New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#26 2022-12-25 13:32:52

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 3,441

Re: Mechanical Storage of Hydrogen

I think transporting hydrogen at speeds of 1km/s is a stretch. I am in a hotel at present and away from my computer, so calculations are difficult. Flowrate through a pipe is proportional to pressure drop divided by pipe length. As we are transporting hydrogen at pressure close to atmospheric, there will be a dP between booster fans, which may be several km apart. For a fan, the difference in pressure between the back and front of the fan is a maximum of about 10%, which is to say -5KPa at the back of the fan and +5KPa at the front. It is this difference in pressure that drives the gas through the pipe. The flowspeed is determined by the balance between frictional forces, which increase with the square of velocity, and the driving dP of the fan, which is limited. By increasing dP we can increase flowrate, but at the expense of higher energy losses. By placing the booster fans closer together we can increase flowrate, but power consumption will scale with the total number of booster fans, as will capital cost.

So there are going to be practical limits to how fast we can pump hydrogen.

https://resources.saylor.org/wwwresourc … lowers.pdf

Without my usual tools, I cannot produce an estimation of how flowrate would vary with power consumption. However, we are pumping a gas with a density of about 0.08kg/m3 under standard conditions. This implies that a fan with fixed dP should be able to achieve about 3x the flowrate of methane for the same power consumption. This implies that an NG pipe and H2 pipe should be able to achieve comparable energy flowrates.

Last edited by Calliban (2022-12-25 13:41:08)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

#27 2022-12-25 14:04:35

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 17,243

Re: Mechanical Storage of Hydrogen

For Calliban re #26

Thanks ** very ** much for taking up the question! I realized it was a stretch, based upon limited knowledge, so I appreciate your giving it consideration.

Dr. Hunter's example is based upon the increase of pressure in the launcher to provide the needed impulse to the payload. I had NO prior knowledge of how a gas pipeline might work, so appreciate your explanation.

When you get back to your office/home ? where your computing tools are available (and if this request is judged worth your time), please consider how increased pressure at the source of the gas flow might change conditions. I recognize there is a practical limit to how much pressure might be applied to a pipe, so I'm not expecting much, but am hoping the explanation will be of interest to forum readers.

On the ** other ** hand, your evaluation of the fan shipment option ** will ** definitely fit current Real Universe capabilities, so that will be most interesting as well.

A related question (I'm just tossing this out - not expecting an answer) is how it might be possible to prevent hydrogen molecules from getting hung up on the rough sides of the transport system.

Ifr the atoms were positively charged, and the walls of the pipe were equally so charged, then (I presume) interactions with the wall could be reduced. Whether ** that ** is practical seems unlikely, but the vision ** should ** be entertaining at least.

Update a bit later, after rereading the question ....

The scenario described would amount to a current transport mechanism .... Positively charged molecules (ie, holes) would be shipped physically between locations, as compared to the normal shipment of electrons.

Whether this could be achieved in the Real Universe seems unlikely, but it would definitely amount to a Direct Current flow.

(th)

Offline

#28 2022-12-25 16:01:05

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 3,441

Re: Mechanical Storage of Hydrogen

TH, I will look into it when I get home.

Regarding your second question: The best way to minimise frictional drag is to make the inner surface of the pipe as smooth as possible and increase pipe diameter so far as practicable. Both factors reduce the relative roughness: k/D.

We certainly don't want to introduce any electric charge into a pipe carrying hydrogen. For reasons that are quite obvious. All components must be carefully designed to avoid the potential for static charge accumulation. This makes my previous suggestion of a polymer lined concrete pipe problematic and probably a bad idea. The high speed flow of hydrogen atoms would induce a static electric charge onto any polymer surface. A steel pipe is much better because steel is electrically conductive and can be earthed.

Last edited by Calliban (2022-12-25 16:09:08)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

#29 2022-12-25 18:12:55

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 17,243

Re: Mechanical Storage of Hydrogen

As a follow up to #28 by Calliban, here is a snippet from a discussion about hydrogen transport/interaction with materials (ie, embrittlement)

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC8194130/

text

Of the three atom types listed, copper is the least expensive, but an application as a thin liner for a concrete pipe would require a ** lot ** of copper.

(th)

What did copper close at today?

Open Price is 3.8575 USD/lb. Close Price is 3.7630 USD/lb.

Even if a pound of copper could be spread over the interior of a pipe for a meter, a pipeline of of 4000 kilometers would cost 16 $ million just for the lining.

That does not include the concrete exterior, the right-of-way, or all the construction costs.

Google found this snippet:

$3b Needed for Building every 1000 km of Gas Pipeline - Shanahttps://en.shana.ir › news › 3b-Needed-for-Building-ev...

Jan 21, 2018 — TEHRAN, Jan. 21 (Shana) -- Construction of every 1,000 kilometers of 56-inch natural gas pipeline costs over 3 billion dollars, an ...

I note that in the collection of snippets found by Google, the "mile/inch" combination is frequently used to describe costs.

(th)

Offline

#30 2022-12-26 03:37:13

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 7,434

Re: Mechanical Storage of Hydrogen

This is where the H2-powered turboprop illustration comes from I provided in a previous post:

PhDs do seem to concoct somewhat unrealistic depictions of how actual aircraft operate. In Drs. Mukhopadhaya's and Rutherford's comparative analysis of a Jet-A (kerosene with additives) powered Aérospatiale (now Airbus) / Aeritalia (now Leonardo S.p.A.) ATR-72-600 with a notional H2-fueled Narrow Body Turboprop (herein, I'll call this conceptual Hydrogen-powered aircraft "NBT-H2"), I could not help but notice that in their attempt to assert a reduced range and increased CO2-intensity using a notionally much heavier NBT-H2, their fully loaded ATR-72 is now 300kg beyond its MTOW. No ATP-rated pilot could've missed that. 70pax at 95kg/pax (6,650kg) plus 3,150kg of fuel is 300kg over MTOW. OEW is certified using scales. The mechanics figure out that part. FAA dictates to you, what each pax weighs. Baggage is weighed. Fuel is weighed. If the crew ran the engines for at least a half hour on the ground, then maybe they could burn off 300kg in that time. If 3,150kg of fuel was actually required to complete the flight with appropriate reserves, then the crew would boot passengers or baggage first. All jet engines drink fuel at idle power, but 97 gallons in 30 minutes seems a touch excessive for some of the most fuel-efficient turboprop engines in service. Whatever. I'll give them that one. Fuel flow at cruise is listed at 762kg/hr, so it'll burn through that pretty fast.

If FAA / TCCA / EASA finds out you've been overloading airframes, then you won't remain in your role as an ATP-rated pilot for very long. I've been told that FAA may grant conditional waivers for operating over MTOW for ferry flights (no passengers, aircrew-only, restricted flight envelope), but I received a lecture on this from my CFI (who is now an ATP-rated pilot). FAA / TCCA / EASA regulations are exceptionally clear on this point. Operating an airliner over the manufacturer's tested (FAA-certified) MTOW is strictly prohibited as a matter of normal operations.

In all probability, the ATR-72 would still takeoff and fly normally if nothing went wrong (no loss of engine power on takeoff) and atmospheric conditions were ideal (low density altitude and low to moderate temperatures), given that we're not that much over the limit, but this is still a non-starter for any airliner and/or ATP-rated pilot, PhD or no PhD. Weight and balance calculations for large / heavy commercial aircraft do have some flexibility built-in, but 300kg is 1.3% over the allowable MTOW. If we're only 50kg to 75kg over, then we'll probably burn that much before takeoff. You either reduce that ATR-72's fuel load by 300kg to compensate (not likely), or offload pax and bags. 300kg represents approximately 9.5% of the ATR-72's total fuel load in their mass calculation, so range would be reduced accordingly if the flight proceeds with all seats occupied. I don't know exactly how much will be lost because how the flight is operated matters quite a bit, but I'll bet subtracting almost 10% of your fuel load decreases practical flight range to a figure that's almost identical to a notional NBT-H2.

