New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#51 2022-11-28 02:41:27

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

SpaceNut,

Economies of scale are created because running your own Acme hydrocarbon fuel synthesis plant from the comfort of your backyard requires a level of education and attention to operation that most people cannot provide. For those who could, they'd normally try to monetize their "special skills", which then leads to the realization that larger plants are more efficient. This is pretty evident from the fact that some of us think we can make a declaration or assertion about what reality should be, which we find convenient for our favorite / aesthetically pleasing idea, and then the universe is supposed to conform to our assertions.

If you have a degree in petrochemical engineering, odds are better than average that you're going to work for someone who has already built a petrochemical refinery, because even a miniature version of a plant that can produce a produce with consistent quality is fairly complex.

Making your own alcohol is not much of an equivalent, either, but for those moonshiners without proper test equipment, they cannot guarantee the alcohol concentration / content, either. I've never seen anyone with no prior knowledge and training make kerosene from crude oil in their backyard, though.

The entire reason Standard Oil became "a thing", was that they were able to guarantee the consistency of their product. If their gasoline said 87 Octane, then it was actually 87 Octane and they tested it at the refinery to ensure that it was.

How many of you are going to spend all weekend whipping up a batch of gasoline to pour into your tank to use on Monday?

Even if you don't blow yourself up, what happens to your engine if it's not at least 87 Octane?

Division of labor exists for a reason. You don't need to be a mechanic or a petrochemical engineer to drive a car.

Offline

Like button can go here

#52 2022-11-28 20:05:20

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,631

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

I look at biodiesel and see that it's very possible, but you need more than the equipment and ingredients to achieve that goal.

https://www.motherearthnews.com/sustain … z15aszmar/

Diesel engines offer consumers 20-40% better fuel economy as well as more torque at a lower rpm than gasoline.

https://www.wikihow.com/Make-Synthetic-Gasoline

So possible but is it wise if you are not knowledgeable to operate it.

Offline

Like button can go here

#53 2022-11-28 21:28:58

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

SpaceNut,

How much monetary and technical knowledge investment is required to build and operate your own biodiesel plant?

I'm sure plenty of people have thought about doing it, but there must be something holding most people, including the farmers who are utterly dependent upon diesel fuel, from doing it.

Going from idea to reliable and repeatable operation is the difference between discovering Tungsten lightbulb filaments and manufacturing incandescent bulbs by the tens of millions.

Offline

Like button can go here

#54 2022-11-29 21:18:17

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,631

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

https://www.backwoodshome.com/make-your … er-gallon/

https://www.motherearthnews.com/sustain … z15aszmar/

https://www.utahbiodieselsupply.com/makeyourownfuel.php

About a $1 a gallon for these articles but less than $2

key staring ingredient is a vegetable oil or the collection from a deep frier from a restaurant.

https://www.survivopedia.com/how-to-make-vegetable-oil/

https://woodlandguide.com/homestead-101 … etable-oil

Offline

Like button can go here

#55 2022-12-02 15:13:13

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,131

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

For kbd512 ...

I noted your (quite reasonable) exchange with SpaceNut about the benefits of Division of Labor and Specialization in design of a facility to make gasoline and other hydrocarbon fuels from original sources, as (I understand) you are advocating.

I'd like to offer an alternative future that allows the vision of SpaceNut to merge/blend with yours...

A facility to make hydrocarbon fuels from original sources might well be tended by an "ordinary" person. We (humans) have often entrusted extremely complex machines and even entire systems to individual "ordinary" persons.

To offer an example, the current (and worrisome) railroad disagreements between management and labor reminds me that a powerful locomotive is placed in the hands of an operator who is skilled at the needed functions. However, this person does not (most likely) have the engineering or other skills that would be needed to duplicate the engine.

I offer this example to (at least try to) illustrate how an ordinary person might be able to operate/manage/look-after a complex solar-powered hydrocarbon manufacturing system.

The issue at hand is scale, as you have pointed out. To (try to) offer another example, the United States (and other countries) produce food stuffs at a truly astonishing scale, but the individual food producing subsystems are managed (in large part) by ordinary persons who have the needed skills.

Funding of a system of the scale you have described would (it seems to me) best be funded by small funders in great numbers, rather than a few funders on a massive scale. And ** that ** might be achieved if the design of the system you have described could be implemented as a great number of small sites, each tended by an "ordinary" person, while the complex design and support activity occurs in a separate location where persons with the required talents collaborate.

(th)

Offline

Like button can go here

#56 2022-12-02 15:16:43

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,131

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

As a follow up to Post #55

There may very well be a minimum size needed for a facility to make hydrocarbon fuel from original sources. I'm thinking here of chemical and physical processes that must operate at some minimal scale in order to produce results efficiently.

It is ** that ** size (whatever it may be) that I am imagining can be operated/supervised/looked-after by an ordinary person.

