New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#101 2023-04-19 13:37:02

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,422

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

SpaceNut,

It would make more sense to use oil instead of water in places with extremely cold temperatures, or to use gases that don't freeze, such as air without humidity / pure Nitrogen / CO2.

Offline

Like button can go here

#102 2023-04-19 21:17:34

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

The oil would go to a heat exchanger for home use heating to keep oil quantity as low as possible. I seem to remember that oil circulates through a heat exchanger, turning a refrigerant into steam, which drives a turbine that, in turn, drives a generator. Here it is...How To Build a Solar Generator, Affordable solar power using auto parts could make this electricity source far more available.

Offline

Like button can go here

#103 2023-04-23 13:47:31

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Heat engines and how to make use of temperature difference to achieve the goal.

The Organic Rankine Cycle (ORC) converts thermal energy into electricity.

https://www.geothermal-energy.org/pdf/I … _Final.pdf

DESIGN AND BUILD OF A 1 KILOWATT ORGANIC RANKINE CYCLE POWER GENERATOR

https://www.popularmechanics.com/scienc … 0/4232571/

A group of recent graduates and grad students from MIT is reconfiguring parts from old cars to create a simple turbine that runs on the heat of the sun instead of the oil drum. They hope to make it available in off-the-grid regions such as remote parts of the African country of Lesotho--where they recently completed a prototype (pictured above)--as a clean, inexpensive source of electricity, hot water and even refrigeration. The team was co-founded by former Peace Corps volunteer Matt Orosz, who was inspired by a locally made parabolic solar bread cooker during his stint in the country.

The solar turbine has three main parts: an array of shiny parabolic troughs that track the sun, an organic Rankine cycle (ORC) engine and an electrical control system. Rather than converting light to electricity using photovoltaics, this system employs solar heat: The four large troughs focus sunlight onto a continuous loop of pipes. Circulating through the pipes is a thermal absorption fluid, such as glycol, the anti-freeze fluid used in car radiators. Reaching temperatures up to 300 degrees F, the glycol passes through a heat exchanger, where it transfers its heat to a working fluid--a refrigerant, such as the R134 found in a car's air conditioner--which vaporizes and spins turbines in the ORC. The turbines generate enough juice (about 1000 watts) to charge a bank of batteries, while the excess steam heats water for domestic use. Add an absorption chiller, and you've got refrigeration as well, rounding out the typical range of energy needs: heating, cooling and electricity.

They kept prices low by using junk auto parts. The ORC's turbines are made from a salvaged turbo charger, which is coupled to an alternator to create electricity.

Organic Rankine cycle engines are not new. In large power plants, they're currently used to convert energy from low-grade, second-stage steam heat. And some very large solar-thermal power plants rely on ORCs, including the recently completed Nevada One, capable of generating 64 mW of power (enough for 40,000 homes). The Solar Turbine Group (STG) is taking an entirely different approach, scaling its equipment way down so that it can be installed in remote locations. Orosz and three partners recently spent a year in the Lesotho mountains working with locals to install a prototype solar turbine at a remote girls' school.

Offline

Like button can go here

#104 2023-05-31 20:05:52

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Here are the 4 troughs that create 10kw hot water and 1 kw of power with crude auto parts.

Here is another view of the troughs collecting heat energy

Offline

Like button can go here

#105 2024-01-30 09:00:40

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,279

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

I wonder if building these devices could be made easier by eliminating electronic control systems that track the sun? For a large plant, a human operator can adjust reflector angle manually. All of the mirrors could be simulateously adjusted using a chain link.

The use of organic fluids within the power cycle has the advantage that a fluid like butane has high molecular weight and high gas phase density. This allows the turbine to be more compact, which improves power density. The use of oil as the primary heat transfer fluid is difficult to get away from because of the overwhelming advantages it offers as a coolant. It is non-corrosive and has low vapour pressure even at temperatures exceeding 300°C. The low vapour pressure means that trough tubes don't need to be pressurised. The only other cooling fluid candidates that meet those requirement are liquid metals like sodium. Sodium doesn't boil until 800°C, so a sodium cooled trough collector could operate at much higher temperature than oil. But sodium leaks would be dangerous, as liquid sodium burns spontaneously in air. Then again, there is a high chance that oil leaks would ignite in air at 400°C.

Liquid sodium operating at temperatures of 550°C, would generate much higher quality steam. This is important, because it increases the pressure ratio and power density of the turbine in addition to improving the amount of electric power yielded per square metre of reflector area, as generating efficiency increases. This would improve the economics of the system, as improved efficiency increases the whole system power density. But dealing with safety issues of hot sodium would impose its own set of costs. Swings and roundabouts.

Low temperature systems (<200°C) could generate power through direct cycles. By this we mean the trough tubes containing pressurised water rather than oil. Hot water would flow into a steam seperator. This type of system would work best in combined heat and power mode, as efficiency would be low. Economic performance depends upon putting the waste heat to work. This sort of system might be useful for supporting district heating schemes in Europe. For much of the year, sunlight is too weak to be put to work generating steam. But warm water, in the 30 - 100°C range, would be valuable for district heating.

Last edited by Calliban (2024-01-30 09:12:21)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#106 2024-01-30 13:12:29

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,822

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

For Calliban re human attention to equipment ....

I am reminded of a video about English history. There are still huge fire places in (some) English castles, equipped with metal beams upon which giant roasts were mounted for slow cooking over a timber fire. A surf (probably a younger person) was assigned the duty of turning the spit slowly, from a position off to the side but never-the-less plenty close to the fire.

That person had a mind numbing job. The chief cook used a human for what a simple control circuit could do, because the chief cook had the surf available (a) and (b) because this was a time when such automation was out of the question.

I would invite you to consider the duty your vision would impose upon some hapless human being, if the society you are thinking about has descended so far into the abyss.