ATR-72 is primarily Aluminum alloy construction. NBT-H2 would primarily use CFRP construction. This follows suit with all new-build / next-generation airliners that use CFRP to reduce inert mass by about 15% to 20%. I don't know precisely how much NBT-H2 would weigh, but they assert ATR-72 is 13,500kg OEW and NBT-H2 is 17,800kg OEW. I know exactly what they did. The took the 17,110kg OEW of the DHC-8-Q400 (because the fuselage is the same length), then added a bit more to that (quite a bit), and asserted that NBT-H2 would weigh as much as an airliner with a similar mission and number of seats, but almost double the horsepower (5,500shp for the ATR-72 vs 10,142shp for the DHC-8-Q400).

That's drastically more empty weight, despite NBT-H2 having a slightly reduced total fuel tankage plus fuel weight, as compared to the ATR-72. That doesn't pass the smell test. How is that even possible when NBT-H2 is using the exact same engines (modified to burn H2), significantly thinner / smaller / lighter wings because there's no longer any fuel stored there, and a total fuel system weight slightly lower than the ATR-72's total fuel system weight while laden with 3,150kg of fuel?

A CFRP NBT-H2 probably wouldn't greatly improve the OEW over the Aluminum ATR-72, but it certainly wouldn't hurt it to the extreme degree that these two used in their calculations. I would expect the weight savings associated with using CFRP to completely recover all added weight attributable to a 700 bar fuel tank. This is for tanks designed to resist 700 bar internal pressures, not to both resist such pressure AND survive severe collisions the way they're designed for cars and trucks. Despite having a considerably longer fuselage (+4.85m) and wings (+5.45m), NBT-H2 should still weigh in at 13,500kg or less, same as the real-life 70-seat ATR-72.

Now let's consider a fuel-cell powered aircraft:

Wright "Electric Turbofans" produce 2MW of power output and weigh 200kg each. A pair of electric motors are therefore equal in weight to 1 of the Pratt & Whitney Canada PW127XT-M turboprop engines, as is power output. Propellers weigh the same regardless of what supplies the input power. The prop doesn't know or care how the power is supplied. For a given torque and rpm input, it generates a given amount of thrust output, simple as that. There are obviously limits to this, but they wouldn't be exceeded by using an electric motor versus a turboprop. For example, "whirl mode" would be worse using a much lighter electric motor, so a stiffer / stronger engine mount is required to prevent the propeller from transmitting oscillations induced by asymmetric aero loads on the prop, into the engine / engine mount / airframe. If the motors were mounted in the tail, then both motors could produce centerline thrust, with no tendency to yaw violently if one motor / engine loses input power, along with a much stiffer motor mount can be built into the fuselage to counteract whirl-mode tendencies. Without knowing the exact Hamilton Standard 568F model (a number of commercial and military airframes use this model) that the ATR-72-600 uses, I'm calling each 6-bladed composite prop 375lbs (exclusive of hydraulic fluid / engine oil; no more than 2 gallons, I would think, and probably closer to 1 gallon), so 340kg for both.

4kW/kg is now state-of-the-art for Aluminum alloy based PEMFCs. Well, plastics weigh about 1/3rd of what Aluminum does, so if the fuel cell operates near room temperature, then 8kW/kg should be realistically achievable by using plastic vs Aluminum alloy plates. That means the fuel cell should weigh about 500kg and a pair of 2MW motors should weigh 400kg. A pair of PWC-127 turboprops weigh 960kg, so if we throw in some mass for short power cables, safety devices, and power conversion, then we should be very near to the weight of those turboprops.

The PW127XT-M that the ATR-72 creates 2,750shp of output from a thermodynamic input of 3,360shp, which means 610shp is blown out the back as waste heat that's never converted into thrust. The prop sees 1,200rpm and is 155 inches in diameter, so 553mph / 0.72 Mach at sea level. It should be reasonably quiet, especially with an electric motor. In all, though, approximately 2.0588kg of Jet-A per kilometer of distance traveled, starting a little beyond MTOW. Obviously it's not quite that bad since there's reserve fuel on board. Fuel flow rate should be about 600kg/hr at 20,000ft (company literature lists it as 762kg/hr, coinciding with faster cruise or lower altitude or both). They also list max range with max pax as 825nm / 1528km. That makes the 3,150kg fuel load appear acceptably realistic after climbout is taken into account, so they get points from their initial fuel load figure, even though it's less than realistic on the regulatory end.

Let's call the flight 3.5 hours, with 15 minutes at full power (4MW) and 195 minutes at 3MW (75% power). The turboprops can't even generate that much horsepower at 20,000ft, but let's pretend. H2 flow rate is 55.55g/second at 4MW or 41.66g/second at 3MW. Air density at 20,000ft will be about 0.6533kg/m^3. 23% O2 by weight implies 0.15kg/m^3, so air ingest rate must be a bit over 2m^3 per second to satisfy the reaction. Given a 275kt cruise speed, the air scoop should be quite small.

Let's say our fuel cell is 60% efficient, which seems quite reasonable. That means each kilo of H2 reacted supplies 20,000Wh of power. We need 487.5kg of H2 for cruise power and 50kg for 15 minutes at full power. That's a total of 537.5kg of H2. This is LESS THAN HALF as much H2 as the NBT-H2. That means our H2 tank is only half as long, so our fuselage is significantly shorter. This is operating at greater power than the NBT-H2 can realistically achieve at 20,000ft, but basic math says our aircraft is no heavier than the ATR-72, even with 4kW/kg fuel cells and 10kW/kg electric motors, both of which are current-state technology. If plastic can halve the weight of the fuel cell, then we're lighter by quite a bit.

Our total fuel system and fuel cell weight is 500kg below their original estimates at 4kW/kg, so we should end up at or below 13,000kg OEW, even with a modestly longer fuselage. Fuselage and wings are therefore the similar to the ATR-72. There's no way we're anywhere near 17,800kg. There's certainly less drag involved if we put everything in the tail. That means we also have completely clean airflow over the wings and tail, plus no asymmetric thrust, so the tail can be smaller while maintaining adequate control authority in an engine-out scenario.

All in all, a fuel cell powered commuter airliner looks pretty reasonable from a basic math and physics perspective, but not from a cost perspective. At $16/kg, fuel is $122.86 per passenger per 3.5 hour flight. Jet-A is presently $3.49/gallon, so 1,022 gallons of Jet-A for the ATR-72 is only $3,566.78 per flight, so $50.94 per passenger per 3.5 hour flight. H2 prices have to fall to about $6/kg to see any fuel cost savings. Some wishful thinkers are throwing out $3/kg to $6/kg Hydrogen fuel costs, but that doesn't seem readily achievable since energy prices keep increasing, especially for so-called "green Hydrogen", which is where the $16/kg figure comes from. Meanwhile, H2 from natural gas is around $2.50/kg.

Basic economics strikes again. Oh well, it was interesting for a moment.

Offline

#31 2022-12-26 07:23:06

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 3,441

Re: Mechanical Storage of Hydrogen

Embrittlement is a problem because it places limitations on the allowable wall stress within a pipe. This may require a greater wall thickness than would otherwise be necessary, making pressurised pipelines more expensive. If hydrogen is distributed at low pressure, embrittlement will be less of a problem. Below is an extract from the Wiki article on coal gas, which is predominantly hydrogen.

'The inter-war years were marked by the development of the continuous vertical retort which replaced many of the batch fed horizontal retorts. There were improvements in storage, especially the waterless gas holder, and distribution with the advent of 2–4 inch steel pipes to convey gas at up to 50 psi (340 kPa) as feeder mains compared to the traditional cast iron pipes working at an average of 2–3 inches water gauge (500–750 Pa).'

Distribution of hydrogen at 50psi gauge pressure through steel pipes is certainly practical, because it has been done before during the coal gas era. At 50psi gauge pressure (65psi abs), a 2m diameter hydrogen main carrying hydrogen at 100' per second (30m/s), will deliver 4500MJ of hydrogen energy each second.

We can anticipate a staged reduction in pressure, with large, high pressure pipelines carrying hydrogen from the southern states, up the east coast at pressures of perhaps 30bar. Intermediate pressure distribution mains operating at 50psi guage could deliver hydrogen to gasometer type tanks around individual towns and cities. Distribution pipes within urban areas could work at lower pressure and could be constructed from steel or steel lined concrete.

