AirCompany argues its AirMade fuel differs from these predecessors in that it’s a ‘drop-in’ kerosene that doesn’t require blending with fossil fuels at all. Furthermore, the conversion reactor doesn’t require an exotic, specially sourced feedstock—it simply needs carbon dioxide, which can be obtained anywhere.

For a good measure, AirCompany claims its carbon-neutral fuel results in a reduction of about 94 to 97 percent greenhouse gas emissions (depending on the source of electricity)—the highest of any on the market the company alleges. According to a chart produced by Air Company, competing biofuels result in only a 60 to 80 percent reduction, and traditional Fischer-Tropsch based PTL-FT processes hit 90 percent. And those must be blended 50-50 with fossil fuels, or worse.

The Brooklyn-based startup was launched in 2019 by Harvard Business School alum Gregory Constantine and Dr. Stafford Sheehan. Their initial products include Air Vodka (“the world’s first carbon-negative spirit”), eau de parfume, and hand sanitizer.

The leap from 80-proof vodka to jet fuel may seem steep, but AirCompany’s AirMade fuel—currently being mass produced in Brooklyn—has already lined up buyers in civil aviation sector:

Virgin Atlantic has agreed to purchase 100 million gallons over 10 years

Jet Blue agreed to purchase 25 million gallons over 5 years

Boom Supersonic agreed to purchase 5 millions gallons annually for their Overture Test Flight Program

Last summer, Air Company, the Air Force Research Laboratory, and the Hsu Foundation collaborated to realize a test flight on an unmanned aircraft that ran on 100 percent AirMade fuel.

There is undoubtedly growing interest in advertising green travel in commercial aviation, and sustainable fuels may represent a more satisfying mechanism than carbon offsets.

Air Company’s collaboration with the military goes beyond adopting greener fuel to where it can be produced: a base with carbon capture and Air Company’s reactor could produce its own fuel without depending on external fuel supply lines, which are vulnerable to attack.

Air Company says the Army lost one soldier killed or wounded for every 24 fuel resupply convoys in Afghanistan. Many of the bloodiest and most decisive battles of World War II revolved around the defense of or denial of fuel logistics. The startup therefore claims its modular reactors could result in a “safer, more robust, and decentralized fuel supply chain” which could be set up “anywhere, globally.”

How It Works

Air Company’s reactor is an advancement over the Fischer-Tropsch process developed in 1925, which involved converting sold carbon monoxide (CO1) and hydrogen into a gas called syngas, which is then liquified using metal catalysts under high pressure at a temperature of 300 to 572 degrees Fahrenheit. This process had an efficiency ranging from 25 to 50 percent. During World War II, an increasingly fuel-starved Nazi Germany leveraged the technique to convert its abundant coal supply into fuel, generating 25 percent of fuel it used for ground vehicles.

Air Company’s reactor simplifies the process by skipping the solid-to-gas conversation, and instead runs on hydrogen and captured carbon dioxide. The CO2 is captured, typically from industrial sites, and cooled, pressurized, liquified, and poured into a storage tank. Presumably, capture devices will be supplied to operator facilities. Meanwhile, hydrogen gas is obtained on-site by electrolyzing water (H2O), separating the hydrogen (used by the reactor) from the oxygen, which is cleanly released.

In the subsequent conversion stage, a catalyzing puck is introduced to catalyze the mix of hydrogen and carbon dioxide, producing a reactor liquid made of alcohols, alkanes and water. These elements are then distilled and separated by leveraging their different boiling points, resulting in outputs of ethanol, methanol and paraffins, as well as water which can then be reused by the reactor.

The process has an energy efficiency of 50 percent. According to a company representative, 23.2 pounds of CO2 are used for every gallon of jet fuel produced.

Thinking Big

Of course, the big question—and challenge—underlying any Green technology is whether it can be implemented cost efficiently on a large scale. Air Company claims that utilizing its tech “across all potential verticals” could remove 4.6 billion ton of CO2 from the atmosphere annually, or 10.8 percent of global emissions.

