New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#251 Re: Human missions » Starship is Go... » 2025-08-20 14:30:05

In post 2135 I heard that the starship was going to be taller and hence the tuning will be different for resonance due to the longer pipe lengths and heavier rocket as well of its length. The engines are also ging up in thrust as well.

#252 Re: Meta New Mars » Bookmark Bookmarks Find it Again help » 2025-08-20 14:25:20

I gave a bit more to this but its still not to the panel level, only gross large scale with little focus on one particular type which have different embedded energy needs to make.

#253 Re: Not So Free Chat » Oil, Peak Oil, etc. » 2025-08-20 14:19:54

I am not sure you, offthe rock meant to make

Reported by offtherock Not So Free Chat » Oil, Peak Oil, etc. » Post #233655

ReasonSolar is currently only about 2% of world energy production.

Its the cheapest way to make energy, cleanest and the fastest growing.

But still, only a few percentages.So therefore, something not being powered by solar, isn't really an argument for anything.

Most thing are powered by something that isn't solar.We come from a dirty past.

But dirty past isn't an argument for a dirty future.

It makes cheap energy but Solar is energy intensive to make.

AI Overview

Creating a solar panel requires a significant amount of energy, often referred to as embodied energy, which accounts for the energy consumed throughout the entire manufacturing process, from raw material extraction to assembly and transportation.

Here's a breakdown of the key aspects related to the embedded energy in solar panels:

Silicon Processing:

The production of metallurgical-grade silicon from quartz sand through carbothermic reduction consumes about 20 kWh/kg. Further refinement into electronic-grade silicon adds another 100 kWh/kg.

Melting and crystallizing this silicon into single crystal ingots consumes 290 kWh/kg.

Overall, after accounting for material losses during these steps, approximately 460 kWh of energy are embodied into each kilogram of silicon single crystal.Solar Cell Production:

Slicing the silicon ingots into wafers and subsequent processing steps, including high-temperature diffusion, oxidation, deposition, and annealing, add another 120 kWh/m² of embodied energy.Module Assembly: Assembling the solar cells with a glass front panel, encapsulant, copper ribbon, foil back cover, and aluminum frame adds 190 kWh/m² of embodied energy.

Support Structure: The type of support structure for the solar panels also impacts the embodied energy. Rooftop installations generally require less additional energy (around 200 kWh/m²) compared to ground-mounted systems requiring concrete, cement, and steel (up to 500 kWh/m²).

Miscellaneous Components: Other components like inverters, wiring, and potentially batteries for energy storage add additional, variable amounts of embodied energy.

Energy payback time

The crucial question is how long it takes for a solar panel to generate the same amount of energy that was used to produce it, which is known as the energy payback time (EPBT).

For silicon solar cells, the energy payback time typically ranges from 1.65 to 4.12 years.

Newer technologies, such as organic and perovskite solar cells, can have even shorter payback times, potentially less than half a year.Utility-scale PV systems in the United States have estimated energy payback times ranging from 0.5 to 1.2 years, according to a recent NREL study.

After the energy payback period, the solar panels generate clean energy for the remainder of their lifespan, which is typically 25 to 30 years or more.

In essence, while manufacturing solar panels requires energy, particularly in the silicon processing stage, the energy they generate over their lifespan significantly outweighs the initial energy investment.

So how do we get a number per panel for energy embedded cost?

AI Overview

Solar Panel Sizes, Dimensions & Wattage for Businesses | GSEThe average mass of a solar panel typically falls within the range of 40 to 60 pounds (18 to 27 kilograms).

Residential solar panels, often containing 60 cells, generally weigh around 40 pounds.

Larger, commercial-sized panels with 72 cells can weigh 50 pounds or more. The exact weight can vary based on factors like size, materials used, and specific panel design.Here's a more detailed breakdown:

Residential solar panels (60-cell): Approximately 40 pounds (18 kg).

Commercial solar panels (72-cell): Around 50 pounds (23 kg) or more.Factors influencing weight:

Size: Larger panels generally weigh more.

Materials: Different materials like the frame, glass, and back sheet can affect the overall weight.Panel type: Monocrystalline panels may be heavier than polycrystalline or thin-film panels.

Additional weight considerations: The weight estimate doesn't include the weight of mounting hardware or racking systems, which can add to the total system weight.

So more fuzzy numbers.

#254 Re: Exploration to Settlement Creation » Companion fo Mars Expedition Number One; 17 crew members » 2025-08-18 17:23:39

AI Overview

Mars cargo specification: Mass of consumables for a 17-person crew

Estimating the mass of consumables required for a 17-person Mars mission requires careful consideration of mission duration and whether life support systems are based on storage or recycling.

1. Daily consumption per person

Food: NASA recommends budgeting 1.831 kg/person/day for freeze-dried food.

Water & Oxygen: While systems like those on the International Space Station (ISS) achieve high levels of water and oxygen recycling (over 90%), some losses and additional needs for hygiene and other activities still require resupply. Some estimates suggest a daily need of roughly 1kg each of water and oxygen per person when considering an open-loop system, according to Quora. However, with recycling, water losses can be largely offset by the water content in food, and oxygen production from atmospheric CO2 and water ice on Mars (ISRU) could significantly reduce the need to transport oxygen from Earth.