(th)

Offline

Like button can go here

#57 2022-12-03 21:39:31

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,631

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Offline

Like button can go here

#58 2022-12-03 21:59:58

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,131

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

For SpaceNut re #57

I've only had a chance to look at the research paper at the bottom of your list in #57, but it looks well done, and potentially of interest to a wide range of possible users. The work seems to be primarily for water heating, as distinguished from the more intense solar troughs that kbd512 has proposed for manufacture of synthetic carbon based fuels.

Design and Fabrication of Parabolic Trough Solar Water Heater for Hot Water Generation

(th)

Offline

Like button can go here

#59 2022-12-03 22:09:19

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,631

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

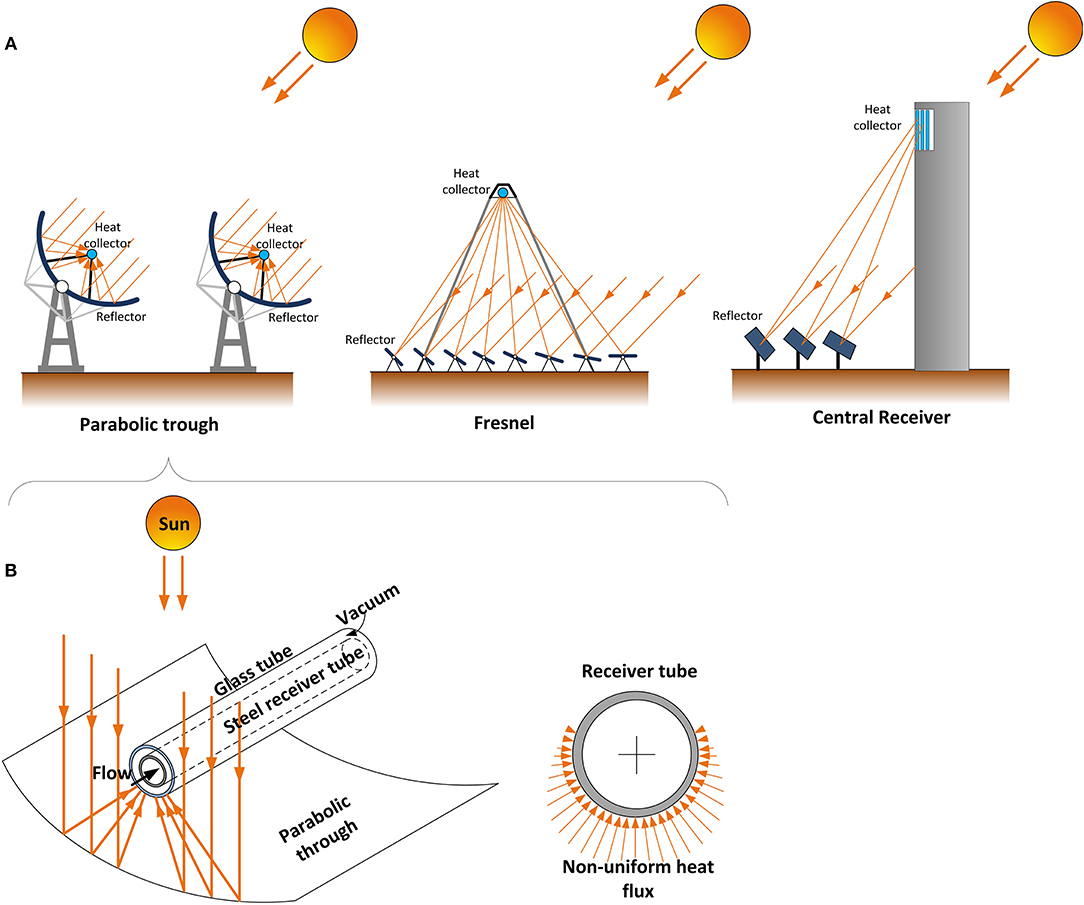

From what I understand about a trough it is the size of the reflective surface to the focal point that gets all of the gain. The posted links talk about the equation to create the shape to the focal point of the reflector.

Repost as it applies here

Found a second topic but this is about chemical conversion off the heat...

https://www.sandia.gov/ess-ssl/wp-conte … mal_Ho.pdf

https://www.frontiersin.org/articles/10 … 00147/full

Experimental In-tube Flow Boiling Heat Transfer Correlations

Solar power tower convert sunshine into clean electricity. The technology uses many large, sun-tracking mirrors commonly referred as heliostats to focus sunlight on a receiver at the top of a tower. The enormous amount of energy, coming out of the sun rays, concentrated at one point (the tower in the middle), produces temperatures of approximately 550°C to 1500°C. The gained thermal energy can be used for molten salt, which saves the energy for later use.

Offline

Like button can go here

#60 2022-12-04 07:41:34

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,131

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

For SpaceNut re #59

From my rapid study/scan of the paper from India, I get the impression that practical construction won the battle with theory.

