New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#401 Re: Planetary transportation » Running on Compressed Air? » 2024-06-30 10:03:41

Estimating the Total Cost of Compressed Air

At $0.25/1,000ft^3 or 28.3168m^3, filling up the 253L tank with 177.1m^3 of compressed air would cost $1.56.

If the car only has a range of 100 miles, then driving 15,000 miles per year costs $234.00.

At 250Wh/mile for the Tesla Model 3 and an electricity cost of $0.13/kWh, 15,000 miles, or 3,750kWh worth of electricity, costs $487.50.

If that same electricity to run the air compressor costs $0.13/kWh, then filling up the air tank costs $0.813, so 15,000 miles costs $121.96 per year.

I guess how much everyone else wants to spend to fill up their car is up to them, but I'm going to go with $121.96 per year, because money is still money.

When you make a car much cheaper to purchase, drive down the road, and maintain, you don't have to worry about selling them. They do that all on their own. You don't need to convince anyone of anything. Money talks. If the air tank lasts for 21,000 cycles, which is about where Type IV compressed H2 storage tank technology was 10 years ago, that represents enough driving to drive to the moon and back 4 times. At 25,000 pressure cycles, you can drive to the moon and back 5 times. The cost of driving to the moon and back 5 times on compressed air is $20,325, which happens to be about the same cost as the battery for a Tesla. Since the price of one of those Type IV tanks is about $5,000, I consider that a bargain.

COMPOSITE 700 BAR-VESSEL FOR ON-BOARD COMPRESSED GASEOUS HYDROGEN STORAGE

Based upon the Type IV 37L water capacity 700bar H2 storage tank figures from Page 8 of that report, the tank survived 15,000 pressure cycles from 20bar to 875bar, with the pressure cycling taking place at the incredible rate of 1 cycle per minute. If 100,000 tanks per year were produced, then the estimated cost of each tank would be $650. 7 of those tanks would be required to provide 253L of storage capacity, and would weigh 196kg. This is very close in total weight to the 182kg 253L Type IV tank that US DoE tested during the past 2 years, so the tanks are getting lighter as fiber technology improves, and you do get a reduction in total tank mass by using a singular larger storage tank, that's to the cube-square law. Total cost for all 7 of the 37L would be $4,550. Fabricating a single larger tank will save money because less material is used, less wear and tear on the tooling, fewer tank fittings such as regulator valves are required, etc.

#402 Re: Planetary transportation » Running on Compressed Air? » 2024-06-30 10:02:27

SpaceNut,

450bar to 850bar Type IV CFRP high-pressure H2 tanks are quite real, even if most people don't normally see them in their daily lives. A Type IV pressure vessel is a very specific US Department of Transportation H2 / CNG storage container rating that comes with safety and testing requirements attached to it, because rated pressure vessels are used for transportation of compressed gases. Type IV works equally well for air and most other high pressure gases. There are highly acidic or basic chemicals for which CFRP is not a good storage container, but they are typically compatible with air, Oxygen, Hydrogen, Methane, Helium, Nitrogen, Argon, and other common gases. For gases such as Chlorine and Fluorine, you're better off using stainless steel, potentially with a fluoropolymer liner, and accepting reduced storage pressures. Composite tanks with fluoropolymer liners can store Chlorine and Fluorine gases, but that's not how it's typically done. I assume there are good engineering and economic reasons for continuing to use stainless steels and reduced pressures for such aggressively oxidizing chemicals.

A 450bar tank with a water storage capacity of 250L / 0.25m^3 can safely contain 112.5m^3 of air, while an 850bar tank can be charged with 212.5m^3 of compressed air. The 850bar tank will be heavier than the 450bar tank, but not in terms of equivalent storage capacity. For example, a pair of 450bar tanks can hold about the same amount of air as a single 850bar tank, but the weight of both tanks will exceed the weight of the single 850bar tank by a considerable amount. If you double the capacity of a singular 450bar tank, then it still ends up weighing a little bit more than the smaller 850bar tank. More importantly, 0.5m^3 is nearing the limit of what a vehicle with the same exterior dimensions as a standard compact car can reasonably carry, which is why the 850bar tank makes more sense for this application. If volume was not as constrained, then it might be possible to make that 450bar 0.5m^3 tank for less money than the 850bar tank because the processing steps are less costly, but it still requires more fiber and resin, so the materials cost will likely remain similar to that of the 850bar tank.

I see the chassis materials and design as 4 major types with various cost, durability, and recyclability trade-offs:

1. CFRP monocoque

A. lightest possible total vehicle weight

B. highest possible specific strength

C. highest possible cost (purely based upon structural materials cost, not cosmetics; apart from CNT and BNNT fibers, Carbon Fiber is the highest energy input fiber, which is reflected in its cost, followed closely by S2 Glass Fiber and Aramid fibers such as Kevlar, followed by the much more commonly used but much weaker E Glass Fiber and Basalt Fiber, which can be quite close to common grades of Carbon Fiber on tensile strength, and the various natural fibers- flax, hemp, cotton, etc)

D. greatest absolute performance (greatest "fuel economy", due to lightest possible weight, which implies less power required, lighter powerplant, etc)

E. most difficult to repair and recycleSpecialty grades of Glass Fiber, Basalt Fiber, and Kevlar can all come remarkably close to Carbon Fiber on specific strength, but not stiffness, so all other composites will be significantly heavier to achieve the same mix of material properties. No natural or synthetic fiber replicates all the mechanical properties of the others, which is why all of them have their own unique roles as structural materials.