Other Consumables: Hygiene products, medications, clothing, and spare parts add to the overall mass requirement.2. Total mass for a 17-person crew

For a rough estimate, considering a long duration mission (around 3 years total, 6 months transit each way, 18 months on Mars) and assuming a reliance on resupply for all consumables, we can approximate a conservative estimate of ~3kg/person/day for all consumables (food, water, oxygen, etc.).

For a 17-person crew, over a ~900 day mission (round trip + surface stay), this translates to approximately 17 people * 900 days * 3 kg/person/day = 45,900 kg (45.9 metric tons) of consumables.3. Considerations and potential mass reduction

In-Situ Resource Utilization (ISRU): The ability to produce water from Martian ice and oxygen from the atmosphere can drastically reduce the amount of consumables needed from Earth.

Recycling Efficiency: Highly efficient recycling systems are crucial for long-duration missions to minimize the need for stored consumables. Improvements to ISS-level recycling systems (which are roughly 90% closed loop) are crucial for Mars missions, according to NASA (.gov).Food Production: Developing technologies like "green walls" could allow for on-site food production, further reducing the cargo mass required.

Mission Architecture: Sending cargo ships to Mars ahead of the crew to deliver supplies and equipment can optimize the overall mission, according to Universe Today.

In conclusion, while a rough estimate for a 17-person crew over a 3-year mission is around 45.9 metric tons, it's important to remember that this figure depends heavily on the mission architecture, technological advancements in recycling and ISRU, and the reliance on resupply mission

#255 Re: Human missions » Dr. Robert Zubrin Moon Direct: How to build a moonbase in four years » 2025-08-18 17:11:52

The standard landing legs for the first stage are roughly 500 kg each and are about 12 meters in length.

Other building blocks are the cygnus cargo ship.

AI Overview

Northrop Grumman's Cygnus Spacecraft: A Decade of Delivering ...

Cygnus spacecrafts have evolved from a standard configuration with ~2,750 kg capacity and 18 m³ volume to an enhanced version with ~3,750 kg and 27 m³, and now an upgraded "Mission B" with a capacity of 5,000 kg and a 36 m³ pressurized volume. These figures vary depending on the specific mission and version, with the enhanced and Mission B versions featuring longer pressurized modules to accommodate the increased cargo.Evolution of Cygnus Cargo Specifications

Standard Version:

Payload Capacity: 2,750 kg

Pressurized Volume: 18 m³

Enhanced Configuration:

Payload Capacity: 3,750 kg

Pressurized Volume: 27 m³

Mission B (Upgraded Version):

Payload Capacity: 5,000 kg

Pressurized Volume: 36 m³

Key Details

What they carry:

Cygnus spacecrafts deliver food, water, spare parts, repairs, and scientific investigations to the International Space Station (ISS).

Design Evolution:

The spacecraft's design has been updated by Northrop Grumman to meet evolving customer needs, including increased cargo capacity.

Late Load Capability:

Enhanced and Mission B Cygnus versions allow for "late load" capability, meaning special equipment and science needs can be added shortly before launch.

Return Cargo:

Cygnus spacecrafts dispose of ISS waste by burning up upon atmospheric reentry.

he Northrop Grumman Cygnus cargo spacecraft typically carries around 800 kg of hypergolic propellant.

The fuel is stored in the Service Module and powers the main engine and smaller thrusters for navigation and orbit adjustments. Cygnus propellant specifications Propellant type:

The Cygnus uses hypergolic propellant, a mixture of hydrazine (\(N_{2}H_{4}\)) fuel and nitrogen tetroxide (\(N_{2}O_{4}\)) or MON-3 oxidizer. Hypergolic propellants ignite spontaneously upon contact, making them easy to use in space without a separate ignition system.

Propulsion system: The propulsion system features a main engine for major orbital adjustments and 32 smaller thrusters for attitude control.

Mission tasks: The fuel is used to perform various maneuvers throughout the mission, including:Phasing and rendezvous with the International Space Station (ISS).Occasional reboosts of the ISS to counteract atmospheric drag.A final burn to de-orbit the spacecraft for a destructive reentry into Earth's atmosphere.

Note on variants While the Standard Cygnus spacecraft had a similar fuel mass, information specifically points to the Enhanced version carrying roughly 800 kg of propellant. Later iterations, like those launched by the Falcon 9, have a larger overall launch mass and carry more propellant to support a heavier payload

The difference between the crew and cargo dragon is around 1,000kg with the cargo coming in dry at 6,600 kg mass.

Of course putting the pieces ordered in the correct order is the key to making the mission even possible.

#256 Re: Human missions » Dr. Robert Zubrin Moon Direct: How to build a moonbase in four years » 2025-08-18 16:24:28

The Falcon Heavy can lift 60 tons to low Earth orbit (LEO). Starting from that point, a hydrogen/oxygen rocket-propelled cargo lander could deliver 12 tons of payload to the lunar surface.

