New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#26 Re: Life support systems » Lunar Air. Shelter. Water. Food, Waste management » 2024-03-29 15:02:00

Lunar cement idea:

#27 Re: Planetary transportation » Trains on Mars - Could a rail system provide martian need » 2024-03-29 12:29:17

Hey All,

Some thoughts on rail construction on the Moon.

Two major environmental factors are different on the Moon as compared to Earth, along with the economic/logistical factors: Temperature and Gravity.

Looking at temperature first: UCLA's Diviner Instrument on LRO got some good measurements of the diurnal temperature variation on the Moon.

Excepting the extreme far north/south, you don't get too much variation in surface temperatures (I'm going to assume the thermal behavior of the tracks would be largely similar to the rest of the surface though there's actually not good evidence for that and it is possible for it to not be the same). Nighttime temperatures are consistently just below 100K everywhere and daytime temperatures reach about 220K at 80° and nearly 400K at the equator. 200K of temperature change in steel generates a ~0.25% change in length: 2.5m per kilometer or 2.5mm per meter.

Gravity is a bit more self-explanatory I think: On the Moon, things weigh about 1/6th as much but have the same momentum. This has a few implications, some of which have been discussed and some of which haven't.

Things weigh 1/6 as much: This means you don't need rails to be nearly as heavy to support a given load. On the other hand, it has more negative consequences. Things are 6 times more easy to tip. It also means the hunting oscillation that keeps the train on the tracks (it's not the flanges on the wheels!) is 6 times less effective.

Louis pointed out, reasonably, that rails on Earth are welded together in order to make for a smoother ride and reduce wear. But lunar transportation may well be slower than Earth, so it won't matter as much. The lower gravity will also tend to mean that the train has a lower tendency to drop in the gap.

On the other hand, the gap can be quite large. A 36m rail (this is roughly standard on Earth) that's the perfect size at 300K will be 9cm too short at 100K. I haven't done the math but that does seem like too much.