As GW pointed out, accurately evaluating potential impact-related structural damage to CFRP and GFRP is exceptionally difficult. All impact damage is cumulative, and structural degradation is not linear in nature. If you beat on Aluminum, applying a given amount of force with each impact (below the point at which it yields, obviously), then its ability to resist future impacts without failure is linear up to a point. This has never been the case with CFRP and GFRP composites. One heavy impact might reduce structural integrity by 50%, while successive impacts might do very little additional damage, or the composite may fail completely. As a general purpose fabrication material, it's a significant compromise compared to steel or Aluminum. It will never corrode the way a metal would, and won't suffer from stress-corrosion cracking the way Aluminum does, but if you ever impact it in any serious way, the entire structure is probably trash, structurally-speaking. It may not outwardly look like it's junk, but appearances can be deceiving. The fibers can and will crack within the resin matrix. As far as absorbing a singular hard impact, CFRP does that better than almost any other material, for a given weight. However, accidents will leave razor-sharp shards of composite on the roadway that will puncture tires and injure occupants or bystanders unless Kevlar liners are applied to the interior and exterior of the parts. It's a mess to clean up, but would allow people to walk away from otherwise unsurvivable accidents.

2. Steel or plastic sandwich cored steel monocoque

A. lightest possible weight amongst metal options using high strength steel

B. lowest total cost

C. least durable due to corrosion and denting

D. simplest and cheapest to repair and recycle, but still high energySteel crumple zones do a fantastic job of absorbing hard impacts. Modern FEA has allowed automotive engineers to deliberately design sacrificial vehicle structures to fold up like an accordian, absorbing most of the force of the impact in the process, while a structural "strong box" prevents intrusion into the cabin of the vehicle. Steel is very easy to work with, and modern hydroforming allows incredibly complex shapes to be formed into a single sheet of metal, work-hardening the metal to the degree of hardness required in the process. The latest sandwich core steels use thermoplastic cores so that very thin sheets with a flexible plastic core can be formed into the desired shapes, and then electrically welded together without affecting the core material.

3. Aluminum monocoque

A. Strength comparable to lower grades of mild steel, but not high-strength steel, ease of fabrication is part geometry-dependent

B. highest cost amongst metal options, similar materials cost to GFRP

C. more durable than steel if modest corrosion protection is applied, less prone to denting for the same weight as steel, but fatigue life strictly limits ultimate durability

D. Repair is possible and no more labor-intensive than steel, but not stress-corrosion damage is non-repairable, easiest and cheapest to recycle of all available optionsGiant pressure casting machines such as Tesla's GigaPress allow automotive manufacturers to press Aluminum into very complex near-net shapes, with very little subsequent machining required.

4. Flax composite monocoque

A. Strength comparable to lower grades of CFRP, especially CFRP cloth / fabrics commonly used in automotive applications, about 5X better than CFRP at noise and vibration dampening

B. Fabrication and materials cost comparable to much less costly GFRP- easier to work with than GFRP and CFRP, less of a health hazard, doesn't shatter in quite the same way as CFRP in a high-speed impact, so less of a cleanup hazard and won't puncture tires

C. Overall performance comparable to a high grade GFRP, total cost is on-par with GFRP, meaning similar to Aluminum

D. FFRP repair options are as limited as CFRP and GFRP, but markedly easier to recycle into fiber boards, so less total environmental impact, and flax crops absorb CO2A passenger vehicle for the masses is going to be of monocoque or semi-monocoque construction. It won't be a body-on-frame design, which always costs more to produce, is markedly heavier since two different crash energy absorbing structures must be designed and fabricated, less passenger-friendly (reduced ride quality and overall handling), typically doesn't protect occupants as well in a major crash, despite what people "feel" about the protection offered by a truck or SUV vs a car (personal belief or marketing and salesmanship vs actual NHTSA testing results which don't paint a pretty picture of large truck and SUV survivability, especially in rollover accidents), and always requires more power to move down the road. In practice, trucks and SUVs are typically body-on-frame designs, and they're great for towing / hauling, but not-so-great for passenger transport safety. Body-on-frame is almost necessary for off-road applications, because monocoques tend to beat themselves to death, or rather, inadequate suspension systems beat monocoques to death.

All that said, those are the practical body designs. Steel will probably be cheapest and easiest to work with, because we already do. Aluminum will be or at least could be exceptionally easy and energy-favorable to recycle. Composites will provide the most efficiency and performance.

What trades are we willing to make?

This WILL work, and it won't burn a single drop of hydrocarbon fuel. That's not even a question mark, at least in my mind. They will not accelerate any faster than economy cars, and EVs will always easily beat them in acceleration performance, but they will run down the road at 75mph and they will take you from Point A to Point B with efficiency similar to an electro-chemical battery after all infrastructure and operational costs are factored in. Air powered cars will be cheaper to operate than electro-chemical batteries or combustion engines.