We therefore proceed by sending two such landers to our planned base location. The best place for it would be at one of the poles, because there are spots at both lunar poles where sunlight is accessible all the time, as well as permanently shadowed craters nearby where water ice has accumulated. Such ice could be electrolyzed to make hydrogen-oxygen rocket propellant, to fuel both Earth-return vehicles as well as flying rocket vehicles that would provide the lunar base’s crew with exploratory access to most of the rest of the moon.

The first cargo lander carries a load of equipment, including a solar panel array, high-data-rate communications gear, a microwave power-beaming set up with a range of 100 kilometers, an electrolysis/refrigeration unit, two crew vehicles, a trailer, and a group of tele-operated robotic rovers. After landing, some of the rovers are used to set up the solar array and communications system, while others are used to scout out the landing area in detail, putting down radio beacons on the precise target locations for the landings to follow.

The second cargo lander brings out a 12-ton habitation module, loaded with food, spare spacesuits, scientific equipment, tools, and other supplies. This will serve as the astronauts’ house, laboratory, and workshop of the moon. Once it has landed, the rovers hook it up to the power supply and all systems are checked out. This done, the rovers are redeployed to do detailed photography of the base area and its surroundings. All this data is sent back to Earth, to aid mission planners and the science and engineering support teams, and ultimately forming the basis of a virtual reality program that will allow millions of members of the public to participate in the missions as well.

So to get a TSTO launch with 63,000 kg payload to LEO we need

To calculate the performance of a Two-Stage-To-Orbit (TSTO) rocket launching a payload of 63,000 kg to Low Earth Orbit (LEO), we can use the Rocket Equation (Tsiolkovsky's equation) and some basic principles of orbital mechanics. Here's the general approach:

Tsiolkovsky Rocket Equation

The rocket equation is:

$$\Delta v = v_e \cdot \ln\left(\frac{m_0}{m_f}\right)$$

Where:$$\Delta v$$ = Change in velocity required (orbital velocity + losses)

$$v_e$$ = Effective exhaust velocity of the rocket (specific impulse $$I_{sp}$$ in seconds multiplied by $$g_0$$, the gravitational acceleration at Earth's surface, $$9.81 , \text{m/s}^2$$)

$$m_0$$ = Initial mass of the rocket (including fuel, structure, and payload)

$$m_f$$ = Final mass of the rocket (structure + payload)Steps to Solve for TSTO

Determine Required $$\Delta v$$:

For LEO, the typical $$\Delta v$$ is approximately 9.3–10 km/s, accounting for:

Orbital velocity (~7.8 km/s)

Gravity losses (~1.5 km/s)

Drag losses (~0.2 km/s)Stage Splitting:

TSTO rockets divide the total $$\Delta v$$ between the two stages. A common split is:

First stage: ~60–70% of $$\Delta v$$

Second stage: ~30–40% of $$\Delta v$$Mass Ratios:

For each stage, calculate the mass ratio $$\frac{m_0}{m_f}$$ using the rocket equation.

Payload Fraction:

The payload fraction is the ratio of payload mass to the total initial mass of the rocket:

$$\text{Payload Fraction} = \frac{\text{Payload Mass}}{m_0}$$Iterative Design:

Adjust parameters like specific impulse ($$I_{sp}$$), structural mass fraction, and fuel mass fraction to meet the payload requirement.

Example Calculation

Assume:Payload: $$m_{\text{payload}} = 63,000 , \text{kg}$$

Specific impulse ($$I_{sp}$$):First stage: $$300 , \text{s}$$

Second stage: $$450 , \text{s}$$Structural mass fraction: $$0.1$$ (10% of total mass is structure)

Total $$\Delta v$$: $$9.5 , \text{km/s}$$First Stage:

$$\Delta v_1 = 0.6 \cdot 9.5 = 5.7 , \text{km/s}$$

$$v_e = I_{sp} \cdot g_0 = 300 \cdot 9.81 = 2943 , \text{m/s}$$

Solve for $$\frac{m_0}{m_f}$$:

$$\frac{m_0}{m_f} = e^{\Delta v / v_e} = e^{5700 / 2943} \approx 5.5$$Second Stage:

$$\Delta v_2 = 0.4 \cdot 9.5 = 3.8 , \text{km/s}$$

$$v_e = 450 \cdot 9.81 = 4414.5 , \text{m/s}$$

Solve for $$\frac{m_0}{m_f}$$:

$$\frac{m_0}{m_f} = e^{\Delta v / v_e} = e^{3800 / 4414.5} \approx 2.5$$Total Mass:

Combine the stages iteratively to find the total initial mass $$m_0$$ that supports a 63,000 kg payload.

This is a simplified overview. Real-world calculations involve more detailed modeling of drag, gravity losses, and staging efficiencies. Tools like payload calculators or simulation software can refine these estimates.