A circular trough is easier for humans to manufacture in the Real Universe. The liquid carrying pipe used to collect photons from the reflecting surface can be sized to collect them all, so the equations you have linked ** should ** be able to tell the builder how large to make the collecting pipe, and where to put it.

The Indian researchers used manual rotation of the trough systems to carry out their observations. They advanced the angle of the trough every thirty minutes.

In a commercial (or serious amateur) system, the trough rotation should be automated, and the rotation can be made continuous with a worm drive. A simple optical feedback control system can insure the trough is aligned with the Sun at all times.

(th)

Offline

Like button can go here

#61 2022-12-04 10:05:17

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

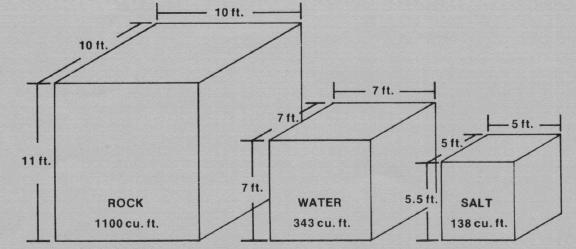

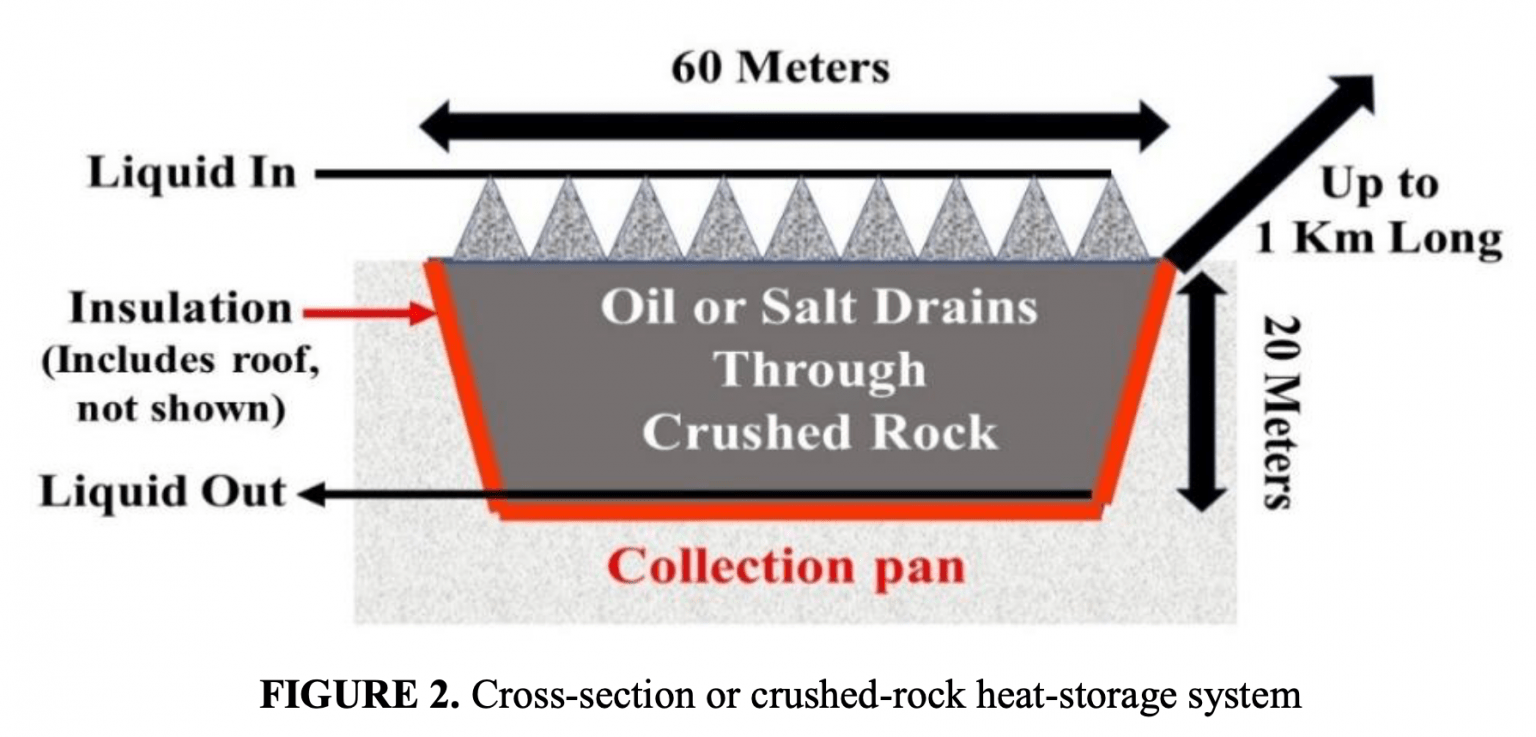

Regarding thermal energy storage: Sensible heat storage may provide a reduced cost option at the expense of more bulk. By this I mean silos filled with crushed rock. Rock will be crushed into pieces no larger than a few inches in diameter. Heat will be introduced into the silo via an oil-air heat exchanger. A fan will blow across the heat exchanger tubes and transfer heat into the crushed rock. The air would return through an inner tube into an air-steam heat exchanger, which would generate the steam needed for power generation. The silo would be a double skinned, thin shell of low alloy steel with I-beams to maintain a cylindrical shape. Insulation would be provided the sand between the two skins.