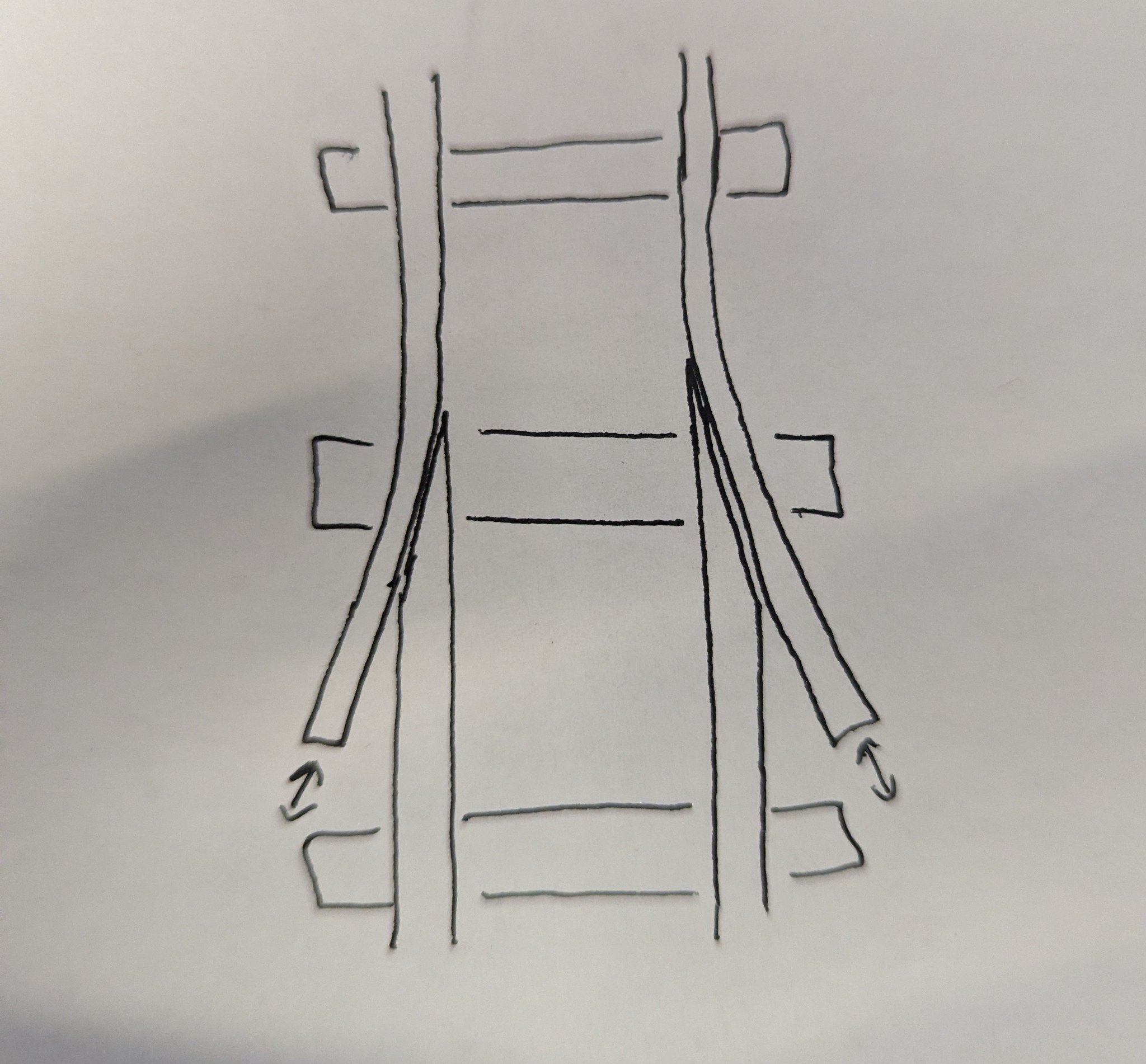

GW suggests a vertical overlap. But even if your angle is just 6 degrees that 9cm corresponds to about 1cm vertical travel (+/- 5mm). I'm not sure about the limits for this kind of thing but even a 5mm cliff seems like it would be a concern. Upwards probably more than downwards.

We could probably extend the contact part of the wheel and introduce a support intended to bridge the gap, which fully supports the wheel at cold temperatures when the rail ahs contracted away. I believe someone else suggested something similar upwards in the thread.

Note the large wheel angle, by the way. This is not an exaggeration for the drawing, it's an intentional choice designed to increase the efficacy of the hunting equilibrium described above. Rail is designed in the terran standard shape, but given this larger angle might actually have a different shape as more of the load is at a non-downwards angle.

The last thing is that you're going to want trains that are more squat, to allow for shorter turning radii at any given speed, probably with a wider gauge than standard gauge on Earth despite having rails that are much thinner.

The diviner website also provided a cool gif of temperature variation which, in a pleasant turn of events, embeds fine in a forum post.

Tahanson: As far as using Dall-E to generate engineering drawings, I think that's a bad use of AI. The neat thing AI can do is use quantitative technology (IE computers) to generate qualitative products. The images that come out of it are a good way to give an impression of what something might look like but not a good way to communicate a specific quantitative design intent like you would in an engineering drawing. A hand scribble is a better low-effort way to do that (I've actually been using Twitter as a free image hosting service).

#28 Re: Meta New Mars » JoshNH4H Postings » 2024-03-26 17:59:03

Good to see you again Spacenut

#29 Re: Meta New Mars » Housekeeping » 2024-03-26 12:05:23

While I'm here: Why are there so many sticky topics?

#30 Re: Meta New Mars » JoshNH4H Postings » 2024-03-26 11:54:42

GW, Tahanson, good to see you guys again.

Was talking about the Northrop Moon Train study with some friends on Twitter, had a look at the forums to show them how long I've been banging on about trains in space for. I'm doing engineering for Rocketlab these days on the space systems side.

#31 Re: Meta New Mars » Housekeeping » 2024-03-26 11:51:12

Hey th,

Good to see you all again.

Unfortunately I don't have the time (or the skills really) to help out with forum maintenance.