#257 Re: Human missions » Dr. Robert Zubrin Moon Direct: How to build a moonbase in four years » 2025-08-18 16:19:44

A Purpose-Driven Plan to Open the Lunar Frontier

We can estimate the weight of this vehicle by considering the Apollo Lunar Module (LM). As noted, our LEV will have a similar profile:

lightweight; intended to fly only in space and around the lunar surface, meaning it would not need a thick shell and heavy heat shield to protect it during re-entry into Earth’s atmosphere; and capable of carrying some

cargo, a crew of two, and life support for up to a few days.The Apollo LM’s dry mass (its weight with crew and cargo but without fuel) was 5.2 metric tons. However, the LM carried two rocket engines and propulsion systems—one for descending from lunar orbit onto the Moon’s surface, another for ascending back to lunar orbit. The ascent portion (the “ascent stage”), which contained the crew cabin, crew, and life support equipment, is most similar to our purposes here. Its dry mass was 2.3 tons. If we used this figure for estimating the weight of our LEV, we would also need to add the weight of the landing legs, and make various other adjustments. But given a half-century of improvements in materials and avionics science and engineering, a LEV could surely make significant improvements in the weight. We will therefore estimate 2 tons for the LEV’s dry mass, again, including crew and cargo.

In Figure 2 (see page 37), we can see the mass requirements of our 2-ton LEV. In addition to the dry mass, about 6 tons of propellant are required for each mission that uses 6.1 km/s of delta-V. So the total mass (known as the “wet mass”), including ship, cargo, and propellant, is about 8 tons. Also, the required weight of the tanks and engines—which take up part of the 2-ton dry mass—still leaves 1.3 tons for the crew, crew cabin, and other cargo.

Of course there is the refueling and other discusions that keep cost down.

#258 Re: Exploration to Settlement Creation » Companion fo Mars Expedition Number One; 17 crew members » 2025-08-18 16:07:40

moon direct a cost effective plan to enable human lunar exploration

what are the requirements to leverage from space x and other what can be done on orbit assembly.

To deliver program success on budget and schedule, project managers develop a common sense list of subsidiary requirements, such as:

– Minimize cost

– Minimize weight

– Minimize fuel

– Minimize risk to astronauts

– Minimize programmatic risk (e.g. getting canceled)

– Emplace infrastructure for a future series of missions

– Avoid technological dead ends (e.g. expendable vs reusable rockets)

– Avoid cost of new rocket (to avoid sticker shock, since rocket development is considered to be expensive)

– Placate constituencies (to avoid sniping)

Some of these requirements are easier to measure. Others are effectively beyond the project manager’s control. Still others give very different answers depending on the order of priority, such as the electric car example above. In a sentence, this varied order and weighting of common sense requirements is what gives rise to such different architectures in an immature product space.

#259 Re: Human missions » Dr. Robert Zubrin Moon Direct: How to build a moonbase in four years » 2025-08-18 15:27:40

https://launchercalculator.com/

Googling for more information,

Moon Direct: A Purpose-Driven Plan to Open the Lunar Frontier [R.Zubrin]

Thoughts on [R.Zubrin Op-Ed] Lunar Gateway or Moon Direct? [4.17.19]

moon direct a cost effective plan to enable human lunar exploration

Table 1. Cargo Lander Mission (single stage)

Launcher Staging Orbit Propulsion Tank Length Payload Delivered

Falcon H LEO LOx/CH4 3.2 m 8.3 tons

Falcon H GTO LOx/CH4 1.05 8.3

Falcon H LEO LOx/H2 7.9 10.4

Falcon H GTO LOx/H2 2.5 9.6

New Glenn LEO LOx/CH4 1.12 6.0

New Glenn LEO ` LOx/H2 2.85 7.5

Vulcan LEO LOx/CH4 1.54 4.0

Vulcan LEO LOx/H2 3.8 5.0

SLS LEO LOx/CH4 1.9 12.0

SLS LEO LOx/H2 4.45 15.0

BFR LEO LOx/CH4 3.2 19.9

BFR TLI LOX/CH4 2.5 60.0

#260 Not So Free Chat » Huricane season 2025 » 2025-08-17 17:52:05

- SpaceNut

- Replies: 6

As Th indicated the season is slowly winding in with Erin.

AI Overview

2023 Atlantic Hurricane Season halfway overThe official Atlantic hurricane season runs from June 1st to November 30th each year, with the peak activity generally occurring from mid-August to mid-October. During this time, forecasters like those at the National Oceanic and Atmospheric Administration (NOAA) issue outlooks for the number of storms, while the public is urged to prepare their families and homes for potential impacts from tropical systems.

Key Aspects of Hurricane Season:

Dates: June 1 to November 30.

Peak Activity: The most active period is typically from mid-August through mid-October.

Forecasting: Agencies like NOAA and Colorado State University provide outlooks, predicting the likelihood of above-normal, near-normal, or below-normal activity.

Factors influencing activity: Warm sea surface temperatures, neutral El Niño-Southern Oscillation (ENSO) conditions, and weak wind shear are factors that tend to favor increased storm development and intensification.