Hydrogen could be stored for long term use in underwater concrete gas holders, in the great lakes or off the Atlantic coast. These could be built onshore, floated to the correct location and then sunk by flooding ballast tanks within the concrete structure. Ballast could be added to the tops of the tanks in the form of dredged shale and mud. This would balance the bouyancy of the stored hydrogen, eliminating any tensile forces in the concrete structure. In this way, thin walled polymer lined concrete structures could contain hydrogen underwater very cheaply. This is important, as hydrogen will be produced in greater quantity in the summer months. But demand from heating will lead to a spike in demand during winter.

Last edited by Calliban (2022-12-26 08:15:17)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

#32 2022-12-26 08:56:18

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 17,243

Re: Mechanical Storage of Hydrogen

It is good to see contributions to this topic by both kbd512 (aircraft) and Calliban (town gas history).

I'm hoping each author can develop ideas further.

This topic is (hopefully) a place where future readers can find information (and perhaps inspiration) about various ways of storing hydrogen.

For aviation, tanks would (I presume) need to be large and light as possible, if the gas is carried in the gaseous state.

Mechanical storage would (if I understand the process correctly) add weight for the capture material, in return for the benefit of eliminating pressure of free gas.

As a reminder for a new reader, this topic opened with a report of research on capture of hydrogen molecules by physical structures.

***

The topic has expanded to include shipment/transport of hydrogen, but the connection to storage remains because wherever hydrogen is shipped, it must be held in a container.

Recently, Calliban suggested holding hydrogen in tanks under water. This storage method would (presumably) require much less energy investment than would be the case for a freshly dug salt mine. On the ** other ** hand, if there is an old salt mine near the location where you want to store hydrogen, then that appears to be an attractive option.

I remain interested in moving the storage system closer to the consumer, so that (for example) a week's supply of energy (heat, power) could be buried (safely) under ground near each urban (or rural) dwelling. The output of combustion is potable water, so a home protected by this system could operate normally for a full week in the event of a severe weather event.

For the inevitable safety objection that I know (from experience) is going to show up, I respectfully request that the storage facility be constructed with safety in mind, and that customers be expected to know minimal safety practices.

In the United States, and around the world, ordinary human beings by the millions safely use dangerous electricity, dangerous gasoline, dangerous gas systems, and dangerous chemicals of all kinds.

(th)

Offline

#33 2022-12-26 17:18:41

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 7,434

Re: Mechanical Storage of Hydrogen

Here's another possibility (low-cost Hydrogen-fueled drones capable of package deliver over significant ranges):

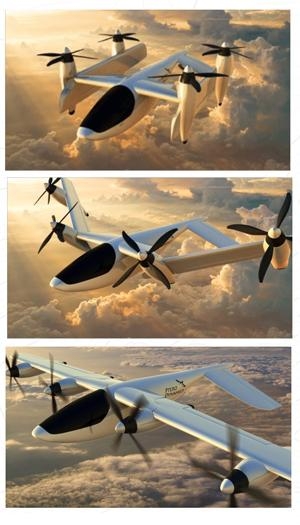

For vertical takeoff and landing in confined spaces, I see this "Trans-Wing" design as more practical than those of Joby and Archer:

/img/iea/lV6DbndKOx/header-transwing.jpg)

First "Trans-Wing" photo disappeared, so here's a second photo:

Joby and Archer are each capitalized to the tune of billions of dollars, but their designs are very inefficient relative to a tilt-rotor or tilt-wing design, as well as taking up a lot of physical space when landing. Joby's eVTOL has had 10 years of development and over 1,000 test flights, but that should tell you just how much testing is required for any of these multi-engine / multi-rotor eVTOL designs to function reliably. Basically, having 5 to 10 motors and propellers / rotors is a sign that your vehicle is not reliable enough. Adding additional levels of complexity isn't helping the matter, nor does it decrease total cost. A single-seat or two-seat trans-wing essentially fits into two parking spaces for a normal car.

Joby's S4 prototype is 24ft long and 35ft, so no less room than a traditional helicopter. It also requires 560hp to maintain a hover with 1 pilot and 4 passengers aboard, although only 119hp to maintain forward flight at 136mph. It was granted a weight increase to 4,800lbs, but apart from briefly being able to hit 200mph before running out of juice, and apart from lower noise, it merely replicates what an OH-6A helicopter can do. In point of fact, the YOH-6A achieved a record speed of about 250mph on March 12th, 1966. This was achieved with a 250hp T-63 gas turbine engine.

At 10kW/kg, an equivalent electric motor for an OH-6A helicopter would weigh 18.65kg. At 4kW/kg, a fuel cell would weigh 46.6kg. Combined, that's 65.25kg. This compares very favorably to the 63kg Allison T-63 turboshaft engine. To fly for about 1 hour, you need 10kg of H2. The OH-6A had a maximum internal fuel load of 61.5 gallons, or 418.2lbs of Jet-A. A South Korean firm makes 450 bar Type 4 H2 tanks which weigh 182kg (270cm L by 55cm D) and stores 12.3kg of H2, so that's 428lbs. That provides 1 hour of flight time with a 20 minute reserve. We're approximately 15lbs heavier than the original engine and fuel supply, but that's with a DOT-rated H2 tank. Since the original OH-6As were made with Aluminum airframes and Aluminum / wood composite rotors blades, we can easily make up the weight differential using CFRP construction.

424L Tank Specifications (supplier of H2 tanks to Hyundai):

Hydrogen Type 4 Cylinder 450 bar 424L by Iljin Hysolus

OH-6A Cayuse in Viet Nam:

OH-6A "Killer Egg" with M134 minigun turret:

The Piasecki PA-890-world’s first hydrogen-powered helicopter enters the eVTOL bandwagon

PERFORMANCE EVALUATION OF SELECT PERSONAL AIR VEHICLES by Paul S. Moller, M. Eng., Ph.D.

In flight, trans-wing has the efficiency of a normal fixed-wing aircraft. It also glides like a fixed-wing aircraft if power is lost. Those are both pretty important design features. Combine better basic aircraft designs with Hydrogen fuel cell power, and we have practical eVTOL aircraft with significant range and payload, for both passenger and parcel delivery service. A trans-wing parcel delivery drone, similar to the one shown in the first photo, could deliver small parcels up to 100km or more from a distribution hub. That would mean far fewer delivery trucks or drivers or fuel expended hauling lots of parcels around neighborhoods at low speeds, negating the need for most of the trucks and their gasoline or diesel fuel. The delivery drivers would then monitor the drones while a smaller fleet of trucks continue to deliver especially bulky or heavy packages. Delivery of most packages could be completed in a day, possibly hours. Hospitals or pharmacies could have drugs and lab test equipment delivered in hours.

Offline

#34 2022-12-27 09:08:54

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 17,243

Re: Mechanical Storage of Hydrogen

For kbd512 re #33

While the entire post is full of detail and interesting observations/recommendations, I would like to highlight your addition of trans-wing to the archive.

SearchTerm:trans-wing

SearchTerm:transwing (future searchers are likely to forget the hyphen)

SearchTerm:VTOL

(th)

Offline

#35 2022-12-28 12:15:45

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 7,434

Re: Mechanical Storage of Hydrogen

My overriding point is that aircraft can be powered in a practical way using alternative fuels such as Hydrogen, but batteries and wildly-complex battery-powered machines are not practical using present technology. It's not physically impossible to do, in much the same way that it's physically possible to use a NASCAR vehicle as your daily driver, but it's so impractical that virtually nobody does it. There are literally dozens of aviation and taxi service companies spending billions of dollars to create battery-powered pseudo-helicopter / fixed-wing aircraft, yet none of them are suitable replacements for helicopters or fixed-wing aircraft. They all make massive concessions to cost and complexity. None of them are presently FAA-certified because they're fundamentally unreliable and dangerous machines.