I did try creating a new thread with no success. Maybe I'll try again in a few days

#32 Re: Meta New Mars » Housekeeping » 2024-03-26 08:11:19

I tried to copy the post text into the above post and it seems like it's something about the post itself that the forum doesn't like. Pretty strange since it was all ASCII

#33 Re: Meta New Mars » Housekeeping » 2024-03-26 08:10:17

Tried to create a topic in Life Support about lunar cement. Got the following error:

_____

Internal Server Error

The server encountered an internal error or misconfiguration and was unable to complete your request.

Please contact the server administrator at webmaster@newmars.com to inform them of the time this error occurred, and the actions you performed just before this error.

More information about this error may be available in the server error log.

_____

Also tried posting as a reply on a related topic. No luck. I've posted in Planetary Transportation and it worked fine. Also tried to post "test post" and it worked fine.

For now, I put it on my blog: https://gammafactor.wordpress.com/2024/ … -concrete/

#34 Re: Planetary transportation » Trains on Mars - Could a rail system provide martian need » 2024-03-25 11:53:28

Thermal expansion/contraction problems are way worse on the Moon than anywhere on Earth. It's a fun design question though. I'd do something like this (probably occurring over a much longer distance than shown here). Rails in the top of the picture allowed to slide against the rail on the bottom but shall always overlap. Ties, probably stiffer at the joint, keep everything aligned left to right. Rails are probably made stiffer also at the joint to partially compensate for tapered shape.

The ability to use regular steel or maybe aluminum (price difference much smaller if both are smelted electrically: See this post) is going to be pretty critical for rail to make sense. If you're using fancy temperature insensitive alloys you might as well just use trucks.

#35 Re: Planetary transportation » Trains on Mars - Could a rail system provide martian need » 2024-03-25 08:41:30

I looked into this a bit because I would certainly apply to the Moon Train team if there was such a team.

The grant was issued as part of the 10-Year Lunar Architecture (LunA-10) capability study which issues grants not to exceed $1,000,000 each. Pocket change for a MIC.

Cool though and I hope the results are public

#36 Re: Planetary transportation » Trains on Mars - Could a rail system provide martian need » 2024-03-23 17:58:25

As much as I love trains, it's not clear to me that any kind of lunar train network will pencil for the foreseeable future. What kinds of goods will even be shipped, and in what quantities, and over what distance? It's a bit hard to say.

But for starters, there will be spaceports at least some distance from each base, iron mines, aluminum mines, silicon mines, water mines, carbon mines, nitrogen mines (though water, carbon, and nitrogen will all likely come from permanently shadowed craters they may not come from the same permanently shadowed craters).

On Earth the case for rail over road is that the rails give you better fuel economy, longer-lived equipment, and the ability to use less labor to ship more stuff. But building a rail line costs money—more than a road, despite having a narrower use case—so it doesn't pencil unless there's high volume (coal and oil are often shipped by train, along with other stuff) or someone's already built the rail line.

On the moon I think the driving factor towards something like a railroad is different: Electric power.

I don't want to get into a big argument over power sources, but in my view solar photovoltaics are the path of least resistance for the Moon if you can make them work. The biggest challenge there is the two-week long lunar night, which would mean very large storage requirements.

But there is another way: Since bases will be clustered around the South Pole, you can build a grid that circumnavigates the pole with solar sites spaced at, say, 120 degrees. At near-polar latitude the panels will cast long shadows, meaning your array will use a lot of land, but the moon has as much land as all of South America and I don't think this is a big deal. You can also build your power stations significantly north and run lines down to the base locations. China has power lines that go 3200km (diameter of the Moon is 3400km) and they're not at the physical limit, meanwhile the low gravity, stable environment, and vacuum make it even easier to build power lines on the Moon.

There is a point to this digression, which is that we should expect the Moon to have a pretty well-built out power network early on. This ends up being pretty important for the idea of long range transport, because burning hydrocarbons is a waste of hydrogen and carbon unless you recapture, which comes with difficulties, nuclear is poorly suited to the size of transport, batteries are inconveniently heavy—especially if you want really good ones brought from Earth, etc. The most logical way to build out a transportation network is to piggyback on your electricity transmission network.