Preparedness: Residents in hurricane-prone areas, like South Florida, are encouraged to create emergency plans and gather supplies well in advance of any storm threat.

Hurricane Erin weakens to Category 3, still poses threat to islands

current path

#261 Re: Human missions » Dr. Robert Zubrin Moon Direct: How to build a moonbase in four years » 2025-08-17 14:26:59

I think that the faith of using the starship and BFR has begun to lose favor seems that it might be time to rethink what can be done with a Facon 9 and Heavy combinations to build an orbital platform and path to Moon and Mars from the pieces.

We recent talked about using the first stage for a build on orbit from its fuel tanks but why not design parts with in the pieces instead.

1) mass of fuel

2) mass of vehicle

3) performance of engines

4) ISP of fuel

First stage Mass ('dry' without propellant) 22,200 kg (48,900 lb) Second stage Mass (without propellant) 4,000 kg (8,800 lb) First stage Mass ('wet' with propellant) 433,100 kg (954,800 lb) Second stage Mass (with propellant) 111,500 kg (245,800 lb)Dec 3, 2020

So we can launch an altered first stage as a habitat on top of a modified second stage.

SECOND STAGE

Height 13.8 m / 45.3 ft

Diameter 3.7 m / 12.1 ft

Empty Mass 3,900 kg / 8,598 lb

Seems more than doable.

moon direct a cost effective plan to enable human lunar exploration

what are the requirements to leverage from space x and other what can be done on orbit assembly.

To deliver program success on budget and schedule, project managers develop a common sense list of subsidiary requirements, such as:

– Minimize cost

– Minimize weight

– Minimize fuel

– Minimize risk to astronauts

– Minimize programmatic risk (e.g. getting canceled)

– Emplace infrastructure for a future series of missions

– Avoid technological dead ends (e.g. expendable vs reusable rockets)

– Avoid cost of new rocket (to avoid sticker shock, since rocket development is considered to be expensive)

– Placate constituencies (to avoid sniping)

Some of these requirements are easier to measure. Others are effectively beyond the project manager’s control. Still others give very different answers depending on the order of priority, such as the electric car example above. In a sentence, this varied order and weighting of common sense requirements is what gives rise to such different architectures in an immature product space.

#262 Re: Exploration to Settlement Creation » Companion fo Mars Expedition Number One; 17 crew members » 2025-08-17 14:08:04

I am wondering what the habitat size for a crew of 17 really need as its looking like anything with a starship has slipped again as the beast is growing in size.

AI Overview

The recommended minimum acceptable volume per person for long-duration space missions, based on NASA studies and Mars mission design reference missions, is generally considered to be 25 cubic meters.For a crew of 17, this would mean a minimum habitat volume of 425 cubic meters (17 crew members x 25 m³/person).

It's important to note that this is a minimum acceptable volume, and factors like mission duration, the nature of activities, and psychological well-being can necessitate larger spaces. The International Space Station (ISS), for example, provides significantly more habitable volume per crewmember than this minimum recommendation, according to NASA.

Ultimately, the ideal habitat size for a crew of 17 would depend on the specific mission objectives and constraints.

Defining the Required Net Habitable Volume for LongDuration Exploration Missions

Falcon 9 has a diameter of 3.6 m and 70 m tall so its volume is V=πr2h=π·1.82·70≈712.51321 m³

So if we go for a habitat that is 10 m in diameter then we have 10 m tall to get V=πr2h=π·52·10≈785.39816 m³

So the question is the tank mass and engines to land something with the dry mass of a falcon.

#263 Re: Science, Technology, and Astronomy » Building Solar from scratch » 2025-08-17 13:49:53

Here is the really issue in that for embedded energy to make solar panels but this is nt the total answer.

AI Overview

The embodied energy to make solar panels refers to the upfront energy consumed throughout the manufacturing process, from mining raw materials to producing the panels. This energy includes the high-temperature processes needed to refine silicon, as well as energy for manufacturing glass, aluminum frames, and other components. The total energy varies by panel type and manufacturing location, but a 1 kW solar system might have about 2.5 MWh of embodied energy, with the silicon component alone being highly energy-intensive.

Key Factors Affecting Embodied Energy

Silicon Processing:

The production of highly purified silicon, the primary material for most solar panels, is a very energy-intensive process.

Manufacturing Location:

Panels manufactured on grids rich in renewable energy sources have a lower embodied energy and carbon footprint compared to those made on coal-rich grids.

Panel Type:

Thin-film solar cells, such as those made from cadmium telluride (CdTe), can have a lower embodied energy than silicon-based panels.

Balance of System (BOS):

The total energy required for a project includes the energy to manufacture the panel itself (the module) and the energy for other components like inverters and mounting structures.

Measuring the Energy Footprint

Energy Payback Time (EPBT):

.

This metric shows how long a solar panel must operate to generate the same amount of energy that was used to produce it. Modern solar panels have a relatively short EPBT, meaning they quickly "pay back" their initial energy investment.

Life Cycle Assessment (LCA):

.