We had compressed air locomotives which powered ore hauling trains used in coal mines 100 years ago, because there was no danger of fuel-air explosions without coal-fired steam engines. It worked using the tech of 100 years ago, and they only quit using compressed air after they shut the mines down. The modern replacements in new mines were either diesel engines with special modifications to suppress open flame or external electrically powered.

A YouTube video of a compressed air locomotive in action, from 2015:

Lea Bailey Light Railway Running on Air Part 1, May 2015These devices exist, they're real, if they didn't work we wouldn't have had our industrial revolution since they powered coal mines and iron foundries, and we can achieve excellent overall energy utilization efficiency by consuming the heat from air compression as hot water or steam, perhaps to power locomotives or power plants, so that we get two or even three different uses out of the energy consumption process. A solar thermal or geothermal power plant can drive the air compressors. While we're pulling heat out, from deep beneath the Earth, we can use solar thermal to inject heat back into the rock so we don't cause any problems for the mantle or core. That is what a real circular energy system and economy looks like. It's simple, it uses natural processes, it's far more cost-effective than short-lived electronics, and the materials and manufacturing processes to make that happen are all in abundant supply and it doesn't take any advanced education to use or maintain them.

The compressed air locomotive is an ancient device using 110psi compressed air stored in an Iron cylinder. A modern air powered car is storing its air at 10,290psi in a linerless or HDPE-lined CFRP cylinder. That means it contains 93.5X more air per unit of cylinder volume. A 250L tank weighs about 182kg. If the tank was made from high strength steel, it would weigh somewhere between 910kg using 250ksi steel and 1,820kg using 125ksi steel. Modern materials therefore have an outsized effect on the practicality of air powered vehicles. Put another way, that air powered locomotive would have 93.5X greater range on a single tank of compressed air, with approximately 1/5th to 1/10th of the weight devoted to its compressed air cylinder for the same volume of compressed air.

We can validly assert that a rubber tire motor vehicle, irrespective of weight, consumes 9X to 10X more power than steel wheels on steel rails due to rolling resistance, but that still means we can go at least 10X further than that old 110psi locomotive if both vehicles required the same amount of power to move their respective payloads. It's hard to do a complete apples-to-apples comparison of two very different vehicle designs and different weights, but that's accurate enough to illustrate how drastically modern materials technology has evolved from 150 years ago.

#403 Re: Planetary transportation » Running on Compressed Air? » 2024-06-30 10:01:44

My own history of tanks of composite materials.

I have seen 5,000 psi scuba style takes used for self-contained breathing equipment that are composite that do not explode when ruptured.

https://wilcoxind.com/backend/wp-conten … ochure.pdf

#404 Re: Planetary transportation » Running on Compressed Air? » 2024-06-30 10:00:50

was a desire to do direct power from the compressed air.

For kbd512 re Post #364

Thanks for a thoughtful review of the comparison between technology options.

Your observation about not buying equipment before a complete system is designed is certainly valid, as experience has shown. I was trying to create a psychological framework for members of this group to solve the problems of creating a small scale compressed air energy storage system. No one asked me to do anything! Calliban specifically asked that no one spend any money on anything.

Had my gambit been successfully we would now have a working compressed air energy storage system able to light a set of 12 volt bulbs.

Now we will remain as we were, just a forum with ideas and plenty of interesting information, but there will be no demonstration of capability in our archives.

The resources available to throw at a problem are certainly a factor in success vs failure.

If you look at Calliban's member text, you'll see a mantra that argues against thinking about how to do something, vs acting to make it happen.

My guess is that you'd find that most entrepreneurs do NOT know how to do something that is new, and many fail, but a few succeed, and our vibrant civilization thrives because of their willingness to take the risk.

Elon Musk is a reasonably good example of an entrepreneur who has the risk tolerance to address an opportunity, whether it is business or a technology or a combination. Losses go with that boldness, and by observation, I deduce that he has the ability to accept the early failures as the price for eventual success.

In any case, the inspiration you and Calliban have provided to forum readers remains available, and it may yet inspire someone to attempt to create a viable compress air energy storage system beyond known capabilities.

(th)

#405 Re: Planetary transportation » Running on Compressed Air? » 2024-06-30 09:59:46

In response in the other topic.

tahanson43206,

1. Immediately going out and buying an electric motor, with the idea of turning it into an air compressor, runs directly counter to the use of basic engineering principles to first work out what to build and then how to build it. Do you recall how we were still debating whether the compressed air or hot fluid power source would work best? I admire your enthusiasm for the idea, but I never asked anyone to do such a thing.

2. The equipment to make an air powered car does exist, but much like the tech to make an internal combustion engine or a battery for a road car, it's not something you're likely to fabricate in your garage, absent a substantive investment in time and money.

Hydrogen Type 4 Cylinder 700 bar 103L

You have to buy at least 3 of these, or they're not interested in selling to you. They're not cheap.