As for cost efficiency, a company representative tells Popular Mechanics “…they’re on track to achieve cost parity with tradition fossil fuel-derived jet fuels as they use renewable energies like wind and solar for their energy input.” That parity is also facilitated by “pursuing an array of government incentives made available to fuel producers generating sustainable alternatives.”

Another challenge will be output volume, as military aircraft notoriously consume huge quantities of jet fuel. For example, an Air Force F-16C short-range jet fighter, for example, typically stores just over 1,000 gallons of internal fuel, which when loaded with weapons, often must be supplemented with external fuel tanks and in-flight refueling. The Air Force will need to figure out how large a physical footprint AirCompany’s technology would require to sustain, say, a flight of four F-16s each flying two sorties per day.

However, if Air Company’s venture proves scalable, it has obvious appeal to the Air Force which is seeking to achieve both its own carbon emission reductions goals, and execute its doctrine of Agile Combat Employment (ACE), in which in wartime combat aircraft are dispersed to numerous satellite bases to reduce their vulnerability to missile attacks. Being able to quickly deploy organic fuel-generating systems to dispersed, remote bases could ease the requisite logistics.

(th)

Offline

Like button can go here

#121 2023-03-03 21:10:05

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Synthetic or Natural Fuel Produced using Solar Power

Its more about not depending on supply lines that can fail for making use of an ability to create something from nearly nothing when you have the energy to create it from. Then it's as close as you get to in-situ material use as one can get. This is one of the key pieces to a successful mar's as well.

Offline

Like button can go here

#122 2023-03-04 04:37:19

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,398

Re: Synthetic or Natural Fuel Produced using Solar Power

SpaceNut,

ISRU demonstration is a side-effect of what the US military wants to do. They don't want to be in a position where they need to ship fuel, mostly via land convoy or tanker aircraft, into a contested area. They want to create a small base, either tunnel underground or pour enough concrete to prevent anything short of a tactical nuke from reaching the reactor, and then use said reactor to make fuel for the aircraft and combat vehicles stationed at that base.

If Bagram Air Base had a small reactor beneath the base, then that could be the only permanent American outpost in-country, and there's almost nothing that the Taliban could ever do to overrun the base, because it has its own supply of water and fuel for all the people and war machines defending it. The drones and some transport vehicles would be sufficient to defend it against pretty much anything they ever had.

Bagram had a 56MW on-premise above-ground generating station that had to be supplied with fuel for the entire 20 years that we were in Afghanistan. The logistics burden and lives lost supplying that outpost and others with fuel was incredible, relative to what Americans are willing to tolerate.

Supplying ammo and food is not a particularly onerous task, relative to water and fuel. We developed parasail (CQ-10 Snowgoose) and helicopter drones (Kaman K-MAX) and gliders (40-ish mile range from a C-130 at high altitude, virtually no noise, low signature, so the enemy doesn't know when they'll arrive, and we resupply at night so they cannot see them easily; some are even disposable- essentially cardboard or wood) to resupply combat outposts. The right combination of low-tech and high-tech makes this possible.

The K-MAX can lift an artillery piece or pallet of shells, but it's infrequently used- weekly to monthly supply runs, no pilot aboard, so nobody to go after if it's shot down. The Snowgoose can transport a casualty who isn't too badly injured, deliver quite a bit of small arms ammo, or ferry hot food to troops in the field. The gliders are for drums of fuel, bulky items like missile launchers, spare parts for vehicles, and other things that are difficult to fit in a much smaller drone or awkward to sling load beneath a helicopter. A tire for a MRAP or Stryker won't fit on a Snowgoose. The K-MAX could carry it, but risks being shot down during delivery, so the best option is to push it out the back of a C-130 that's flying so high that nobody on the ground can see it or hear it. There's also the range aspect to consider. Cargo helicopters cannot match the range of fixed-wing aircraft and they guzzle fuel for the range they do achieve. If there's a better way to achieve a given outcome, then we typically have the hardware available to do that and aren't shy about using it.