All those troughs could be chained together, and turned from a single crank. A simple water wheel could turn the crank, if the society you are considering still has enough wits to make one.

(th)

Offline

Like button can go here

#107 2024-02-07 09:01:31

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,279

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

On Mars, solar thermal power generation and production of synthetic fuels has some advantages over an Earth based operation. Sunlight intensity is only half that of Earth, but the atmosphere is so thin that there is far less cloud cover. It is mostly sunny, outside of dust storms.

The thin, dry, CO2-dominated atmosphere has some advantages as well. Steel structures will not corrode, provided we keep them away from brine in the soil. The cold is a problem for carbon steels, but they may still be acceptable in low stress situations. On Mars, we can use liquid sodium as the heat transfer fluid within the trough collectors. If we do get a sodium leak on Mars, it will do little more than smolder in the thin CO2 atmosphere. Using sodium allows coolant temperatures exceeding 550°C. This allows superheated steam to be raised or even an S-CO2 cycle to be used on the power generation side. This allows power to be generated at 40% efficiency, rather than the 20-30% that we are stuck with using oil as our primary coolant and saturated steam power cycles. So this partially compensates for lower sunlight intensity. The low atmospheric density would make it easier to engineer structures against wind loading.

On Earth, if we want CO2 to make fuel, we must extract it from air or seawater. The second option is better, because CO2 is more soluble than other atmospheric gases. But the CO2 still needs to be seperated from other gases. On Mars, the atmosphere is 95% CO2. And it is cold enough to compress it down to liquid, probably without intercooling. An axial compressor could produce a steady stream of liquid CO2. So solar synfuel production may be simpler on Mars.

Using point focus collectors, it is possible to generate heat at high enough temperature for thermochemical hydrogen production. This is potentially cheaper than electrolysis if done at large scale. The problem with this that I can see is that the sulphur-iodine cycle which is generally considered most promissing, involves decomposition of sulphuric acid at temperatures above 800°C. Sulphuric is always corrosive. But dealing with H2SO4 and SO2 at temperatures that high is going to be a real materials challenge. Specialty stainless steels and nickel alloys probably. Coating are possible. Ceramic coatings will resist corrosion, but would be vulnerable to cracking. This is something that needs a lot of thought.

Last edited by Calliban (2024-02-07 09:20:48)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#108 2024-02-07 11:43:01

- Void

- Member

- Registered: 2011-12-29

- Posts: 9,153

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Your work looks very useful to me. A hypersaline lake could serve as a heat sink, and technically a thermal storage at say 20 to 90 degrees C.

Then using some type of suitable fluid, I hope maybe a hydrocarbon, the heat of the lake can drive a turbine system with solar panels or mirrors doubling as radiators to take advantage of the deep cold that Mars can provide.

Done

Is it possible that the root of political science claims is to produce white collar jobs for people who paid for an education and do not want a real job?

Offline

Like button can go here

#109 2024-02-22 18:47:43

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,822

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

The article at the link below is about a hybrid of a trough collector and solar cells...

https://www.msn.com/en-us/news/technolo … 5c2&ei=105

Research team develops parabolic trough solar module for hybrid electricity and heat generation

Story by Science X staff • 9hThe parabolic trough collector is manufactured using industrial production methods such as injection molding. Credit: EMS–TU Graz

© Provided by Tech XploreSolar rays focused on concentrator photovoltaic cells using parabolic mirrors not only supply electricity, but also thermal energy for industrial processes, heating or cooling. Three technological innovations significantly reduce costs.

An international team led by Armin Buchroithner from the Institute of Electrical Measurement and Sensor Systems at Graz University of Technology (TU Graz) has developed a parabolic trough collector with cost-effective photovoltaic cells that can be used to generate solar power and thermal energy at the same time.

The solar module developed consists of a trough-shaped concave mirror that focuses the sun's rays onto the photovoltaic cells arranged in the focal line. The waste heat from the solar cells is transferred to a heat transfer fluid that flows along the back of the cells in a system of pipes. The thermal and electrical energy generated in this way can, for instance, be used for climate-neutral heating and cooling of buildings or for various industrial purposes, e.g., in the food or textile industry.

The idea of generating electricity and heat from solar radiation at the same time has been around since the 1970s, but has not been successful due to high costs and technological problems. This could now change, as Buchroithner's team has succeeded in developing several technological innovations in the course of the ECOSun—Economic COgeneration by Efficiently COncentrated SUNlight research project.

Related video: New Solar Panel Concept Could Help Drive the Transition to Renewable Energy (Dailymotion)

Solar radiation is amplified 60- to 120-fold

In cooperation with the partner IMK Solarmirrotec, the parabolic trough collectors were manufactured much more efficiently using industrial production methods such as injection molding technology. The silicon solar cells developed with the Turkish research center GÜNAM are cost-effective and robust, so that they can withstand the high temperatures of concentrated sunlight.

This is an important factor, since the parabolic trough mirrors amplify the solar irradiation by a factor of 60 to 120. The researchers were also able to optimize the cooling of the solar cells, making the waste heat more usable for further applications.

"This approach has the potential to make a significant contribution to the energy transition," says Armin Buchroithner. So far, parabolic trough solar power plants have been located almost exclusively in particularly sunny regions such as Spain or the Persian Gulf.

"However, our tests have shown that it can also be useful here in Austria or other regions to replace fossil fuels in industrial processes," says Buchroithner. "Given the rising energy prices and the desire for energy independence, the importance of independent, efficient, and cost-effective solutions for the supply of electricity and heat is increasing."

Provided by Graz University of Technology

This story was originally published on Tech Xplore. Subscribe to our newsletter for the latest sci-tech news updates.