3. I wouldn't waste my time and money or anyone else's on ideas that I wasn't already quite certain would actually work. I would hope that anyone investing their own money has the attention span and level of understanding required to fully comprehend what we're proposing and why, before they ever spend one cent of their money. I would insist that they show some baseline level of comprehension before taking their money. I'm not a salesman for climate change or any other religion, so I don't offer up "solutions" that are not actually solving real problems for most people in practical ways.

I'm not the least bit interested in selling more disposable appliances to rich people. There's an endless variety of novelties for rich people to spend their money. I'm not enamored with novelties. If I never see my customers again, unless they wreck their car or their kids need cars, too, then I will consider that an actual worthwhile achievement. There are plenty of other ways to make money. After I solve one problem, I move on to the next. That's why Elon Musk went from payment software, to rockets, to cars, to tunnel boring, to AI machines. If a prospective investor has a problem with conducting business that way, then I don't want their money. If that means none of these ideas ever see the light of day, I really don't care.

I guess the kind of investor I'd be after is someone who genuinely cares about both people and the environment, and does not look down their nose at their fellow man merely because he has more money than they do. There aren't many Henry Fords left in this world, but there have to be some, and all it takes is one.

As I see it, the EV market is presently floundering due to intractable material scarcity issues that no amount of climate religion or happy talk will ever resolve, technical issues related to the fact that current battery technology is now well past any step-change performance improvements, and because the world's supply of snobbish wealthy leftists wishing to tell everyone else how green and clean they are, merely because they went out and bought a fancier disposable appliance than most other people could afford, has mostly dried up. Very few people who actually require a reliable car are buying EVs. They're status symbols for city-dwelling hipsters and middle-aged tech and finance guys with no wives or children- the kind of people who have plenty of disposable income, but would never get their hands dirty working on a car, because that's something they pay someone else to do for them. For the rest of the driving public, which is most people, buying a car with an internal combustion engine remains their only realistic option. The people who mow lawns, turn wrenches, or weld pipes are my target customers, regardless of how much disdain our snobs have for them. The major automotive manufacturers, at least those not presently firing all of their employees, are collectively returning to making more combustion engine vehicles, because they don't have any other workable solutions.

Yes, GM could've sold EVs to our Hollyweirdos back in the 1990s. They'd be the only people buying that product, and there simply weren't enough of them to justify the many billions spent trying to make EVs work at the scale required.

In the 1960s, Ford sold a million Mustangs in about 18 months. Tesla sold their millionth vehicle after 92 months of operations- almost 8 years of losing billions of dollars, every single year. Investors and governments wanted to force the technology into existence, so they kept dumping money into it, continued the PR campaign, and then they mostly sold them to people overseas who wanted to be "green and trendy". Your pizza delivery driver doesn't care about being trendy. He's not trying to keep up with the cool kids. He's busting his rear end to try and make ends meet. China now has acre after acre of EVs rusting in scrap yards, never to be sold to anyone. They keep their local firefighters gainfully employed, but that's about it. Nobody is buying the product because they can't afford to and they're not getting any cheaper than they already are. Most people need a reliable car that doesn't require factory disassembly because one battery cell out of thousands quit working. Putting a minor dent in the battery pack casing is grounds for the insurance company to total the entire car. I'm not sure how ridiculous the results have to become in order to convince people to try a different plan.

EVs remain an utterly impractical solution to personal mobility for most people, unless we're talking about a bicycle or moped. The people who buy those don't care at all about the clean green electrification religion. Transportation is purely a practical proposition for them. They either get a reliable vehicle, of whatever variety, or they don't get to work to make their money and pay their bills. EVs were sold to the general public as being a lot of things they're clearly not. 10 years from now our illustrious "scientists" will suddenly "discover", much the same way they did with corn-based Ethanol production, that in point of fact, the EV is no cleaner or greener, it merely shifts when and where the CO2 emissions occur to some place that nobody is presently fixated on measuring. EVs are not more reliable. I had an oil exec coworker who told me how reliable his Tesla had been, while it was sitting in the shop for 3 months, after asking him where his car was. EVs are not cheaper than gasoline powered cars, unless you get one that performs very differently than a normal gasoline powered car. They're not any less polluting until you drive the thing longer than most people keep a car and you power it using an energy mix that doesn't presently exist in most countries on planet Earth, and won't exist for lack of all that Copper and Lithium that we don't have and flatly refuse to invest more money into. They're nearly impossible to service, and the dealership won't even sell the parts to you to make your own repairs, if they even had parts to sell, because most of them don't.

4. It doesn't matter to an engineer if you know you're wrong, or not. All those people who swore up and down that the Earth was flat were still wrong. Valid math and therefore science is not consensus-based. If 97% of "scientists" agree that the Earth is flat, that only means 97% of them have no business attempting to apply the principles of valid science, never mind engineering, because they prioritize their ideological / philosophical / religious beliefs over observational evidence, or whatever makes money, which means what they're doing is no longer science. It's like a doctor selling pills he knows is killing his patients. Wearing that white lab coat is the most meaningless part of what makes you a medical doctor.