So what you end up with is roads—paved in the busiest corridors (with what I'm not sure, possibly just sintered) or cleared and leveled elsewhere, under an electrical catenary which provides power to the vehicles running underneath it.

I asked Bing's AI image generator to make this, just to see what I could get. Didn't capture everything I'd want (had a tough time getting it to put Earth in the sky) but it's a cool look anyway:

On Mars though? Plain old combustion engines in trucks, in all likelihood. Possibly bigger trucks. Oxidizer is a tougher question than fuel. Pressurized oxygen is probably the easiest thing. Electrified routes probably come later.

#37 Re: Meta New Mars » Okay guys, we need new moderators... - Want a job? Post here or nominate. » 2020-01-12 12:00:52

Hi everyone!

I noticed that I still have mod powers on the forum and I wanted to ask again to have them removed as I have resigned as a moderator

#38 Re: Science, Technology, and Astronomy » Plasma Optics » 2020-01-04 11:45:36

Hey kbd512,

Happy New Year!

Glad to see I was on the track of something real and potentially useful.

Using one of these guys as a temporary fix for climate change seems like a definite possibility. From there I would say there are obvious applications also to Mars and Venus for their respective terraforming projects, and at that point possibly any outer-system body looking to heat itself up (in combination with other terraforming methods like greenhouse gases).

Looking even further into the future, plasma mirrors would definitely be useful for interstellar lightsail missions. By locating one close-in to the Sun you might direct concentrated light at a far-away lightsail hosting a similar plasma mirror array. You might achieve a multiplier of the intensity by bouncing the light back and forth between the craft and the concentrator array.

Plasma mirror telescopes? It's hard to imagine that this technology could achieve the necessary precision to get good imaging, but it's not impossible, and if planet-sized plasma mirrors are already in use I have to think astronomers will do anything to get that much signal. At that point (and this is unfounded speculation) I have to think you'd be able to look at extrasolar planets light-years away in substantial detail. As a point of comparison, James Webb Space Telescope is supposed to have a mirror 6.5m across; The one I'm talking about is literally a million times bigger, and thus would have a million million times more area/signal.

Where this ends, I suppose, is with a dyson sphere, which becomes at least conceivable when you do not need to build it from solid matter.

#39 Science, Technology, and Astronomy » Plasma Optics » 2019-12-31 15:01:19

- JoshNH4H

- Replies: 4

I would describe this thread as being more about science fiction than actual science or engineering, because I am describing a technology that is probably theoretically possible but which is unlikely to exist any time soon.

Here's the idea: Plasma Optics.

Here's the theory:

Regular matter is opaque to regular light because of the energy difference between the electron energy levels in normal matter. These correspond generally to the energy levels of visible light, which can thus easily interact with the electron clouds that surround atoms and molecules. In principle, you could also create this kind of interaction in a plasma by creating electrical potentials, which will cause the plasma to interact with incident light. If we get really good at working with plasmas and electromagnetic fields (and the interaction I have described is actually possible) this creates a lot of potential technological applications.

I think of this as being a sort of "Tier 3" M2P2 (mini-magnetospheric plasma propulsion) system. Tier 1 is the system that was worked on and tested at NASA that uses plasma to inflate a magnetic field to use as a magnetic sail. Phase 2 is a hypothetical version with a translucent plasma that acts as a light sail, and this is Phase 3.

Anyway, here's some applications I can think of:

Reflecting sunlight into a solar thermal engine for thrust: Potentially high Isp (1000 s or more than that with advanced engines) and high thrust and T/W

Solar Sailing: Nothing has a lower mass than plasma so you can get high thrust compared to physical lightsails

Plasma Photovoltaics: At least in principle it should be possible to convert electrons moving up a potential well into electrical energy. Given the relative ease of building big structures from plasma as compared to matter you might be able to generate truly massive amounts of energy in this way

What I wonder is as follows: Is it possible? How would it be done? What else could plasma optics be useful for?