Ad

Tech Xplore

Visit Tech Xplore

ChatGrid: A new generative AI tool for power grid visualization

Emergence of machine language: Towards symbolic intelligence with neural networks

Diminishing ether-oxygen content of electrolytes enables temperature-immune lithium metal batteriesAd

Sponsored Content

(th)

Offline

Like button can go here

#110 2024-02-22 18:56:38

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Solar cells breakdown and drop in power output as the temperature of them rise.. These must be a high temperature cell that is a differeent product.

Offline

Like button can go here

#111 2024-02-22 19:12:36

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,822

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

For SpaceNut re #110...

Thanks for noting the work done with a hybrid trough and solar cell system... You are absolutely right ... according to the article, the solar cells are robust to handle heating, but they are also cooled by circulating fluid, which is itself a source of thermal energy to be used elsewhere.

I hope our members will search for additional information about the new system.

(th)

Offline

Like button can go here

#112 2024-03-21 19:48:26

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

8.3. Solar Thermal Electric Power Generation

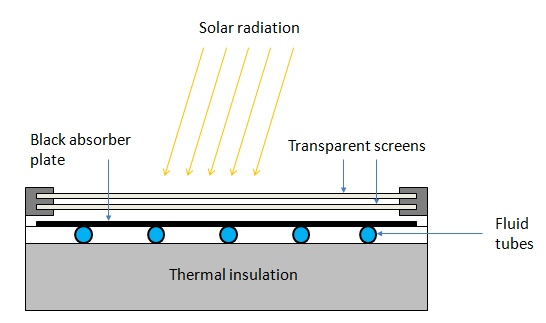

Flat plate collectors

Flat plate collector is the simplest technology of this kind, which is typically used for reaching temperatures usually no more than 100 degrees above ambient.

Concentrating collectors

The above collectors are combined to a bigger energy conversion system. The larger scale solar thermal systems have higher efficiency than small systems.

The utility scale solar thermal systems include the following designs:

linear reflectors (heating temperatures ~280 oC);

parabolic trough (heating temperatures ~400 oC);

dish / engine systems (heating temperatures ~650 oC);

solar tower (heating temperatures ~>1000 oC).

Offline

Like button can go here

#113 2024-03-21 21:59:18

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,422

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Observations from the Curiosity rover in Gale crater, Mars have shown the presence of high abundances of manganese (>3 wt% MnO) within sedimentary rocks throughout the traverse. Such high Mn abundances point to the past presence of abundant liquid water and strongly oxidizing conditions.

We're going to use Mangalloy steel on Mars, because Mars has lots of Manganese and Sulfur. Removing Sulfur impurities from steel is very important for strength / longevity / resistance to stress-corrosion cracking. Here on Earth, Managanese is primarily utilized for removing impurities from steel, but Mangalloy is the original high-alloy steel.

It's tough, abrasion resistant, and in concentrations of 30% to 40% in steel or cast Irons, there is no crystalline phase change at LOX/LCH4 temperatures. That means it will not loose that all-important ductility property during the frigid Martian nights.

Mangalloy has been or still is used for tank and off-road heavy machinery tracks, steel combat helmets, knives, swords, bank vaults, farming hand tools such as shovels / hoes / axes / bolt cutters, hard use off-road bicycle and motorcycle frames, passenger car structural components, piping, shot-peening steel, power hammers and anvils for metal forging, and rock crushers. More recently, it's found use in cryogenic liquids storage tanks for LNG at terminals and aboard ships. It's yield strength is better than austenitic stainless steels, which are no better than garden variety A36 plain carbon steel. Mangalloy is non-magnetic.

Using what we already know exists in abundance on Mars, namely Iron and Manganese, we will have superior steel for a multitude of low service temperature applications. These are the materials we need to fabricate habitable living spaces, tools, solar thermal power arrays, water and liquid cryogen storage tanks, manufacturing machinery, and vehicles.

High-manganese steel aims to lower LNG cargo and fuel tank costs

Hanwha Ocean R&D Institute head details the drive behind the successful development and commercialisation of high-manganese steel Type B and Type C LNG tanks

Most LNG cargo and fuel tanks are made using IMO-approved 36% nickel steel (invar), 9% nickel steel, stainless steel and aluminium, but a new, less expensive, robust material — high-manganese steel — is gaining increasing attention.

While traditional IMO-approved materials have proven robust and safe for handling the rigors of LNG cryogenic storage, they are expensive, and their production is inefficient, resulting in high manufacturing costs. This, in turn, increases the cost of building LNG carriers and LNG-fuelled ships — two core high-value products of South Korean shipbuilders.

This led to South Korean shipbuilder Hanwha Ocean (formerly Daewoo Shipbuilding and Marine Engineering) and domestic steel manufacturer POSCO undertaking a joint development project (JDP) in 2010, examining the feasibility of using high-manganese steel as an alternative to these traditional materials.

Joining in the JDP were five leading class societies (ABS, BV, DNV, KR and Lloyd’s Register). The goal of the JDP was ambitious: to develop and commercialise LNG cargo and fuel tanks that exhibited the same or superior qualities of handling the stresses of cryogenic storage, while reducing material cost and improving productivity. Completed a decade ago in 2013, the JDP also had national significance for South Korea, a global leader in LNG carrier and LNG-fuelled ship construction.

“High-manganese steel is 30% cheaper than 9% nickel steel”

In a paper presented as part of a panel on Advances in LNG carrier design and LNG-fuelled ships at LNG 2023 in Vancouver in July, Hanwha Ocean R&D Institute head, Joong Kyoo Kang, detailed the findings of the JDP and the South Korean shipbuilder’s subsequent development and commercialisation of IMO Type B and IMO Type C fuel tanks using high-manganese (Hi-Mn) steel.

To evaluate high-manganese (Hi-Mn) steel, Hanwha Ocean compared its cryogenic performance to current materials, including 9% nickel steel, stainless steel, and aluminium used in LNG storage tank manufacture approved by IMO and listed in the International Gas Code (IGC) and International Fuel Code (IGF).