Joby Aviation may pull it off because they've spent so much engineering time and money on development (well over $1B at this point, fast approaching $2B), at least equal to the time and money spent to develop a turboprop or turbofan powered military trainer type aircraft. That should tell you pretty much all you need to know about the difficulty involved with making the control system and all other components reliable enough for commercial operation. No military trainer type aircraft are used for commercial operations. As a function of cost, they're used solely to train jet pilots. Their projected per-unit production cost is somewhere between $1.5M and $3M. This is acceptable for a small private / corporate jet, or something like a Cessna 208 Caravan turboprop that seats 9 passengers or carries lots of cargo for FEDEX.

Joby Aviation's S4 "EV Air Taxi" is flying 4 to 5 passengers to a 150 mile maximum range using a 200kWh battery pack, similar to a Robinson R66 helicopter ($1M per copy) used for sight-seeing tours in major cities. To fly a R66 450 hours per year, cost per flight hour is $662.64 (an analysis done from operator-submitted operations cost data)- a $165.66 "taxi ride" for 4 passengers. I've flown between cities on turboprops and 737s for less money. We'll be lucky to make 2 such trips per day if it takes a couple hours to charge the batteries without damaging them, and the batteries are the greatest operational cost driver. S4 is IFR-equipped, so it can fly at night and in some types of bad weather, which is a good thing. Even if the electricity is free, we're approaching the cost of a plane ticket to avoid California traffic to make it to the airport ("Escape From LA"). The R66 is pertinent because it flies at the same cruise speed as the Joby S4 (at the S4's L/D Max, which maximizes cruising range), but the R66 has a 373 mile range.

Joby's 235Wh/kg, the battery pack weighs 1,876lbs (still doesn't actually exist, from what I understand; Rolls-Royce still occupies the top slot). A pair of 450 bar H2 tanks weigh 802.5lbs and are loaded with 54.25lbs of H2. A 4kW/kg fuel cell weighs 230.5lbs. All told, we're at 1,087.25lbs. We're 788.75lbs lighter, and very close to the original MTOW for the S4. Since we're so much lighter at all times, we have more than double the S4's range, plus a 30 minute reserve. We're quite close to the performance of the Jet-A powered R66. This is using DOT-rated H2 storage tanks on top of that, the exact same ones that H2-powered motor vehicles use.

A H2-powered trans-wing machine would match the weight (2,700lbs MTOW) and range (373 miles) of the R66, match the top speed of the YOH-6A (250mph; but it will also "normal cruise" 50mph faster than the OH-6A's maximum cruise speed), as well as being significantly lighter than the S4. In the real world, that means the machine costs less money to make and fly, because in the realm of commercial aircraft cost is closely tied to weight. The Rutan-designed Cozy MkIV (180hp, 4-seat composite aircraft, 2,050lbs MTOW) is in the same empty weight class as the OH-6A and cruises at 220mph. Since the "landing gear" of the trans-wing are fixed to the rear of the four engine nacelles, no retractable landing gear is required to reduce drag, so more cost / complexity / weight has been deleted.

The AW609 (Augusta-Westland, originally, but these companies have changed hands multiple times now) civil tilt-rotor facsimile of the Bell-Boeing V-22 Osprey is decades late (in development for over 20 years, fast closing in on 30 years), billions over budget (yes, you read that correctly- billions of dollars have been spent trying to force a civil helicopter-plane into existence, but Leonardo S.p.A., the present company making and testing the prototype aircraft, is still not across the finish line), and if nothing else goes wrong (the list of things that went wrong is almost endless, but the stumbling block shared between the AW609 and S4 has been the flight control avionics software, as both are fly-by-wire machines like the F-16 and all subsequent fighter jets), then it might be certified for operations by FAA and EASA in 2024.

Can we force civilian tilt-rotors into existence if money is no object? Sure. It can be done. Similarly, a few diesel aircraft engines have also been forced into existence. However, numerous companies went bankrupt along the way, to include Continental and Lycoming and a slew of European companies. All of these aero-diesels are significantly more expensive than gasoline engines of comparable horsepower (if you think $125K for a 300hp IO-550 is a bit steep, then how does $200,000 for a 150hp aero-diesel sound?), there have been relentless reliability problems, all of them are heavier than equivalent gasoline engines, none of them meet the TBO figures of the traditional opposed-cylinder air-cooled gasoline engines, and the fuel cost savings associated with using Jet-A are so marginal that they only get used in places where AVGAS is unavailable. In short, they make no good sense unless you're after a specific result and you're willing to ignore weight, reliability, safety, and cost. FAA was formed for the express purpose of assuring reliability and safety to the flying general public, so imagine their take on this. EPS completed certification of an aero-diesel intended to replace power plants like the Continental IO-550 (more money than an IO-550, but a lot less than a PT-6A turboprop), then promptly went bankrupt. Commercial agricultural businesses have been funding alternative engines like aero-diesels because PT-6As are so expensive to operate that the pilots can't afford to fly at what farmers can afford to pay them. Air Tractor funded the all-Aluminum turbocharged Big Block Chevy gasoline engine development to replace R-1340 radials and lower-power PT-6A variants, but Orenda (project dropped) then Thunder (went bankrupt) then Trace Engines (also went bankrupt) all either dropped the project after realizing it wasn't going anywhere, or their companies ceased to exist from lack of funding.

We already know what the problems are with our 1930s state-of-the-art carbureted or fuel-injected, magneto-fired, gasoline-fueled, air-cooled, opposed-piston engines. They burn more fuel and oil than required and they have high maintenance and expensive maintenance. You need $30,000 to buy a brand new 100hp Continental O-200 engine. Overhauling an existing O-200 costs $10,000 to $15,000. A factory overhaul can be had for $19,665 from Continental. Some O-200 examples have seen a dozen overhauls. The high overhaul cost comes from expensive inspections and complete replacement of major components such as the cylinders, which cost $1,000 to $1,500 each. The crankshaft, crankcase, accessory case and some other small parts get reused most of the time after inspection and repair / refurbishment. Everything else gets scrapped most of the time. Cylinder or "jug" reuse is discouraged and most pilots view it as dangerous at best- the danger being the thing splitting in half from metal fatigue in flight, with a fire or forced landing being the inevitable result. Used jugs are very cheap, because nobody wants them. Oil changes are required every 25 to 50 hours or so and costs about $100 (similar to changing the oil in a car), magnetos require 500hr inspections ($300 to $400) and 1,000hr to 1,500hr overhauls ($500 to $600; brand new mags are a little more so most are brand new and then trashed after 2,000hrs or so), and carbs need carburetor heat to prevent icing. There are lots of other expensive consumable parts like camshafts and lifters, consumables such as aircraft-specific spark plugs ($30 to $50 each, 2 per cylinder, so the O-200 has 8 of them) and aircraft bolts (those "unimportant" little things that hold the entire engine together), but that's a pretty good list of major cost drivers. A brand new crankshaft is now about $10,000, regardless of engine type.

In return, these expensive and maintenance-intensive engines are now highly reliable (don't fail very often in-flight) after 70+ years of experience using many thousands of them (discovering which parts failures killed pilots and passengers along the way). The same cannot be said of any type of aero-diesel engine or electric motor, although I will assert (with good evidence) that modern electric motors are highly reliable. As a general rule, electric motor failures are few and far between. Now they're more than good enough to replace anything from a small 100hp O-200 to a 2,500hp turboprop, if only we had a fuel that could power them long enough for them to be useful. We would validly expect modern electric motors to be about as reliable as a gas turbine engine in terms of hours of operation between overhauls (TBO), but again, we must kill enough people to discover what fails.

Joby Aviation eventually conceded that an on-board pilot was required to ever receive FAA approval because autonomous control systems are presently not developed to the point they would need to be. They're left with a 6-rotor / 6-engine machine with a 150 mile range, tops, that costs millions of dollars per copy. They're using 5-bladed props with similar capability to the ones I have, although they've improved the tip design to reduce noise. Those propellers are about $25,000, each.

Conclusions:

1. Present STOL aircraft costing $75K to $150K can takeoff and land in spaces not much bigger than a standard parking space. No, they're not helicopters, but do they really need to be? If someone wanted to do a realistic air taxi service, why was this not a logical starting point? Why did they start with a fly-by-wire battery-powered multi-rotor machine that can't auto-rotate like a helicopter and can't fly as fast as a fixed-wing aircraft, that costs as much or more than either for equivalent capability? If they wanted a practical zero-emissions aircraft, then fuel cells were and are a much more realistic proposition. If a battery powered car is barely possible and none achieve the range of a gasoline-powered car for equivalent weight and cost, then what is this special brand of silliness all about (apart from spending mad money while achieving very little of lasting value)?