This is a comprehensive tool used to assess the total embodied energy and carbon emissions of a product over its entire life cycle.

Trends and Innovations

Grid Decarbonization:

As more renewable energy enters the grid, especially where panels are manufactured, the embodied energy of solar panels decreases.

Alternative Materials:

Research into thin-film technologies and materials like those derived from food waste aims to reduce energy consumption and carbon emissions in solar panel production.

#264 Re: Human missions » Going Solar...the best solution for Mars. » 2025-08-17 13:35:43

Here is the really issue in that for embedded energy to make solar panels but this is nt the total answer.

AI Overview

The embodied energy to make solar panels refers to the upfront energy consumed throughout the manufacturing process, from mining raw materials to producing the panels. This energy includes the high-temperature processes needed to refine silicon, as well as energy for manufacturing glass, aluminum frames, and other components. The total energy varies by panel type and manufacturing location, but a 1 kW solar system might have about 2.5 MWh of embodied energy, with the silicon component alone being highly energy-intensive.

Key Factors Affecting Embodied Energy

Silicon Processing:

The production of highly purified silicon, the primary material for most solar panels, is a very energy-intensive process.

Manufacturing Location:

Panels manufactured on grids rich in renewable energy sources have a lower embodied energy and carbon footprint compared to those made on coal-rich grids.

Panel Type:

Thin-film solar cells, such as those made from cadmium telluride (CdTe), can have a lower embodied energy than silicon-based panels.

Balance of System (BOS):

The total energy required for a project includes the energy to manufacture the panel itself (the module) and the energy for other components like inverters and mounting structures.

Measuring the Energy Footprint

Energy Payback Time (EPBT):

.

This metric shows how long a solar panel must operate to generate the same amount of energy that was used to produce it. Modern solar panels have a relatively short EPBT, meaning they quickly "pay back" their initial energy investment.

Life Cycle Assessment (LCA):

.

This is a comprehensive tool used to assess the total embodied energy and carbon emissions of a product over its entire life cycle.

Trends and Innovations

Grid Decarbonization:

As more renewable energy enters the grid, especially where panels are manufactured, the embodied energy of solar panels decreases.

Alternative Materials:

Research into thin-film technologies and materials like those derived from food waste aims to reduce energy consumption and carbon emissions in solar panel production.

#265 Re: Single Stage To Orbit » A SSTO research project. » 2025-08-13 15:16:07

AI Overview

My 2nd SSTO. How can I give it more delta V when it reaches ...

A Single-Stage-To-Orbit (SSTO) vehicle's payload fraction, the ratio of payload mass to initial mass at liftoff, is a critical factor for its viability. While SSTOs aim for a high payload fraction, achieving a truly competitive one is challenging, often requiring advanced technologies. Typical payload fractions for SSTO vehicles range from 1% to 5%, with some advanced designs potentially reaching 10% or even higher.

Factors Influencing SSTO Payload Fraction:

Propellant Fraction:

.

A large portion of an SSTO's mass is dedicated to propellant. High specific impulse (Isp) engines are crucial for reducing the required propellant mass, but even with high Isp, the propellant fraction can still be significant.

Inert Mass Fraction:

.

This refers to the mass of the vehicle structure, engines, and other non-propellant components. Reducing the inert mass fraction is vital for increasing the payload fraction.

Engine Technology:

.

Advanced engine technologies, like air-breathing engines, offer potential for higher Isp and reduced propellant needs, but they also come with their own set of engineering challenges.

Launch Altitude:

.

Launching from a high altitude can significantly improve performance, reducing atmospheric drag and allowing for higher engine performance, which can translate to a higher payload fraction.

Vehicle Design:

.

The overall design of the SSTO vehicle, including its aerodynamics and structure, plays a crucial role in maximizing payload fraction.

Examples and Considerations:

Reusable SSTOs:

.

Reusable SSTOs face the challenge of balancing reusability with low inert mass. The need for robust structures to withstand multiple flights can make it difficult to achieve high payload fractions.

Expendable SSTOs:

.

Expendable SSTOs, where the vehicle is not recovered, can achieve higher payload fractions due to lower structural requirements, but at the cost of reusability.

Air-Breathing Engines:

.

Air-breathing engines, which utilize atmospheric oxygen, offer the potential for significant performance gains, but they are complex and require significant technological development.

Nuclear Propulsion:

.

Nuclear thermal or nuclear electric propulsion systems offer the potential for very high Isp, which could drastically improve SSTO payload fractions, but they present their own set of challenges and safety concerns.

In essence, while achieving a high payload fraction for an SSTO vehicle is difficult, it is a key factor in determining its economic viability. Advanced technologies and careful design are necessary to push the payload fraction to levels that make SSTOs truly competitive with traditional multi-stage rockets

#266 Re: Single Stage To Orbit » The Space Plane Corporation » 2025-08-13 15:11:53

Take off from a runway search

AI Overview

Determining the precise runway launch length for a hypothetical "space plane" or future runway-launched spacecraft is complex, as it depends heavily on the specific design, weight, and desired flight profile of the vehicle.