Under the three-year project, the JDP undertook several complex technical challenges. The shipbuilder developed high-manganese steel construction technology, fabricated mock-ups, performed cryogenic tests, designed cryogenic tanks, and evaluated safety.

Steelmaker POSCO developed Hi-Mn steel materials and welding materials, while the class societies provided engineering support and material approval, conducted cryogenic tests and devised mock-up inspections.

In his paper, Mr Joong Kyoo Kang noted several attempts to commercialise Hi-Mn steel for cryogenic applications had been made in other countries but had failed due to the difficulty in producing steel without defects. One of the major reasons for failing to produce sound steel was the difficulty in developing the correct welding materials.

Using various fatigue tests, Hanwha Ocean in collaboration with POSCO was able to develop and improve welding materials suitable for each welding process. The JDP was completed in 2013.

One of the key takeaways noted by Mr Joong Kyoo Kang was that using Hi-Mn steel in the manufacture of the LNG tanks can achieve a weight reduction through reduced thickness, compared to other materials with similar low-temperature strength. This yielded improved productivity and increased competitiveness through material savings.

Additionally, its low coefficient of thermal expansion compared to other low-temperature materials reduces thermal stress caused by temperature changes in the LNG tank, making it superior in terms of design, he said.

POSCO reported its cryogenic Hi-Mn steel has globally high production rates and is relatively inexpensive. Besides noting its superior toughness and tensile strength compared to conventional materials, high-manganese steel is 30% cheaper than 9% nickel steel, according to the steelmaker.

“Hi-Mn steel is being examined for use in tanks for ammonia-powered ships”

The steel contains 22.5 to 25.5% manganese, maintaining excellent strength, even at cryogenic temperatures of -196 °C. Expectations are high in country that Hi-Mn steel will boost the competitiveness of several South Korean industries, from steelmaking to shipbuilding to LNG tank manufacture for land, vehicles and marine-based applications.

In 2018, IMO’s Marine Safety Committee approved interim guidelines for applying Hi-Mn steel in cryogenic LNG storage and fuel tanks. These guidelines outlined the requirements for designing and manufacturing Hi-Mn steel for LNG cargo and fuel tanks, ensuring compliance with IMO’s safety codes.

Hanwha Ocean has developed its own IMO Type B and C LNG tank designs, which are marketed under High Manganese steel Cargo Tank Independent Type- B (MCTIBR) and High Manganese steel Cargo Tank Independent Type-C (Mc-CR), respectively to distinguish them from existing IMO type B and C LNG tanks made of 9%-Ni steel.

Mr Joong Kyoo Kang noted general industry consensus was reached that IMO Type B tanks are the most effective and reliable solution for LNG fuel tanks for container ships because of their space effectiveness and structural robustness against sloshing. The featured characteristic of the Type B tank is the application of a partial secondary barrier instead of a full secondary barrier. This partial secondary barrier consists of a leakage path on the primary barrier, drip tray, and high-end verification engineering on the safety of the primary barrier, ie, tank boundary, against leakage.

Due to the comparatively more spacious open-deck area, IMO Type C tanks have been adopted for LNG fuel tanks in the LNG dual-fuel design of bulk carriers and very large crude carriers (VLCCs), one of the core ship types constructed by Hanwha Ocean. Working with a partner fabrication yard in South Korea, Hanwha Ocean developed a Hi-Mn IMO Type C independent tank.

The culmination of this 10-year development effort with POSCO has begun to bear fruit. According to Mr Joong Kyoo Kang, Hanwha Ocean has secured orders for its HiMN tanks for 36 LNG-fuelled ships, including orders for MCTIBR Type B fuel tank systems for 22 container ships and Mc-CR Type C fuel tank systems for 14 VLCCs. The first two VLCCs equipped with these Mc-CR Type C fuel tank systems were delivered last year.

Hanwha Ocean reported the first cube-shaped MCTIBR Type B fuel tank system was installed in a 24,000-TEU LNG dual-fuel container ship last year.

Hanwha Ocean also has plans to employ Hi-Mn steel beyond LNG. Mr Joong Kyoo Kang confirmed that Hi-Mn steel is being examined for use in tanks for ammonia-powered ships and for hydrogen carriers. It has been confirmed that high-manganese steel has high stability at the supercool temperatures required for liquefied hydrogen (-253°C) compared to the existing stainless steel. Based on various tests and studies, plans are being made to apply the results to a mock-up of a liquefied hydrogen tank for verification tests.

Offline

Like button can go here

#114 2024-04-09 04:24:58

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,988

- Website

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

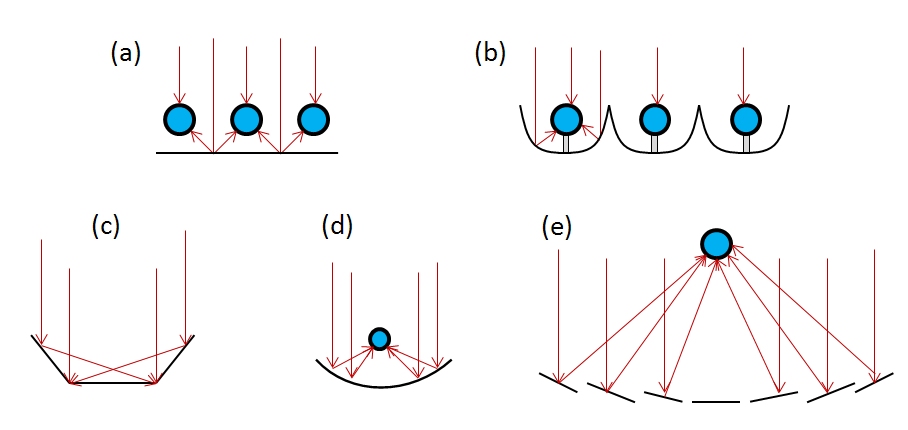

Compact Linear Fresnel Reflector

Instead of using a curved parabolic trough, it uses a number of flat reflective strips to focus light, much as a Fresnel lens does with refraction. Supposed to reduce costs and simplify manufacture. Even if efficiency is lower, it might win out for simplicity?