I can use simple historical observational evidence to "know" that at no point in time in all of human history has production of a metal that we already mine expanded by 50% in 10 years time. The probability that Copper and Lithium become the only exceptions to that rule is statistically zero or near-zero. That is precisely what any real engineer would tell you, because he doesn't care about his ideology, your ideology, or that of anyone else's while he's making math-based decisions about what will or won't work at the scale required, in the time frame required, and at the cost required to implement the new tech. Someone who is simply collecting a paycheck while not telling the truth to his employer about the practicality of what they're attempting to do is likewise, an engineer in name only.

5. I would like to see a practical application of these ideas as well, if only to finally realize the otherwise "impossible dream" of this cleaner and greener energy that we're thus far not getting, but maybe that won't happen until we run out of oil and specialty metals. I already see the engineers coming to the realization that in the future centralized power plants using dramatically simpler and cheaper energy production and storage methods than those involving power electronics will be required, else there will not be any energy transition.

Everyone seems to want to live the Jetsons lifestyle, which demands more and more energy, while they also demand that energy consumption to somehow be less impactful to Earth's environment. Those are opposing engineering requirements. Pick one or the other. If you want cleaner and greener, that requires using more abundant materials, simpler and longer lasting machines that are easier to recycle, thus fewer of them, and people who broadly accept that you can't randomly throw money every which way with the expectation of a desirable outcome. In short, learn how to prioritize in a way most people can live with.

#406 Re: Planetary transportation » Compressed Air » 2024-06-30 09:55:34

We keep putting topic information in as off topic responses that have nothing to do with where it is posted for the, most part.

In KBD512's case it is related to making a better fuel-efficient vehicle that is not a battery in the true sense.

#407 Re: Interplanetary transportation » Spin Launch SpinLaunch Vacuum Launches Centrifuge Launched Mass » 2024-06-30 09:46:32

The kick stage means this is a TSTO rocket

https://i.sstatic.net/boqDU.jpg

https://www.youtube.com/watch?v=TGO4LtCctTk

The customer payloads launched by the accelerator had to survive up to 10,000 Gs (that's 10,000 times the force of Earth's gravity) as the 108-foot-long (33 meters) rotating arm hidden inside a white casing spun up the payload faster than the speed of sound.

The full-scale orbital accelerator could shoot small constellations of satellites into low Earth orbit, the region below the altitude of 600 miles (1,000 kilometers), as soon as 2026, the company envisions.

#408 Re: Interplanetary transportation » Spin Launch SpinLaunch Vacuum Launches Centrifuge Launched Mass » 2024-06-30 09:33:55

https://en.wikipedia.org/wiki/SpinLaunch

SpinLaunch is developing a kinetic energy space launch system that reduces dependency on traditional chemical rockets, with the goal of significantly lowering the cost of access to space while increasing launch frequency. The technology uses a vacuum-sealed centrifuge to spin a rocket and then hurl it to space at up to 4,700 mph (7,500 km/h; 2.1 km/s). The rocket then ignites its engines at an altitude of roughly 200,000 ft (60 km) to reach orbital speed of 17,150 mph (27,600 km/h; 7.666 km/s) with a payload of up to 200kg. Peak acceleration would be approximately 10,000 g. If successful, the acceleration concept is projected to lower the cost of launches and to use much less power, with the price of a single space launch reduced by a factor of 20 to under US$500,000.

At Spaceport America in New Mexico on 22 October 2021, SpinLaunch conducted the first vertical test of their accelerator at 20% of its full power capacity, hurling a 10-foot-long (3.0 m) passive projectile to an altitude of "tens of thousands of feet." This test accelerator is 108 ft (33 m) in diameter, which makes it a one-third scale of the operational system that is being designed. The company's first 10 test flights reached as much as 30,000 feet (9,100 m) in altitude.

For SpaceNut re addition to SpinLaunch topic ...

Thanks for bringing over the images and text from earlier work on the payload delivery procedure.

The high ellipse method does not seem possible for the SpinLaunch system, at this point. It would be challenging for the gas gun method, at it's present state of development.

Major advances would be needed in both systems to permit the use of the high ellipse concept. However, if it ** can ** be achieved, then it provides a way for mission planners to manage flights with greater control and much longer windows. The payloads in high ellipse will remain in orbit until a suitable delivery window can be arranged, while the low ellipse method will have one and only one chance to reach the fuel depot. Failure in that case will result in loss of the payload.

(th)

Its why a kick stage is being add to the spin launch rocket so as to achieve orbit.

The rocket once released will slow as it follows the profile such that it will need addition energy to get to orbit.

#409 Re: Interplanetary transportation » Spin Launch SpinLaunch Vacuum Launches Centrifuge Launched Mass » 2024-06-30 06:46:38

Another post that belongs here

This post is about the collaboration between GW Johnson and tahanson43206, to study options for delivery of payload to an orbiting refueling station when the launch device is a ballistic launcher, such as Dr. John Hunter's gas gun or the SpinLaunch rotary device.

The result of the collaboration was a clarification that a burn is required to circularize orbit with either the traditional fly-up-from-below approach, or the drop-down-from-high-apogee approach which I'd been wondering about. What remains to be determined is whether there is any difference in dV between the two approaches.

Above: Four studies of elliipses

Below .... Study of "inside" and "outside" docking scenarios...