However, we can look at existing and proposed spaceplane systems and their runway requirements for landing, which can provide insights into potential launch needs:

Space Shuttle: The Space Shuttle orbiters landed on a 15,000-foot (4,572-meter) concrete runway at the Kennedy Space Center (SLF), according to NASA.gov. While the Shuttle launched vertically, this demonstrates the significant runway length required for landing a vehicle returning from space at high speeds.

Stratolaunch: This aircraft, designed to air-launch rockets carrying spacecraft, requires a 12,000-foot (3,700-meter) runway for takeoff.

Radian One: This proposed spaceplane aims to take off horizontally from a runway and fly directly into orbit. While the exact runway length needed is still under development, a Futurism article suggests it will utilize a rocket-powered sled for initial acceleration.

Virgin Galactic's SpaceShipTwo: This suborbital spaceplane takes off on a 2-mile (approximately 10,500 feet or 3,200 meters) runway, attached to a carrier aircraft, before being released at altitude to proceed under its own power.

In conclusion, while there isn't a universally standardized runway launch length for spaceplanes, based on existing and proposed systems, it's evident that runways in the range of 10,000 to 15,000 feet (approximately 3 to 4.6 kilometers) or longer would be necessary to accommodate future spaceplanes designed for horizontal takeoff, and even longer runways or additional launch assistance might be needed for orbital launches. This is considerably longer than the runways required for typical commercial aircraft, which generally fall within the 1,500 to 3,000 meter range.

#267 Re: Planetary transportation » Shutterbugs Shoot 'Scarecrow' » 2025-08-13 15:06:48

Reading the topic did remind me.

AI Overview

Mock Mars Rover Takes Desert Test Drive | Space

The "Scarecrow" rover is a testbed for NASA's Curiosity Mars rover. It's a full-scale replica of Curiosity, but stripped down and without an onboard computer, allowing engineers to test its mobility and suspension performance in a Mars-like environment without the risk to the actual rover. It's designed to weigh the same on Earth as Curiosity weighs on Mars, accounting for the difference in gravity.

Here's a more detailed explanation:

Purpose:

Scarecrow is used to evaluate the rover's mobility and suspension system. This includes testing its ability to climb slopes, traverse different types of terrain, and handle various driving conditions.

Design:

It's a full-scale replica of the Curiosity rover, but without the complex computer brain. This makes it lighter and allows engineers to focus solely on the mechanical aspects of mobility.

Weight:

Scarecrow is designed to weigh the same on Earth as Curiosity weighs on Mars. This is crucial for accurately simulating how Curiosity will behave in the Martian environment.

Testing Location:

Scarecrow is tested in the Mars Yard at NASA's Jet Propulsion Laboratory (JPL), a simulated Martian landscape that includes rocks, slopes, and other obstacles.

Benefits:

By testing with Scarecrow, engineers can identify potential problems and refine the rover's driving capabilities before sending it to Mars, minimizing risks to the actual Curiosity rover.

Example:

In one instance, Scarecrow was used to test a new traction control algorithm designed to reduce wheel wear on the Mars Curiosity rove

#268 Re: Meta New Mars » Scarecrow Postings » 2025-08-13 15:04:22

Hopefully Scarecrow will make an impact with this memebership.

#269 Re: Meta New Mars » Housekeeping » 2025-08-13 15:03:06

Good that decision to create as fresh an acount as possible. I did look at my email to see if I remembered the user but did not. Hopefully this new memeber will join in.

#270 Re: Meta New Mars » Housekeeping » 2025-08-11 17:20:33

What was the username?

As for the fuel tank they are of different configuration. Also anything smaller than an ISS module is not practical.

#271 Re: Terraformation » Exponential Growth of Solar Powered Industry » 2025-08-09 16:00:23

Depends on the type of panel and materials in metals that are needed.

AI Overview

Do we have enough silver, copper, and other materials to ...

Solar panels require several types of metals for construction, including aluminum, steel, copper, and silver. Aluminum and steel are often used for the frames and support structures, while copper and silver are crucial for wiring and electrical contacts within the solar cells. Additionally, minor metals like indium, gallium, and tellurium are used in specific types of solar cells.

Here's a more detailed breakdown:

Aluminum:

Used for the frame that holds the solar panel together, providing a lightweight yet durable structure. It is also sometimes used for wiring.

Steel:

Often used in conjunction with aluminum for the support structure or racking system of the solar panel.

Copper:

Essential for wiring and electrical connections within the solar panel and the overall solar array.

Silver:

A key component in the conductive layer of solar cells, facilitating the flow of electricity.

Zinc:

May be used in the solar panel's construction, although its specific role varies.

Minor Metals:

Indium, Gallium, Selenium, Tellurium: These are used in certain types of thin-film solar cells like CIGS (Copper Indium Gallium Selenide) and Cadmium Telluride (CdTe) solar panels.

Cadmium: Used in CdTe solar panels.

Silicon: The most common material for solar cells, formed into wafers and used as a semiconductor to convert sunlight into electricity.