Use what is abundant and build to last

Offline

Like button can go here

#115 2024-04-09 20:59:05

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,822

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

For Terraformer ... It's late after a long day, and I have been thinking about the debate between kbd512 and Calliban on one side, and Louis and the PV enthusiasts on the other. I'm posting in the Solar Trough topic because it sort of fits, but this is an idea that would be a hybrid of the two, if it can work which is doubtful.

The problem I see with the basic solar trought idea is that it heats up material that has to be shipped off somewhere else to provide thermal energy to make power.

A PV panel ships electrons to where they are needed, and cuts out the middle man. The objection to greater use pf PV seems to involve materials needed to make them.

In any case, my idea is to pass little energy collectors through the solar trough pipe where solar energy charges the little packets (somehow) and they travel out of the pipe to a separate area where the stored energy is drained out so the little object (whatever it is) can return to the trought to be recharged.

(th)

Offline

Like button can go here

#116 2024-04-09 23:04:24

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,422

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

tahanson43206,

The material that solar thermal power heats up isn't shipped very far. It doesn't have much time to lose a lot of its thermal energy. The flow rate of the molten salt through Crescent Dunes is 10,000 gallons per minute. If you removed a hot loaf of bread from your oven, then during the time it took you to carry the bread from your kitchen to your dining room using a pot holder, would you be able to immediately touch the bread with your bare hands the moment you arrived in your dining room, or would you receive severe burns if you attempted something so foolish?

In any case, my idea is to pass little energy collectors through the solar trough pipe where solar energy charges the little packets (somehow) and they travel out of the pipe to a separate area where the stored energy is drained out so the little object (whatever it is) can return to the trought to be recharged.

We are passing "little energy collectors through the pipe", but we're calling them "molten salt", and they are returned to the trough to "get recharged" by the Sun.

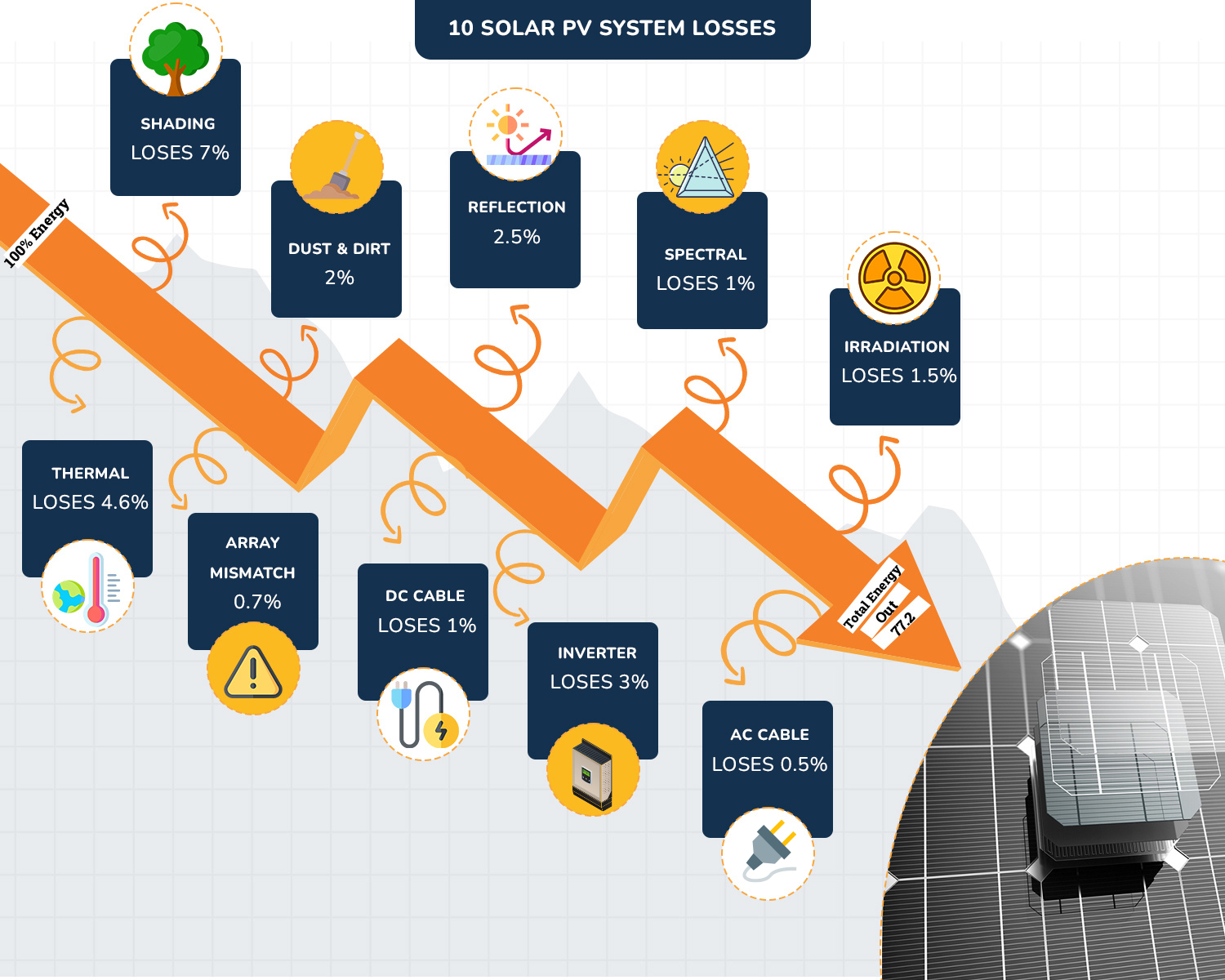

This fictitious idea that you and so many other people have stuck in their heads about the efficiency of electricity is not reality-based if it pertains to low-voltage and low-amperage electronic devices that we call photovoltaics. There's nothing remotely efficient about them.