The question that remains unanswered is whether that are any business advantages to the "outside" docking maneuver... the "inside" docking maneuver has been thoroughly studied and is the accepted solution for any ballistic launcher system I've read about. I asked Dr. Johnson to take a look at the "outside" maneuver to see if it might have any advantages. It requires more dV to reach the higher apogee, but the dV from a ballistic launcher is not limited the way it is with a traditional rocket system. The question I am trying to answer is whether there is any business advantage to the higher apogee approach.

In his previous analysis of the "inside" docking maneuver, GW concluded that the window for meeting a "dumb" payload is about two minutes, which is unlikely to be practical. This scenario featured a space tug that departed the refueling station to meet the arriving "dumb" payload, slow to match velocity, and then accelerate to catch up with the refueling station.

The traditional approach is to allocate part of the ballistic launcher payload to a small solid fuel rocket and some minimal electronics to match orbit with the refueling station itself.

What I am curious to know is if there is any business advantage to launching the payload package to a higher apogee and then performing short burns to extend perigee, and to match orbit precisely with the refueling station when the two are close.

Update next day:

Here is a document that explains the crossings study:

https://www.dropbox.com/scl/fi/s5fxvvp8 … m9ov1&dl=0Here is an updated version of the spreadsheet used for these calculations. It is an updated relative of the spreadsheet used in the course on Basic Orbital Mechanics:

https://www.dropbox.com/scl/fi/gkqxhkjz … pzrsg&dl=0

(th)

#410 Re: Not So Free Chat » News about 2024 Atlantic Hurricane Season Begins » 2024-06-29 18:48:23

We have had a couple of tropical storms that have made land fall in the past few weeks with Tropical Storm Beryl forecast to become a major hurricane as it approaches the southeast Caribbean

Beryl’s center is forecast to pass about 26 miles (45 kilometers) south of Barbados, said Sabu Best, director of the island’s meteorological service’s director.

On Saturday, Beryl was located about 820 miles (1,320 kilometers) east-southeast of Barbados, with maximum sustained winds of 65 mph (100 kph). It was moving west at 23 mph (37 kph).A major hurricane is considered a Category 3 or higher, with winds of at least 111 mph (178 kph). Hurricane watches were in effect for Barbados, St. Lucia, Grenada, and St. Vincent and the Grenadines, while a tropical storm watch was issued for Martinique and Tobago.

#411 Re: Interplanetary transportation » Spin Launch SpinLaunch Vacuum Launches Centrifuge Launched Mass » 2024-06-29 18:28:22

payload carrier cone will need to have a heat shielding material on it to cut through the atmosphere as the speed at which it's going to cut through the lower atmosphere is going to create heat greater than the same item would have on orbital re-entry.

THE AERODYNAMIC HEATING OF ATMOSPHERE ENTRY VEHICLES - A REVIEW

normal heat shield re-entry path

https://i.sstatic.net/wuIVB.jpg

Of course with that we are going to see the payload slow

https://x-engineer.org/aerodynamic-drag/

#412 Re: Human missions » Shipyard? » 2024-06-29 14:45:53

Without a spacewalk it's going to be hard to open the craft to see what the real issues are.

Just one more reason to add a space shipyard port so as to be able to make repairs by allowing it into a shuttle sized bay or larger as required so that a crew can go into it once the bay doors are closed. Inside the bay would be a shuttle arm to catch and secure anything brought in for repairs. This could also include satellites.

#413 Re: Human missions » Boeing Starliner OFT-2 » 2024-06-29 14:37:32

Without a spacewalk it's going to be hard to open the craft to see what the real issues are.

Just one more reason to add a space shipyard port so as to be able to make repairs by allowing it into a shuttle sized bay or larger as required so that a crew can go into it once the bay doors are closed. Inside the bay would be a shuttle arm to catch and secure anything brought in for repairs. This could also include satellites.

#414 Re: Interplanetary transportation » Spin Launch SpinLaunch Vacuum Launches Centrifuge Launched Mass » 2024-06-27 20:25:01

https://en.wikipedia.org/wiki/Centripetal_force

cross section mass will not distort the solid rock-hard propellant in a booster.

If it does, then brace it on the inside to oppose the direction of the outward motion like a curved flat bed of a truck trailer.

Also, if it does become a gel then it's going to flow out of the engine nozzle.

#415 Re: Interplanetary transportation » Spin Launch SpinLaunch Vacuum Launches Centrifuge Launched Mass » 2024-06-26 16:51:38

I got thinking about rockets that already use solids to launch from the ground to orbit and it might be possible to use what exits.

https://spaceflight101.com/members/wp-c … taur-V.pdf

https://www.nasa.gov/wp-content/uploads … v_fact.pdf

https://www.northropgrumman.com/space/minotaur-rocket

https://en.wikipedia.org/wiki/Minotaur_(rocket_family)

Not sure of the length of burn that is required on thrust at this point for the payload to make it to orbit.

About those things that are known is that exit from the spin is hgih but the payload is small.