The amount of energy stored in the rock is a function of the temperature difference between the hot oil and the steam. If a 10K temperature difference is sustained, then the energy stored per cubic metre will be:

Q= 3000kg/m3 x 1KJ/Kg.K x 10K = 30,000KJ (8kWh).

To generate 100MWe for 8 hours (night) at 33% efficiency, requires 2400MWh of stored heat. This would require some 300,000 cubic metres of rock. A cylindrical steel silo some 73m in diameter and 73m tall would be sufficient.

Last edited by Calliban (2022-12-04 10:11:28)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#62 2022-12-04 14:22:33

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

The far western spur of Texas and south New Mexico appear to be the best places to start a large scale solar synfuel initiative.

1. They have excellent solar resources, as indicated on the map linked below.

https://www.seia.org/sites/default/file … ale_01.jpg

2. The western spur of Texas is also the southern most part of the rocky mountains. The map below shows that it has good wind power potential in this area. This is important because by combining the solar thermal and wind power, the electrolysis stacks can be operated at greater capacity factor, reducing costs. To keep costs to a minimum, all infrastructure must operate at high capacity factor, ideally 24/7.

https://i.pinimg.com/736x/8b/12/94/8b12 … 4eae0d.jpg

3. West Texas and southern New Mexaco have a freight railway running through them. This provides a direct rail link to the port of Houston. This allows powerplant componants to be shipped by sea to houston and then by rail to within a few tens of miles to the solar sites.

http://www.destination360.com/travel/ra … ad-map.jpg

4. Texas has a lot of pipeline infrastructure and an established industrial infrastructure for creating more. We need pipelines to get the finished product out. The south coast has the largest concentration of product expirt terminals in the US, including gasoline, LPG and LNG. Dimethyl ether, which is a commonly considered diesel substitute has similar vapour pressure to propane (LPG).

https://eaglefordshale.com/efs-news/mor … nes-needed

5. Texas and southern NM have iron deposits than can be used to produce cast iron and low carbon steel close to where we need it. The scale of the solar synfuels project is such that it makes sense developing dedicated metallurgy facilities close to where we intend to deploy the materials. Iron oxide can be reduced to metallic iron by heating crushed ore to 800-1000°C and passing hydrogen gas through it. The resulting iron powder can be turned into higher grade cast iron and steel by melting it in an electric arc or induction furnace and using an oxygen lance to burn off impurities. The H2 reduction phase could be carried out in batches. The steel making phase should be run continuously, to avoid thermal cycling which would damage the furnace lining.

https://etc.usf.edu/maps/pages/7100/7192/7192.htm

The scale of operations allows tailored facilities to be developed. For example, Kbd512s plan calls for use of aluminised mild steel mirror components. These will be 1-2mm thick steel plate, with 50 micrometre thick aluminium-silicon alloy coating. To recycle this material, we would chop the steel, heat it to 600°C and centrifuge it, allowing the alloy to drain off of the steel. This would need to be carried out in an argon, nitrogen or CO2 atmosphere. But it would cut the long-term need for aluminium by about half. The steel can be recycled in an electric arc furnace with close to 100% efficiency.

To produce synfuel a steady flow of CO2 is needed. This could be imported as liquid from a terminal on the Texas coast. The difficulty here is that to get to the best solar regions, the pipeline would need to traverse the entire state. It would need to be several hundred miles long. Ammonia can be produced from nitrogen extracted from the air. The problem is that ammonia is a less useful fuel than methanol or DME.

Last edited by Calliban (2022-12-04 15:48:58)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#63 2022-12-04 14:35:47

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,631

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

We actually did cover the thermal storage before

repost

The size of the rocks are important to the levels of heat curve that you are desiring from the capture of the heat that is coming into the system. Typical size is 3/4" to 2" size for the capture for the air circulating system to give off the heat over a period of time.

https://inspectapedia.com/Energy/Rock_B … Design.php

Of course, smooth larger rocks can also be used in a design.

Of course with solar concentrated reflected energy the design would be altered versus other heat sources.

http://www.scienceasia.org/2010.36.n3/scias36_237.pdf

A rock fills based solar thermal energy storage system for housing

Changing the media type can also be done to improve the collection retention system as well

Zeolite thermal storage retains heat indefinitely, absorbs four times more heat than water

Offline

Like button can go here

#64 2022-12-04 16:27:08

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Thanks Spacenut, a good find. Zeolite storage seems to work best at low temperatures. Ideal for space heating or hot water. I wonder if a combined approach might be effective for town heating. We could have a solar thermal station with seasonal rock storage system outside of town. Trailers containing zeolite could be towed to the station and recharged by blowing hot air through pipes. This would vent the moisture. A trailer tank containing say 3 cubic metres of zeolite would carry about 500kWh of heat. That would be enough for about 1 week of heating for a small house.