Edit:

Here's an even better chart:

Last edited by kbd512 (2024-04-09 23:18:29)

Offline

Like button can go here

#117 2024-04-10 06:48:42

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,822

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

For kbd512 re #116

Thank you for an interesting puzzle to solve!

Here is a snippet from your post:

We are passing "little energy collectors through the pipe", but we're calling them "molten salt", and they are returned to the trough to "get recharged" by the Sun.

The distinction between baryons and electrons is difficult to make, and when folks think about systems in which the two have different roles, it is sometimes confusing. I'm not saying this happened to you. It appears that you are never confused. However, for the sake of any readers who may come upon this discussion, I will try to make the distinction.

The heavy baryon clusters you've described can be likened to a full back football player, barreling down the field with a full load of momentum. The football player is carrying the football, and after a great deal of effort, the football is delivered to the end of the field.

The football can be likened to an electron. The quarterback in a PV system just throws the football to the end point. There is much less fuss and noise.

There are those who like the hustle and bustle of the fullback approach, and you may well be one of the millions of fans who do.

Others like the efficient technique of the PV quarterback.

Both approaches obviously work, so everyone is a winner.

(th)

Offline

Like button can go here

#118 2024-04-10 11:04:28

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,422

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

tahanson43206,

Can you explain what you think is efficient about photovoltaics, apart from the fact that they directly generate electricity?

What valuation do you assign to all other relevant metrics, or do you not believe any other metrics are relevant?

Offline

Like button can go here

#119 2024-04-10 11:16:29

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,822

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Inspired by the recent work of kbd512 in this topic, I asked ChatGPT4 to try to assist Nikola Tesla in imaging a hybrid of thermal and photovoltaic solar collection systems. Here is the result. PV systems (of course) are NOT subject the Carnot.

Innovative Solar Energy Capture and Storage Device: A Conceptual Exploration

In a speculative collaboration inspired by the inventive spirit of Nikola Tesla, we conceptualize a revolutionary device designed for capturing and storing solar energy. This compact, mobile device, ideally navigating through a sunlit pipe, embodies a fusion of photovoltaic technology and advanced energy storage solutions, releasing stored electrical energy upon demand.

Core Components:

Photovoltaic Layer: A layer of highly efficient, flexible material that converts sunlight into electrical energy, optimized for broad-spectrum solar radiation absorption and high-temperature resilience.

Electrochemical Storage Medium: Beneath the photovoltaic surface lies an advanced storage medium, akin to supercapacitors or solid-state batteries, designed for rapid energy charge and discharge, high capacity, and thermal efficiency.

Thermal Insulation and Management: An integrated layer of thermal insulation and phase change materials ensures optimal temperature control, preserving the efficiency and lifespan of the storage medium.

Control and Release Mechanism: Equipped with sensors and a microcontroller, this system manages energy storage and triggers energy release upon exiting the lighted environment, utilizing wireless electromagnetic activation.

Protective and Conductive Casing: The device is encased in a protective, conductive shell that doubles as an electrode, ensuring durability and efficient energy transmission.

Dynamic Alignment and Mobility System: A system for optimizing sunlight exposure and ensuring smooth navigation through the pipe, potentially incorporating magnetic levitation technology for reduced friction.

Feasibility and Challenges:

While rooted in contemporary technological principles and emerging innovations, the realization of this device faces significant challenges, including the integration of its components into a compact, efficient, and durable package. Advancements in materials science, energy storage technologies, and miniaturization are paramount to overcoming these obstacles and bringing this visionary concept to fruition.This conceptual exploration seeks to push the boundaries of solar energy technology, inspired by the legacy of Nikola Tesla's relentless innovation. It represents a bold stride towards harnessing solar power in more efficient, versatile ways, contributing to the ongoing evolution of renewable energy solutions.

(th)

Offline

Like button can go here

#120 2024-04-10 13:31:41

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,422

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

tahanson43206,

A 25% efficient photovoltaic cell produces about 250W or 900,000J of energy per square meter, per hour.

H=mcΔT

H = 1,000g * 1.559J/g·°C * 305°C

H = 475,495J/kg

The solar salt used at Crescent Dunes is around 1.559J/(g·°C) at 565°C, so 1,559J/kg·°C. The "cold" reservoir is 260°C. Solar salt is about 1,890kg/m^3. The flow rate is 10,000gpm, and 1m^3 is about 264.172 US gallons, so 37.85m^3 per minute is being heated back up to about 565C, so 71,544.3kg per minute, so 34,018,956,928.5J/min, or 2,041,137,415,710J/hour.

566,982,615Watt-hours of thermal energy input, with a nominal output of 110,000,000 Watts, is 19.4% efficient. That sounds totally plausible for a steam engine, which is what they're using. Crescent Dunes has 1,200,000m / 1.2km^2 of collector area in total.

1,200,000m^2 * 900,000J = 1,080,000,000,000J = 300,000,000MWh per hour

Looks great, right? We outright "proved" that electricity is more efficient. If only it was that simple...

1. You're going to lose about 30% of that electrical power inside the photovoltaic farm, so you only get to keep about 270MWh, per hour. One of the photovoltaic farms near our house was proud of only losing 29% of their power inside the photovoltaic farm. Long story short, they were smart and used more Copper to reduce electrical resistance.

2. I'll give you 8 hours per day at that full rated output level to produce that much power over a year using photovoltaics alone, because in the Northern hemisphere we have seasonal solar irradiance fluctuations that we call "winter" and "summer". This is not as much of a problem in the South, but it's a consideration in the North. This is very optimistic unless the photovoltaics are located in a desert, but let's assert the optimal case.