2. We already know how to make aircraft cheaper. We've known since the dawn of powered flight. Technology hasn't altered the fundamentals in any way, shape, or form, nor will it ever. You eliminate all unnecessary weight and complexity, you accept that basic physics always wins, anti-humanist climate religion be damned, so you make them lighter still and use smaller engines that burn less fuel. You cannot make them heavier, because then they require more power and burn more fuel, which means they will always cost more to make and operate.

3. The fact that someone was dumb enough to thumb their nose at the fundamentals tells me what I need to know about them. They're not pragmatic thinkers. Thus, their invention, if ever approved, is unlikely to see widespread adoption. They're competing with Robinson in the 5-seat helicopter market and every light aircraft maker on the planet for long distance travel. There are literally a dozen different STOL kit-built aircraft that do a better job at flying cheaply at helicopter speeds. You can build a squadron of these machines for the purchase price of a single R66, or an entire air wing for the price of Joby's S4. Tesla and Panasonic have spent more money on battery development than Joby Aviation or a dozen other companies like Joby will ever have available to them. Tesla doesn't have batteries that can create 235Wh/kg battery packs. Actual analysis of Tesla's new 4680 batteries says 244Wh/kg for the battery alone, vs 269Wh/kg for the Panasonic 2170 cells. If you add anything but conductor wire to carry the current, you're below 235Wh/kg for the battery pack. That means the S4 ain't gonna fly 150 miles.

4. Nobody, however, has asked the most painfully obvious question, which is... How do we make the fuel cheaper? That's the question I've attempted to answer. Long-term, we have to synthesize it from scratch. The oil will run out over enough time, so we either start recycling some of that CO2, or we're no longer flying and driving and living in fancy buildings with central heating and air conditioning. There's not enough readily accessible metals on the planet to convert everything to use batteries. Even if there was, there are no practical aircraft that can use batteries that are byproducts of known materials science. Winding up in a state with none of our modern conveniences seems pretty dumb, if you ask me.

5. Hydrogen fuel is modestly more dangerous than kerosene and gasoline, but it's not dumb. Using Hydrogen agrees with the fundamentals of flight. To wit, Burt Rutan's observations about building aircraft: "Take your favorite aircraft building material, whatever that is. Throw it up in the air. If it comes back down, then it's too heavy." For those who don't know, Burt Rutan designed and Scaled Composites (his company) built the first piston and jet engine aircraft that flew non-stop around the world without refueling. No other aircraft have achieved that same feat, and no, launching something into orbit doesn't count. There have been plenty of aircraft that have circumnavigated the world using numerous refueling stops or inflight-refueling, but no others have taken off with all of their fuel, flown around the entire planet, and then landed with a little extra fuel in their tanks. It's a pretty safe bet that Burt Rutan knows a few things about aircraft design. Burt's take on this was / is the same as mine. "This is truly great stuff guys, but where is your power coming from?"

With all that in mind...

Q: What problem are we trying to solve with these battery-powered VTOL designs?

A: There's no value proposition tied to a $2M 5-seat helicopter / light plane. Joby has spent almost $2B. If they can sell 1,000 S4s for $2M per copy, then they break even. Robinson has sold a little over 1,000 R66 helicopters to various users around the world for $1M per copy, over the past 15 years. Robinson sold a little over 6,500 R44 helicopters (half the cost of the R66) over the past 30 years. Where's the market for a R66 replacement with less than half the range and double the cost? Who thought that was a problem that needed to be solved? The fuel could be free, but it still doesn't make any economic sense. Your fuel bill savings was merely replaced by your loan payment to the bank. If $650 per flight hour was unaffordable, then how did $1,300 per flight hour become more affordable?

Q: Do we want good planes or good helicopters?

A: We can't have both. We keep trying to get both, but physics keeps smacking us upside the head every time we try. It's a thought process problem. Lots of things technically work that are also wildly impractical. None of us drive rocket-powered cars to work, for example. This is supposed to be the vehicle used to implement a flying taxi service, not a moon shot.

Q: Are we using appropriate tools and technology?

A: Batteries can't replace hydrocarbon fuels. This will never change unless and until batteries can come within 50% of the gravimetric energy density of hydrocarbon fuels. Nothing of the sort is on the near (5 to 10 years) or far term horizon (25 years). That's a tough pill to swallow for our battery enthusiasts, but they need to come to terms with it.

Q: Are we asking our technology to do something it can realistically do, or are we trying to overturn physics with money?

A: As near as I can tell, we keep trying to overturn physics. If we want zero-CO2 aviation, then that's only feasible using Hydrogen. Batteries aren't worthy of consideration, let alone funding. No company that specifies Lithium-ion batteries for power should receive one lousy dime of investment funding from governments or from venture capitalists who are using other peoples' money. Companies are spending good money on something that their own engineers know doesn't work well enough. The engineers will keep showing up to their "money throwing parties", because they want to design new things and you're throwing money at them to do that. Heck, if I was an aerospace engineer, then I'd still show up to their party. A paycheck is a paycheck. Unfortunately, none of their efforts will amount to very much. The honest engineers will tell you that.

Hydrogen as an energy source is 1,266Wh/kg after a DOT-rated 450 bar storage tank is included in the mix. Using non-DOT-rated H2 tanks, which are about half as heavy, we suddenly hit that non-magical / real-physics 2.5kWh/kg figure. It's almost as if General Motors knew what they were talking about when their research scientists asserted that that's where they needed to be for practical EVs. If we still can't quite get to kerosene energy density using a 60% efficient fuel cell and a fuel stock with 5X more energy density than the best Lithium-ion batteries, then who the hell thought batteries were a workable idea?

If Joby Aviation had instead spent a couple billion on CNT tape composites and 8kW/kg plastic PEM fuel cells, then even with 60% efficiency their concept starts looking like a practical helicopter without any CO2 emissions. More importantly, if the airframe and rotor blades were also made from CNT composite, then we can cut that airframe weight in half. We then have an OH-6A equivalent in terms of every performance metric. Our "technology problem" then becomes lowering CNT tape manufacturing cost, which is itself a major challenge. However, we've already proven that a Hydrogen fuel helicopter is equal to an existing gas turbine helicopter using the correct materials. That was far and away the most significant design hurdle to overcome. We're more than half-way to the finish line. After proving that it can be done, someone else will come along and determine the most practical and economical way to make light helicopters. Henry Ford didn't discover gasoline or invent the combustion engine or the motor car, he simply came along after all the basic functional problems were solved and used assembly line production to both increase production rates and lower manufacturing costs to the point that a car became the most practical and affordable means of transportation for the masses. The same will be true of zero-emissions aviation.

This is also why all of your "green dreams" remain within the realm of your futurism fantasies. You don't ask the correct questions because you're not interested in solving existing problems in more practical ways. Simply throwing more and more money at physics problems like energy density solves nothing because making up for a multiple orders of magnitude energy density deficit is not practical and is likely not feasible at all, regardless of how much money is thrown at battery development. You refuse to stop pursuing technological dead-ends that you find aesthetically pleasing. The idea behind the battery is quite beautiful, but the reality of trying to use it to solve all energy storage problems is very ugly. You'll keep squandering other peoples' money until they get tired of the lack of results. Apart from making humanity poorer and less able to support your futurism fantasies using surplus energy wealth provided by fossil fuels, nothing of consequence will be achieved. If I was a loan officer or venture capitalist, I would refuse to fund any of this nonsense until someone comes to me with a battery that stores at least 2.5kWh/kg. After that happens, then you can have all the money we can afford to throw at you. Solve that problem first. The rest is minor engineering details by way of comparison.