This Throw-Away Drone Could Rush Supplies to Marines in Need

...

Though it looks like it might have a shorter range, a refined Supply Glider design could be a simpler and cheaper option. This could make it a good choice for both emergency and routine resupply missions. And the requirement for something like the Snowgoose or the LG-1000 isn’t going away.

“By the end of 2011, more than 27,000 soldiers at 43 Forward Operating Bases (FOBs) in Afghanistan relied solely on airdrop for everything from food to fuel,” Logistic Gliders says on its website. “As precision anti-aircraft weapons proliferate and conflict spreads to more remote regions, military supply chains of the future will face increasing pressure to reduce risk while increasing their reach.”

The fact that these gliders can make it into tight and very hostile spots without putting a helicopter crew at risk, or relying on more cumbersome parachute systems, is highly attractive. And at such a low cost, the system could even be used for regular logistics as well.

So, it might not be long before Marines in hot spots around the world are getting their emergency, or even daily supplies via a boxy glider drone.

A nuclear reactor is a simpler and inordinately cheaper option to make fuel inside active combat zones at our main base(s) of operation. If we had this option available to us in Iraq and Afghanistan, then the cost to the tax payer would've been literal tens of billions of dollars cheaper. The technology will pay for itself during the very next war we fight, and we haven't stopped fighting wars since long before I was born. CBS News did a story on this back in 2011. We paid about $400 per gallon and we consumed an average of 22 gallons per person per day. Between 2008 and 2016, the total cost was 104 billion dollars. We'd have to work quite hard to make a reactor that expensive, though no doubt our MIC will try. We have this concept known as "tooth-to-tail ratio" (T3R), which describes how many people and machines we have to use to support one trigger puller in the field. The more we can do to improve that ratio, the less total cost to the tax payer. Much of the fighting involved massive quantities of low-cost munitions- small arms ammo, artillery shells, JDAMs, etc. We expended very few big and expensive missiles because there wasn't much worth shooting them at, and our preference is iron bombs, which pack the most explosive into the lightest and cheapest package. The 2,000 pound Mk84 iron bomb costs $3,100, whereas the JDAM guidance kit adds another $19,000, and the 155mm artillery shell is only slightly cheaper due to the cost of the machinery required to make one. Dropping bombs is cheaper than dropping empty external fuel tanks and the fuel costs more than the bombs do by a lot.

If fuel cost was covered by reactors, then we can drop Mk83s (10 155mm artillery shells worth of ordnance weight, but much more explosive proportionally speaking) or Mk84s (20 artillery shells worth) all day long for less money than supplying a single artillery battery. That said, the only reason the shells are more expensive is very low production rates, relatively speaking. We don't make nearly as many Mk83s or Mk84s as 155mm. The bombs are superficially cheap because explosive is cheap, whereas forging steel is very expensive and artillery shells are made with much greater precision. If we built shells like we build bombs, but dropped them from low-cost combat aircraft, then the "artillery bombs" would become much cheaper. This is why I wanted to start making cheaper war machines that are powerful enough to do the job, yet easy to manufacture in large quantities, thus reducing the marginal cost of manufacture. We can kill anything short of a warship or bunker using 155mm.

Back to the war...

The Taliban are not stupid. They attempted all manner of schemes to fight the US military like a pseudo-conventional military with heavy weapons support and achieving local numerical superiority in surprise attacks on outposts or pre-planned ambushes. Many of their most experienced fighters were killed when we invaded, so it took time to make alliances with China to acquire new weapons (working ones, not the worn out garbage left over from the Soviet era or cottage industry models made locally in Peshawar, even though some of those are every bit as good as factory-made weapons- most were not), train new recruits in Pakistan or Iran (a considerable logistical challenge), etc. Their greatest problem was that our intel was better over time, it was delivered rapidly to people in a position to capitalize on it, and they could not match our battlefield surveillance capabilities and persistence when operating in small groups- no terrorist organizations have spy satellites, at least not yet. They had to make or steal their own food, because you can't eat money. Beyond that, their training was still insufficient to match our tactics and combat experience. Some of their fighters were quite skilled, but most were not, which is typical of a conscript army. They did have lots of volunteers to fight "the great Satan", but many were paid actors or intimidated into working for the Taliban, thus not so motivated to take the fight to their enemy (America).