#416 Re: Planetary transportation » Running on Compressed Air? » 2024-06-25 19:02:44

Part of post

Hot water, salt, or rock could potentially damage the road surface or vehicles or burn people involved in the accident, but compressed air becomes cold air during an accidental release. 700bar H2 tanks struck by bullets will release their stored H2, but they don't burn or explode, so compressed air stored in the same manner would result in a lot of nothing happening.

The CFRP Type IV (HDPE liner or liner-less) H2 tank that US DoE is evaluating at has a 253L water storage capacity, operates at 700bar, and weighs 182kg. That would provide 177.1m^3 of compressed air (0.253 * 700 = 177.1m^3 or 6254.2275ft^3).

A 1hp air motor regulated at 90psi is equal to a volumetric flow rate of 12scfm to 15scfm. Actual flow rate depends upon the type of air motor involved. Turbines tend to be more efficient than pistons and gerotors, because pistons have more friction and starting torque to overcome. They provide more torque, but not more power per volume of air flowed through them.

6,254ft^3 / 12ft^3 per minute = 521 minutes of operation at 1hp, or 8.68hp-hrs

6,254ft^3 / 15ft^3 per minute = 417 minutes of operation at 1hp, or 6.95hp-hrsThat's not very much, but the horsepower required to move a vehicle at a given speed is a function of aerodynamic drag and rolling resistance. As speed increases, aerodynamic drag force becomes the limiting factor.

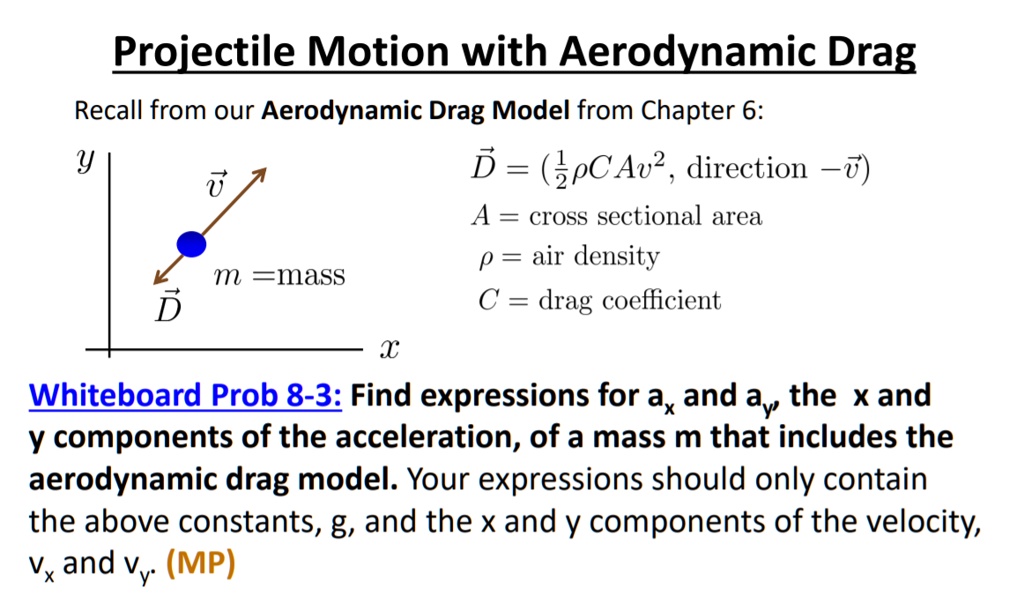

Force(drag) = 0.5 * Density(air) * velocity^2 * Area * Cd (drag force coefficient)

F = 0.5 * rho * V^2 * A * Cd

rho = 0.07647lbs/ft^3 (sea level "standard atmospheric density")

V = 55mph

A = 8ft^2 (standard full size passenger car frontal area)

Cd = 0.31 (Toyota Corolla drag coefficient used, most passenger cars fall between 0.25 and 0.3, 0.35 to 0.45 for most trucks and SUVs)F = 0.5 * 0.07647 * 3,025 * 8 * 0.31

F = 286.84ft-lbsThat means aerodynamic drag requires 0.522hp to overcome at 55mph.

Coefficient of rolling resistance (Crr) is mass, gravity, and surface-dependent. On a concrete roadway, which is what we have here in Houston and in many other major cities, the following is what your rolling resistance looks like for a 1,000kg total vehicle weight and "grippy" tires rather than absolute minimum coefficient of friction tires:

F = mass * gravitational acceleration * Crr

F = 1,000kg × 9.81m/s^2 × 0.015 = 147.15N

F = 108.54ft-lbsIn total, 395.38ft-lbs of force needs to be produced by the drive system to maintain 55mph, or 641.92ft-lbs to maintain 75mph.

#417 Re: Not So Free Chat » Fixing Americas car industry » 2024-06-25 18:47:33

I have seen 5,000 psi scuba style takes used for self-contained breathing equipment that are composite that do not explode when ruptured.

https://wilcoxind.com/backend/wp-conten … ochure.pdf

#418 Re: Interplanetary transportation » Spin Launch SpinLaunch Vacuum Launches Centrifuge Launched Mass » 2024-06-25 18:40:05

I was thinking of stacking these cones which has the inverse shape inside to allow them to bend but not break.