Offline

#36 2022-12-28 15:19:57

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 3,441

Re: Mechanical Storage of Hydrogen

Using liquid hydrogen would avoid the need for heavy pressure tanks and would allow H2 planes a similar range to kerosene fuelled planes.

https://en.m.wikipedia.org/wiki/Energy_density

For a number of reasons, LH2 is more practical for planes than for most other vehicles. Liquefaction can take place on a large scale at a centralised plant at each airport and LH2 would be stored in a large underground tank. The low density of LH2 allows it to be transferred to tanker trucks using gas pressure in the tank to force it through fuel transfer tubes. Large liquefaction plants are more efficient than the smaller liquefaction plants that would be needed at service stations on highways. LH2 would only need to be transported short distances to refuel aircraft. Insulation can be provided to tanks within wings. Because planes are large vehicles and are fuelled shortly before takeoff, boiloff is far less of a problem. Gas turbines are better suited than piston engines to burn low energy density hydrogen.

There are technically easier fuels than hydrogen. Methanol cannot be used as an aircraft fuel because of its high corrosivity towards aluminium. But liquefied natural gas, gasoline, LPG and DME, would all be easier to use with better energy density than hydrogen. Presumably, jet aircraft could burn these fuels with little modification.

Last edited by Calliban (2022-12-28 15:27:35)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

#37 2022-12-28 16:17:38

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 28,923

Re: Mechanical Storage of Hydrogen

Liquification means a smaller tank but now you need to ensure area surrounding does not metal fatique with less feul used throughout the flight as the mass of the plane is greatest at the start of the journey and decreases as you fly.

Is hydrogen changing the power dynamics in the energy world?

What is the energy safety How Hydrogen Compares To Jet Fuel In Terms Of Safety

Offline

#38 2022-12-29 20:26:51

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 7,434

Re: Mechanical Storage of Hydrogen

These people are blowing mad mad money on battery-powered VTOL because they're dishonest with themselves. A "low cost" battery powered tilt-rotor helicopter-plane hybrid is a complete contradiction in terms. The battery powered cars with smaller / heavier / less costly batteries are not less expensive than any of the gasoline or diesel cars and trucks that they're intended to replace, even though power-to-weight ratio is far less important for cars and trucks. Most are double to triple the price of otherwise comparable vehicles in terms of range and payload. The batteries are simply too heavy for the power they provide. Nobody wants to accept that undeniable fact. Nobody knows how to make batteries substantially lighter, if such a thing is even possible. To top it all off, those batteries are functionally non-recyclable for any reasonable cost.

Aircraft drink fuel, so they will also drink electrons, consuming batteries by the truckloads. Commercial aircraft cost is primarily weight-driven. Weight determines power requirements. There's a "snowball rolling down hill" effect from there. The heavier the aircraft, the more it costs. No part of electrification changes that paradigm. Apart from potentially cheaper fuel, assuming we can supply these aircraft with power in an energy future hamstrung by more and more unreliable energy, batteries make that intractable weight problem far worse, rather than better.

Archer Aviation say they want to achieve airliner-like reliability levels, meaning one serious failure roughly every billion flight hours. Their Maker prototype weighs 3,324lbs and has a range of 60 miles using a 75kWh battery pack. A similar Tesla Model 3 has a range of 300 miles using a similar capacity battery pack constructed using very similar batteries, possibly the exact same cell chemistry and form factor. Archer's "Maker" / "Midnight" aircraft have a dozen electric motors, 6 used for lift-only, the other 6 connected to custom-fabricated 5-bladed constant speed propellers that also translate or "tilt" through 90 degrees for hovering and then into forward flight. There is no way for that to be any cheaper or less complex than a traditional helicopter of similar size and payload capability.

A production version of Joby Aviation's S4 prototype is projected (by them) to cost approximately double what a gas turbine powered Robinson R66 of almost identical practical performance, except for having a lower top speed combined with more than double the range that the S4 is capable of. In terms of max takeoff weight, it's approximately equal to 1.75X the weight of the R66. If the market could support 1,000 R66s at $1M per copy, then what is the potential market for 1,000 S4s with less than half the range (using a battery with a power-o-weight ratio that doesn't presently exist) and the same cruising speed (same cruising speed as the R66, in order to achieve max range in the S4), at $2M per copy? Methinks that must be a rather small market for all the hundreds of millions of dollars spent to develop the S4. In the past, this is why "better aircraft" weren't built. If the market was too small for a marginally better design, then aircraft companies didn't spend money chasing down perfection, only to bankrupt themselves in the process. The fact that so many startups are willing to burn through hundreds of millions to billions of dollars, mostly without result, is very telling. It's clearly ideologically motivated.

Both the R66 and S4 require a pilot, but the S4 requires additional special training because it's a multi-engined tilt-rotor, which means rotary wing license / fixed wing license / complex aircraft endorsement (constant speed props and retractable landing gear; all of my training has been in this type of aircraft) / high performance endorsement (S4 is over 300hp) / multi-engine endorsement (a de-facto IFR-rated commercial pilot). That's about 200hrs and $100,000 worth of training, minimum. Guys and gals like that are either CFIs or type-rated ATP pipeline pilots. CFIs tolerate their low pay because after they have accumulated 1,500hrs, they're eligible for ATP testing and a job with an airline service.

The R66 has 2 rotor blades and 2 tail rotor blades. The S4 has 30 constant speed rotor blades and 6 electric motors. The R66's main rotor blade set / assembly is $60,400, and its tail rotor assembly is $8,900. Those prices come from Robinson's 2022 parts price list / catalog. The S4 has 6 of those 5-bladed propellers. Archer's Maker has the same number of constant speed props with the same blade count as the S4 (maintenance cost goes up, per-blade), plus 6 additional fixed-pitch props (still requires inspection and refurbishment after a specified number of hours accumulated). The composite 5-bladed MT propellers I own (composite over a wooden core) cost $26,000 each (price as of about 10 years ago; no telling what they cost today, but rest assured that the cost hasn't gone down). Overhaul cost is somewhere between $10,000 and $15,000, each. Who here thinks propeller and motor maintenance will be any cheaper than a helicopter for Joby's S4 or Archer's Midnight eVTOLs? Those gas turbine helicopters are starting to look downright economical to own and operate, aren't they?

I appreciate and agree with Archer's desire to achieve extreme levels of reliability. I disagree with how they're going about doing it. Modern airliners don't increase reliability by hanging a half dozen engines off the wings. Drastically increasing the number of propellers and motors doesn't add safety, but it does decrease maintainability while increasing cost to a considerable degree. Inspecting and repairing 1 propeller or main rotor is a very expensive proposition. Multiply that by a dozen propellers and a dozen motors, and you have a maintenance nightmare. Asserting that maintenance is not required because "muh EV", is a crock. All aircraft require maintenance, especially the kind the takeoff vertically.

MagniX has reliable electric aircraft motors that produce 375hp and 750hp. The 750hp model is intended to replace a PT-6A, it has comparable weight to a PT-6A (347lbs). One look at it, and you can tell it's a purpose-built unit that will reliably deliver the power. The kW/kg may be somewhat less spectacular, but it's also highly unlikely to fail. It's clearly not stressed to its limit. The 750hp magni500 weighs in at 135kg / 297lbs, produces 2,075ft-lbs of continuous torque, runs between 1,900rpm and 3,000rpm, has a beefy output shaft / mounting tabs / power connection terminals. In their test run video, it even sounds like a propeller connected to a PT-6A. Build a real electric helicopter if you want a vertical takeoff aircraft so badly, bolt up that 375hp MagniX motor, and call it a day.

750 Horsepower Electric Aviation Engine Tested By MagniX

The only realistic way to make both aircraft and cars meaningfully more efficient is to make them much lighter than they presently are. This means 1,000 pound electric or fuel cell vehicles made from fiber-impregnated plastics in the case of a car chassis, or composites in the case of airframes. Most importantly, this means ceasing and desisting with an entire range of ridiculous "features" that make these machines less affordable, less maintainable, less sustainable, and less practical overall. A car is a good car if it reliably takes you from Point A to Point B with minimum fuss and hassle. Any other features are great if they add nominal weight and cost very little to make and maintain.