#40 Re: Exploration to Settlement Creation » Construction technology for Mars? » 2019-12-16 11:05:39

Hey OldFart,

Here's what I've been able to find:

1) Compressive strengths are not often provided for polymers but the tensile strength for Polystyrene is cited in various places as 35-55 MPa. You can correct me if you believe I'm wrong but it seems to me that the compressive strength should be in a similar range, thus roughly 50 MPa±25 MPa. I was surprised to find that this is roughly also the compressive strength of both portland cement and typical concrete. One thing I am truly uncertain about is whether sand/aggregate will bond to a styrene matrix in the same way as it bonds to a cement matrix. Both cement and sand/aggregate are sort of rocky materials with somewhat similar structures and similar mechanical properties (densities, hardnesses, etc). Styrene has very different properties--would a styrene-sand composite be as well-matched as cement-aggregate? Would it last as long? Would the components bond to each other? Or would their different thermal expansions and hardnesses cause it to shred itself from within over time?

2) As far as pricing goes, it looks like polystyrene goes for about $10/kg, which is about $9500/cubic meter. By contrast, concrete costs around $113/cubic yard, which is about $150/cubic meter or about $0.11/kilogram--much less. It makes sense that this would be the case, because concrete is made from lightly processed bulk materials whereas styrene monomers have to be produced via a somewhat complex process of chemical purification and synthesis. On the one hand, the availability of CaO or CaCO3 deposits on Mars is something of a question mark. On the other hand, Styrene monomers are ultimately produced from crude oil which is almost certainly not present on Mars. (Crude oil comes from fossilized life-forms; CaCO3 most often exists as limestone accreted from living organisms but can also form naturally in water depending on pH and Calcium availability).

3) I'll talk about 3D Printing in my next post.

#41 Re: Exploration to Settlement Creation » Construction technology for Mars? » 2019-12-14 20:51:00

Hi Oldfart,

Three questions.

1) How does the compressive strength of your proposed substance compare to the compressive strength of cement or concrete?

2) What is the cost per tonne and cost per cubic meter of this substance on Earth and how does it compare to concrete?

3) Why is it desirable to 3D print concrete when 3D printing is expensive and slow while pouring concrete is cheap and fast?

#42 Re: Exploration to Settlement Creation » Construction technology for Mars? » 2019-12-14 19:15:54

Hey GW,

Yup, we were just talking about mild pressurization for the concrete to set. Understood on all sides here that pressure containment in the actual building is much harder.

#43 Re: Exploration to Settlement Creation » Construction technology for Mars? » 2019-12-14 15:29:48

Yes, that's exactly the point. When you have too much more pressure than is needed to support the roof you start needing to build increasingly heavy or complex tiedowns. The specified pressure for pressure-supported structures is mostly to counteract the weight of the structure. If you are going to have an inflatable structure with a pressure of +6 mb on Mars, the canopy should have a mass 2.5 times as much as the canopy for a corresponding internal pressure as Earth.

#44 Re: Exploration to Settlement Creation » Construction technology for Mars? » 2019-12-14 14:33:50

Gotta divide by ~2.5 for lower Martian gravity, but making things heavier than they need to be presents no difficulty at all.

#45 Re: Exploration to Settlement Creation » Construction technology for Mars? » 2019-12-14 11:01:12

Hey GW,

I think the design I discuss in the second blog post (very similar to the one I discuss earlier in this thread) deals with the tension well with separate tension and compression elements.

As far as concrete goes you make a good point, but a bit of googling suggests an option, for Mars at least.

On Earth our concretes are typically made from Portland cement, which is a "Hydraulic" cement because it does not need to lose its water to harden. These cements work, as you've said, by forming hydrates and hydroxides from their internal water.

There are also non-hydraulic cements. These aren't used much these days, but typically they're made from "Slaked lime", IE CaO in water. They work by first losing all their water to the environment, then absorbing atmospheric CO2 to form carbonates, IE CaCO3.

Non-hydraulic cements are almost never used these days because they're slow to dry out and also slow to absorb CO2 due to its low concentrations, so it takes a long time for them to reach their full strength.