The energy contained in hot rock is a function of the temperature range over which it is heated. If the rock is heated to 300°C and continues chargeing zeolite tanks until its temperature drops to 100°C, then each cubic metre will store 166kWh of heat. I wonder if there are cheap and easy ways of building these thermal stores. It is worth thinking about given the cost of natural gas these days.

Last edited by Calliban (2022-12-04 17:00:37)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#65 2022-12-04 16:57:58

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

tahanson43206,

I can't envision a singular person doing this, if that's what you're after. A larger number of smaller-scale companies could run independent fuel synthesis plants, but we're talking about at least the same number of people devoted to running a normal utility-scale power plant, plus the personnel running the chemical synthesis plant, plus personnel to distribute the product.

For various reasons, producing less than 10,000 (1 tanker truck) per day is unlikely to be a long-term profitable venture. If you're selling 10,000 gallons of product at $2.50/gallon, or $25,000/day, then your gross yearly revenue is $9,125,000. If you employ 50 people, each making $50,000/year, then $2,500,000 is already spoken for. The rest of the equipment has to be paid for and turn a profit over its lifetime of 25 to 50 years.

Take a look at this 10,000GPD facility. A similarly-sized and staffed plant will be running either 24/7 with thermal power storage, or over a 12-hour shift:

Used-PESCO Oil Re-Refining Plant. Rated for 10,000 Gallons / 250 barrels per day

Tell me if you think a single person is going to operate that. I'm thinking a dozen people looks a lot more realistic. The solar side of the plant may only require periodic cleaning and replacement of seals, which could be subcontracted work so that those people can specialize in operating the equipment to do that (a spray truck and welding equipment). Keeping a plant running for 50 years revolves around two words: "cleaning" and "maintenance". This is how the US Navy makes an aircraft carrier last for 50 years. There's no magic to it. It's just a lot of grunt work over time.

Can we streamline the layout of the plant and ensure that it's as compact and simple to operate as possible?

I bet we can do that.

1. CO2 and H2O and solar thermal power inputs

2. Sabatier reactor to make Methane

3. Socony-Mobil Zeolite-based Methane-to-liquid fuel (Propane / gasoline / diesel / kerosene)

4. Pipeline to send the product to regional storage tanks

5. Trucks distribute the product to service stations

Energetic liquids are easy to transport, they take up very little space, and they can be stored for months at a time. Propane can be stored for years, since it doesn't break down and nothing has evolved to eat Propane (unlike plastics or diesel or kerosene).

However superficially inefficient or aesthetically-unpleasing it appears to be, it's a recipe that works. Since metal requires constant power to keep it molten, this is the only solution that works for making huge quantities of metals that batteries mandate. Mining and refining run on constant power, much like ships / trains / aircraft / national-scale electric girds.

Going back to our talk about a modern gasoline vehicle vs a cell phone, a passenger vehicle is 10,000 times heavier than a cell phone (10,000X more material input) but only requires 400 times more energy (embodied energy in a cell phone is sky-high). Electronics are incredibly energy-intensive to produce and don't last very long before they need to be replaced, hence more and more electronics is clearly not the solution, unless the unstated goal is to burn through hydrocarbons at an even faster rate. If that isn't sustainable now, then it's even less sustainable when done at a multiple of the present rate.

* Simpler power generation and storage systems (common materials, limited toxicity, long service lives, easier recycling because nothing last forever)

* Simpler vehicles (lower cost, longer service life, easier to repair)

* Simpler and shorter supply chains using very common materials (if people and energy are approaching limits)

* Recycling of CO2 (better than no recycling, better than squandering energy and money to dump it into the ground)

* Development of longer-lasting / faster-charging batteries using materials that present no supply constraints or potential future conflicts, again (assuming the goal is to maximize utility, minimize cost, and to eschew "planned obsolescence" in favor of "planned foreverence")

You can't do this stuff without energy and lots of it. The technology to do electric or electronic everything in a practical way doesn't presently exist. Over the coming decades, if it proves workable, then of course we'll implement it. We won't be mining thousands of years worth of scarce materials in the span of a decade or two. We certainly won't be doing it without an energy bridge, which can only come from recycled CO2 that's turned back into liquid fuels. That will never happen, so we should quit pretending that it will.

Making everyone poorer is idiotic beyond belief. We've already seen what that world looks like. There was nothing good about it, according to the people who lived through it. There was nothing "green" about it, either, unless burning wood and poop counts as "green energy". That is why they moved away from it the moment technology to use coal / oil / gas became available. Those were the "less bad" alternatives. Along the way, nuclear power became available, but nuclear energy requires a level of education and technology well beyond the reach of many nation-states, even today. Nuclear fusion requires another leap up the education and technology ladder, achievable by some but not all. Our energy mix is likely to remain a hybrid for at least the next century, possibly several. If everyone is ultimately lifted up out of poverty, then we're not stagnating as a species, we're slowly but surely elevating basic quality of life for everyone while making some significant scientific discoveries along the way.