Meanwhile, a few people are finally trying something more practical (5.5kW/kg and 6kW/L):

ZeroAvia Places Evaluation Order for Hyzon Motors’ High Power Density Fuel Cell

30kW/kg electric motors for fuel cell powered aircraft (by revving it to the moon, which is generally not a good idea, but whatever):

First steps toward high-speed motors for fuel cell components

If a billionaire wanted to develop a practical electric helicopter or electric light aircraft powered by Hydrogen, then Joby or Archer or a dozen other tech companies would already be over the finish line. Instead, Joby's spent 10 years in testing. Leonardo / Augusta-Westland has spent so many years testing their tilt-rotor that the original companies basically don't exist anymore.

Tesla and Elon Musk say they want more people driving electric cars. In the real world, price sells cars. If people had $5,000 EVs to drive around in that could go 100 miles, almost nobody would buy gasoline powered cars for commuting to work and school or the grocery store, because it wouldn't make any economic sense to do that.

So, how the heck do you do that?

To wit, you eliminate all the unnecessary and superfluous crap they load up modern vehicles with, you stop trying to make a battery equal to a combustion engine because that's impossible, and you only add the essential features that make them controllable / usable as cars. They add all that other gadgetry to increase profit margins, per vehicle sold. It doesn't help facilitate their stated goal of seeing everyone driving an EV. They don't do what they do because they care about the environment or saving the planet or any other such utter nonsense. There's a sucker out there who can't do basic math, and they're going to relieve him or her of their money by selling them something they probably can't afford. If any of this "energy transition" religion was intended to be practical, then it would've been achieved by now, because appropriate compromises would've been made, and the tech is still quite useful with those compromises.

As far as airliners are concerned, those could run on LH2 in a practical manner, but light aircraft and land vehicles don't need energy density quite as badly as intercontinental jet aircraft. As a percentage of total time spent flying versus holding down the tarmac, most light aircraft do a lot more of the latter than the former, which means LH2 is impractical. Perhaps flight schools, light cargo transport (FEDEX Cessna 208s and the like), and short haul passenger services are exceptions to that rule. A Cessna 208 could hang LH2 tanks off the wing tips, for example, similar to how many light twins have fuel tanks hanging of the wings. That said, we'd have to first build new composite airframes optimized for carrying those tip tanks.

Can we do electrification and Hydrogen in an affordable and practical way?

I think it's quite feasible to do, but pragmatic concessions have to be made to the limitations of existing batteries and fuel cells. Safety regulations for Hydrogen storage need to be drawn up. We have plenty of experience using Hydrogen, but the experience is very concentrated. Focused effort to bring fuel cell power-to-weight ratios up to 10kW/kg needs to be actively pursued, with assistance from NASA and government labs, if need be. Mass production techniques for composites, electric aircraft motors, and propellers need to be developed using the century of mass production experience from our car manufacturing industry. These are the sorts of actions and programs that will maximize the speed of transition, minimize costs, and ultimately sustain our technological advancement for this generation and future generations to come.

Offline

#39 2022-12-30 16:36:03

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 28,923

Re: Mechanical Storage of Hydrogen

sounds like this belongs here

This post is for Void's Geostored Energy topic .... it reveals plans to store hydrogen underground on a massive scale.

https://www.yahoo.com/news/company-brin … 11099.html

This company is planning large scale hydrogen storage in underground purpose built salt caverns.

The will be located between 3000 and 2000 feet underground, so I deduce they are vertical shafts, but would appreciate any further detail our members might be able to find.

Biloxi Sun Herald

This new company will bring zero-emission energy to MS, creating hundreds of jobs

Jenni CamhiFri, December 30, 2022 at 11:13 AM EST

Hy Stor Energy is building a green hydrogen hub in Mississippi that will generate zero emission hydrogen energy while also creating a new industry with hundreds of jobs and economic growth for the area, according to the company.

The project will be the largest of its kind in the United States, and will produce clean energy at scale that can be used as an alternative to fossil fuels in industries that are hard to decarbonize.

Hy Stor is Jackson-based but has land across the state, all the way down to their office in Gulfport. The company has acquired over 70,000 acres from Jackson south to the Gulf Coast, which will be used for green hydrogen energy production and storage.

What is green hydrogen?

Green hydrogen is a form of renewable energy that is produced by splitting a water molecule into its hydrogen and oxygen parts via electrolysis. When this process is powered using renewable energy sources, such as wind and solar, it has zero carbon and zero methane emissions. Hydrogen energy can be stored for long periods of time and used during extreme weather events, when the power may be out for days at a time, and can also be transported over long distances.

Green hydrogen produced by the Mississippi Clean Hydrogen Hub will be used to support business, industrial, transportation, and utility sectors across the state. Though the project will start in Mississippi, Hy Stor plans to distribute hydrogen energy to neighboring states, then the eastern U.S., and eventually internationally.

Hy Stor’s Chief Commercial Officer Claire Behar said hydrogen energy is an essential part of bringing flexibility and reliability to the energy grid because it can be used as an alternative to fossil fuels or electricity. It will also bring economic growth and job opportunities to Mississippi while providing diversity of energy supply.

“The development and commercialization phases of the Mississippi Clean Hydrogen Hub are expected to create hundreds of new jobs and attract new businesses to the state, diversifying the state’s economy while also driving innovation and empowering our workforce with quality, high-paying jobs,” Behar said.

A rendering of the building where electrolysis, the process where hydrogen energy is created by splitting a water molecule into its hydrogen and oxygen parts, will take place.

Behar added that the hydrogen energy sector is an opportunity “to build upon the existing skill sets of those working in the fossil fuel industry.”

Hy Stor is partnering with the Port of Gulfport and Hancock County Port and Harbor Commission (HCPHC) to help bring renewable hydrogen energy to the Gulf Coast region. HCPHC is home to Port of Bienville Industrial Park and Stennis International Airport. This partnership will allow Port Bienville to be the first Gulf Region port to use renewable hydrogen fuel in its daily operations.

“Our goal is to attract companies that have a strategic interest in being a part of a clean hydrogen facility and create an ecosystem of entrepreneurship and innovation in the Mississippi Gulf Coast,” Behar said.

How is the energy stored?

The company will store the hydrogen energy it makes in salt caverns, where it can be kept for months or years at a time and used as needed.“These salt caverns are going to be purpose-built for the storage of hydrogen,” Behar said. “Salt cavern geology is only found in specific locations around the world, and the Mississippi Gulf Coast is one of them. Salt caverns provide that multi-day, multi-week energy storage that can be dispatched on demand.”

Hy Stor has four salt caverns fully permitted and ten under their control in total. One is in Louisiana, and the rest are in Mississippi.

The salt caverns sit over 3,000 feet below the surface and have a height of 1,000 feet.

“It’s like the Eiffel Tower sitting underground or the Empire State Building. That’s the magnitude that we’re talking about,” Behar said. “So people ask ‘why store underground?’ and it’s because you can store magnitudes larger volume underground than above ground. And that makes the most economic and safe solution for storing hydrogen. It’s far away from the hydrosphere, the biosphere, and communities.”

Why Mississippi?

Mississippi is a strategic geographic location for the company because of the state’s naturally occurring geology and its proximity to existing distribution channels, such as the Mississippi River, deep water ports, interstate highways, railways, and gas and electric transmission lines. Having access to ports is going to be crucial for the company as they grow, expand, and seek to transport energy internationally.

“It’s really all about that suitable geology and then interconnected critical access to shipping and logistics corridors like the Mississippi River and deep water ports in the Gulf,” Behar said. “We really see green hydrogen developing into a major global market, where I believe strongly that the United States is going to play a dominant role as a global green hydrogen supplier and exporter.”

Construction will start next year for the Mississippi Clean Hydrogen Hub, which will be fully built by 2026.

A rendering of the solar and wind energy in Hy Stor’s hydrogen production facility that will be used to power the plant and the electrolysis that will generate hydrogen energy.

View comments

(th)

Offline

#40 2024-03-17 07:42:46

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 17,243

Re: Mechanical Storage of Hydrogen

In a search for 700 bar tanks to hold compressed gas, I found this article about aircraft ...

https://leehamnews.com/2022/03/25/bjorn … n-storage/

The article provides detailed comparison of storage considerations for gaseous and liquid hydrogen for an aircraft.

The article mentions 700 bar tanks and suggests they may be an industry standard developed for the automotive industry.