I believe the rates for both of these reactions will be increased on Mars. Because of the very low ambient pressure, vaporization of water will be much quicker, and the CO2 partial pressure on Mars is actually higher than Earth by about a factor of 20.

Neither of these observations themselves solves the issues raised by RobertDyck or GW.

The low-temperature problem is the easier of the two to solve, as it can be fixed by heating.

The low-pressure problem is harder. The boiling temperature of water at 7 mb is a bit above 0°C. One solution is mild pressurization. The boiling point of pure water is 9 mb at 5°C, 12 mb at 10°C, 17 mb at 15°C. It's worth mentioning that at Mars gravity and assuming a density of 2000 kg/m^3 and an ambient pressure of 6 mb these pressures will be generated by the action of gravity at a depth of 4 cm, 8 cm, and 15 cm respectively. This means the boiling problem is mostly a problem for the top surface. A plate of steel 2 cm thick would generate enough pressure beneath it to raise the boiling point to 10°C.

So for the rapid boiling problem we're really talking mostly about the upper layer. Not to say that makes it not a problem, because it definitely is a problem.

I do wonder whether the vapor pressure of pure water is relevant here. Cement and concrete are mixtures, and while the components of cement are not highly soluble in water there’s a lot of “stuff” there, and it seems reasonable to me that you would see meaningful freezing point depression and boiling point elevation. You might be able to further encourage this by doping the cement with salt or for a non-hydraulic cement mixing water with another liquid.

I’d be interested in looking more into the properties of non-hydraulic cements but don’t see many useful references online and I would definitely appreciate if anyone has any useful links.

Follow-Up: I found this PhD thesis PROPERTIES OF HYDRAULIC AND NONHYDRAULIC LIMES FOR USE IN CONSTRUCTION by Andrew J Edwards at the Napier University in Edinburgh, Scotland. Looks like I've got some reading to do!

#46 Re: Exploration to Settlement Creation » Construction technology for Mars? » 2019-12-13 09:50:37

The idea of 3D Printing with concrete is a little weird because it's actually slower and harder than just pouring concrete down into a mold.

In my opinion the most interesting thing would be to start 3D Printing the molds (rather than framing them out with wood per current practice) and then pouring the structural concrete in to save labor.

Concrete is also extremely poorly suited for being a structural wall material for Mars because it has virtually no tensile strength.

I think a good design for insulation would be modular "insulation panels" that can be bolted onto the structure and onto each other. Probably best for them to remain unpressurized: Insulation filled with gas at Martian ambient pressure is an even better insulator than insulation filled with gas at Earth ambient pressure.

I haven't done the numbers, but it would come as no surprise at all to me if air at 1 atmosphere and -20 C carried away more heat through convection than air at 0.007 atmospheres and -70 C.

Mars is also a lot drier than Canada (it basically never rains or snows) and never thaws. This has downsides from a settlement perspective but also upsides in that the freeze-thaw cycle can be extremely damaging.

#47 Re: Exploration to Settlement Creation » Construction technology for Mars? » 2019-12-12 15:12:18

Hey Louis,

Cut and cover goes back to what I have described, here and elsewhere (including repeatedly in both blog posts), as the First Rule of Space Construction.

Here's what I had to say about a similar idea in the Covered Craters, Tented Towns thread.

As far as your "gorges" go: I'm not opposed to the idea per se but I don't think you've fully thought it through. You can correct me if you disagree, but the effective difference between a "domed crater" and a "gorge" is that, per square meter of roof, the gorge has more internal volume because you've dug down inside the enclosure.

I have no problem with this (in fact I think it's a good idea) but many of the design constraints for a roofed trench and a domed crater are the same:

The fundamental law of space construction still applies: The key design criteria is how you contain the pressure

Assuming the pressure is the same (and why would it be different?) there's just as much upwards force on the roof of the gorge per unit area as the roof of a dome

No matter how you're containing the pressure, the exterior walls of the gorge need to be sealed against leakage. Rock and regolith are not airtight and shouldn't be used for this purpose, not just to prevent air loss but also because pressure can, over time, cleave rocks apart and cause a catastrophic blowout.