We made great progress during the last century- more progress than all the previous thousands of years of human history crammed into a single century. This century should be devoted to ensuring a decent quality of life is universal to humanity, to razor's edge refinement of all our exiting technology, and the first implementations of next-level technology (interplanetary colonization, fusion power, atomic-level assembly of near-perfect structures, universal immunity to diseases and molecular level disassembly of cancer, initial warp drive experiments, etc). All of these lofty goals start with abundant and readily available energy, which must be sourced from somewhere. The most logical starting point is using our old but reliable heat engines to recycle the combustion waste products already generated.

In military terms, we're consolidating all of our gains (that came from abundant energy) and ensuring that even if we "lose" during the course of some greater endeavor (interplanetary colonization, fusion, warp drives, etc), where we default back to is still a great starting point for future generations to pick up at, and possibly succeed where we failed. The alternative is over-extending of our supply lines. There's only one probable outcome associated with doing that, and it's not good. That should not be our fate. Turning humanity into a plot device for some Hollyweird dystopia is not the answer. We're better than that.

Offline

Like button can go here

#66 2022-12-04 17:48:04

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,631

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

The business model for creation and supply is broken as it inhabits solar pv as it's not possible to build the arrays that would supply to the grid without there approvals. It's that connection that net metering stops from private groups that are not power company suppliers. This does not stop there as it's from doing the same to all other types of derived sources that could be much cheaper than they are. Such things are still in the customized build for these large companies and not available to the individual.

It's the off grid and do it yourselfer that has shown that it can be done even if it's not totally efficient it's still supplying the need for power or heat for what is built within the means of the owner.

Offline

Like button can go here

#67 2022-12-04 18:51:06

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,131

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

For SpaceNut ... this topic is not about solar panels.

On the other hand, your post #66 contains valuable insight that definitely deserves to be published in the NewMars forum.

Let's try to find a topic where your post might better fit?

For kbd512 ... your long and detailed (and interesting) post deserves a thoughtful reply to match your contribution.

** This ** post is just to acknowledge yours!

It may well turn out that there is a better topic into which your post would slip comfortably.

I was (and still am) hoping ** this ** topic will become a repository for knowledge/insight that a future reader would find valuable.

Topic: Trough Solar Collector- Design- Construction- Operation- Maintenance

I think we need a topic devoted to management of a solar powered carbon based fuel manufacturing process.

(th)

Offline

Like button can go here

#68 2022-12-04 20:57:33

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

SpaceNut,

I understand what you want, but there's not a magic box that you can buy to gain energy independence. You need a lot of land, a lot of equipment, and a lot of people to design, build, and operate the equipment. No man is an island. We didn't get to where we are today without a lot of cooperation. Where we've broken down in recent times is a result of plausibly well-intentioned but wrong-headed ideas that were popularized by mass media propaganda without any serious technical scrutiny applied to the mathematical / scientific validity of those ideas. A lot of people who liked the aesthetics of the ideas then supported those ideas with pseudo-analysis and a refusal to accept that the ideas, however pleasing to them, were utterly impractical at human civilization scale.

When we had cheap Chinese coal combined with slave labor and no environmental protections at all, photovoltaics and batteries superficially appeared very cheap and easy to come by. When Western standards for employee and environmental protections are applied, those devices immediately become prohibitively expensive to manufacture, which is why nearly all of them came from third world countries. Any place outside of Chinese metropolitan area is third-world. I know this, because I've actually been there, as well as many other third-world countries, which is why I'm against exploiting other people to make things we should be making ourselves if we're serious about using them as part of our overall energy mix.

Solar thermal does not require advanced semiconductor manufacturing or expensive electronics to troubleshoot and repair problems. That was one of the reasons to use it. China may be able to cut off or destroy advanced semiconductor manufacturing (China / Taiwan / Korea / Japan), but they can't cut off steel and concrete. They can't cut off semiconductors made in America, either. My argument is that some things shouldn't have or require semiconductors to function at all. Ovens, refrigerators, toasters, passenger motor vehicles, trucks, trains, and ships shouldn't require anything beyond metals, paints, plastics, and fuel. There are good arguments for incorporating advanced materials and internet-connected computerized control systems into aircraft and spacecraft. There are no good arguments for why an oven or a refrigerator or a passenger motor vehicle requires an internet-connected computer control system. That's purely a marketing gimmick or an attempt to monitor and control people, because that's how all such systems are ultimately used. You won't find an exception to that assertion, because that's literally what they were designed for.