3. 270MWh * 2,920hrs per year is 788,400MWh per year for ideally located photovoltaics.

4. Crescent Dunes has a 90% capacity factor, so it produces 110MWh over 90% of the hours per year, meaning 110MWh * 7,884 hours per year, or 867,240MWh per year.

5. Since photovoltaics alone do not "load follow", any excess power they produce around mid-day, which is not otherwise stored, is delivered to the ground wire. As photovoltaics age, they produce less power over time. The photovoltaics have to be replaced about 3X as often as thermal power plants.

That takes us back to supercritical CO2. The 10MWe sCO2 turbine was determined to be about 28.3% efficient in testing at the pilot plant here in Texas, at the same temperature that Crescent Dunes operates at, but the heat exchanger temp drop was larger than it was for Crescent Dunes. A 100MWe+ sCO2 turbine would be more efficient because it's larger, but maybe we want multiple small turbines to optimize load following capabilities and provide a measure of redundancy. That gives us around 160MWe worth of power from the same starting temperature as that used by Crescent Dunes, albeit using atmospheric heat exchange to drop the temp of the sCO2 below the solidus temp of the solar salt (consuming heat at a faster rate, thus requiring more storage capacity), which works out to 1,261,440MWh per year.

That's how inefficient direct electrical power generation is without electrical energy storage or higher efficiency photovoltaics. A 25% photovoltaic array that performs direct conversion of photons into electricity can't beat a 19.4% efficient steam engine on total power output over a year, simply because the steam engine is operable over 90% of the hours in a year vs 33% of the hours in a year for photovoltaics. That's also total annual output from the exact same sized array, so those power output figures are near to absolute for 25% efficient photovoltaics. For you to get more electrical power from the photovoltaics, you have to increase the efficiency of the cells, increase the size of the array, or add significant storage and extra photovoltaic array capacity / surface area.

Offline

Like button can go here

#121 2024-04-10 18:36:43

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,422

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

I cannot stress enough that if photovoltaics are not ideally sited, then you may get 1/3rd of the very optimistic power output figure I quoted.

Dec 13, 2022 - The average capacity factor of U.S. solar projects operating all 12 months in 2021 was 24.4% nationally, in line with 2020 levels.

In Arizona, photovoltaic capacity factor is about 29%. In Ontario, Canada, it's 17%. In Bavaria, Germany, it's around 12%.

Therefore, the 33% capacity factor figure I quoted for photovoltaics is overly-optimistic, not reflective of the US as a whole, and certainly not reflective of the world's photovoltaic installations as a whole. What it does show is that even if the photovoltaic panels were a little more efficient at converting photons into electrons, the power output over time is still less than that of solar thermal. Topaz photovoltaic farm in California, one of the largest in America, averages a 27% capacity factor, IIRC.

It is time to talk about "Capacity Factors" by Lars Shernikau

From the article on LinkedIn (written by an energy economist and commodities trader):

Worldwide average solar natural capacity factor (nCF) reaches about ~11-13%. Best locations in California, Australia, South Africa, Sahara may have above 25%, but are rare. (see www.globalsolaratlas.info, setting direct normal solar irradiance)

Worldwide average wind natural capacity factors (nCF) reach about ~21-24%. Best off-shore locations in Northern Europe may reach above 40%. Most of Asia and Africa have hardly any usable wind and the average nCF would be below 15%, except for small areas on parts of the coasts of South Africa and Vietnam. (see www.globalwindatlas.info, setting mean power density)

Natural capacity factors in Europe tend to be higher for wind than for solar. Wind installations in Northern Europe may reach an average of over 30% (higher for more expensive offshore, lower onshore), but less than 15% in India and less than 8% in Indonesia. Average, and the emphasis is on average, annual solar PV capacity factors reach around ~10-11% in Germany, ~17% in Spain, ~25% in California, and may reach 14-19% in India, but they reach less than 15% in Indonesia’s populated areas. Carbajales-Dale et al. 2014 confirm higher capacity factors for wind than for solar; they estimate global average wind capacity factors to be around 23-29% and solar around 11-13% (see figure above).

The figure further below illustrates a two week period in May 2022 (when I wrote the chapter of our book "The Unpopular Truth... about Electricity and the Future of Energy" on capacity factors), where the average wind capacity factor reached only ~5% for ALL German wind installations (on- and offshore).

The “natural capacity factor (nCF)” is the % of the maximum possible output of the “power plant” (coal, gas, nuclear, solar, wind, hydro, etc), achieved under the natural conditions of the site, assuming no operational or technological failures or outages.

I define “utilization” is the % of the power plant’s workable capacity used on average over the year, which is only reduced because of technological, operational, economical outages, or curtailments… completely independent of the nCF

The “net load factor” – in my definition – is then the product of natural capacity factor x utilization

Thus, when we speak of the natural capacity factor, we are only referring to the nature-derived capacity factor, not the technological or operationally driven “utilization” (often referred to as uptime, plant load factor, or PLF). In other words, when technology fails, or a power plant is turned off on purpose, this will reduce the utilization but not the natural capacity factor.

Offline

Like button can go here

#122 2024-04-11 02:30:54

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,422

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Now let's use the real capacity factor for Arizona, which manages 29%, a remarkably high value. That equates to 2,540 hours per year of full rated output. Let's further assert use of the most efficient triple-junction solar cells developed and tested by NREL under real world conditions, which would be 39.5% efficiency, or 395W/m^2. NASA uses these extraordinary solar cells for their Mars missions. NASA pays around $1,000,000/1kW for that advanced capability.