The quality of troops we had to work with ranged from consummate fighters to thuggish local Police who probably spent more time stealing from the villagers they were supposed to protect than doing any real fighting. Most were illiterate and many barely capable of speaking their own language- a natural consequence of decades of oppressive Taliban rule and the brutality of the Soviets that wiped out entire villages. Still, it would be a mistake to think they were all incapable of learning or fighting effectively. They successfully repelled a Soviet invasion force vastly more capable than they were, at least on paper, whilst a dozen European countries fell to the Red Army.

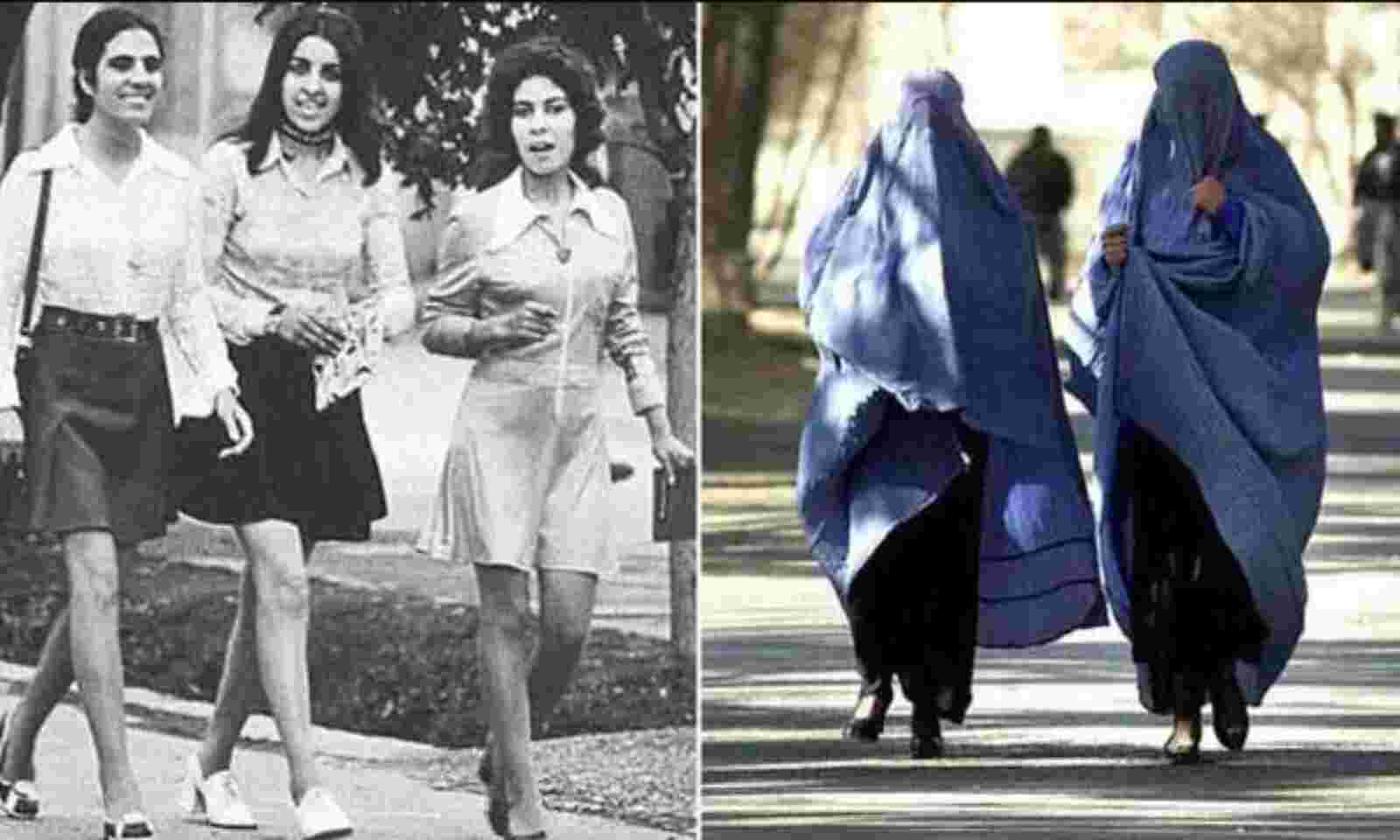

What kills me is that before the Soviets invaded, downtown Kabul could've been mistaken for downtown Los Angeles.

Afghanistan before the Soviet invasion, and then ever after:

Edited to include one more for those who think this was so long ago (1979, the year before I was born):

Many of the firefights did not end with Americans calling in airstrikes or artillery fire. Most small units performing bounding maneuvers to escape from ambushes or assault suspected enemy positions. The Army has always viewed airstrikes and artillery as a last resort. Use of force is only escalated if your enemy's position has been fixed and there's little worry about hitting friendlies or civilians, you're in an active firefight where the enemy has more ammo (their weapons and ammo are heavier than ours, so this was seldom the case unless they were defending a weapons cache) or numerical superiority (requires considerable coordination and prep work), and your air or artillery assets are available and usable (if weather is bad or machines are not available, then you're SOL, so heavy emphasis was placed on solving your own problems and communicating events to commanders so they could decide to send reinforcements if they thought the battle was going badly for their subordinates). The initial phases of the campaign clearly involved a lot of air power and artillery fire, but after that phase, it was all about patrols, winning hearts and minds, gathering intel, and capturing or killing enemy leadership, with the intent to disorganize resistance to the point that it was ineffective or nonexistent.