Thermal power plants can be built with steel, concrete, and other similarly common and readily available materials. Creating a functional monopoly over steel and concrete is much more difficult to achieve. Chasing after every last fractional percentage point of efficiency is what made photovoltaics and batteries impractical for the average person to afford to use. Is it great that those technologies advanced as a result? Sure. That doesn't improve their general applicability. A battery wasn't meant to power a car unless the car is lightweight and range is short, which still means they can be applied to commuter-type vehicles, which is the overwhelming majority of practical use cases for passenger vehicles.

So... We have at least 210 million adults in the US. Assume that all of them use cars to get from Point A to Point B, because this is pretty much true, and explains why we have 291 million registered vehicles. Uncommon sense says that you don't pay money to register a vehicle that's not being used. Assume each car is a commuter-type EV (most efficient possible) with a 10kWh battery pack and 100 miles of range (fantasy world, basically). Assume each of them drive about 39 miles per day since the average American drives 14,263 miles per day [edit:"per year", not "per day"]. Every 2.5 days, they have to refuel. It's not optional. People have to go to work, get food, drop their kids off at school, do work that requires trucks, etc. If someone is driving fewer miles (elderly and infirm), then someone else is making up the difference by driving more (like the people taking care of he elderly or infirm, for example), because useful work doesn't get done without it (in the real world, obviously).

The constant electricity supply requirement is then a bare minimum of 637GW, just to meet energy demands from EV motor vehicles. Annual peak demand is 786GW (all uses), NERC reserve capacity is 117GW, and surplus capacity is 63GW. If you understand what that means, then you also understand that the constant supply increase associated with all-EV commuter passenger cars, all of them built to be as light and energy-miserly as we can realistically achieve, mandates a rough doubling of constant electric grid load, merely to refuel the vehicles. 70% of our power presently comes from burning something, because otherwise we wouldn't have a functional electric grid and all the green dreams go right out the window without one. That is why the notion of powering every single vehicle off photovoltaic panels and batteries remains fantasy-based. It works so long as you can't count and don't see how the secret sauce is made. After you see how the sauce is made, calling it "green energy" is a total farce.

This is why low energy density hampers EV adoption so significantly. The entire notion that we could mine enough metal and double the capacity of our electric grid in 10 years is not reality-based thinking. It's not doable because doing it requires input energy coming out the wazoo.

My alternative states that combustion is still required, thermal power plants still produce power after the Sun quits shining and the wind quits blowing, and therefore an energy store not dependent upon drilling activities to tap underground reserves or wildly increasing mining for metals, is the sort of bridge solution that doesn't assert that this new fantasy world materialize before our eyes with near-zero energy input or entirely new energy storage built from materials with even worse energy density than batteries, above and beyond what we already have for petroleum storage. If thermal power plants can generate and store excess energy, then you can use some of that to build more electric motors and batteries over time.

Last edited by kbd512 (2022-12-18 14:07:21)

Offline

Like button can go here

#69 2022-12-05 19:47:16

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,631

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Yes th I am off with PV but how many homes do you know that have evaporated tubes for solar thermal, or passive thermal transpiring thermal air walls, and I am sure that there is near to zero solar troughs as well at the personal or family levels as well as that would go against the machine of the power companies monopoly in power generation.

Yes kbd512 you need land and equipment but very little is made for the family sized plot of land to be sustainable. I recall that California led the way for solar hot water in the early 1900's before oil became a more reliable method to guarantee that it was hot all the time.

Offline

Like button can go here

#70 2022-12-16 20:42:26

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,131

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Void posted encouraging news about improved performance of solar trough systems:

http://newmars.com/forums/viewtopic.php … 10#p204210

(th)

Offline

Like button can go here

#71 2022-12-16 20:54:42

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,631

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Sure, if you are attempting to isolate the atmosphere from the trough but for most applications that's not needed.

A flat plate collector would require it on its back side to keep heat from wicking to the back of the box that we place it in.

Then again, we can on earth make use of oven insulation for that purpose.

Offline

Like button can go here

#72 2022-12-17 08:44:27

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,131

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

For SpaceNut re #71

This topic was set up following the work done by kbd512 to show that it is possible (ie, could be done if humans invested the time to do it) to generate hydrocarbon fuels from original sources (water/air).

However, the industrial scale of the operation would require high performance of the solar trough equipment.

In your post, I got the impression you were not thinking of kbd512's vision. Instead, I got the impression you might have been thinking of a back yard grill or something of similar small scale.

The process envisioned by kbd512 is going to need high temperatures, and capture of the maximum amount of solar energy would be a priority for the plant management team.

Please provide more detail for this assertion:

but for most applications that's not needed.

What applications are you thinking about?

(th)

Offline

Like button can go here

#73 2022-12-17 17:53:22

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,631

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Kbd512 application

Notice no insolation at all is required for the temperatures generated to the tube in the center of the image above the reflector.

This is the flat plate collector

As you can see its got insolation to separate the tubes from the back panel.

Now make the reflector larger and plate this in the focal point and you get more flow of hot fluid due to the greater size.

Both can get to high temperatures to make use of as heat energy.