The conclusion of the article is that liquid hydrogen is a better bet for commercial aircraft, since the pressure required to contain the material is only 1.2 bar. Expense is associated with the means of keeping heat flow into the stored liquid as low as possible.

RSS Leeham News and Analysis

Bjorn’s Corner: New aircraft technologies. Part 50. Wrap up.March 11, 2024

Bjorn’s Corner: Sustainable Air Transport. Part 12. Hydrogen storage.DOWNLOAD

By Bjorn Fehrm

March 25, 2022, ©. Leeham News: Last week, we looked at the energy density by mass and volume for hydrogen and regular Jet fuel (Kerosene), Figure 1.With this information, we now look at how these fuels can be stored in an aircraft.

(th)

Offline

#41 2024-03-17 14:03:38

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 7,434

Re: Mechanical Storage of Hydrogen

tahanson43206,

My conclusion is that commercial aircraft don't require LH2 with existing 10kW/kg electric motor, 5.4kW/kg fuel cell, and 700 bar CNTRP tank technology, in order to beat gas turbines and kerosene on weight. LH2 would beat gas turbines and kerosene by an even greater margin, but the headaches and expense of dealing with cryogenic fuels are not worth the additional cost.

H2 is 143MJ/kg, or 39,722Wh/kg.

Hysata's water electrolyzer requires 41.5kWh of electricity per 1kg of H2 produced, so H2 production requires 104.476% of the embodied energy contained in H2 when reacted with O2.

1.35kWh of electricity is required to compress H2 to 700 bar.

41,500Wh/kg + 1,350Wh/kg = 42,850Wh/kg

(42,850Wh/kg / 39,722Wh/kg) * 100 = 107.875%

7.875% more energy is required to produce 1kg of H2 and store it at 700 bar, than it contains to begin with. A 7.875% loss is negligible. Nobody points this out when it comes to Lithium-ion battery losses. Why is that?

Assume that a Lithium-ion battery has a charge / discharge efficiency is 96% (also known as electrical efficiency), and a power inverter efficiency of 96%. This is achievable with top shelf batteries and power inverters:

(0.96 charge eff. * 0.96 discharge eff. * 0.96 power inverter eff.) * 100 = 88.4736%

That's an 11.53% energy loss right there, from simply charging and discharging the battery and pushing the power through a power inverter / conditioner to give you the desired voltage and amperage.

Now let's show 98% for a battery (something that doesn't exist, but let's pretend):

(0.98 charge eff. * 0.98 discharge eff. * 0.98 power inverter eff.) * 100 = 94.1192%

We're remarkably close to the losses of 700 bar H2, aren't we?

Batteries still suffer from a 60X weight penalty over gasoline / diesel / kerosene. Batteries still lose capacity over time, especially when discharged at rates suitable for aviation applications. If current fuel cell and 700 bar tank technology beats gas turbines and kerosene on weight, by a good amount, then batteries look even worse when compared to fuel cells. I think Elon Musk never counted on Hysata or similar companies using capillary action to raise electrical efficiency of water electrolyzers to 95%+. Waste heat from compression can also become hot water. Hot water has many uses. Humanity burns crazy amounts of fuel to vaporize water. That makes efficiency, all said and done, look remarkably similar to Lithium-ion batteries, but without the insurmountable weight penalty of batteries.

If fuel cells or electric motors become even more power-dense than they already are, then the combination of their weight and efficiency is going to squash any argument about whether or not they beat gas turbines on weight. It will become an objectively true statement, not subject to any vague assertions or interpretations from our battery or gas turbine enthusiasts.

Based upon Wright Electric's 2MW 200kg electric motor, which they claim is scalable from 500kW to 4MW, a 1MW motor would weigh 100kg. Toyota's passenger car fuel cell is 5.4kW/kg, so 185kg. The 948kW PT6A-67D weighs at least 250kg with engine oil, exhaust ducting, and accessories. If Wright makes a lighter motor or Toyota makes a more power dense fuel cell, say 6.7kW/kg, then the electric motor and fuel cell combination weighs as much as a gas turbine with equivalent power. That said, if Wright Electric makes an engineering plastic casing or 3D printed Aluminum casing, then their motor loses more than 15kg of weight, so no fuel cell performance improvement is required at all to be at the same weight as the Pratt & Whitney PT6A.

The most likely case is that Wright Electric and Emrax eventually produce electric aircraft motors of greater than 10kW/kg power density, and that fuel cell power density continues to improve. 10 years ago people were talking about 2kW/kg to 2.5kWh/kg being near the limit. Now we have 5.4kW/kg PEMFCs in production cars. CNTRP will take over where CFRP falls short, which is already happening, so whether or not LH2 or 700 bar H2 is used, it will make little difference to the end result. The fuel cell and electric motor will best gas turbines and kerosene on weight, and to such a significant degree that it becomes impossible for any less power dense technology to compete.

CNTRP airframes, combined with CNTRP H2 or LH2 tanks, will continue to advance aviation efficiency, power, and propulsion. This is the way of things, though. Tech that most people take for granted or outright ignore continues to improve, while tech that people had pinned their hopes and dreams to, such as flying cars, battery powered aircraft, etc, fall by the wayside when it becomes increasingly apparent that the concept or technology can't compete on weight or cost.

Offline

#42 2024-04-13 18:50:10

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 17,243

Re: Mechanical Storage of Hydrogen

The article at the link below is about mechanical storage of hydrogen in a salt cavern. The headline writer used the term "battery" in the generic "energy storage" sense. That is the same sense in which a hydroelectric dam is a "battery".

https://www.msn.com/en-us/weather/topst … 0f20&ei=27

However, aside from the word used to describe the system, it does appear able to hold a significant amount of energy...

Photo Credit: Advanced Clean Energy Storage

© Provided by The Cool Down

A small town in central Utah is set to be the home of a new underground "battery" that will store hydrogen as a clean energy source.According to The New York Times, developers are creating two caverns as deep as the Empire State Building is tall from a geological salt formation near Delta, Utah. These caverns, which are expected to be complete next year, will be able to store hydrogen gas.

The hydrogen will be produced nearby through a process called electrolysis. This will be done using excess solar and wind power in spring and fall, when demand for energy is low. Then it can be stored until peak energy demand hits in the summer — at that time, it would be burned at a power plant as a blend of hydrogen and natural gas.

The burning of hydrogen does not release planet-warming pollution, but it's unclear just how eco-friendly the new plant will be. The amount of pollution produced will depend on the hydrogen/natural gas ratio used.

Nonetheless, the new facility will help clean up the air for local residents as it replaces a coal plant. Exposure to pollution from the burning of coal contributes to respiratory illnesses, neurological and developmental damage, and lung disease, according to the U.S. Energy Information Administration.

Investments in clean energy sources, such as hydrogen produced with renewable energy, are also crucial to slow down the overheating of our planet. While the burning of hydrogen releases no planet-warming pollution, coal, oil, and gas are the biggest contributors, accounting for over 75% of global planet-warming pollution and nearly 90% of all carbon dioxide released into the atmosphere, per the United Nations.

If burning coal or gas fuels it, hydrogen production can create pollution. However, the fuel becomes a clean storage resource, or "green hydrogen," when solar or wind energy powers its production, as will happen in Utah.

Green hydrogen as an alternative power source is gaining traction in the United States. For instance, a Texas factory is planning on producing green hydrogen that uses wind and sun as energy sources for the electrolysis process. It will be the largest facility of its kind in the U.S.

Meanwhile, the Biden administration recently announced $7 billion in funding for hydrogen projects across the country to jump-start production.

While the Utah project looks promising, it still has its challenges. Ilissa Ocko, a scientist at the Environmental Defense Fund, told the New York Times that getting to 100% hydrogen in the next 20 years would very likely require major facility upgrades or complete rebuilding.

"The costs can very easily add up when you make the adjustments that you need to the infrastructure," she told the publication. "There are so many complicating factors here that can make it very easily turn into something that is not beneficial to the climate."

Still, "It's a massive amount of storage," Jigar Shah, head of the Department of Energy's loan program office, told The Times, noting that the plant will complement other renewable energy projects in the West that together can produce surplus electricity in the spring and fall. "This is a great way to deal with all that excess supply."

(th)

Offline