Anyway, all of this is about fighting to win. We don't do tit-for-tat. If we're fighting somewhere, then we're always fighting to win. The only metric that ever mattered to us, is who is left after the shooting stops. The Monday morning quarterbacks can always be counted upon to nit-pick whether or not they thought we did too much or too little. They have that luxury because nobody is actively shooting at them, and our use of military force endeavors to ensure that such is always the case (for our Armchair Generals that is, not us, obviously). If it's your son or daughter in harm's way, you will not care that we expended an expensive Javelin missile to take out "just one guy with a SVD or mortar". We can always make another Javelin. We can't bring your child back from the dead because we allowed a sniper to fire away at them with impunity, for fear of appearing to use too much force or spending too much money. Any sense of fairness is the exclusive purview of fair maidens, who are a rarity in combat zones.

Last edited by kbd512 (2023-03-04 04:48:14)

Offline

Like button can go here

#123 2023-03-04 05:43:04

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,398

Re: Synthetic or Natural Fuel Produced using Solar Power

This is the lifestyle that energy abundance and internal security enables. It took less than 10 years for Afghanistan to be transported back in time to the Middle Ages- a time when life was short, bleak, and brutal. America is a special place, but it's not so special that it cannot revert back to the way it was before we had energy abundance, which was little changed from the Middle Ages. Everybody in this world is selling something. America is selling the photo of the women on the left and below. Our enemies are selling the photo on the right.

Unless you wish to see the entire world devolve into the photo on the right, which has little to do with religion and almost everything to do with a fear-based scarcity mindset that crushes the human spirit, then it would be in everyone's best interest to make appropriate use of energy and technology to continue living lives of abundance. Nobody from the Middle Ages was the least bit concerned about global warming, because they had to struggle to survive. They consumed whatever was available in the natural environment until they died or none was left. That is why there are so few trees in Europe that are older than America.