Offline

Like button can go here

#74 2022-12-19 01:28:45

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Methanation doesn't require extremely high temperatures, although it does require considerable pressure. I wonder about whether or not the Sabatier reactor could be contained within that stainless steel tube that's normally used to transport hot oil from the trough to a heat exchanger. Less thermal power would be lost that way since no oil has to be present to transport the thermal power to a separate power generating device, plus millions of gallons of special high temperature oil are removed from the process entirely. The temperatures generated within the tube already closely match those in a Sabatier reactor.

We need to remove as much complication from the process as we can manage. The goal here is to build a minimum complexity fuel synthesis plant that produces Methane first, then Propane / Ethanol / gasoline / diesel. We're not going to be able to mine enough metal to transition to batteries within the next 30 years. If we foolishly try to do that anyway, then our total CO2 emissions will be far higher than they presently are. Assuming that increasing CO2 emissions is what we wish to avoid, then the only realistic way we can achieve that is by synthesizing fuels. If this upsets our purists who think electrification is a magic totem, then so be it. If dramatically better batteries and photovoltaics and wind turbines never materialize, then we still have a viable way to power humanity, even if all the oil and gas wells run dry.

In addition to more or less completely replacing most of the gasoline and diesel powered vehicles, you simultaneously have to double the generating capacity of the electric grid without burning anything, bolster the ability to transmit inordinately more electricity at any given time to avoid brown-outs / black-outs caused by many tens of thousands of superchargers dragging down the grid, and you have to do all that without burning inordinately more fossil fuels, or your net accomplishment is increasing CO2 emissions. That seems like a horrendously more complex undertaking than swapping out the fossil fuels with fuels made using atmospheric CO2.

The more and more you understand about how the very nature of this low energy density issue affects material requirements to generate or store equivalent power, the better and better liquid hydrocarbon fuels appear after you understand that water and CO2 can be endlessly recycled using solar thermal input power. In point of fact, this is the sole reason life exists on Earth to begin with.

If you fixate on the problem itself, rather than what the problem indicates, then you end up with the current type of idiocy which implies that we're going to extract thousands of years of supply, at present extraction rates, of various "must have" metals, but somehow decrease CO2 emissions. In the end, this is (to me, at least) an excruciatingly simple basic math problem. We, as in all of humanity, are not going to mine thousands of years worth of metals to make these "green energy" machines without burning coal and diesel like it's going out of style.

If we had built factories to fabricate small modular nuclear reactors like ships about a half century ago, then we'd at least have reliable electricity (without burning coal and gas by the shipload) to charge everything powered by a battery. That would've at least made battery-electric vehicles and trains a practical option. Since we didn't do that, specifically because of the bad press created by our fake environmentalists / real humanity haters, the next most practical option is fuel synthesis. As a result, since all this "green energy" isn't coming from rainbows and unicorn farts, we're burning coal and diesel like it's going out of style. That seems like an important little detail, but unfortunately the same people who think this Chinese fire drill constitutes "action", aren't very good with details. That's why entire states like California and entire continents like Europe are having problems keeping the lights on. They have grand plans, which is all well and good, but suck at thinking through the implications of their actions.

I don't love or hate new technology, but I appreciate it when new technology actually does what it claims to do. The only "improvement" I see thus far, if that's what you want to call it, is the sticker price charged to the customers. We have no energy security or independence. We have no solution that solves any existing problem. That's what irritates me about the hyperbolic claims surrounding the use of photovoltaics, wind turbines, and battery-powered vehicles. If we actually get measurably improved batteries that can make this all-electric future feasible, then of course I'll buy one. As of right now, such batteries are nowhere to be found, all of them are a direct product of burning lots of fuel, and almost none of that fuel uses recycled CO2. This is a recipe for making our emissions problem worse, not better. I can only speak for myself, but I think making an existing problem worse, while also introducing new problems that don't have good solutions, is pretty dumb.

Offline

Like button can go here

#75 2022-12-19 02:31:37

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

The methanation reaction is exothermic. From a cold start, the reactor will need to be heated to 400°C. After that, the methanation reaction will release sufficient heat to be self-driving.

https://en.m.wikipedia.org/wiki/Methanation

The energetically difficult step is breaking down water into hydrogen and oxygen. There are two ways of achieving this at the scale needed. (1)Thermochemical decomposition of water; (2) Electrolysis. It is hydrogen production that will consume most of the energy from the solar plants. Thermochemical production of hydrogen would be highly desirable, because it avoids the capital and operating cost of steam powerplants. But the second law of thermodynamics will not be cheated. The relatively low quality heat provided by a trough collector (400°C), places limits upon the efficiency of the process. Trough solar collectors do not appear capablevof producing heat at 530°C. Maybe a hybrid process can be developed.

https://en.m.wikipedia.org/wiki/Copper% … rine_cycle

https://en.m.wikipedia.org/wiki/Water_splitting

Last edited by Calliban (2022-12-19 02:45:53)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here