Could triple-junction photovoltaics be produced more cheaply? Probably. 10,000X more cheaply, meaning $100/kW? Probably not. 100,000X more cheaply, meaning $10/kW, or twice as expensive as single-junction? Get real. Well, why not? For starters, 10,000X is a steeper price drop than single-junction cells experienced over the past 40 years ($105/kW in 1975 to $4/kW today, in terms of 2015 dollars), by about two orders of magnitude. The current low price of single-junction photovoltaics manufactured in China involves 40+ years of manufacturing process refinement, burning coal to make the Silicon, no environmental regulations, and slave labor for panel assembly. 80% of the cost of photovoltaics is now the materials, essentially energy to take highly disordered matter and transform it into the most highly ordered type of matter humans know how to produce- semiconductors. $100/kW is still a 25X higher price than for single-junction. That might still be worth it if they produced 25X more power per unit area, but they can't do that. All that extra money pays for an additional 14.5% efficiency improvement. A photovoltaic panel that already costs almost as much per installed kW as the total delivered power production cost of Crescent Dunes ($135/MWh or $0.135/kWh), which is inclusive of 10 hours of thermal energy storage providing full rated output, is probably going to remain cost-prohibitive well into the foreseeable future. Anything is possible, but the required cost reduction seems implausible, because it requires an even greater degree of ordering of the disordered matter.

Ignoring economic realities, if only for a moment:

1,200,000m^2 * 395W/m^2 = 474,000,000Wh per hour or 474MWh

474MWh * 2,540 hours per year = 1,203,960MWh per year

Remember that 160MWe solar thermal plant powered by a 28.3% efficient sCO2 gas turbine from my Post #120?:

That gives us around 160MWe worth of power from the same starting temperature as that used by Crescent Dunes, albeit using atmospheric heat exchange to drop the temp of the sCO2 below the solidus temp of the solar salt (consuming heat at a faster rate, thus requiring more storage capacity), which works out to 1,261,440MWh per year.

1,203,960MWh per year using 1,200,000m^2 of 39.5% efficient triple-junction photovoltaics

1,261,440MWh per year using 1,200,000m^2 of solar thermal collector area powering a 28.3% efficient sCO2 gas turbine

Within the realm of commercial photovoltaics technology, that's how inefficient direct electrical conversion is without battery energy storage. After we invoke 39.5% efficient $1,000,000/kW triple-junction NASA Mars probe / military spy satellite level photovoltaics, we still can't beat a silly little gas turbine on total annual electrical power output, despite the fact that it has the same thermal efficiency as a carbureted gasoline piston engine built during the 1950s.

Recall how power generated by Crescent Dunes was deemed "too expensive"?

It produced power for $0.135/kWh, which is at or below the market rate today. Add electrochemical battery storage with half the cost of today's battery storage, plus $4/kW photovoltaics, and you still arrive at a cost figure of around $0.322/kWh, using NREL's 2030s $159kWh battery storage cost projection. If we're going to pay for electricity that expensive, then we may as well pay for advanced nuclear reactors, which also produce power over 90% of the time.

I see no reason to pay for nuclear reactors when solar thermal is so inexpensive compared to any other energy source except coal, or natural gas in select parts of the world. Since coal and natural gas won't last forever, we use some of our excess solar thermal power to recapture CO2 and synthesize liquid hydrocarbon fuels and coal. Nature uses sunlight and CO2 to make liquid fuels, namely starches and sugars.

Nuclear thermal and geothermal still have roles to play in places where sunlight is a scarce commodity. Wind is so unpredictable in most parts of the world that it defies forecasting attempts, but in certain places like the UK, it's an important energy source. When and where we can get lots of sunlight, we immediately convert that into thermal energy storage, and then generate electricity on-demand, or use it to directly synthesize hydrocarbon fuels. That gives us a market reason to collect and store CO2. That's why we need a strategic CO2 reserve.

However superficially inefficient thermal power appears to the untrained eye, it's a hard requirement for a cleaner energy future, one that can be delivered over a relatively brief period of time, one that is both long-lasting and boringly reliable, as well as simple to repair and maintain into perpetuity. The cherry on top is that it doesn't place any strain on available mineral and metal resources when scaled-up to the degree required to replace coal and natural gas as baseload power. The true beauty of thermal machines is how something so simple can be so profoundly effective in its ability to improve our lives. Thermal power is an effective application of brute force.

Rather than being upset over the fact that photovoltaics and wind turbines cannot deliver on what the unscrupulous amongst us assert they can do, we should be overjoyed that there are pragmatic and effective solutions available that give us what we say we want- cleaner energy at affordable prices. It's there for the taking whenever we come to our senses.

Offline

Like button can go here

#123 2024-04-12 06:25:12

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Concentrated Solar Power on Demand (CSPond): Solar Harvesting and Storage

Lecture # 17 Solar Thermal Energy

Of course, we need to do this at the homestead level to slow the level required from a large system that is becoming more and more costly.

Offline

Like button can go here

#124 2024-04-19 19:20:32

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

This is the bespoken solution as not much of it can be scaled as the parts to do so are not sitting on a shelf ready for use. They must be designed, tested and fitted for use from scratch.

https://www1.eere.energy.gov/ba/pba/pdf … trough.pdf

Offline

Like button can go here

#125 2024-04-28 18:16:02

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Once the gas or liquid of choice changes phase one needs to recompress it for the next use and a scroll compressor will moost likely be the choice.

Expander design procedures and selection criterion for small rated organic rankine cycle systems

Now that we have expansion due to heat being applied we need that pressure energy to move a turbine or in this case why not a scroll compressor in reverse.

Conversion of a scroll compressor to an expander for organic Rankine cycle: modeling and analysis

Which means modifying Study on Design modifications and feasibility in Conversion of scroll compressor into Scroll expander for using as battery charger.

Fundamentals of turboexpander design and operation

Hybrid Compressor/Expander Module

Experimental Investigation of a Hermetic Scroll Expander-Generator

Now to do my homework to apply what I have found and posted about.

Offline

Like button can go here