Until the "We Love the Space Rock" Democrats in California overran that beautiful state, and then America, there were forests in California dating back to the Middle Ages. Now many of them have burnt to a cinder as a direct result of their inability to manage a lemonade stand. They can't figure out something as simple as removing dead wood and brush to prevent forest fires that denude the land of vegetation for as far as the eye can see. The good idea fairies must not be allowed to govern because they don't know how. They all think they're the smartest people in the room, but none of them can count and none of them have ever organized anything but their own destruction. It'll be another thousand years before the children of Californians can gaze up in wonderment at the massive redwood forests there. They think the climate has changed, rather than their general level of naivety for buying the utter nonsense they're being fed by their dysfunctional government. In the pasts, both Democrat and Republican governors understood that leaving piles of kindling beneath giant high voltage electric wires was a generally bad idea. Nobody on the Republican side is smart enough to explain to these people why leaving a ready-made brush fire in place is a bad idea, because they're not that smart, but they know enough to never do it. The drug cartel cretins are burning the rest of the trees so they can plant marijuana fields so the people living there can get stoned out of their minds to avoid dealing with their growing list of real problems.

Meanwhile, there hasn't been a real wage increase in America since before I was born. I've lived my entire life under a failing economic principle called "globalism", or the "liberal world order" as the most illiberal amongst us like to call it. There was a brief period of improved economics under President Trump, but even that wasn't enough, because the Democrats convinced the people to throw out the baby with the bath water after one of their ilk, Dr Fauci, spent our tax money to kill a bunch of his fellow Americans. They had to destroy prosperity somehow. They have no acceptable arguments to be made for what they're doing to us. This is why government need not be involved in every aspect of our lives. From that belief system we get evil clowns like him who will use tax money he should have never had access to, for their own pet projects. People like him are utterly incapable of introspection or learning from his own abhorrently bad ideas.

When you have energy and therefore economic prosperity, you don't need idiotic "get rich quick" schemes or welfare handouts from the government, because you can already provide for yourself. No group of wannabe tyrants ever wants to allow that to happen. They can't control people who have no use for them. Their ideas are relegated to being the fringe nonsense they've always been.

Offline

Like button can go here

#124 2023-03-04 18:24:59

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: Synthetic or Natural Fuel Produced using Solar Power

Yes, we are seeing that reversion to the past with the ever-increasing homeless population.

It's a problem when I am taxed on the property which is something that I can purchase for trying to bring about energy change to bring one's family out of energy poverty.

Offline

Like button can go here

#125 2023-03-04 19:25:17

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,398

Re: Synthetic or Natural Fuel Produced using Solar Power

SpaceNut,

Are you aware of how the Federal Reserve reduces the purchasing power of those who can least afford it by printing more money, ultimately forcing them into homelessness, and all the bad behaviors associated with clinical depression (drug abuse, alcohol abuse, suicide) that follows?

They've been playing a shell game with the money supply because the energy and labor supply doesn't exist to make up for resource depletion. We simply dive deeper and deeper into fantasy world, rather than going back to the basics. Nothing we've done or are now doing is addressing the root cause of the problems we face.

1. We need our own mining, refining, and industrial base. Those are the jobs that went away, and that was the starting point on the road to greater prosperity for many Americans, certainly the ones who were working in the 1940s to 1970s.

2. We need functionally inexhaustible energy sources that do not require wonky schemes to maintain.

3. We need longer-term thinking that is conspicuously absent from modern corporate culture. Fixating on the next quarter's P&L statement is a sign of no long term strategic planning going on.

4. We need acceptance that social norms exist for a reason, namely the continuation of the society, and that the nuclear family was foundational to continuation of our existence as humans, even before we organized into more complex social structures.

5. We need a political class that foregoes tribalism in favor of broader policy objectives. Right now we have none of that, and it's a major problem.

Offline

Like button can go here