Rock and regolith are poor structural members and probably can't be used for wall or floor support without modification (read: a construction project)

Again, the key consideration for a roofed trench or a domed crater is how you're going to keep the roof and walls on against the internal pressure. If you'd like the roof to be transparent, the answer is probably one of the ways I described, or a different method that I didn't think of that deals with that force in a different way. If not, piling regolith on top is probably the best way to get vertical pressure containment and radiation protection at the same time.

To restate the point here, which I made at length at the beginning of the first blog post as well as at other points (including the quoted post and earlier in this thread), pressure containment is key and is *not* the same thing as leak prevention. Your cut and cover design depends on the structural integrity of raw earth in the horizontal direction (even if it's covered in masonry) to avoid explosive decompression, and I don't think that is an adequate pressure containment method.

#48 Re: Exploration to Settlement Creation » Construction technology for Mars? » 2019-12-12 14:43:28

Hey Tahanson,

Absolutely feel free to share that post wherever you like.

As far as using stripped ions for digging:

You asked me to disregard practicability, so I will: Yes, it could be done.

I maintain that it is not practical. These things are hard to create and even harder to store. It's basically impossible for that to be the cheapest or easiest way to deliver energy into rock.

#49 Re: Exploration to Settlement Creation » Construction technology for Mars? » 2019-12-12 10:32:33

Hey All,

Much of the articles should be familiar if you follow this thread, but I'm doing a series on my blog about construction architectures on Mars. So far parts one and two are up:

Construction on Mars, Part One: General Principles and Design Assessment Criteria: In this post I give a broad overview of design constraints and produce the following six criteria for evaluation:

The structure sustains a pressurized atmosphere

The structure provides protection from radiation

The structure is failure resistant

The structure is failure tolerant

The structure can be constructed in an affordable way

The structure is useful as such

Construction on Mars, Part Two: Design, Details, and Evaluation: In this post I go into the details of my design (familiar to you all from this thread) and discuss how it meets the criteria described in Part One.

The next posts are going to discuss materials and specifications (IE dimensions), Construction technology and methods, setups for different functions, building entire settlements using these structures as units, and more!

Interested in hearing your comments and thoughts.

#50 Re: Single Stage To Orbit » A SSTO research project. » 2019-07-24 17:02:43

kbd512, GW, Bob Clark, et al:

I've been thinking about this some more, and here are some thoughts I've had about how I'm going to simulate the trajectory, in no particular order.

1. The point about doing the pitchover basically at the time of launch makes sense to me; a rocket launch is a fundamentally horizontal affair and time spent travelling vertically is basically wasted impulse.

2. I had initially thought to start the simulation with a zero-time impulse (meaning to start the rocket off with some horizontal velocity relative to the ground at t=0 as a simplifying assumption) and fly a non-lifting trajectory from there, then go back and calculate the correct angle/duration (given a fixed total horizontal impulse, pitchover angle and duration are directly related to each other). Taken together this would turn a 3-dimensional optimization into a 1-dimensional one, and while a finite duration pitchover will result in a slightly lower orbit than a zero-duration pitchover, the difference is small and easily corrected for. This will not work, because if you start with horizontal velocity and no vertical velocity (the zero-time impulse pitchover) your flight angle will be zero.

3. Therefore I need to think more carefully about how to simulate the timing, angle, and duration of the pitchover. Suggestions are appreciated.

4. Strictly (theoretically) speaking, a pitchover maneuver is not required to reach orbit. An object sitting on the equator that is motionless relative to Earth has a velocity of 465 m/s. This corresponds to a two-body newtonian orbital radius around 2 million km (in practice this is interplanetary space, but you'll be orbiting something regardless).

5. A zero lift/zero AOA trajectory is not quite the same thing as firing in the direction of motion in inertial space, because the earth and the atmosphere both rotate, and therefore a craft that is stationary with regards to the atmosphere still has rotation and velocity in inertial space. Presumably the global effect of the difference is small for reasonable trajectories but at the beginning of the trajectory the difference in implied angle is a full 90 degrees.