#419 Re: Human missions » Boeing Starliner OFT-2 » 2024-06-25 18:26:06

Boeing has just 45 days before the capsule is considered expired and no longer capable to return on a safe trajectory from the launch date.

#420 Re: Human missions » Deaths in Space and Orbital Rescue » 2024-06-25 18:23:42

ISS has plenty of resources that can be managed but planning is just that to be able to maintain the crew count and supplies. This is no different that when a crew is on mars and we need something critical in a period of time. It still comes down to safe level of resource to survive.

#421 Re: Not So Free Chat » Fixing Americas car industry » 2024-06-24 17:25:39

Operational replacement of parts that wear out is a different problem for owning either vehicle type as they age.

Changing the source of the energy that makes the car move does not really change the cars mileage as the energy still comes from the same sources that will fill the vehicles tank to make it move.

#422 Re: Interplanetary transportation » Spin Launch SpinLaunch Vacuum Launches Centrifuge Launched Mass » 2024-06-24 17:20:02

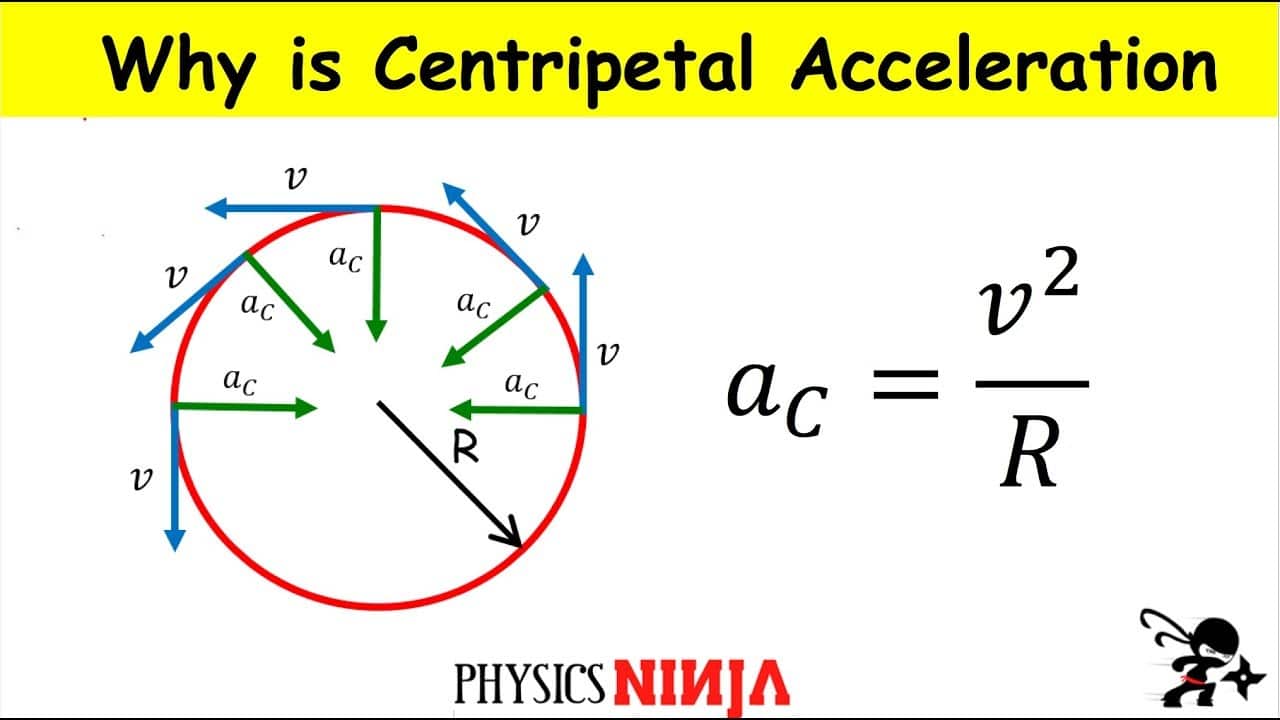

Centripetal forces as GW would indicate that once spin stops, and projectile is releases must realign back long ways to the direction that the rocket is taking. Even with a slight curve the rocket is climbing at a slope towards the orbit.

The reason for the srb to bend is due to the long ways grain and burn openings that allow it to create chamber pressure to eject through the nozzle of the rocket.

A pancake slice will still require the same long ways means to burn.

So the fuel mix requires pure metal inside the fuel to act as a stiffener to the bending so as to keep it ready to burn.

#423 Re: Interplanetary transportation » Spin Launch SpinLaunch Vacuum Launches Centrifuge Launched Mass » 2024-06-23 19:36:49

SRB grain and oscillation was due to chamber length fundamental over tone.

Solid Rocket Booster (SRB) - Evolution and Lessons Learned During the Shuttle Program

https://wikis.mit.edu/confluence/displa … Geometries

#425 Re: Interplanetary transportation » Orbital Mechanics Class Traditional » 2024-06-23 18:52:53

last night's meeting where I listened to GW and Th discussion of course material and the excel spread sheets.

I had algebra back in the 5th grade, but GW is right that they are delaying much for education into high school now.

For the spin launch and direction of spin is something that can add to the launch speeds.