Other Materials:

Glass: Typically used to protect the solar cells from the elements and provide a transparent surface for sunlight to pass through.

Ethylene tetrafluoroethylene (ETFE): A polymer material used in some solar panel designs as a transparent encapsulant.

Nickel: While not directly involved in energy conversion, nickel may be used in plating for corrosion resistance or in the support structures.

Tin: Used to protect contact layers and prevent corrosion

#272 Re: Human missions » Starship is Go... » 2025-08-07 14:41:48

Saw a youtube video that indicate that they are for the block 2 of starship that is going to be 10M taller.

AI Overview

Evolution of the Raptor engine, by @cstanley : r/SpaceXLounge

SpaceX's Raptor 3 is an upgraded version of the Raptor rocket engine, boasting increased thrust, higher efficiency, and a simplified design compared to its predecessors. It eliminates the need for an external heat shield by utilizing a secondary cooling loop and is lighter and more powerful, enabling Starship to carry heavier payloads.

Here's a more detailed breakdown:

Key Improvements:

Increased Thrust:

Raptor 3 delivers significantly more thrust than previous versions. For example, it produces 280 tons of thrust at sea level, a 21% increase over Raptor 2.

Higher Efficiency:

The engine features a higher combustion chamber pressure and improved fuel efficiency, enhancing its overall performance.

Simplified Design:

Raptor 3 incorporates a more streamlined design with fewer components, including the elimination of the external heat shield and the integration of secondary piping and electronics into the engine structure.

Weight Reduction:

The simplified design and removal of the heat shield contribute to a significant weight reduction, with Raptor 3 being lighter than both Raptor 1 and 2.

Enhanced Durability:

The engine is designed for 1,000 flights with minimal maintenance and utilizes welded joints for increased strength and reduced potential for leaks.

More Payload Capacity:

The lighter weight and increased thrust of Raptor 3 allow Starship to carry a greater payload mass to orbit.

Key Features:

Full Flow Staged Combustion Cycle:

This advanced cycle maximizes efficiency and performance.

Liquid Oxygen and Methane Propellants:

These propellants enable cleaner burning and potential in-situ resource utilization on Mars.

Regenerative Cooling:

The engine uses a secondary cooling loop to manage extreme temperatures and pressures, eliminating the need for a heat shield.

Welded Joints:

Welded joints replace screws, bolts, and flanges in many areas, improving structural integrity and streamlining production.

Impact:

Enabling Deeper Space Exploration:

.

The improvements in Raptor 3 are crucial for SpaceX's ambitious goals of establishing a self-sustaining civilization on Mars.

Advancing Rocket Engine Technology:

.

The Raptor 3 engine represents a significant step forward in rocket engine design and manufacturing.

Increasing Launch Efficiency:

.

The engine's increased thrust, reduced weight, and higher efficiency translate to greater payload capacity and lower launch costs

#273 Re: Science, Technology, and Astronomy » Invelox Wind Turbine » 2025-08-07 14:39:06

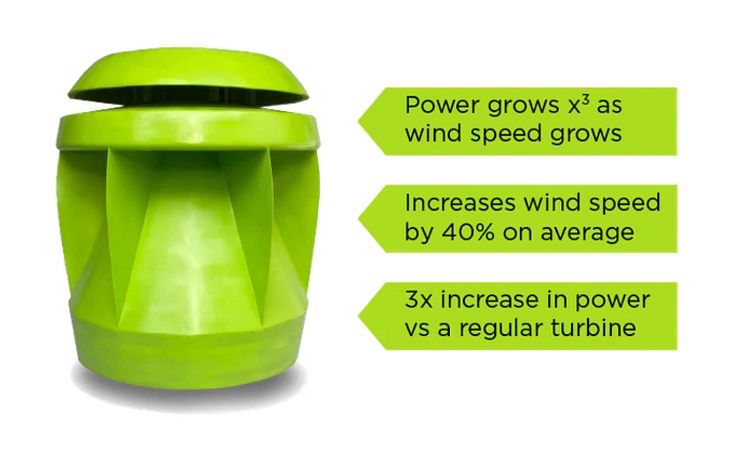

I have seen another that is simular.  Is this the ‘safest, most powerful wind turbine in the world’?

Is this the ‘safest, most powerful wind turbine in the world’?

#274 Re: Meta New Mars » Housekeeping » 2025-08-07 14:35:09

You can also find the post in GW Johnson Postings and @Exrocketman1 YouTube videos

#275 Re: Single Stage To Orbit » The Space Plane Corporation » 2025-08-06 14:38:35

For PhotonBytes...

GW is working on a spreadsheet to calculate a complete SSTO design.

The prototype has run through scenarios with LH2, methane and RP1.

He is looking for ** real ** data on two specifics and perhaps your company can help:

a) mounts for engines which do NOT gimbal

b) mounts for engines with gimbal

3) plumbing to carry fluids from tanks to enginesThe spreadsheet depends upon real data to produce reasonable results.

(th)

These question have been looked up for the Delta rocket and Atlas family of rockets